Method for treating coking wastewater

A treatment method and technology for coking wastewater, which are applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, flotation water/sewage treatment, etc. Small footprint, air saving, high volume load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

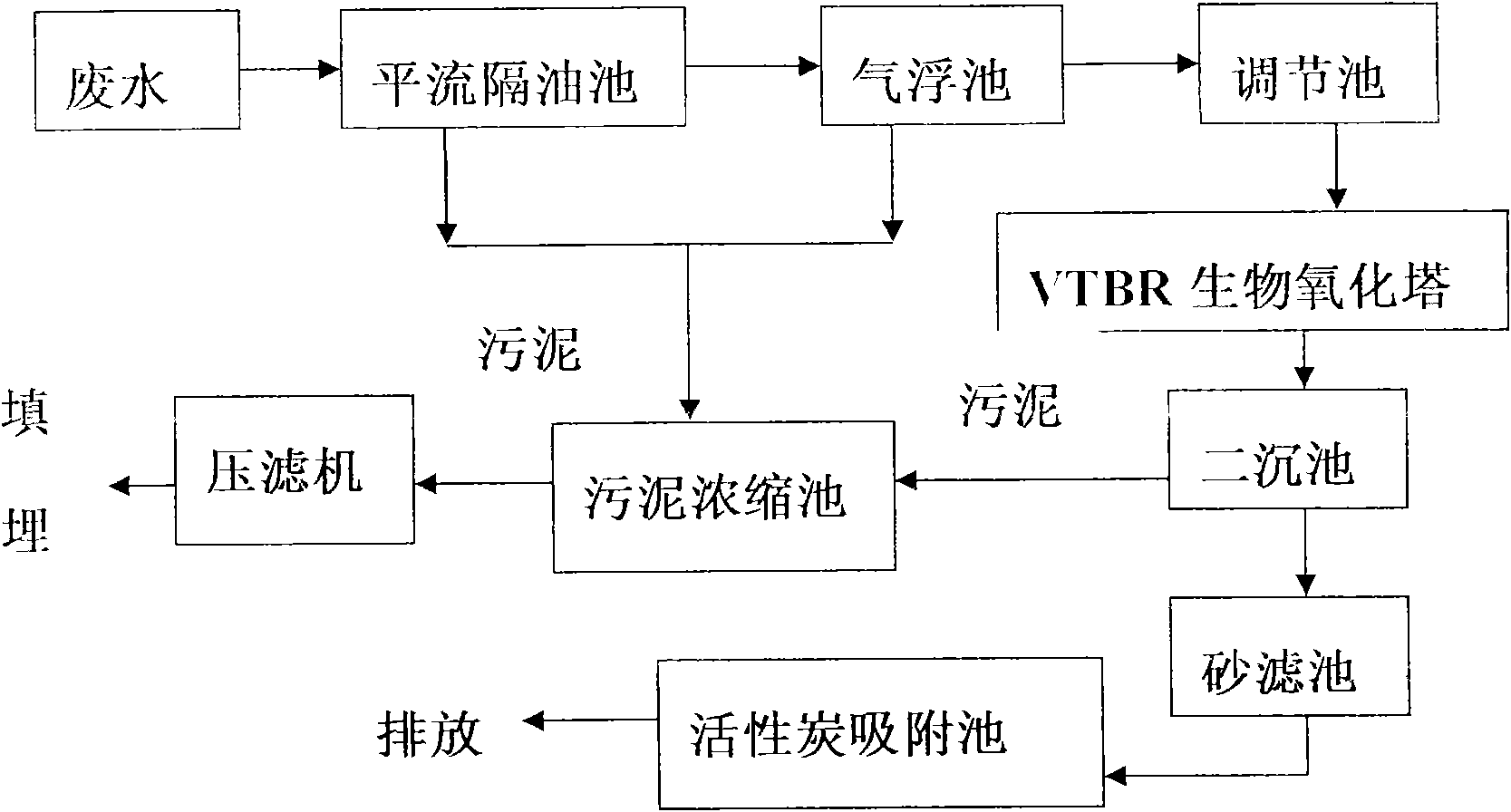

[0013] (1) All kinds of wastewater in the factory are discharged into the advection grease trap through the sewage pipeline. The grease trap is equipped with an oil scraper to regularly remove the oil floating on the surface. The residence time of the grease trap is 2 hours. Floating system degreasing;

[0014] (2) The effluent of the air flotation system flows into the wastewater mixing adjustment tank to balance the water quality and quantity, and the residence time is 8 hours;

[0015] (3) The effluent from the mixing adjustment tank is treated by the lift pump into the VTBR biological oxidation tower to remove most of the COD, remove phenol, cyanide and other harmful substances, and denitrify through nitrification and denitrification. The VTBR biological oxidation tower adopts a closed fixed-film biochemical reactor, which can realize both aerobic and anaerobic processes. The VTBR biochemical reaction tower is a steel tower container with a monomer diameter of 9 meters an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com