Reaction furnace for producing green and healthy DIY part basic material

A basic material and reaction furnace technology, which is applied in the field of basic material reaction furnaces for the production of green and healthy DIY parts, can solve problems such as low efficiency and inconvenient operation, and achieve the effect of improving work efficiency and avoiding air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

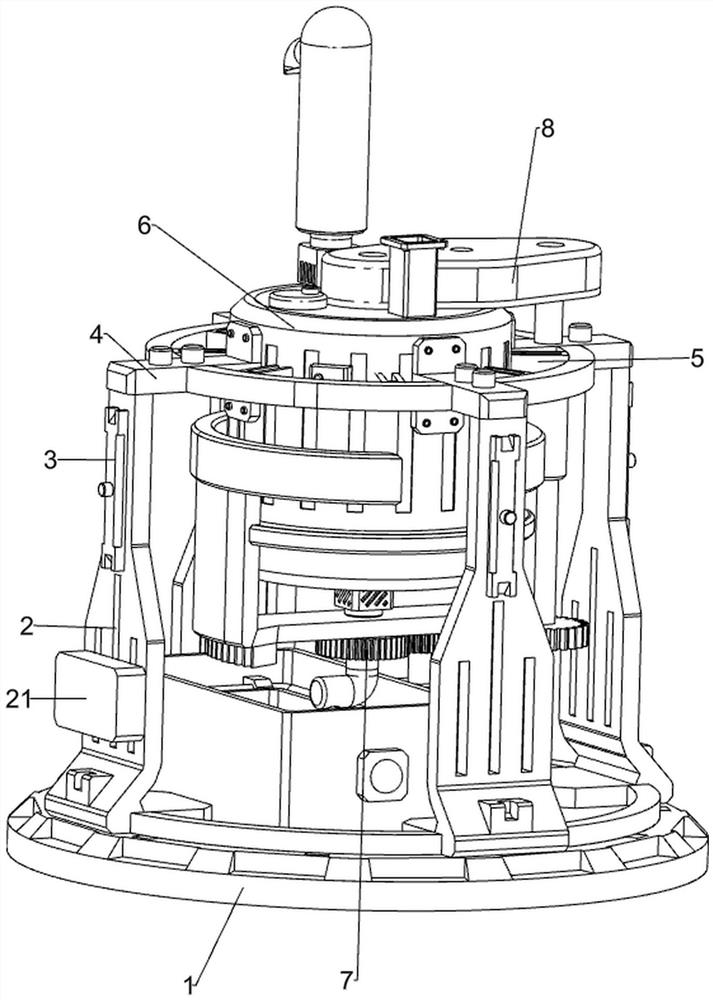

[0034] A basic material reaction furnace for the production of green and healthy DIY parts, such as Figure 1-5 As shown, it includes a bottom frame 1, a support plate 2, a matching key 3, a first fixed rod 4, a second fixed rod 5, a holding mechanism 6 and a heating mechanism 7. The bottom frame 1 is provided with a support plate 2, and the support plate 2. Cooperating keys 3 are provided on the top, front, rear, left, and right sides. First fixed rods 4 are provided on the front, rear, left, and right sides of the top of the support plate 2. Second fixed rods 5 are arranged between the first fixed rods 4. The first fixed rods A holding mechanism 6 is arranged between 4 and the second fixed rod 5, and a heating mechanism 7 is arranged between the support plate 2 and the parts of the holding mechanism 6.

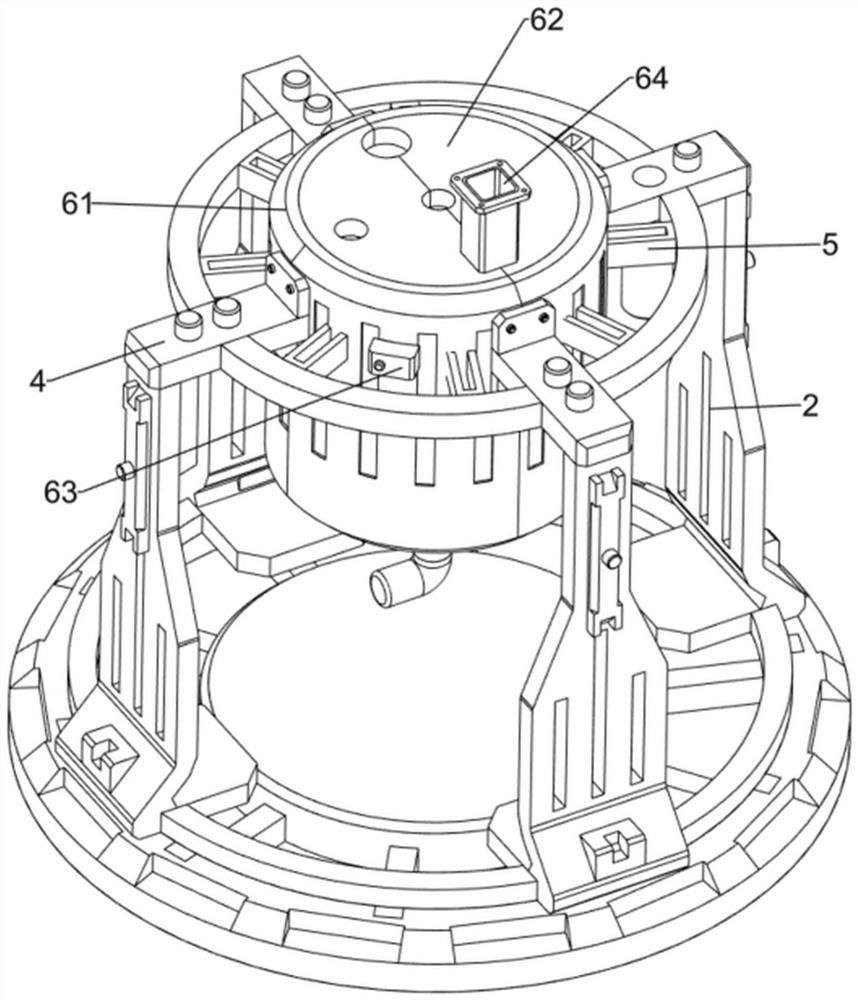

[0035] The holding mechanism 6 includes a reaction furnace 61, a top cover 62, a temperature sensor 63, a discharge port 64, a discharge 65 and a first electromagnetic valve...

Embodiment 2

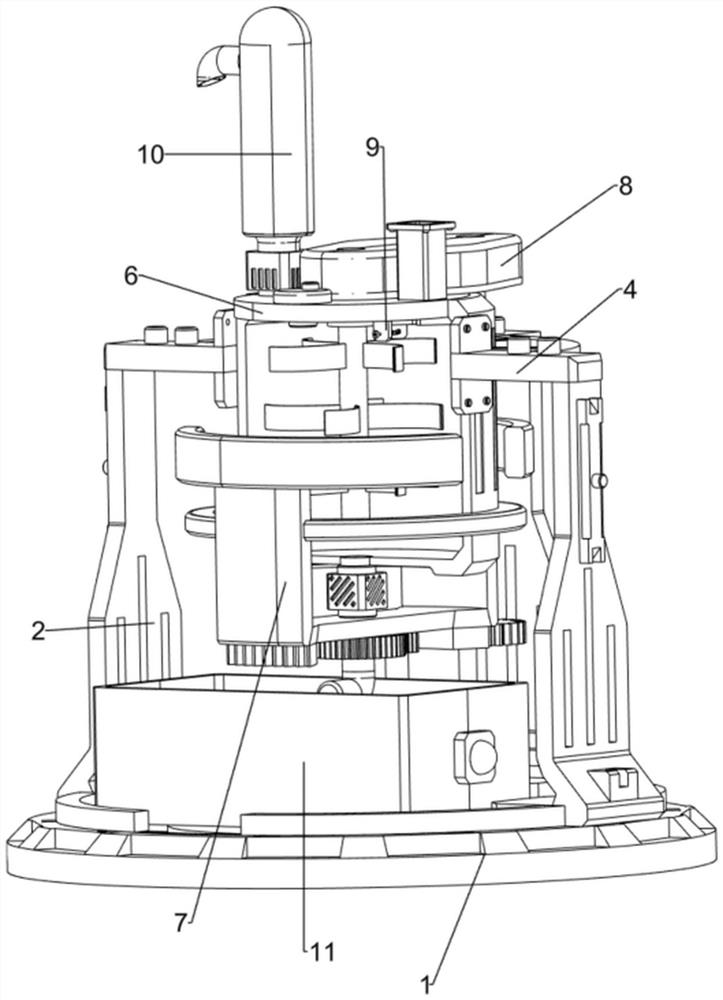

[0039] On the basis of Example 1, such as Figure 6-12 As shown, a stirring mechanism 8 is also included, and the stirring mechanism 8 includes a stirring rod 81, a transmission rod 82, a third gear 83, a fourth gear 84, a fifth gear 85, a sixth gear 86, a missing tooth block 87 and a protective shell 88, the top right side of the top cover 62 is provided with a protective shell 88, the middle part of the top cover 62 is rotatably provided with a stirring rod 81, the stirring rod 81 is connected with the left side of the protective shell 88 in a rotational manner, and the top of the stirring rod 81 is provided with a third gear 83, The third gear 83 is located inside the protective shell 88, and the middle rotating type inside the protective shell 88 is provided with a fourth gear 84, the fourth gear 84 meshes with the third gear 83, and the middle part of the first fixed rod 4 on the right side is rotatably provided with a transmission rod 82, the upper part of the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com