Method for maintaining profiled steel sheet roofing

A technology of profiled steel plates and steel plates, which is applied to roofs, roofs using flat/curved panels, and roof coverings, etc., can solve problems such as poor actual results, construction, accelerated corrosion, etc., to reduce direct investment and production shutdown losses, The effect of improving the working environment and improving the condensation situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

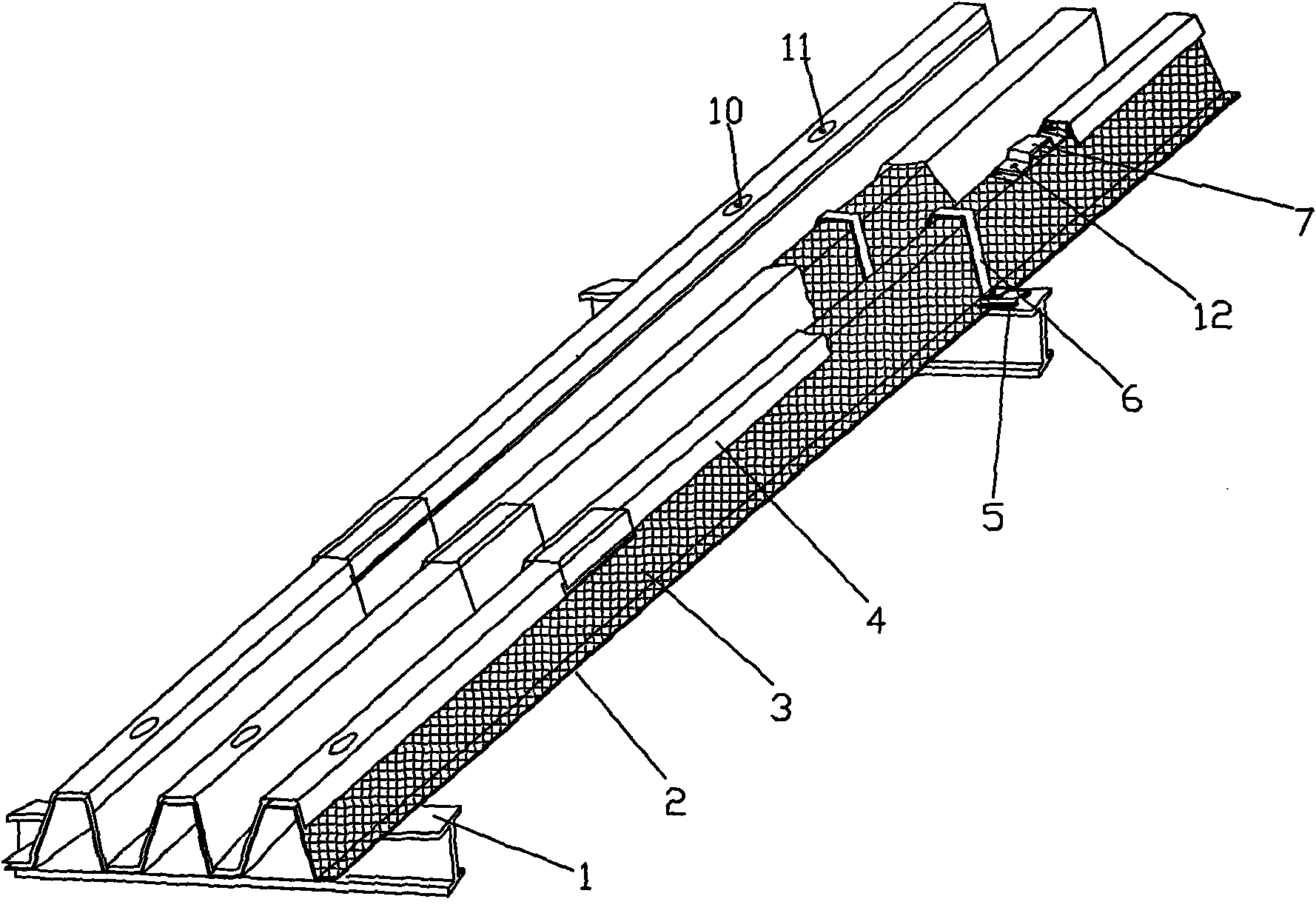

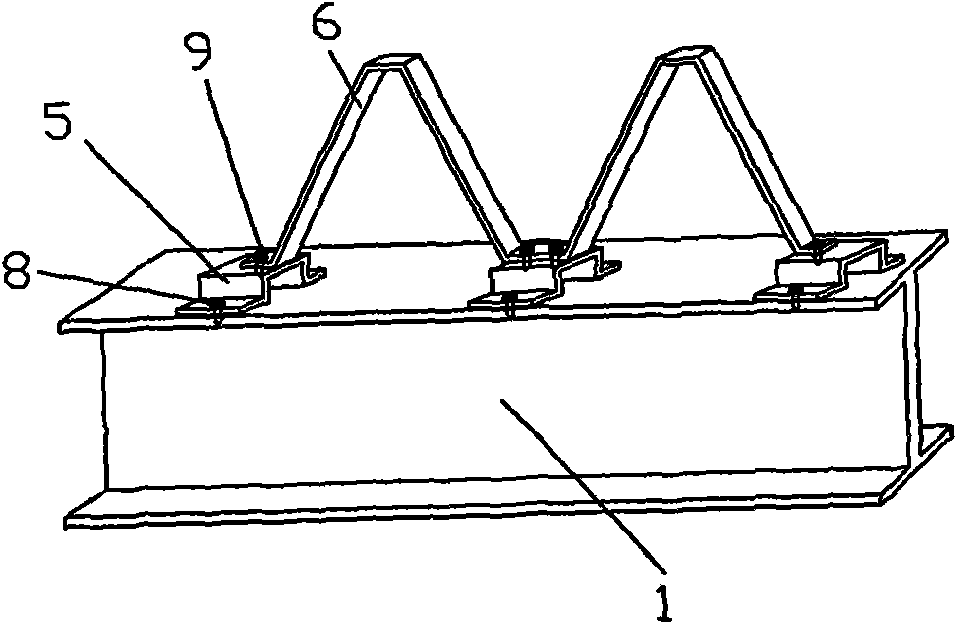

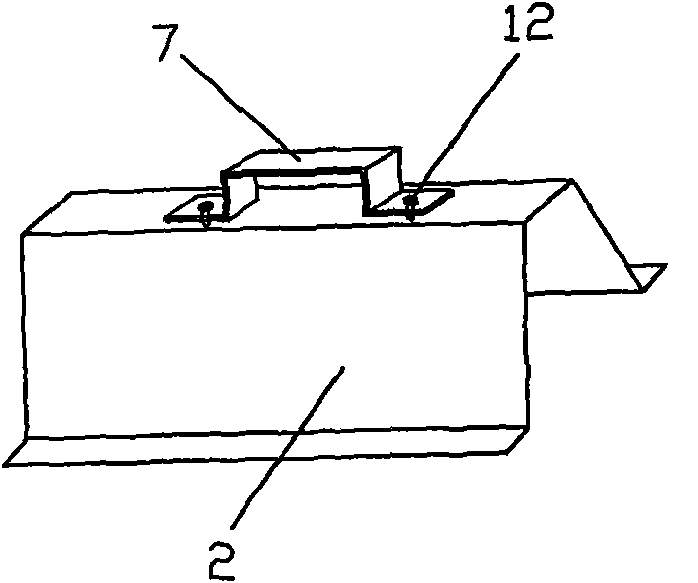

[0048] see Figure 1 ~ Figure 3 , the present invention is further described according to the accompanying drawings:

[0049] To repair the existing YX130-300-600 (W600) type profiled steel roof, the plate thickness is 0.6mm, and the purlin 1 spacing is 4000mm. Clean the surface of the existing profiled steel plate 2, remove the rust on the part of the perforated part and cut the surrounding area, cover the hole with a repaired steel plate of the same specification that is 50mm larger than the hole, and seal the repaired plate with the existing profiled steel plate with silicone sealant 2 Glue, and use stainless steel core-pulling rivets to fix around, and then cut and form a rectangular hole above the roof panel 2 wave valley purlin, the size of the hole is 118mm×67mm, clean the surface of the purlin 1 at the hole position, and then cut the purlin 1 with a size of 116mm×67mm. The 65mm × 22mm special bracket support 5 is placed flat in the hole, and the two wings of the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com