Quick clamping device

A fast, curvilinear technique

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

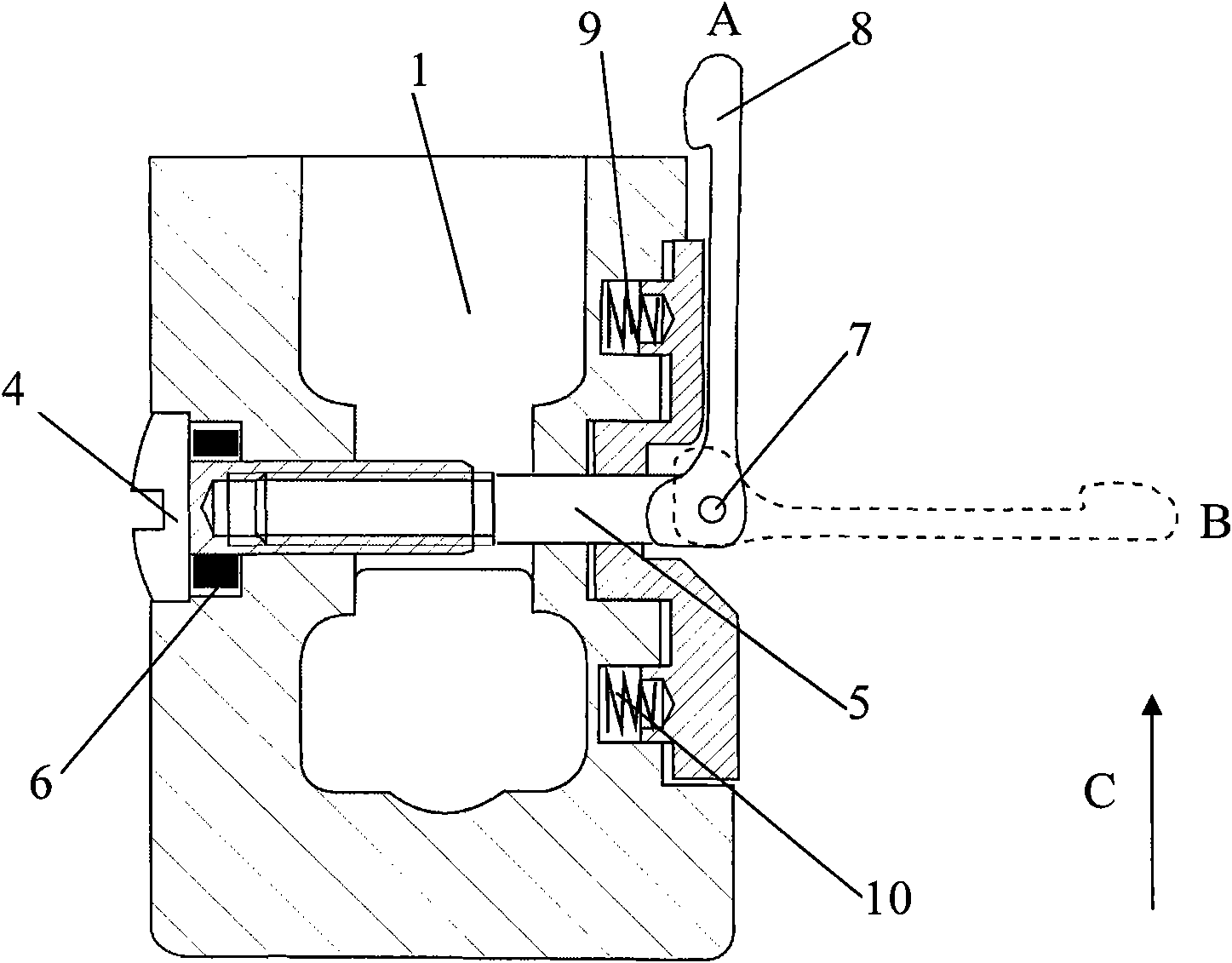

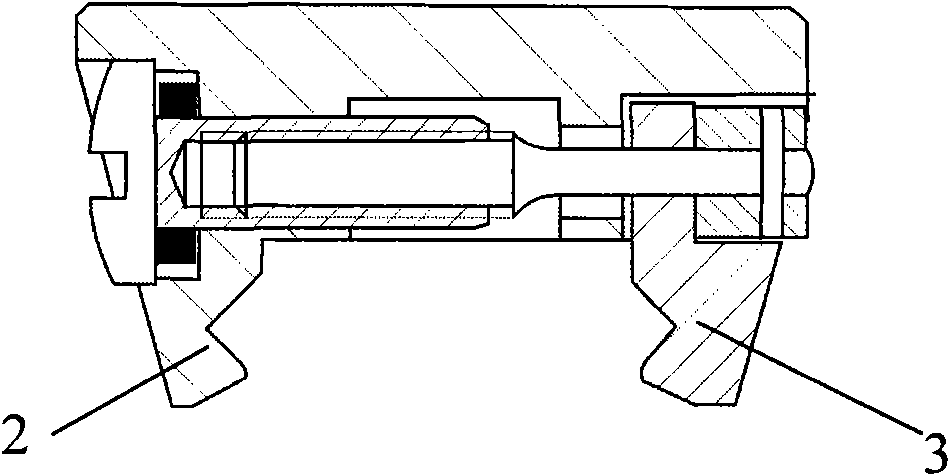

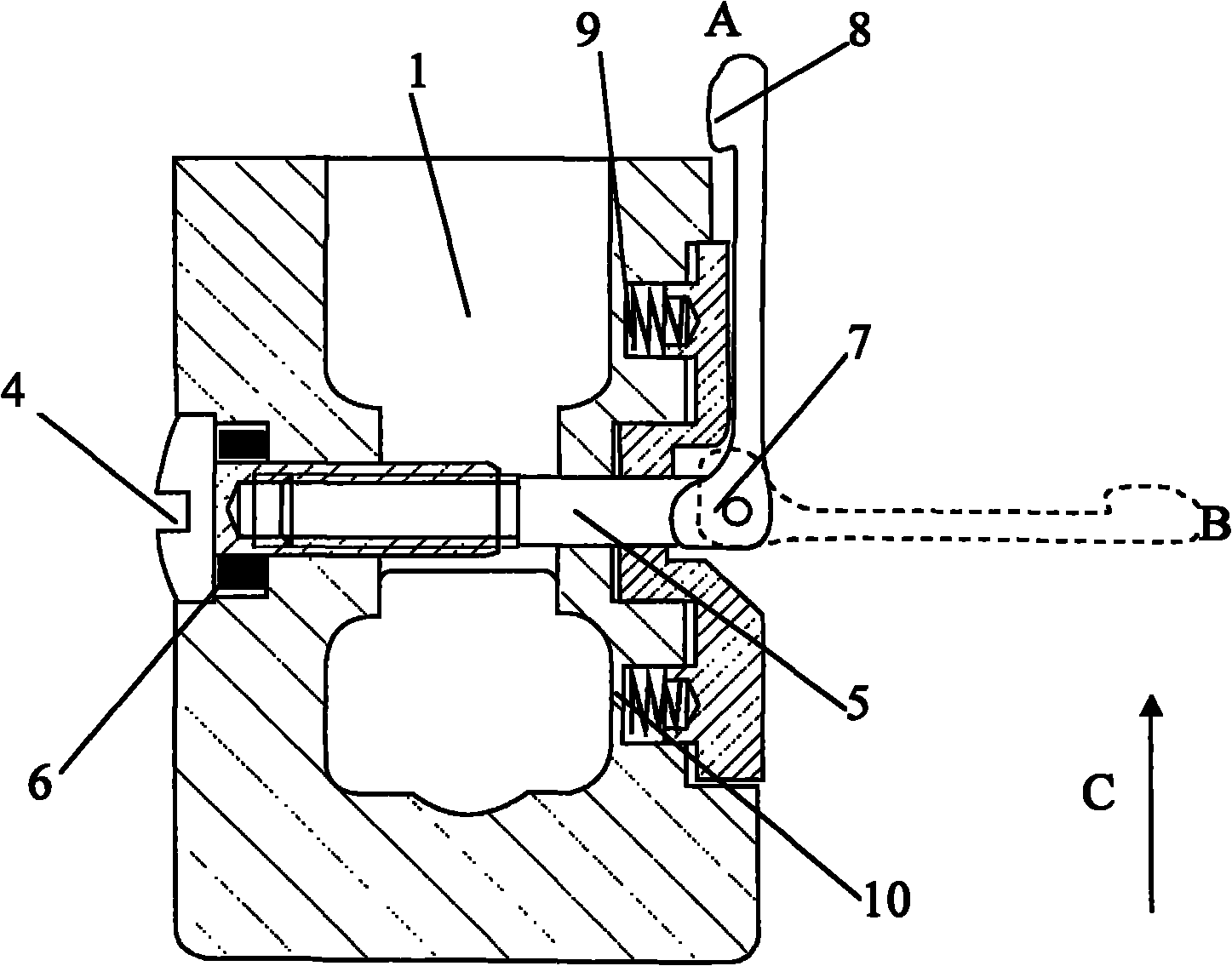

[0010] see figure 1 , 2 , the implementation device of the present invention includes: body 1, fixed slot 2, movable slot 3, pull rod sleeve 4, pull rod shaft 5, butterfly spring 6, latch 7, nonlinear curve eccentric cam handle 8, tension spring 9, 10 composition. Wherein the fixed card slot 2 and the movable card slot 3 are arranged at the lower end of the body 1 . The pull rod sleeve 4 is arranged in the middle hole of the fixing slot 2 , one end is arranged outside the fixing slot 2 , and the other end is screwed to one end of the pull rod shaft 5 . A butterfly spring 6 is arranged between one end of the pull rod sleeve 4 and the fixing slot 2 . The other end of the pull rod shaft 5 is set in the hole in the middle of the movable card slot 3 , extends to the outside of the movable card slot 3 , and is connected with the non-linear curve eccentric cam handle 8 through the latch 7 . Tension springs 9 and 10 are respectively arranged between the two ends of the movable car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com