Process for manufacturing high-strength low-elongation polytetrafluoroethylene filaments

A polytetrafluoroethylene, high-strength technology, applied in filament/thread forming, stretch spinning, textiles and papermaking, etc., can solve the problems of reduced strength, increased elongation, and large elongation, and achieves Improved density and uniformity, reduced air, and low elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

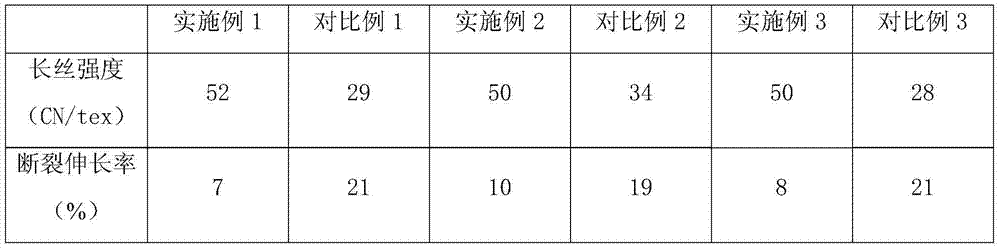

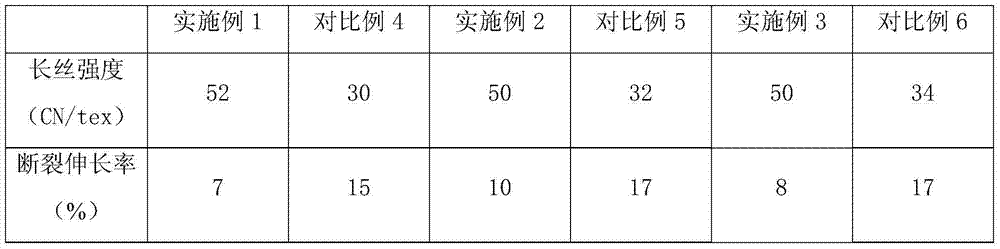

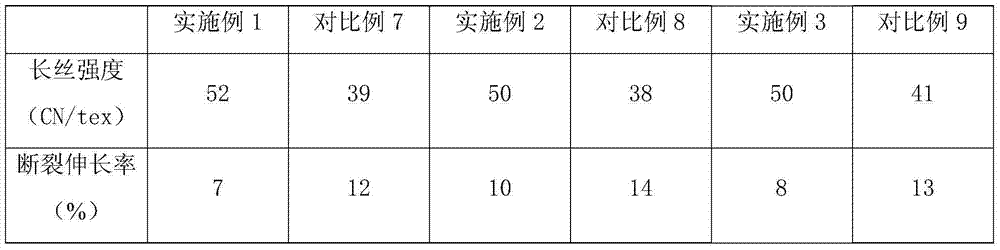

Embodiment 1

[0030] (1) Oil supply at low temperature: Put the PTFE dispersion particles with a particle size of 550-560um in a low temperature environment of 2°C for 8 hours, and in this low temperature environment, mix paraffin oil with PTFE The dispersed granules are mixed evenly, wherein the amount of paraffin oil added is 10% of the mass of the polytetrafluoroethylene dispersed granules to obtain the polytetrafluoroethylene mixture processed by low-temperature oiling;

[0031] (2) High-temperature aging: put the polytetrafluoroethylene mixture processed by step (1) low-temperature oiling into a high-temperature environment of 55° C. for aging for 10 hours;

[0032] (3) Vacuum compression molding: put the polytetrafluoroethylene mixture matured in step (2) into the mould, vacuumize, keep the vacuum negative pressure at 0.05MPa, and perform compression molding;

[0033] (4) pushing and extruding: placing the polytetrafluoroethylene compound through compression molding in the step (3) in...

Embodiment 2

[0043] (1) Oiling at low temperature: Put the PTFE dispersion particles with a particle size of 590-600um in a low temperature environment of 0°C for 10 hours, and in this low temperature environment, mix paraffin oil with PTFE The dispersed granules are mixed evenly, wherein the amount of paraffin oil added is 12% of the quality of the polytetrafluoroethylene dispersed granules, and the polytetrafluoroethylene mixture treated with low-temperature oiling is obtained;

[0044] (2) High-temperature aging: put the polytetrafluoroethylene mixture processed by step (1) low-temperature oiling into a high-temperature environment of 58° C. for aging for 7 hours;

[0045] (3) Vacuum compression molding: put the polytetrafluoroethylene mixture matured in step (2) into the mould, vacuumize, keep the vacuum negative pressure at 0.06MPa, and perform compression molding;

[0046] (4) pushing and extruding: placing the polytetrafluoroethylene compound through compression molding in the step ...

Embodiment 3

[0056] (1) Oil supply at low temperature: Put the PTFE dispersion particles with a particle size of 570-580um in a low temperature environment of 5°C for 12 hours, and in this low temperature environment, mix paraffin oil with PTFE The dispersed granules are mixed evenly, wherein the amount of paraffin oil added is 8% of the mass of the polytetrafluoroethylene dispersed granules, and the polytetrafluoroethylene mixture treated with low-temperature oiling is obtained;

[0057] (2) High-temperature aging: put the polytetrafluoroethylene mixture processed by step (1) low-temperature oiling into a high-temperature environment of 52° C. for aging for 10 hours;

[0058] (3) Vacuum compression molding: put the polytetrafluoroethylene mixture matured in step (2) into the mould, vacuumize, keep the vacuum negative pressure at 0.06MPa, and perform compression molding;

[0059] (4) pushing and extruding: placing the polytetrafluoroethylene compound through compression molding in the step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com