Feeding assembly and coating device

A material supply and component technology, which is applied to devices and coatings that apply liquid to the surface, and can solve problems such as paint adsorption, damage to the air pump, and no immediate stoppage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

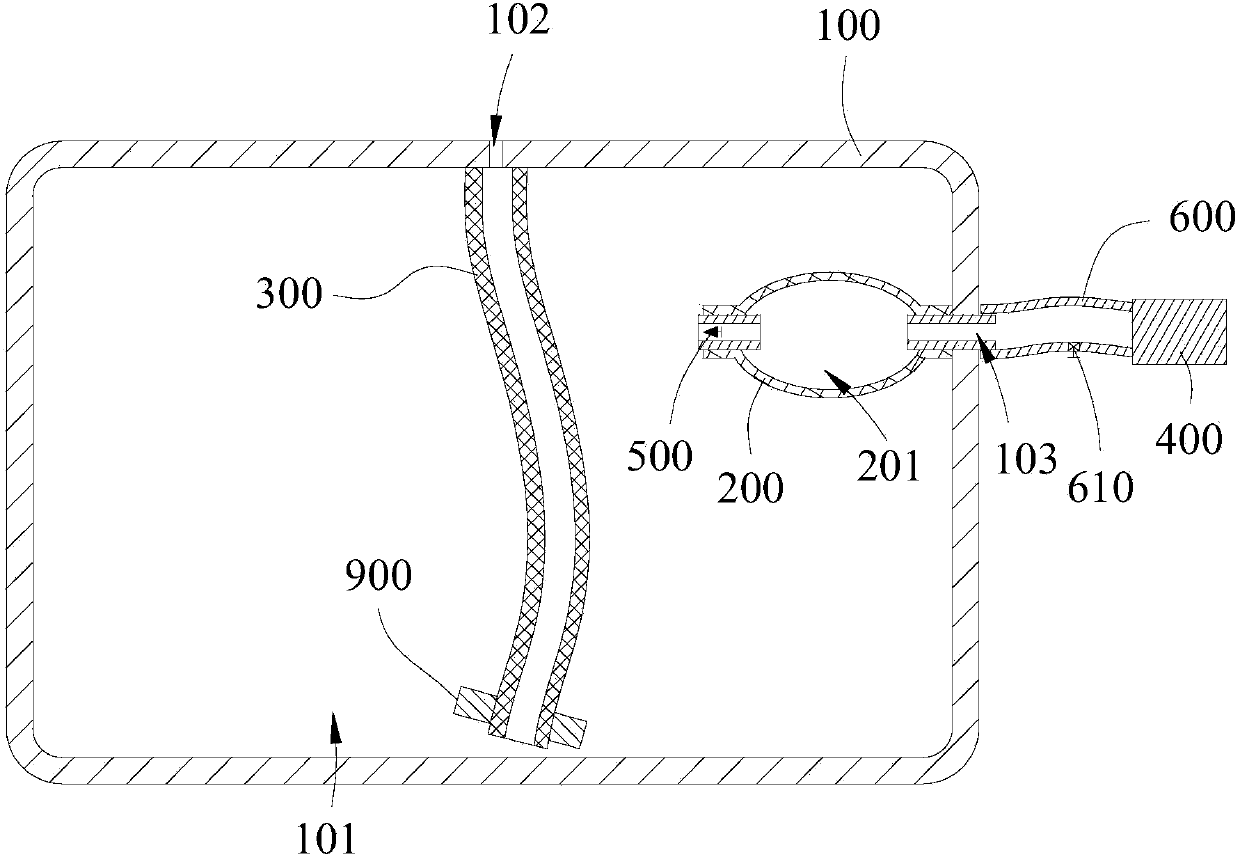

[0027] see figure 1 , the embodiment of the present invention provides a feed assembly, including a feed container 100 , an air bag 200 , a first connecting pipe 300 and an air pump 400 . In a specific application, the feeding component can be set in the roller, directly supply material to the roller, and then brush through the roller, or it can be set between two rollers, directly supply material to the surface to be brushed, and then pass through Apply with two rollers.

[0028] The storage container 100 has a container cavity 101 for storing paint, the size and shape of the storage container 100 and the container cavity 101 can be adjusted according to the needs of use, and the storage container 100 can be made of metal material or plastic material . The material storage container 100 is provided with a material outlet 102 and an air guide hole 103 on the wall of the container cavity 101 , wherein the material outlet 102 is mainly used for overflowing the paint stored in ...

Embodiment 2

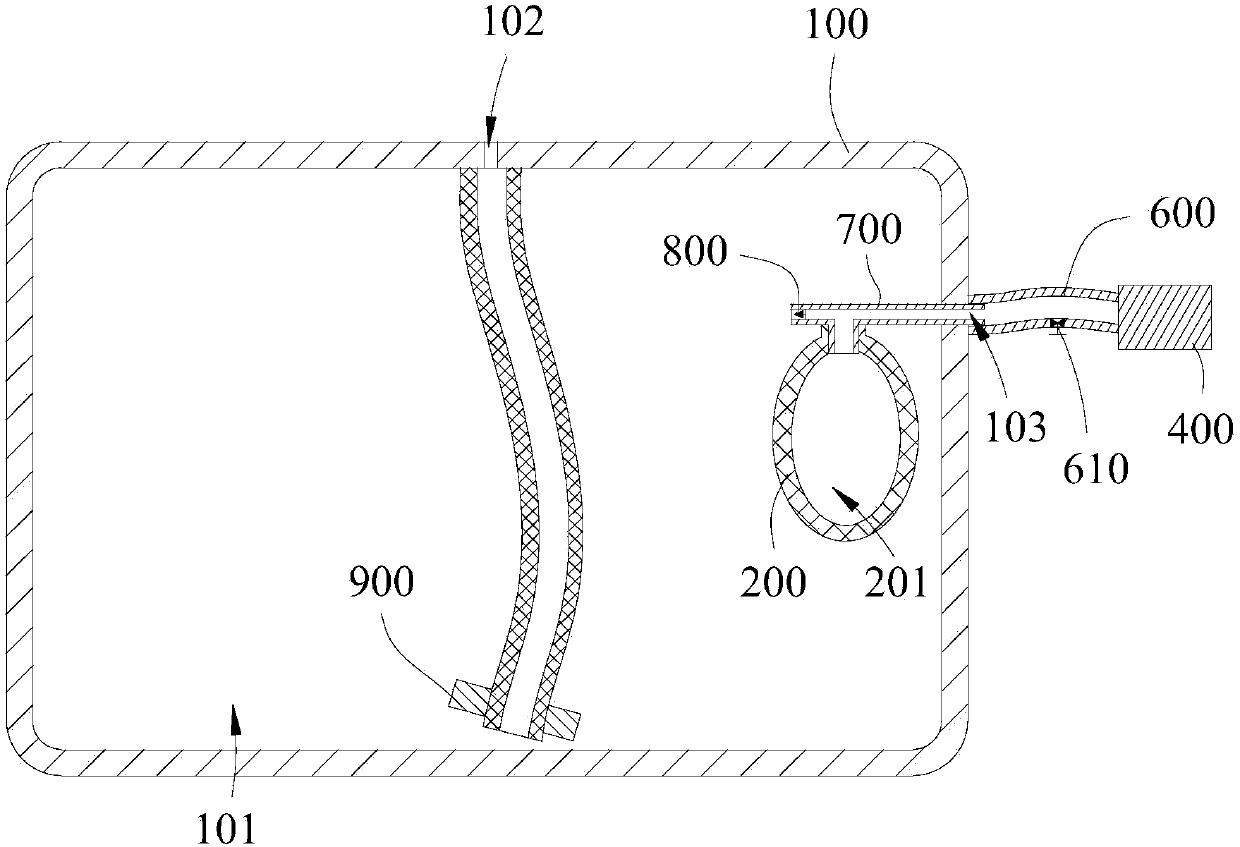

[0040] see figure 2 The difference between the second embodiment and the first embodiment is that the feeding assembly includes an air duct 700 and a second one-way valve 800 disposed in the air duct 700, and the second one-way valve 800 is used to restrict the flow of fluid from the container cavity 101 Into the airway tube 700, the airway tube 700 is provided with a through hole (not marked in the figure) on the tube wall between the second one-way valve 800 and the air guide hole 103, the air bag 200 is connected to the airway tube 700, and the bag cavity 201 passes through the The hole communicates with the air guide hole 103, wherein the air bag 200 is connected to the storage container 100 through the air guide tube 700, and the air bag 200 indirectly isolates the communication between the container cavity 101 and the air guide hole 103 through the air guide tube 700 and the second one-way valve 800. Based on this structural design, when the air pump 400 inflates the ai...

Embodiment 3

[0042] The present invention also proposes a brushing device, which includes a discharge assembly. For the specific structure of the discharge assembly, refer to the first or second embodiment above. The technical solution, therefore, also has all the beneficial effects brought by the technical solution of the above-mentioned embodiment 1 or 2, and will not repeat them one by one here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com