Ultrahigh-property concrete and preparation method thereof

A technology with ultra-high performance and manufacturing methods, applied in the field of concrete, can solve problems such as no obvious improvement in waterproof performance, lower waterproof and impermeability, and easy rusting of steel fibers, so as to improve resistance to chloride ion penetration, save energy costs, and reduce steel costs. The effect of fiber rust problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

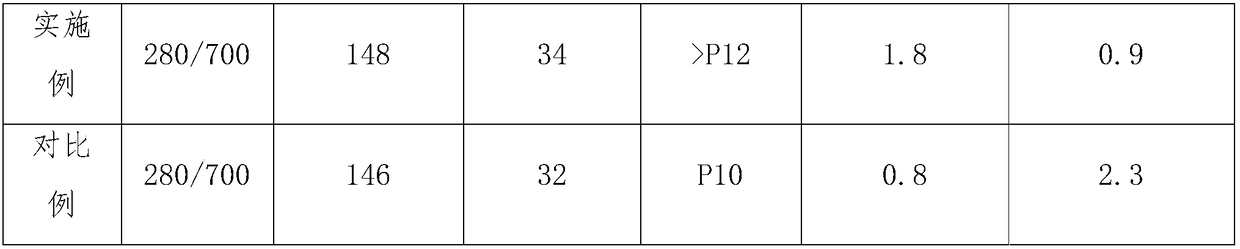

[0034] Embodiment: a kind of super high performance concrete, comprises following component and content thereof: PO42.5 cement 700kg / m 3 , Class II fly ash 70kg / m 3 , superfine silica fume 100kg / m 3 , Fine sand 1000~1300kg / m 3 , Steel fiber 80~160kg / m 3 , polymer emulsion 20kg / m 3 , tap water 160kg / m 3 , water reducer 40kg / m 3 And coalescent 0.2kg / m 3 .

[0035] Wherein, the specific surface area of the ultrafine silica fume is 15000m 3 / kg, Si02 content 95%, activity coefficient 108%; fine sand is quartz sand and quartz powder with particle size less than 10 mesh, fineness modulus is 2.10; steel fiber is round straight copper-plated steel fiber, diameter 0.2mm, The length is 13mm; the polymer emulsion is butadiene-styrene copolymer emulsion with a solid content of 50%; the water reducer is a high-efficiency polycarboxylate water reducer with a solid content of 13% and a water reducing rate of 30%; Dialdehyde butyl ether EB, content 99.5%.

[0036] A method for man...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com