Assembly tolerance optimization method based on quality loss and cost minimization

A tolerance and quality technology, applied in the field of assembly tolerance optimization based on quality loss and cost minimization, can solve problems such as large influence on calculation results, low precision, and unstable calculation results, so as to optimize economic benefits and improve design accuracy , the effect of stable calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

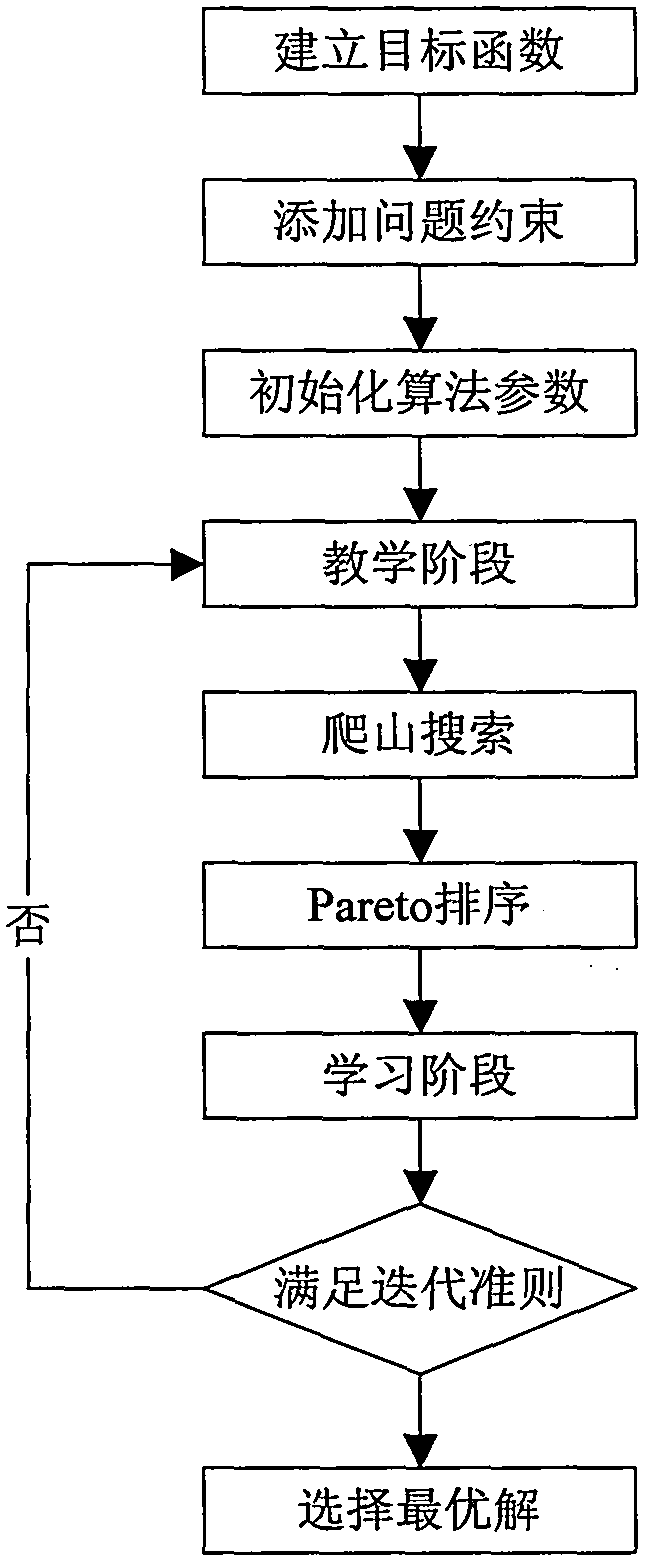

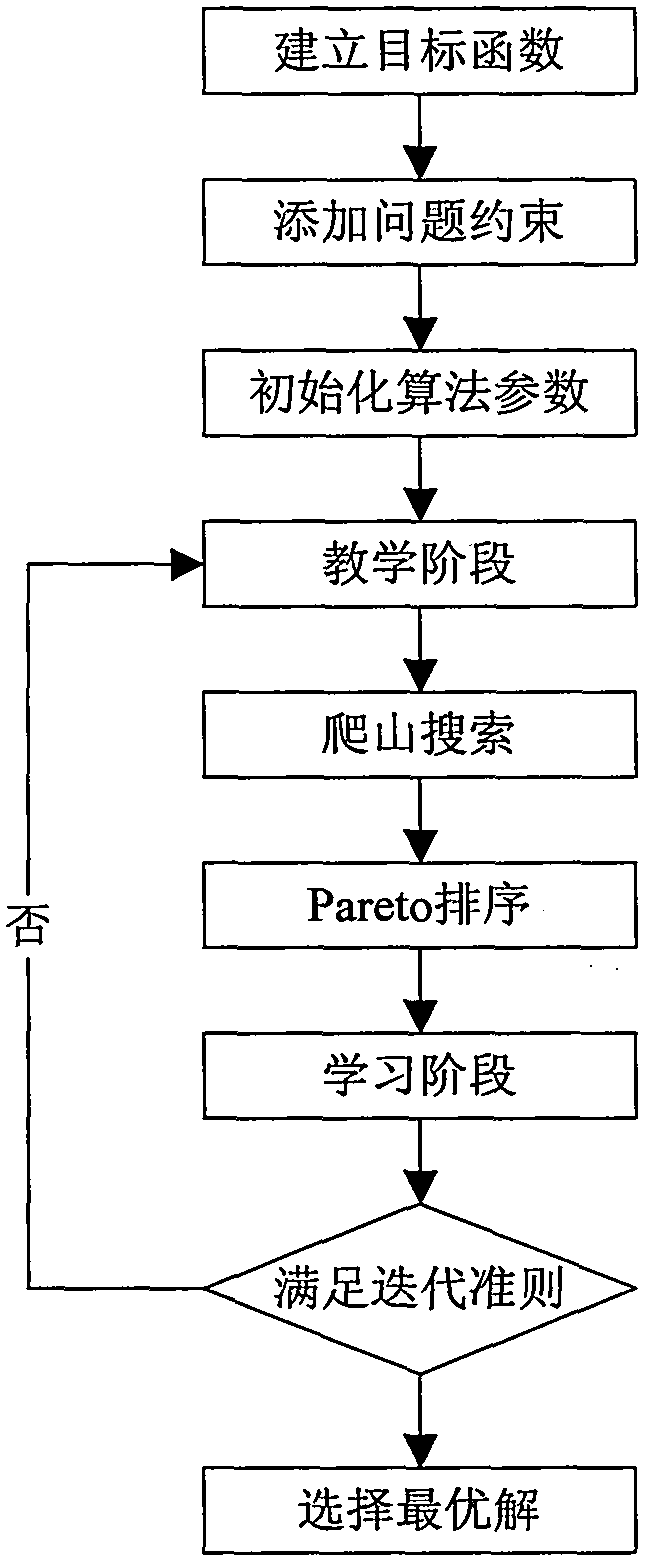

[0038] Depend on figure 1 You can see the entire algorithm flow.

[0039] Step 1: Establish the total cost model of the tolerance, which is formed by superimposing the cost model of each process in the processing process. The exponent expression of the cost of a process is shown in formula (1), and the exponent of the cost function of the assembly chain The expression is shown in formula (2).

[0040] A(t)=qe -wt (1)

[0041]

[0042] In the formula: A(t) is the processing cost of a certain process, q is the constant coefficient of control cost and tolerance, w is the constant coefficient of defining cost and tolerance, A′(t) is the processing cost of the general assembly, λ is the cost of each component ring Weight coefficient, i is the serial number of the constituent rings, and n is the total number of constituent rings.

[0043] Step 2 establishes the objective function of the mass loss model, using Taguchi Genichi’s mass loss model, the expression is shown in (3),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com