Multistation automatic upper sleeve system

A multi-station, sleeve technology, applied in the field of metallurgical equipment, can solve the problems of large floor space, complex overall structure, large investment cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

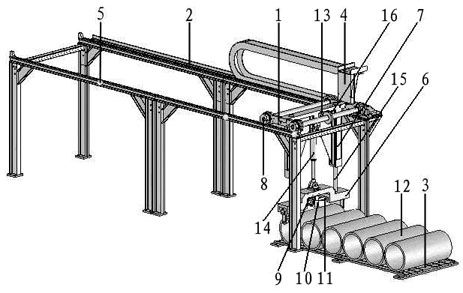

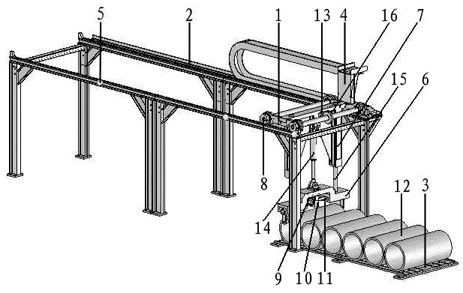

[0016] Such as figure 1 As shown, the multi-station automatic sleeve loading system at least includes a body 1, a track body 2, and a sleeve storage rack 3. The track body 2 and the sleeve storage rack 3 are fixed on the foundation by anchor bolts, and the body 1 includes clamping Mechanism 6, lifting mechanism 7 and traversing trolley 8, the traversing trolley 8 of the main body 1 is connected with the track body 2 through rollers; the clamping mechanism 6 and the lifting mechanism 7 are respectively connected with the traversing trolley 8, and the clamping mechanism 6 is used for Clamp the sleeve of the sleeve storage rack 3; the lifting mechanism 7 is used to move up the sleeve clamped by the clamping mechanism 6, and then the traverse trolley 8 on the track body 2 completes the pairing of sleeves along the track body 2. The conveyance of cylinder 12, when not working, traversing dolly 8 stops at the end of track body 2. The track body 2 includes a track and a support fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com