Tolerance optimization method of feed mechanism

A technology of feeding mechanism and optimization method, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of contradiction between manufacturing quality and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

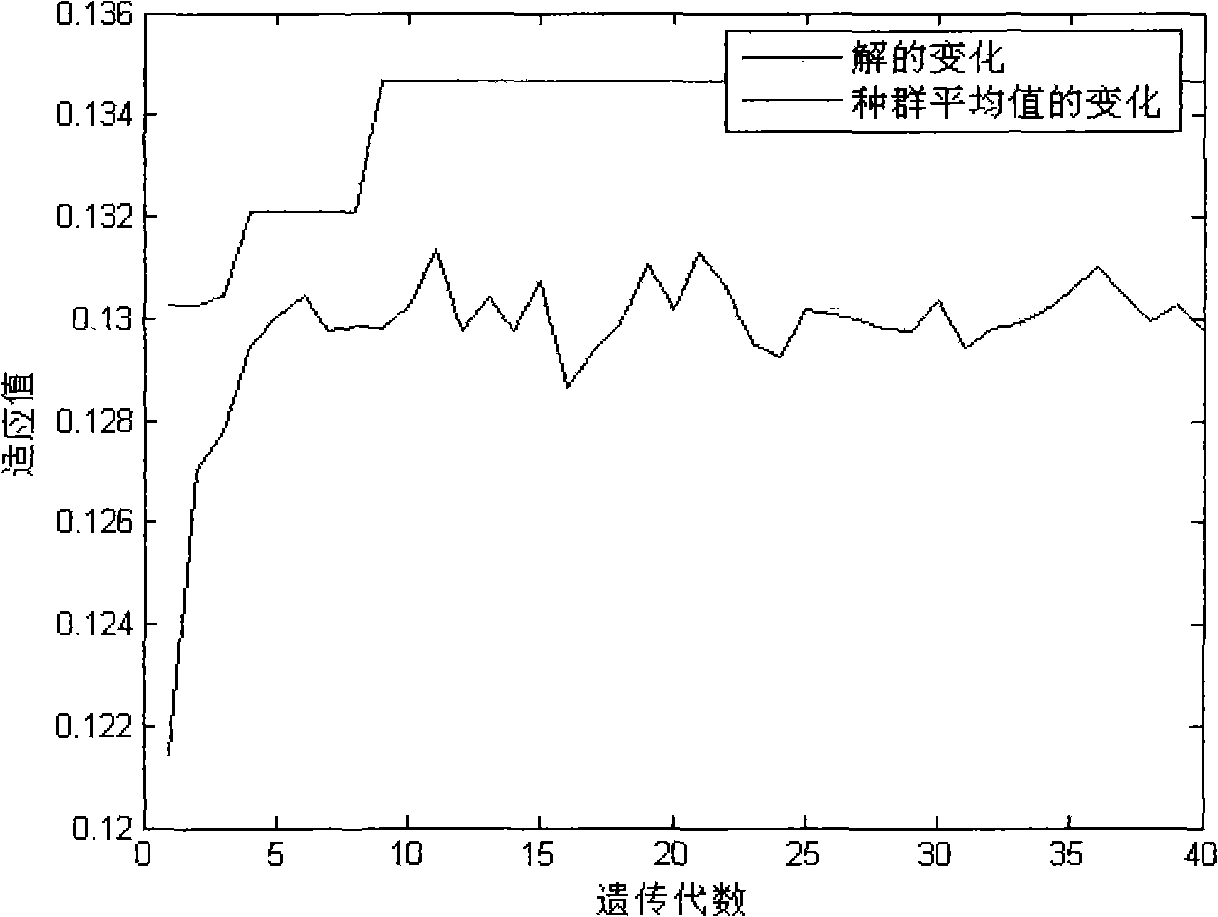

[0038] A feeding mechanism tolerance robust optimization embodiment of the present method invention is described as follows:

[0039] This embodiment is based on the design parameters of the feeding mechanism of a certain type of cold heading machine provided by the enterprise, and its tolerance is robustly optimized.

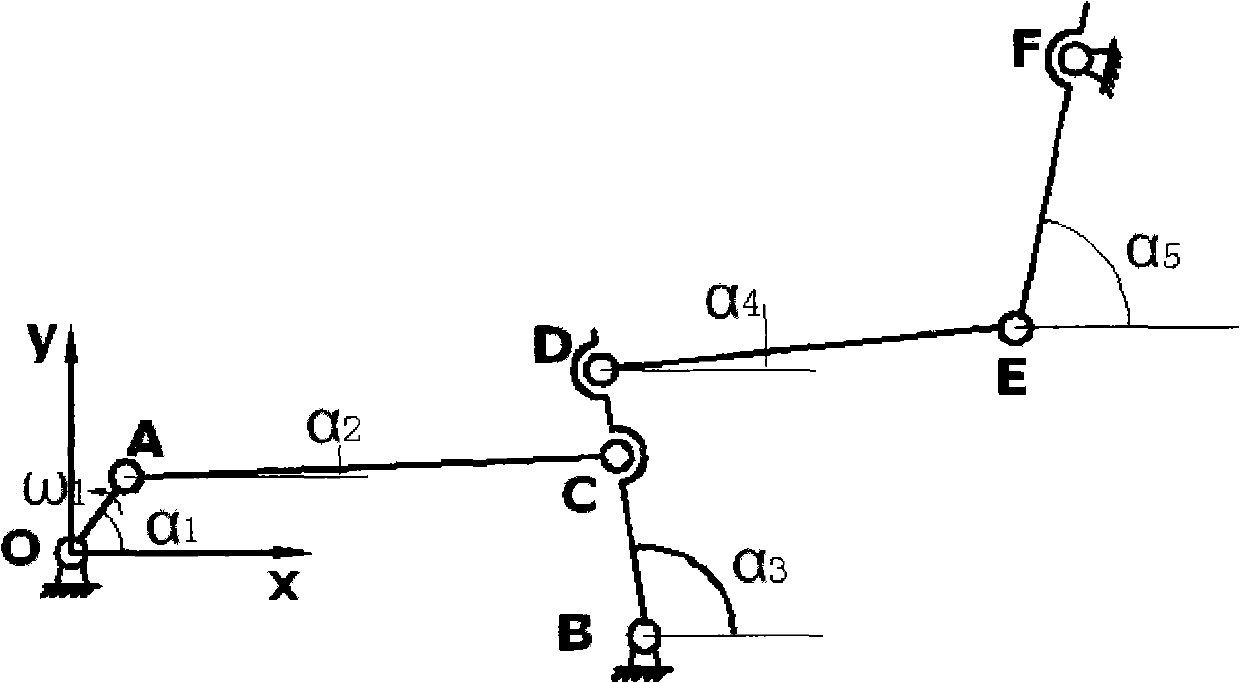

[0040] (1) The feeding mechanism model can be simplified as a serial combination of two sets of linkage mechanisms, and the simplified model diagram is as follows figure 1 As shown, wherein, rod OA is a crank, which corresponds to the feeding eccentric wheel structure; rocker BCD corresponds to the feeding rocker structure, wherein the length of BD is an adjustment parameter (which can be less than the length of BC) to meet the requirements of different feeding lengths; The rod EF corresponds to the structure of the ratchet rocker arm, and the maximum swing angle that it can achieve in one working cycle determines the length of the feeding.

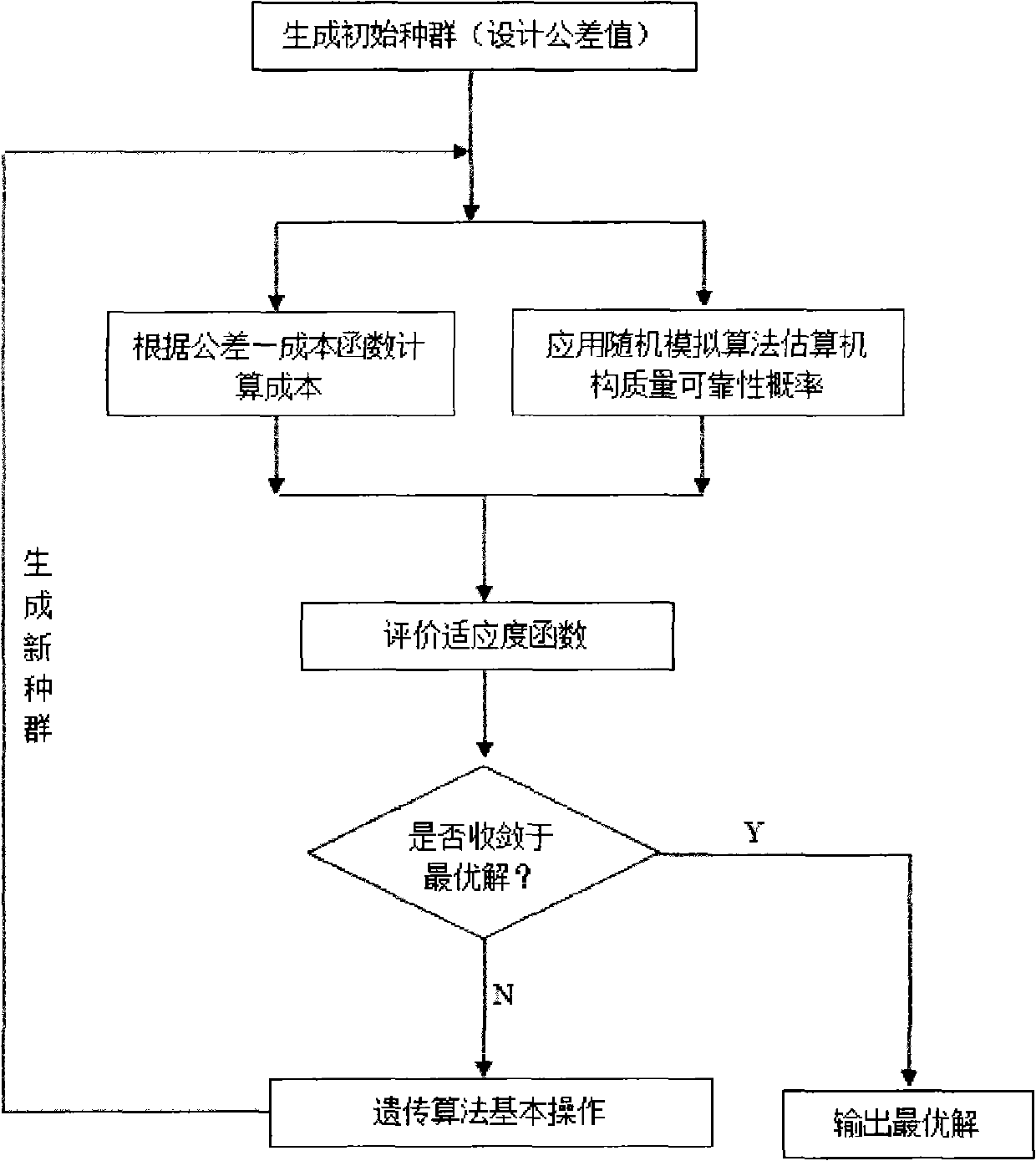

[0041] (2) In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com