Lubricating device with pneumatic tire pressure oil tank and oil tank lining

A pressure oil tank and lubricating device technology, which is applied in the direction of engine lubrication, lubricating parts, lubricating oil control valves, etc., can solve the problems of difficult pumping capacity, evacuation, and difficulty in sucking high-viscosity grease, etc., to achieve expanded application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

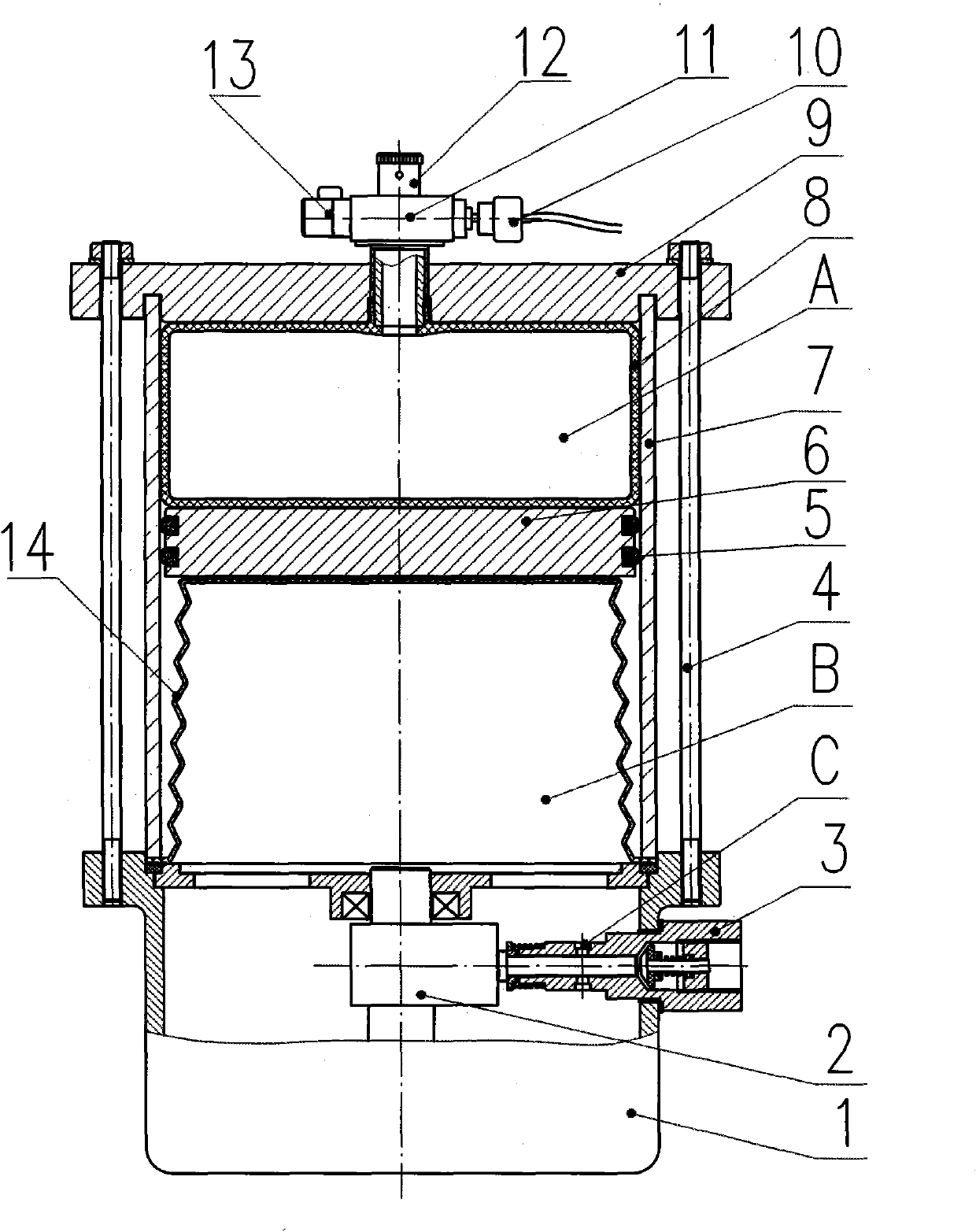

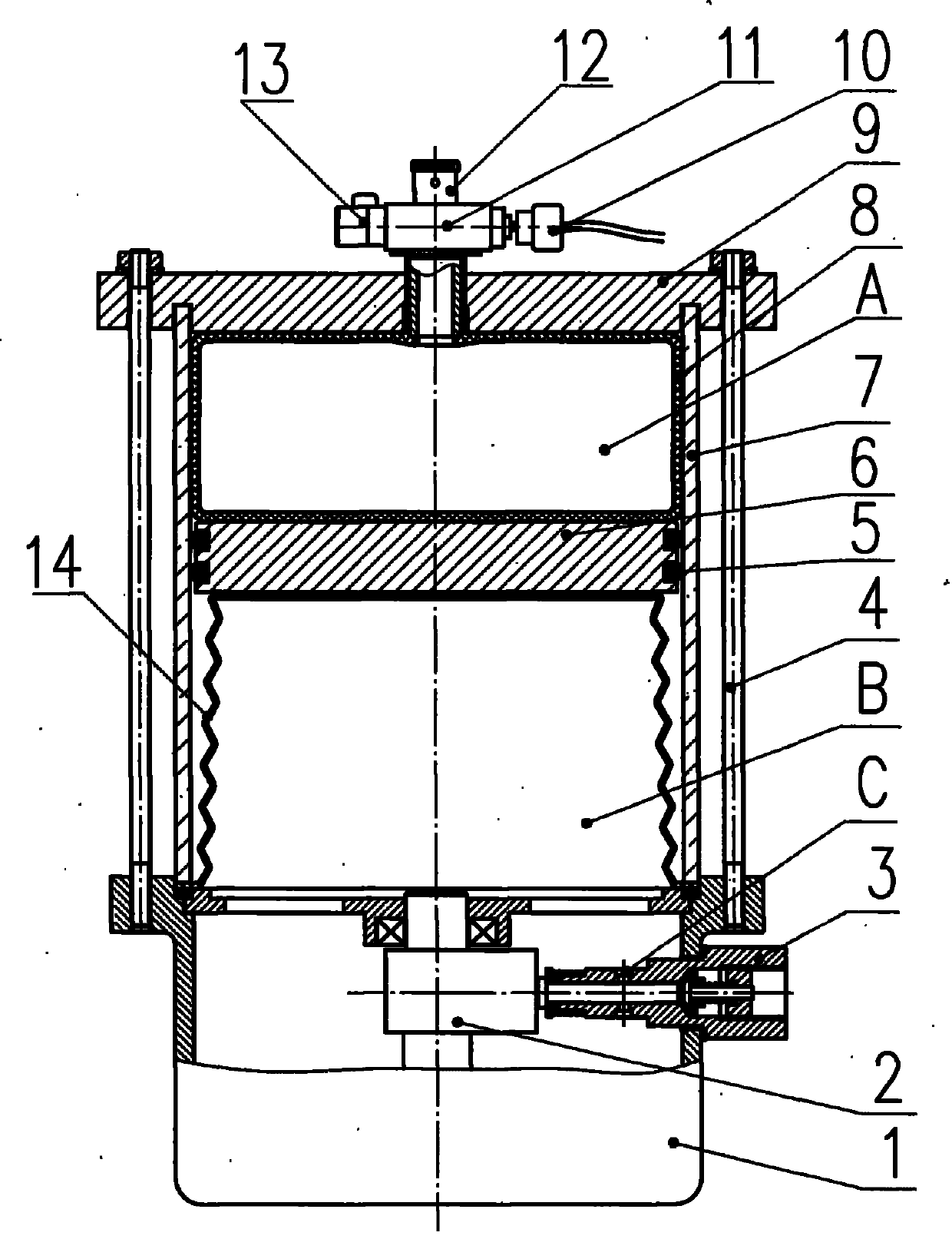

[0011] The present invention is further described below by accompanying drawing. In the structural schematic diagram of embodiment 1 of the lubricating device with pneumatic tire pressure oil tank and oil tank liner shown in the accompanying drawings, the lubricating pump casing 1, the cylindrical oil tank 7 and the upper cover 9 are compressed and fixed by four studs 4, wherein the lubricating The joint surface between the upper part of the pump housing 1 and the lower end of the cylindrical oil tank 7 is sealed. The power assembly 2 and the lubricating pump 3 driven by it are installed on the lubricating pump housing 1. The cylindrical oil tank 7 is separated by the piston 6 and the sealing ring 5. The upper chamber A of the fuel tank and the lower chamber B of the fuel tank are mutually sealed. The piston 6 and the sealing ring 5 can move along the inner wall of the cylindrical fuel tank 7 under pressure. The periphery of the lower opening is fixed and sealed with the perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com