Tolerance optimization method for all-welded assembly

An optimization method, all-welding technology, applied in design optimization/simulation, constraint-based CAD, special data processing applications, etc., can solve problems such as no public reports, application objects, and implementation methods are greatly different, and achieve the realization tolerance. Optimize and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

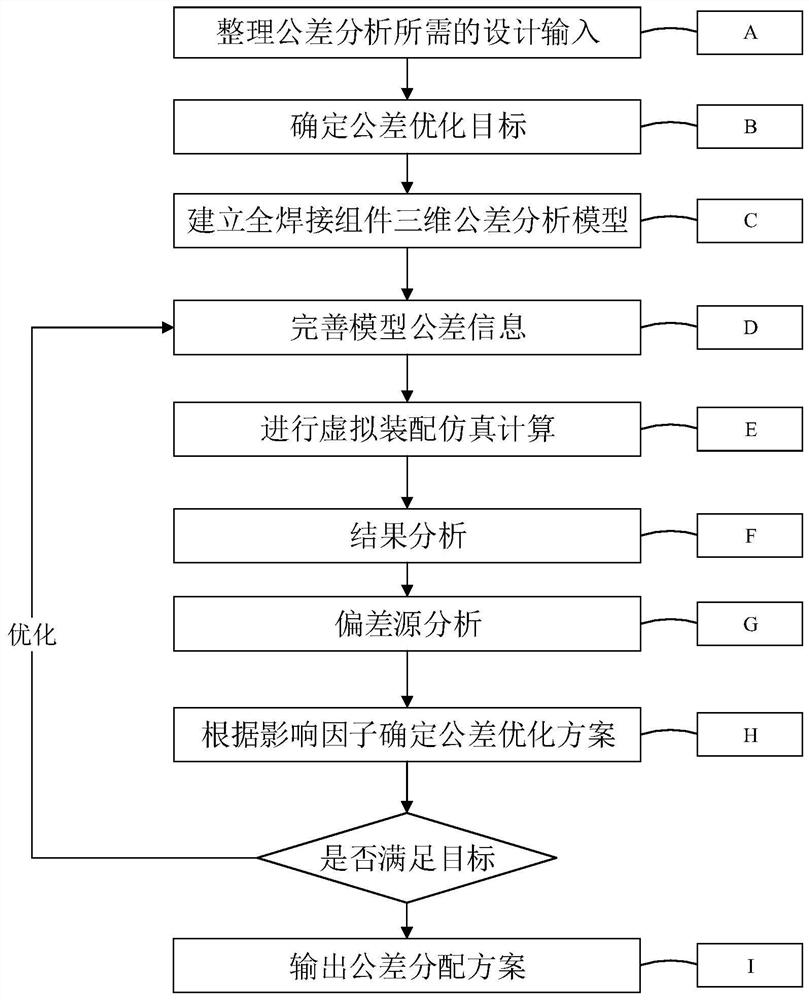

[0033] like figure 1 As shown, the steps are as follows:

[0034] Step A, sort out the design input required for tolerance analysis, specifically including: the component size of the component, design tolerance and other information; the statistical error of the assembly process and fixtures; the statistical results of welding deformation in welding steps obtained from experience ; And focus on the statistics of error sources, control methods and control difficulties of each tolerance.

[0035] Step B, determine the tolerance optimization goal, specifically include: the technical indicators expected to be achieved in the current tolerance optimization, such as the qualified rate of finished product quality requirements through tolerance optimization analysis, and the dimensional requirements to be met in the subsequent process.

[0036] Step C, establishing a three-dimensional tolerance analysis model of the fully welded assembly, specifically includes: establishing a three-dim...

Embodiment 2

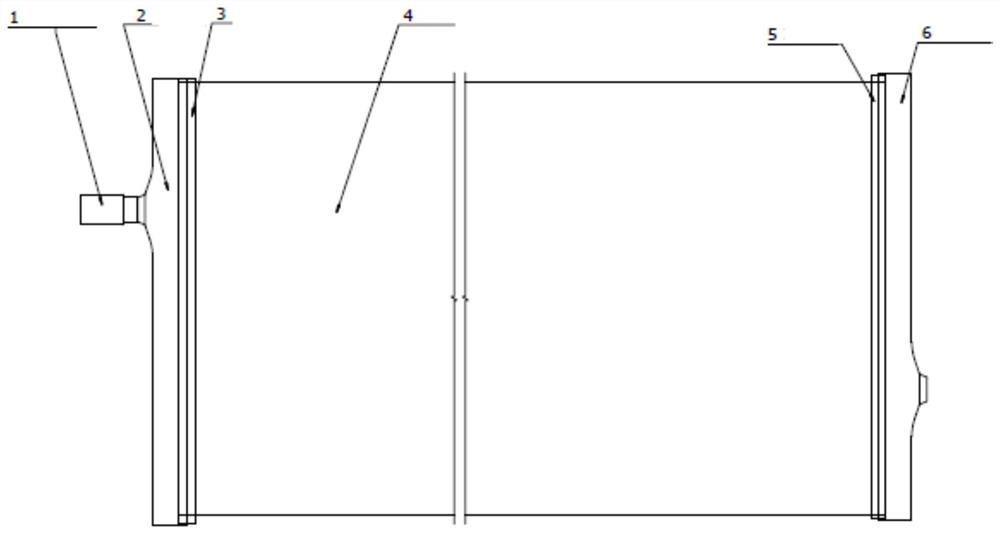

[0045] On the basis of Embodiment 1, the technical characteristics and advantages of this method are described in more detail through an example of tolerance optimization of a large complex structural part.

[0046] A large complex structural part is welded and connected by various components. The quality of the finished product is closely related to the deflection of the joint components. If the deflection is too large, it will directly affect the subsequent processing. Therefore, it is necessary to calculate the cumulative error of the welding deformation of each working step Predict and optimize the tolerance to ensure that the final deflection meets the processing requirements of the subsequent design process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com