Automatic aligning and clamping device and method for circular parts

A ring type, parts technology, applied in the direction of positioning device, metal processing machinery parts, clamping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

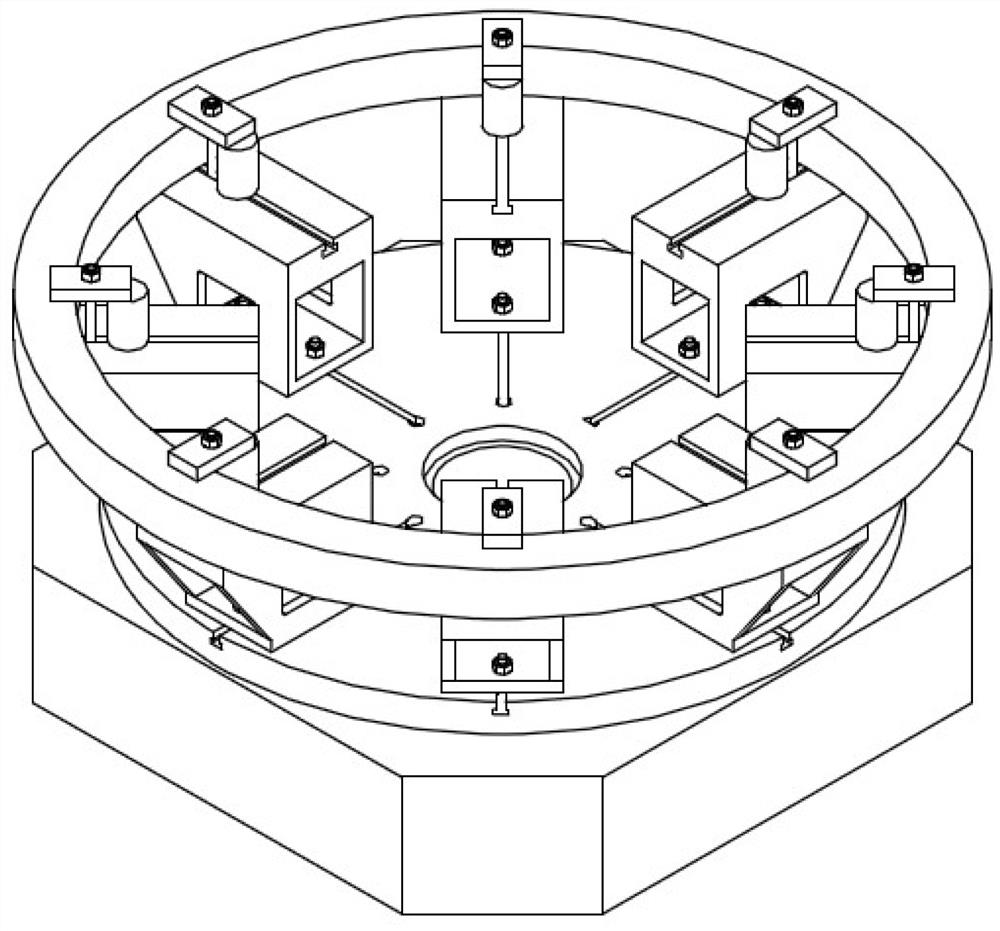

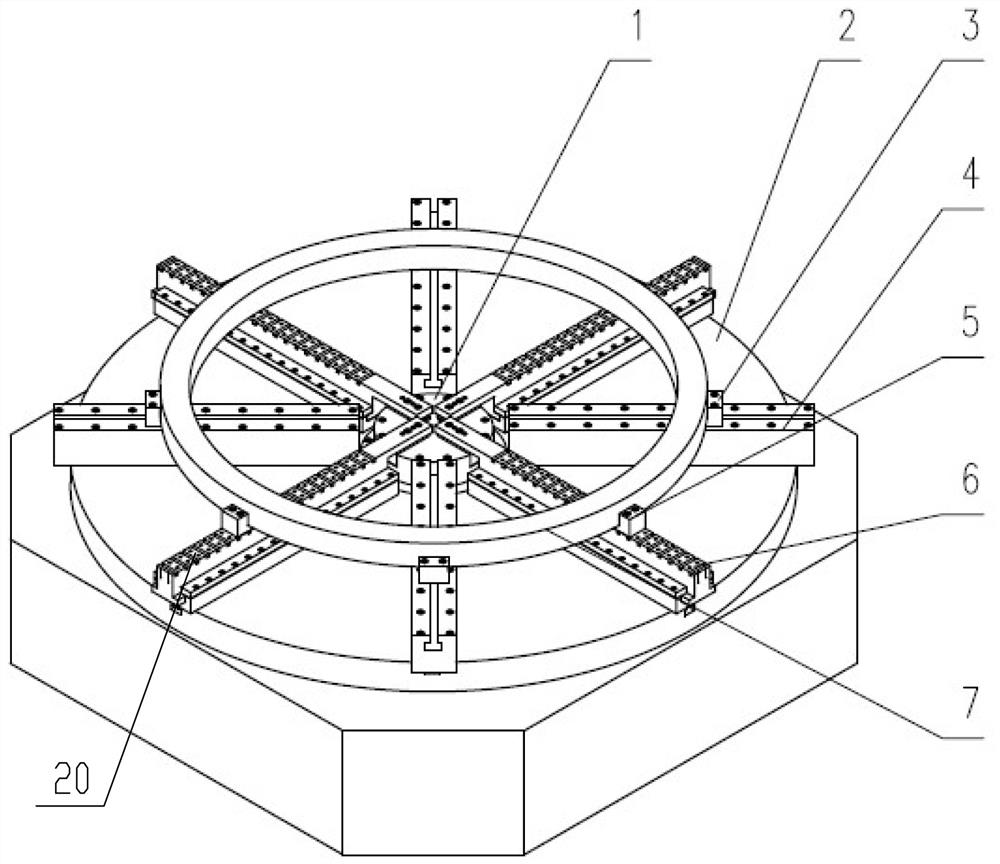

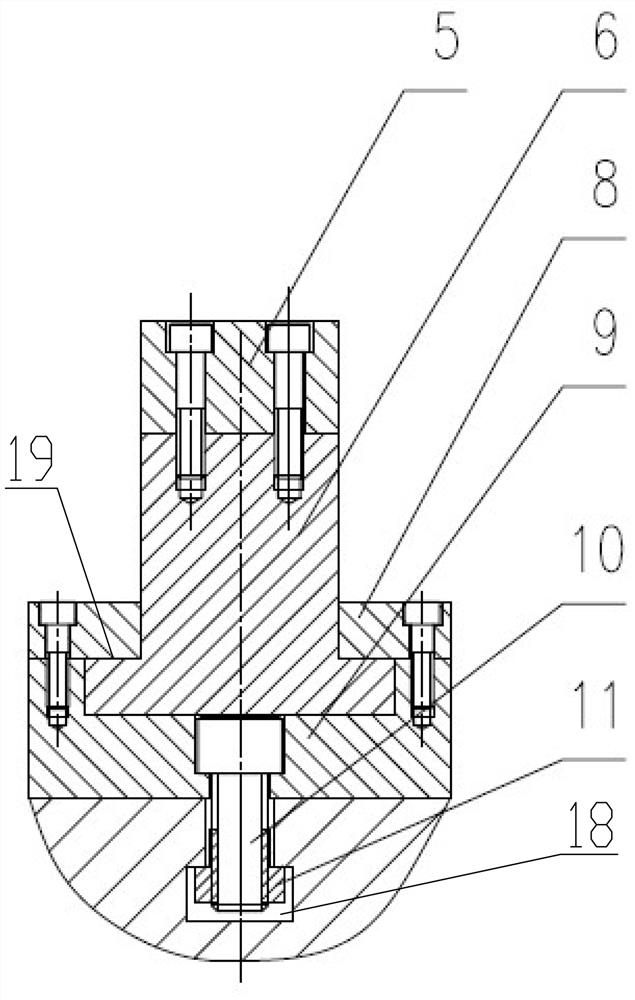

[0036] See Figure 2-4 A ring-type part automatically finds a clipper, which includes a rotary table 2, and the central portion of the rotary table 2 is fixedly mounted with a power chuck 1; the rotary table 2, and is located in the power chuck 1 The peripheral fabric processing has a plurality of T-slots 18 that are radially arranged, and a rail assembly 19 is fixed to the T-slot 18, and the rail assembly 19 is mounted with a slide 6, The inner end of the slide rail 6 is fixedly connected to the jaw 17 of the power chuck 1, and the slide rail 6 is synchronized under shrinkage or deployment operation of the plurality of jaws 17; top setting of the rail 6 There is a limit structure for limiting the workpiece. By using the above-described structure, the power chuck 1 of the appropriate size series is selected according to the diameter of the workpiece, and the power chuck 1 is applied, and the clamping operation of the power chuck 1 is used to realize the automatic workpiece 7. Care ...

Embodiment 2

[0044] The method of finding a piercing clip is used to automatically find a plurality of ring parts, including the following steps:

[0045] Step 1: Regulate the assembly position on the claw 17 on the jaw 17 according to the outer dimensions of the workpiece 7;

[0046] Step 2: After the positional adjustment of the transfer pad 14 is completed, the rail 6 is fixed to the correct position on the transition pad 14 by the cylindrical pin 13;

[0047] Step 3: Tighten the rail 6 to the jaw 17 by screw 12;

[0048] Step 4: The casing 5 is disposed at a suitable card slot 20 on the rail 6 according to the different diameter sizes of the workpiece 7;

[0049] Step 5: Start the power chuck 1, shrink by the drive jaw 17 synchronized by the power chuck 1, and then drive the slide rail 6 through the jaws 17, through the slide rail 6, and then by multiple synchronous motionsThe seat 5 clamps the workpiece 7 and ensures that the center of the workpiece is coincident with the center of the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com