Device for recycling surplus materials of fine aggregate concrete and processing method thereof

A concrete and fine aggregate technology, applied in ceramic molding machines, molds, manufacturing tools, etc., can solve the problems of difficulty in promotion, heavy grouting pipes, high labor intensity, etc., and achieve a simple and convenient demoulding process and reduced bonding resistance. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

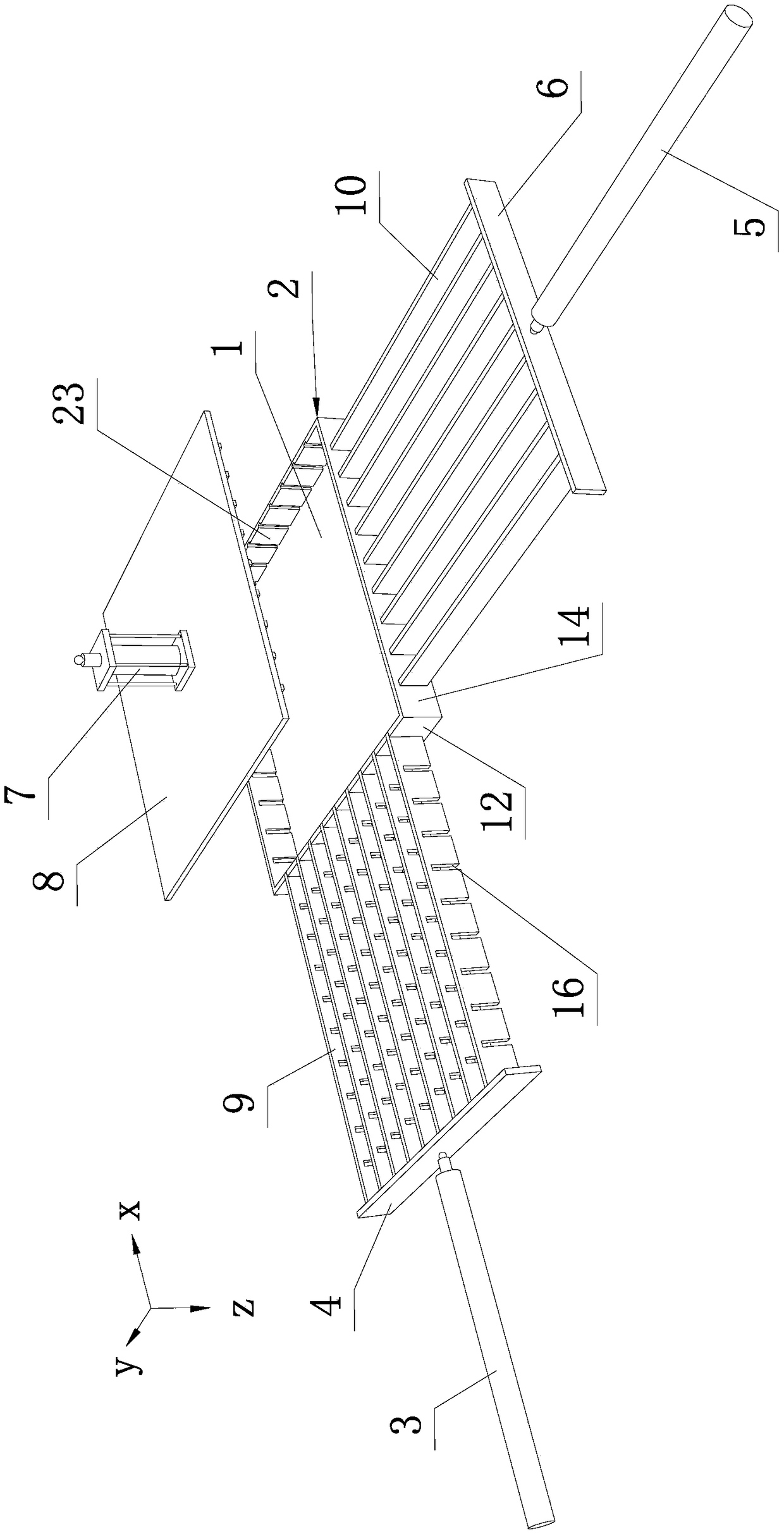

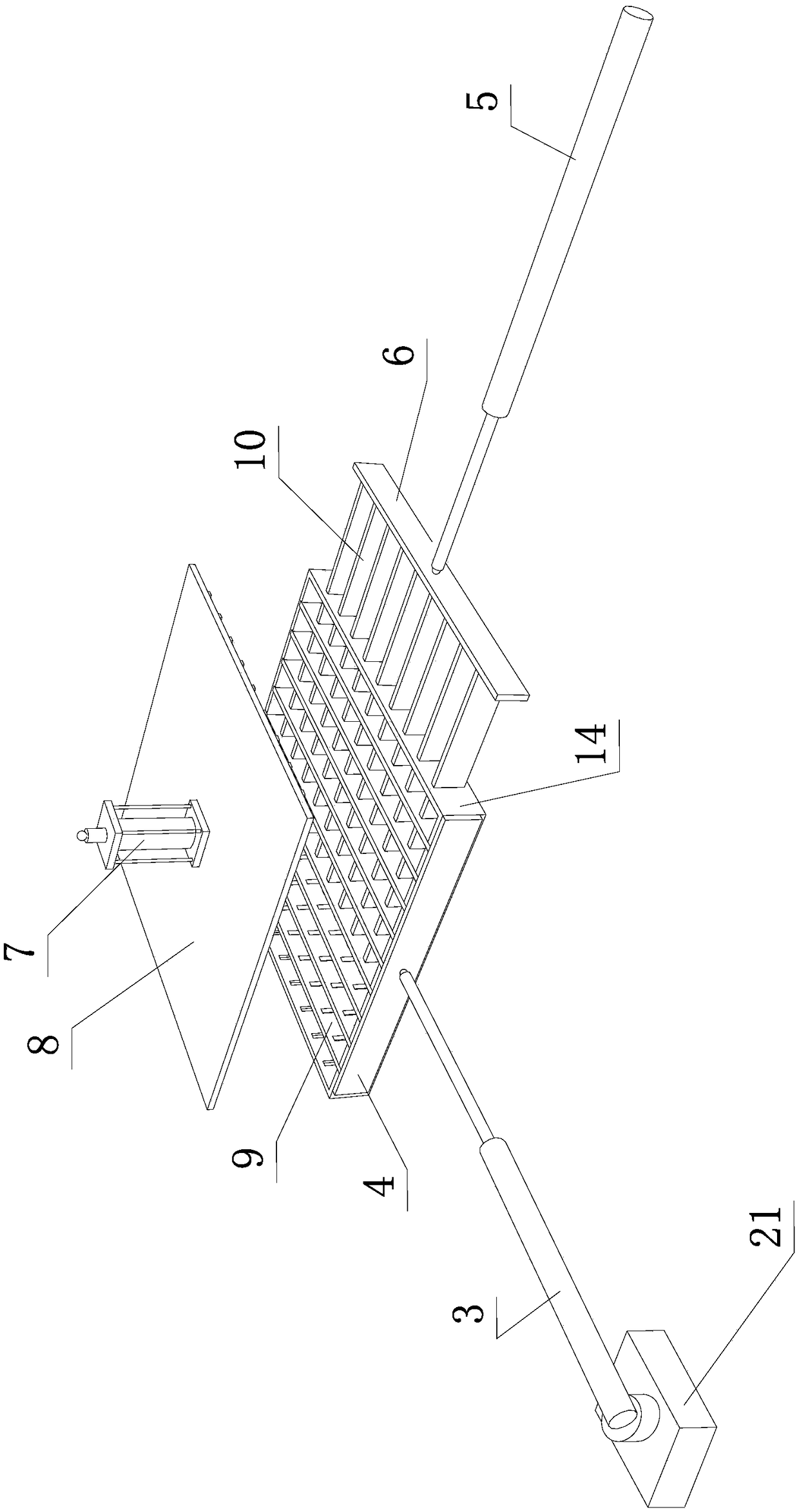

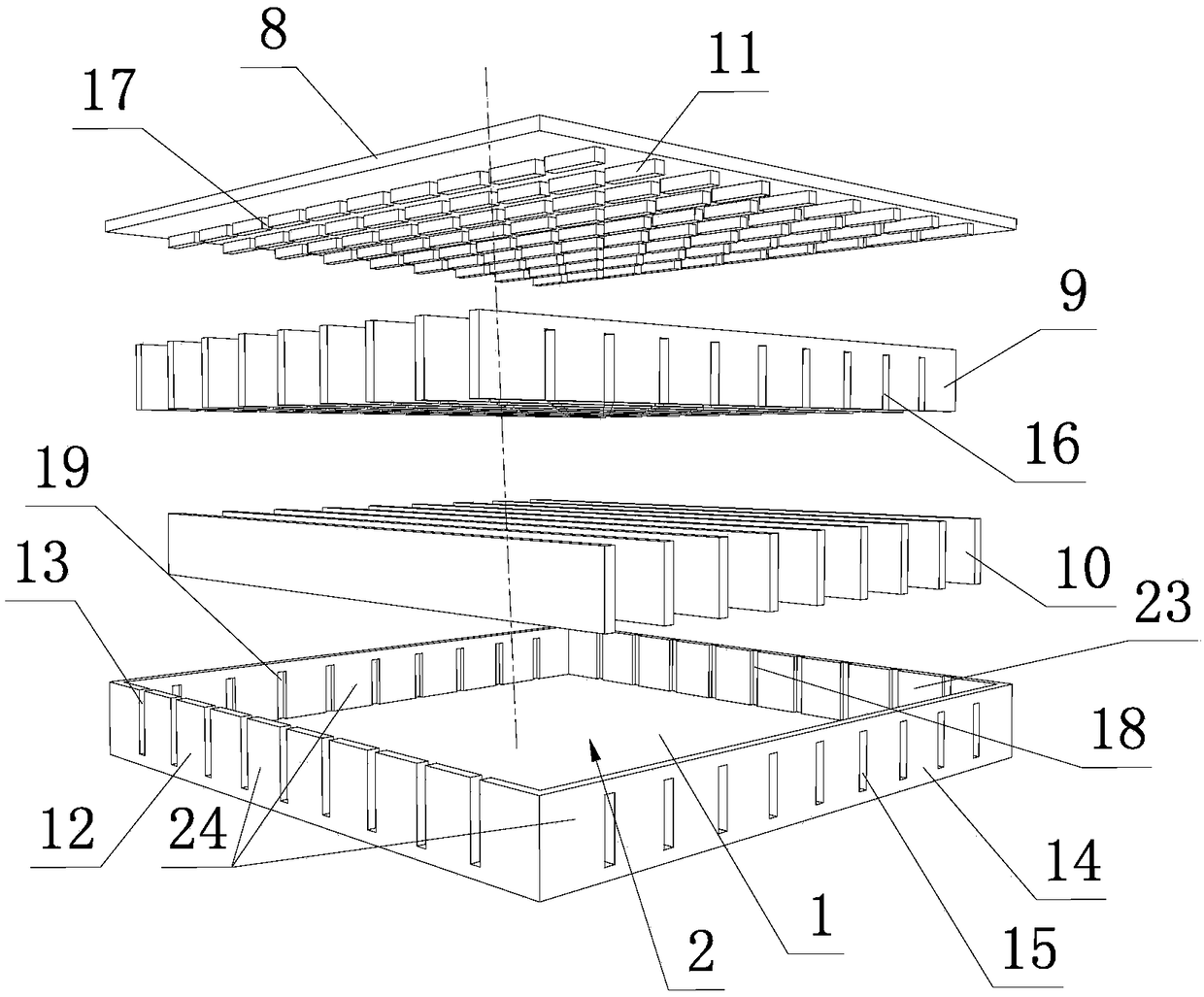

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the reutilization device for fine aggregate concrete of the present invention includes a hopper 2 composed of a bottom plate 1 and four side walls, an x-direction drive cylinder 3, a first connecting plate 4, a y-direction drive cylinder 5, The second connecting plate 6 , the z-direction driving cylinder 7 and the pressing plate 8 .

[0039] The piston rod of the x-direction drive cylinder 3 is fixed with a row of toothed inserts 9 extending along the x direction through the first connecting plate 4; The in-line bar 10 for horizontal insertion extending along the y direction; the piston rod of the z-direction drive cylinder 7 is fixed through the pressing plate 8 with a row of pressing bars 11 extending along the y direction for press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com