Glass lubricating powder spraying device for inner wall of pipe during high-temperature extrusion

A glass lubricating and spraying device technology, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of extrusion die damage, uniformity dependence of dusting, adhesion, etc., so as to reduce the probability of damage and improve the quality of hot extrusion , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

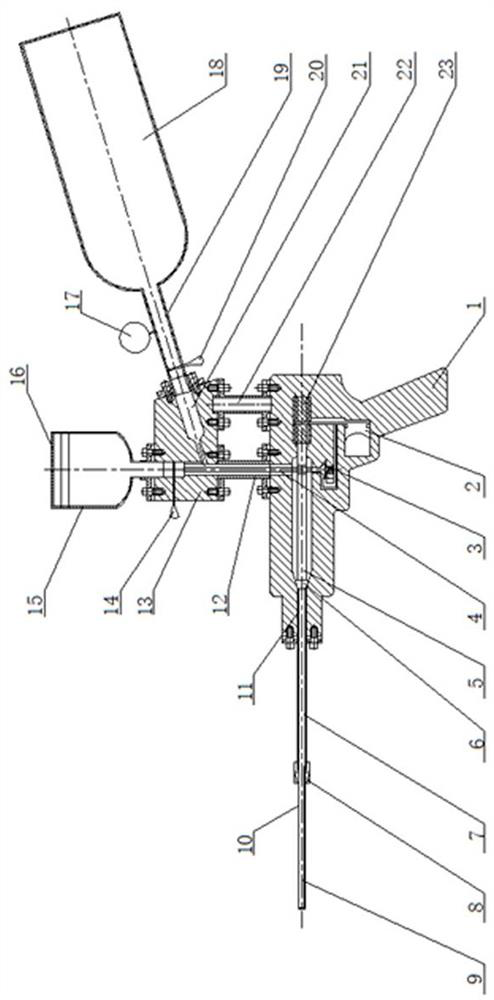

[0008] Such as figure 1 As shown, the present invention is a glass lubricating powder spraying device for extruding the inner wall of a pipe at high temperature, comprising a gun body 1, the upper end of the gun body 1 has a mixing chamber 12 and communicates with it, and the upper end of the mixing chamber 12 has a fixed Block 13, the left side of the fixed block 13 is provided with a first regulating valve 14, the feed assembly includes the first regulating valve 14, the first regulating valve 14 is located at the junction of the mixing chamber 12 and the material cup 15; the fixed block The upper end of 13 has a feeding assembly composed of a material cup 15 and a material cup cover 16 and communicates with the mixing cavity 12; And it communicates with the mixing inner cavity 12; at the front end of the gun body 1, there are a discharge nozzle extension section 9 and a discharge nozzle fixed section 7 to be locked by a locking screw sleeve 8; a plug 6 is provided inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com