Steel ball immersion oil storage bucket and application method

A technology of steel balls and dresses, which is applied to the device and coating of the surface coating liquid, can solve the problems of easy corrosion, etc., and achieve the effects of prolonging the service life, reducing rust, and good oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

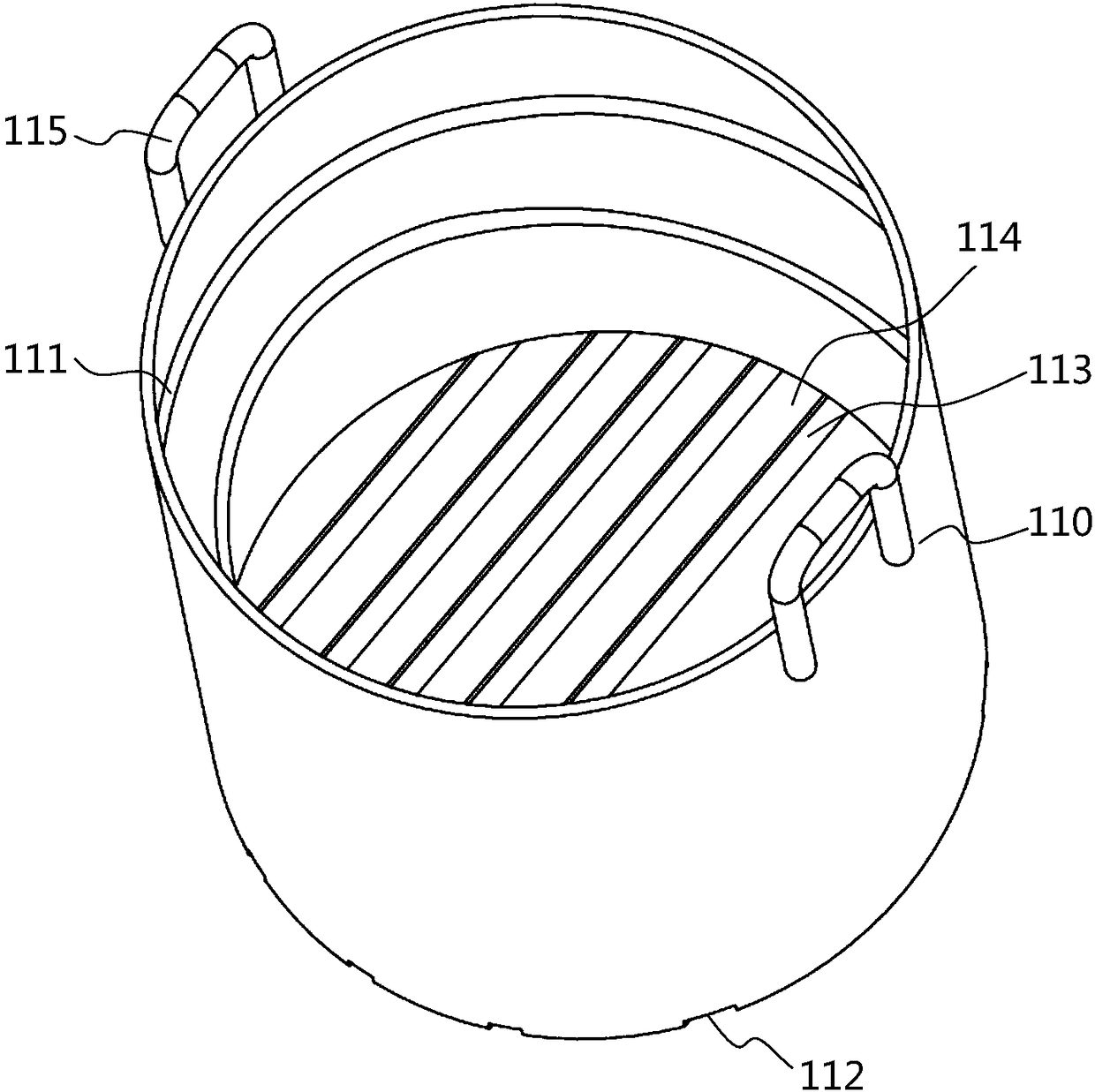

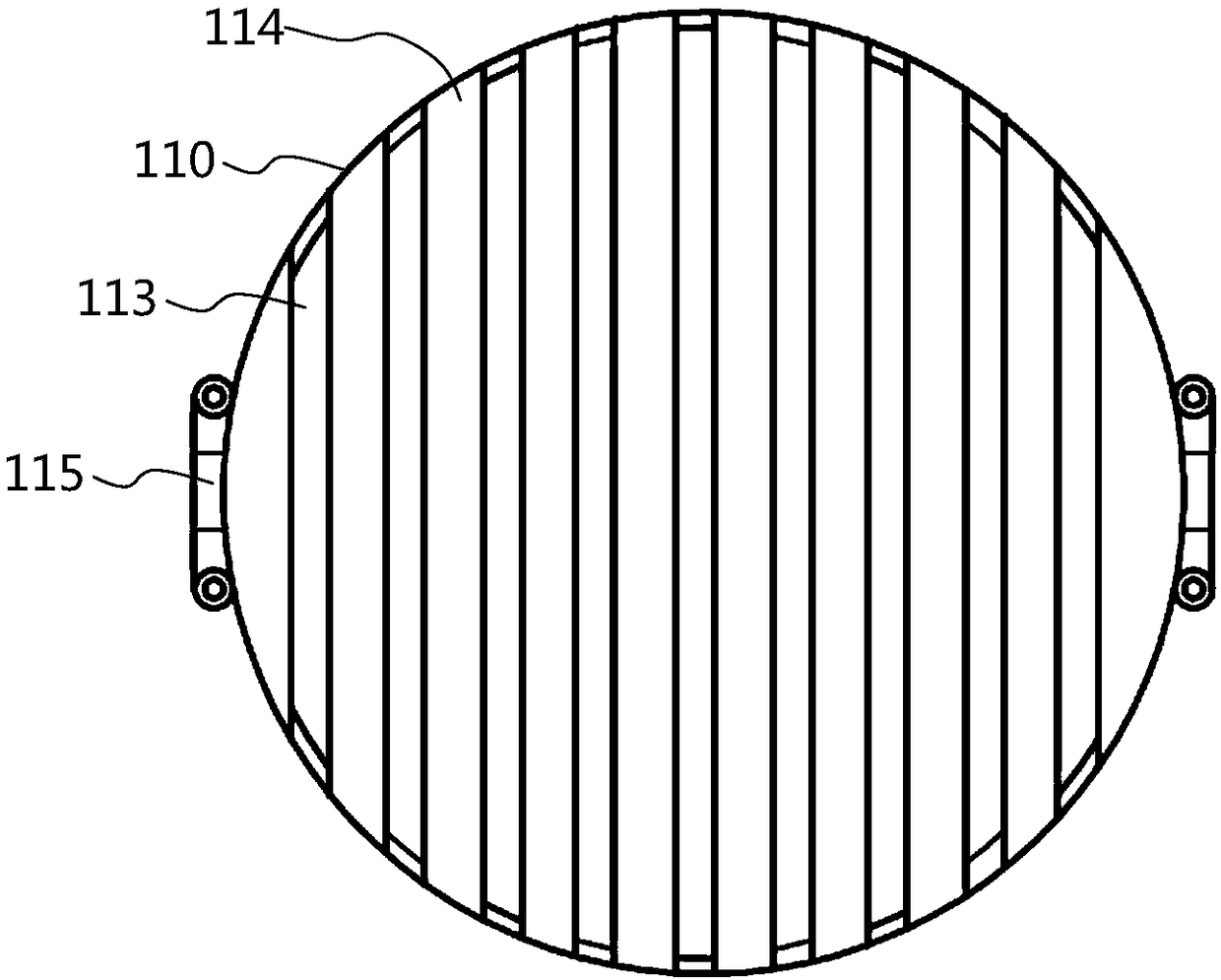

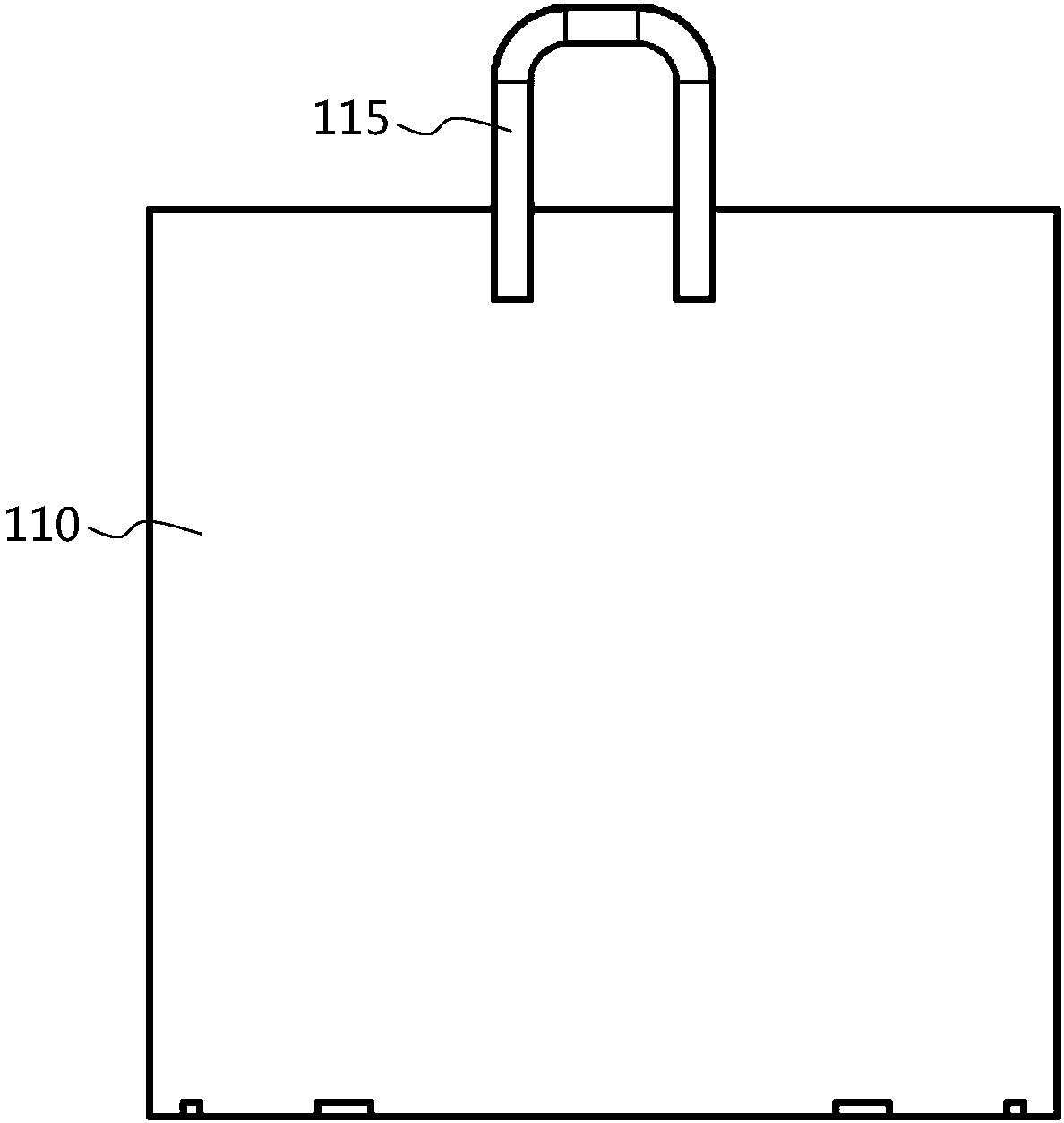

[0038] see Figure 1 to Figure 5 , describing a steel ball immersion oil container according to a preferred embodiment of the present invention, wherein, figure 1 It is a structural schematic diagram of the steel ball immersion oil containing barrel of the present invention; figure 2 It is the bottom view of the steel ball immersion oil containing barrel of the present invention; image 3 It is the front view of the steel ball immersion oil containing barrel of the present invention; Figure 4 It is the top view of the steel ball immersion oil containing barrel of the present invention; Figure 5 It is another structural schematic diagram of the steel ball immersion oil storage barrel of the present invention.

[0039] Such as Figure 1 to Figure 5As shown, a steel ball oil-immersed barrel in this embodiment includes a barrel body 110 whose cross-section is circular or oval, and at least one spiral groove 111 is opened on the inner wall of the barrel body 110, and the spi...

Embodiment 2

[0048] The basic structure of the present embodiment is consistent with that of Embodiment 1, except that the bucket also includes a goal funnel 120, the goal funnel 120 is conical, wherein the cone head is downward, and the lower end surface of the cone head is in contact with the partition. The distance between the bars 113 is greater than the diameter of the steel balls to be loaded, and the goal funnel 120 overlaps with the top edge of the barrel body 110 . If the steel balls are directly poured into the barrel, the spacer will be damaged or bent due to the large impact force of the steel balls, which will affect the service life of the barrel.

[0049] A method for using a steel ball immersion oil containing barrel of the present invention comprises the following steps:

[0050] S101, lap the goal funnel 120 on the barrel body 110 with the cone head facing down, and fix the goal funnel 120;

[0051] S102. Then pour the steel balls into the goal funnel 120, and the steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com