Automobile transmission shaft high-antitorque-reliability tolerance optimization design method

A technology for optimizing design and transmission shafts, applied in computing, special data processing applications, instruments, etc., can solve problems such as difficulty in obtaining optimal solutions, damage interaction, and inability to guarantee the safety of automobile transmissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

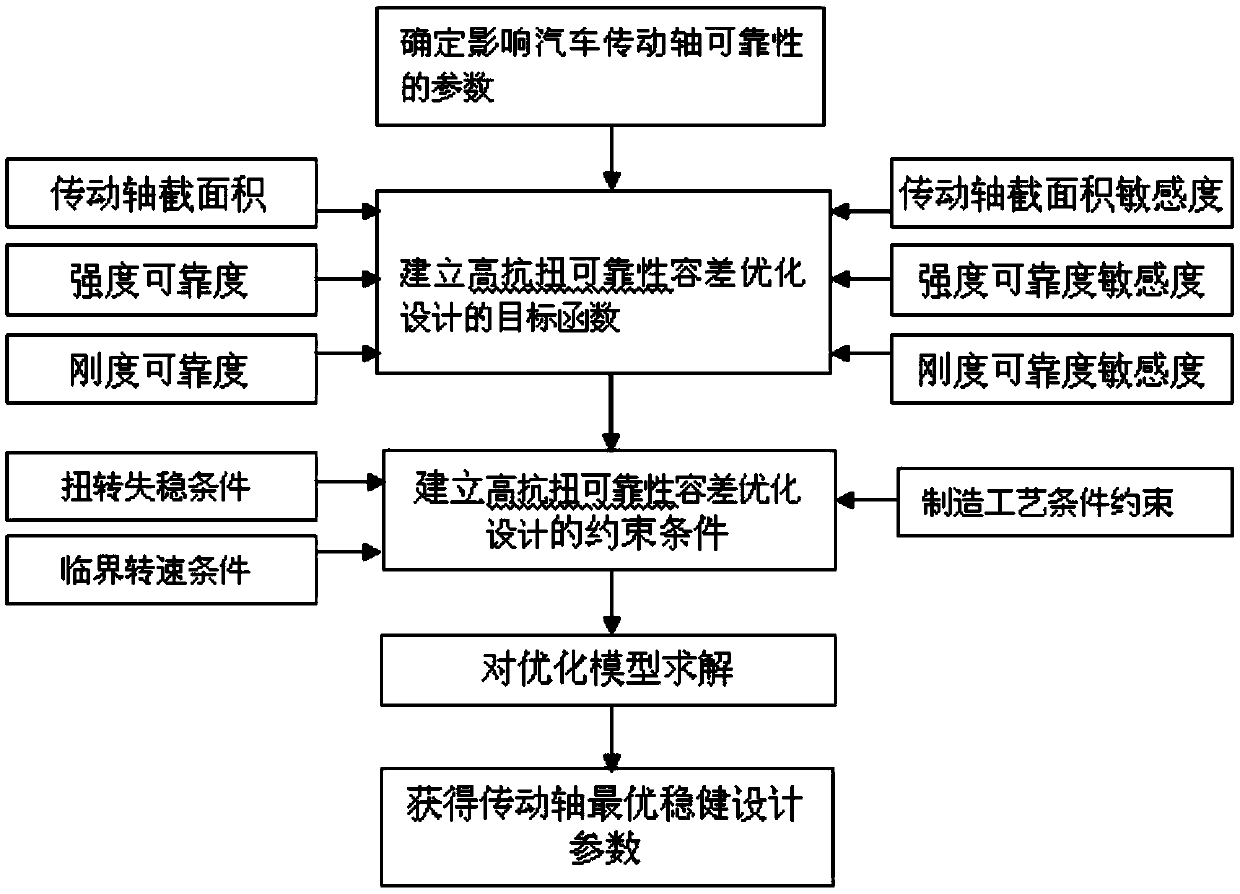

[0081] see figure 1 , the present invention discloses a high torsional reliability tolerance optimization design method of an automobile transmission shaft, comprising the following steps:

[0082] (1) According to the structure and material characteristics of the automobile transmission shaft, determine the parameters that affect the reliability of the automobile transmission shaft;

[0083] (2) Establish a multi-objective function for the optimal design of the high torsional reliability tolerance of the automobile transmission shaft;

[0084] (3) Establish multi-mode constraint conditions for optimal design;

[0085] (4) Solve the optimal design model of the high torsional reliability tolerance of the automobile transmission shaft to obtain the optimal design parameters.

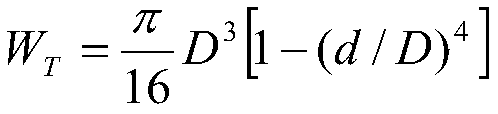

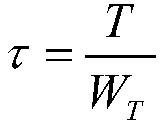

[0086] As preferably, step (1), under the certain situation of power, influences the parameter of automobile transmission shaft reliability to set: the modulus of elasticity of transmission shaft is E, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com