Waste lead-acid storage battery disassembling equipment

A technology for lead-acid batteries and equipment, which is applied in the field of dismantling equipment for waste lead-acid batteries, and can solve problems such as loss, inconvenient recycling and classification of battery shells and lead blocks, and damage to lead-acid quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

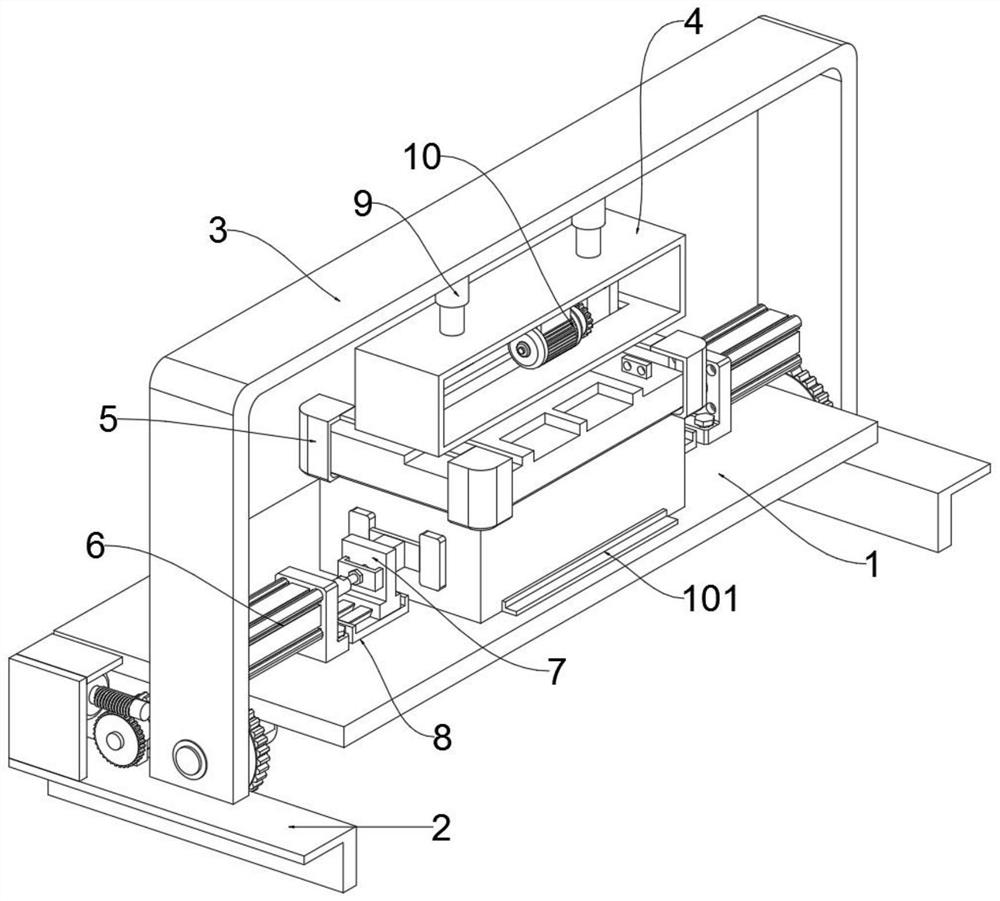

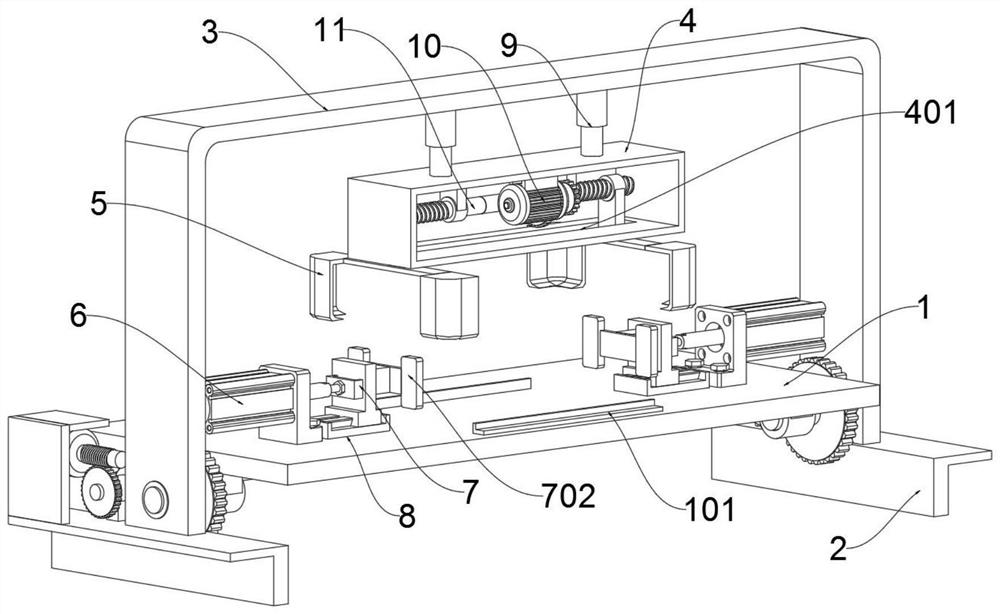

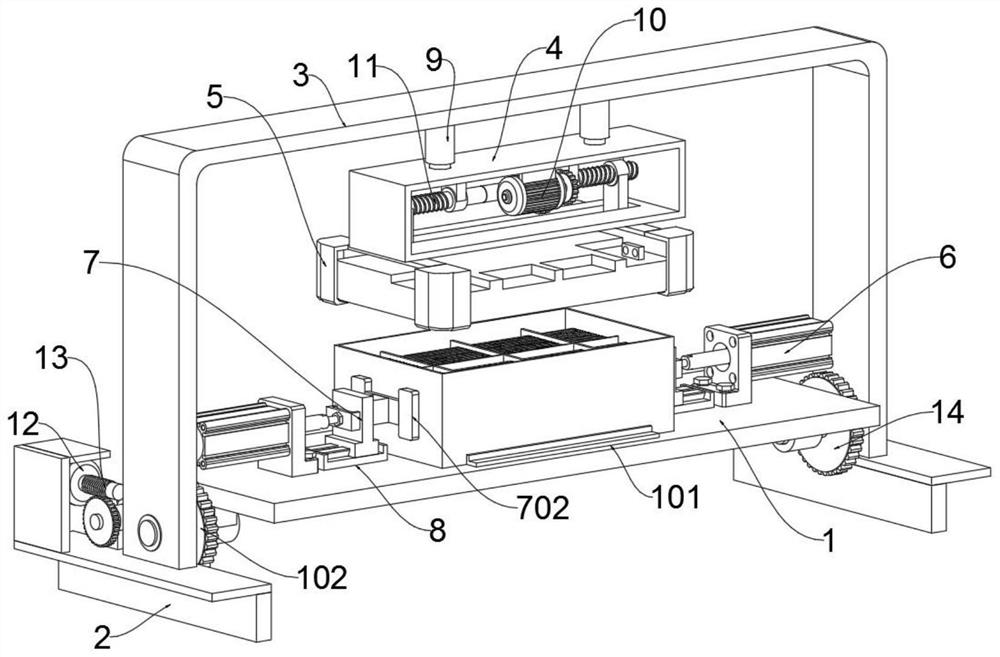

[0034] as attached figure 1 to the attached Figure 9 shown:

[0035]The present invention provides a waste lead-acid battery dismantling equipment, comprising a turning table 1, a base frame 2, a lifting box 4, a dividing device 5, a cylinder 6, a clamping block 7, a sliding seat 8, a hydraulic lever 9, a driving device 1 10, The double-ended screw 11, the second driving motor 12, and the synchronizing shaft 15; the two ends of the turning table 1 are connected to both sides of the support frame 3 through bearings; the upper surface of the base frame 2 is connected with the support frame 3 by welding; the hydraulic rod 9 The upper surface of the lift box 4 is fixedly connected to the end of the piston rod of the hydraulic rod 9; the driving device 10 is fixedly connected to the inside of the lift box 4; the double-ended screw 11 passes through the bearing It is rotatably connected to the shaft frame 402 of the lifting box 4, and the driven gear 1101 of the double-ended scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com