Oil coating equipment used for production and manufacturing of motor rotor

A motor rotor and oiling technology, which is applied in the manufacture of motor generators, stator/rotor bodies, coatings, etc., can solve the problems of low efficiency, decreased consistency of finished product quality, and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

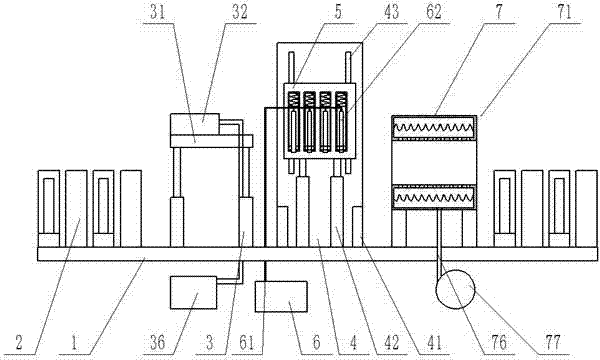

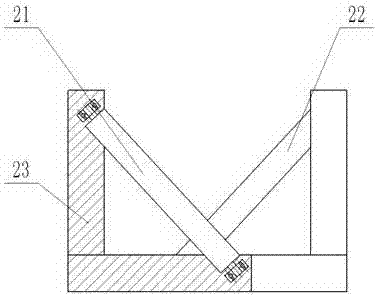

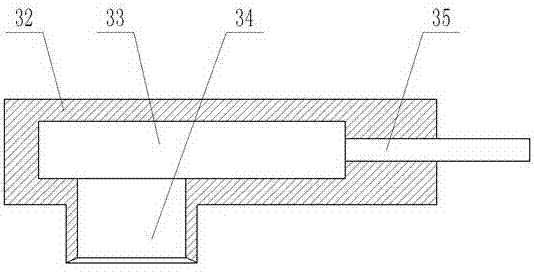

[0022] See Figure 1-5 , An oiling equipment for the production and manufacture of motor rotors, including a worktable 1, a dust removal device 3, and an oiling device and a drying device 7. The worktable 1 is symmetrically provided with two supporting roller groups 2 and supporting roller groups 2 Including a first supporting roller 21 and a second supporting roller 22 arranged relatively obliquely, each of the first supporting roller 21 and the second supporting roller 22 is provided with four; the first supporting roller 21 and the second supporting roller 22 both pass through the L-shaped The bracket 23 is installed on the table surface of the workbench 1, the L-shaped bracket 23 is fixedly connected to the workbench 1 by bolts, the first supporting roller 21 and the second supporting roller 22 are rotatably connected to the L-shaped bracket 23, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com