Automatic tying technology for edible fungus bags

A technology for edible fungi and fungus bags, applied in the field of fungus stick processing, can solve the problems of excessive air, loose fungus material and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

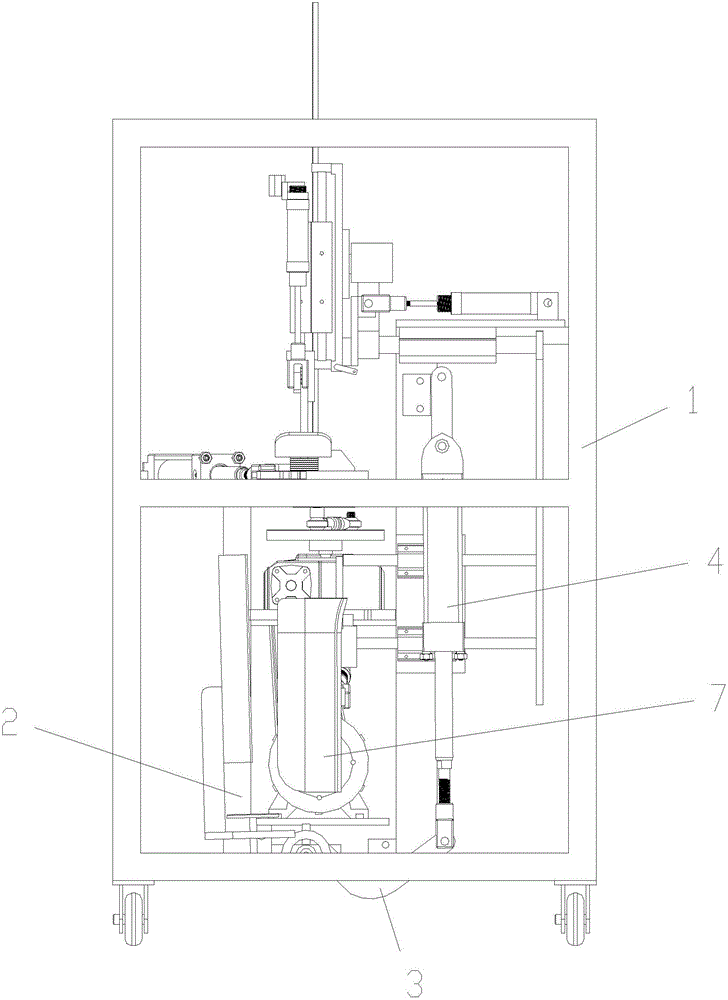

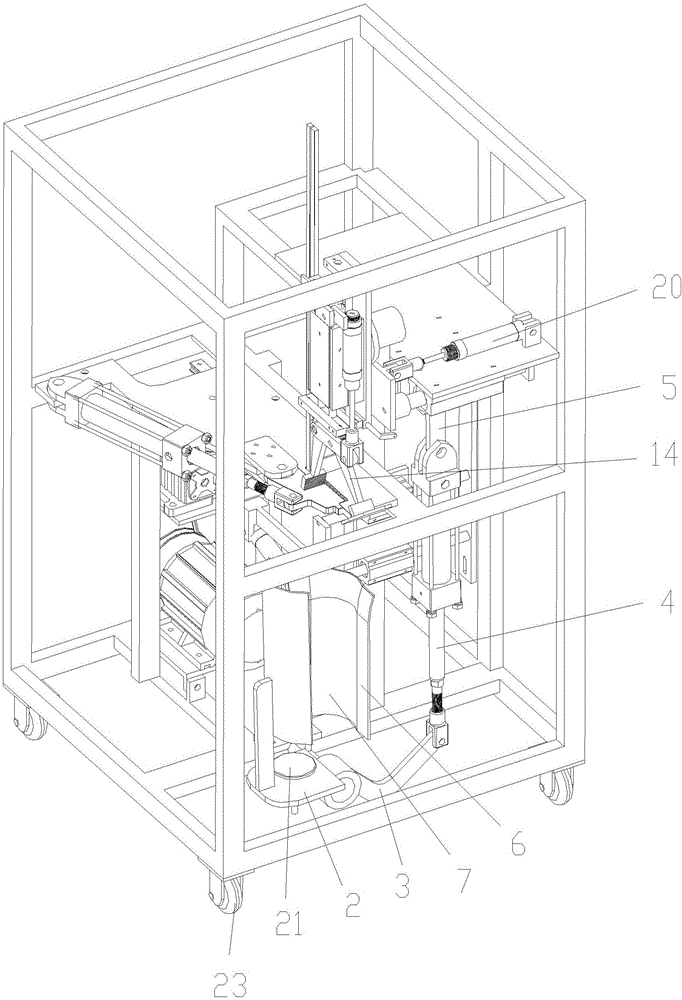

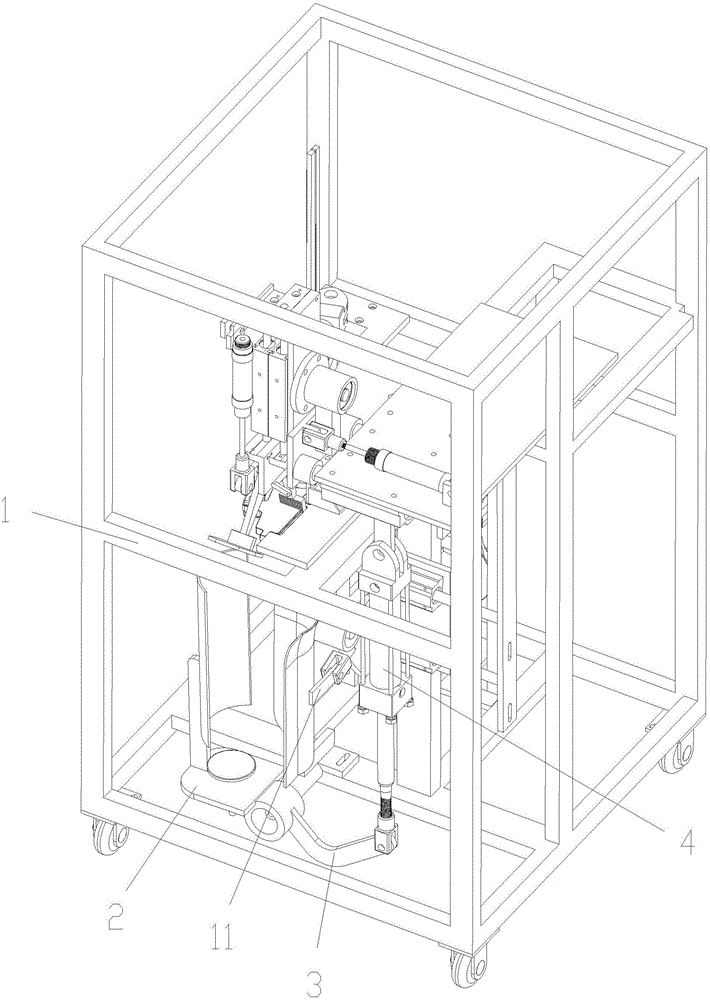

[0027] The present invention will be further described below in conjunction with accompanying drawing:

[0028] With reference to the accompanying drawings: in the present embodiment, the automatic sealing process of edible fungus bags includes a fixed frame 1, and one side of the fixed frame 1 is obliquely equipped with a bacterium rod receiving seat 2, and the bacterium rod receiving seat 2 includes a bottom plate 2-1, The fixed rod 2-2 that is fixed on the left end of base plate 2-1, the arc plate 2-3 that is fixed on the fixed rod 2-2, the right end of base plate 2-1 is connected on the fixed mount 1 in rotation, the right end of base plate 2-1 A drive rod 3 is fixedly connected, and the outer end of the drive rod 3 is rotatably connected with a rotating cylinder 4 that drives the bacterium rod receiving seat to rotate, and the upper end of the rotating cylinder 4 is movably connected to the fixed frame 1 through a movable rod 5;

[0029] Wherein the inboard direction of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com