Water-saving tailing discharge method

A technology of tailings and tailings ponds, which is applied in the field of metallurgy and mines. It can solve the problems of difficult operation, high infrastructure investment and dehydration operation, and easy dusting of tailings ponds. It achieves high permeability coefficient, high safety factor, and anti-skid stable big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

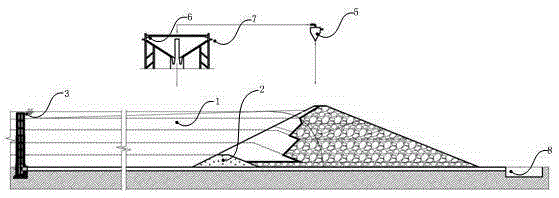

[0028] When the amount of coarse tailings in the tailings is relatively large, the tailings dam can adopt the downstream dam filling method.

[0029] figure 1 Among them, the height of the initial dam 2 is determined according to the storage capacity formed by it, which can store at least the amount of tailings more than half a year after the concentrator is put into operation, and meets other regulations of the specification. The initial dam is preferably a permeable rockfill dam, or an earth-rock dam with seepage drainage facilities on the inner slope of the dam, which can guide the seepage water from the tailings slurry to the outside of the dam, speed up the consolidation of the tailings, and increase the stability of the dam body.

[0030] Flood drainage system 3 is arranged according to terrain and geological conditions, and generally adopts other types such as drainage well-drainage pipe type, drainage well-drainage tunnel type or drainage chute-drainage pipe type.

[...

Embodiment 2

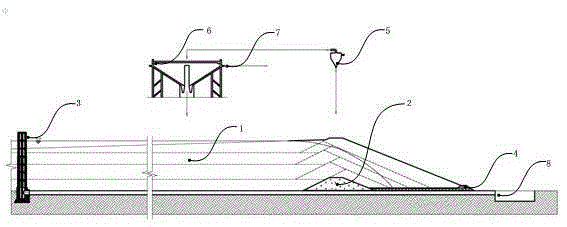

[0036] When the amount of coarse tailings in the tailings is small, but there are more ore dressing or mining waste rocks, the tailings dam can adopt the improved downstream dam method. The inside of the dam uses classified coarse tailings, and the outside of the dam uses waste rocks. A reverse filter layer is set in the middle joint part.

[0037] figure 2 Among them, the height of the initial dam 2 is determined according to the storage capacity formed by it, which can store at least the amount of tailings more than half a year after the concentrator is put into operation, and meets other regulations of the specification. The initial dam 2 is preferably a permeable rockfill dam, or an earth-rockfill dam with seepage drainage facilities on the inner slope of the dam, which can guide the seepage water from the tailings slurry to the outside of the dam, speed up the consolidation of the tailings, and increase the stability of the dam body.

[0038] Flood drainage system 3 is ar...

Embodiment 3

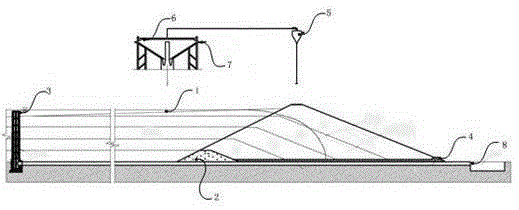

[0044] When the amount of coarse tailings in the tailings is small, and the ore dressing or mining waste is small, the tailings dam can adopt the centerline dam method.

[0045] image 3 Among them, the height of the initial dam 2 is determined according to the storage capacity formed by it, which can store at least the amount of tailings more than half a year after the beneficiation is put into production, and meets other regulations of the specification. The initial dam 2 is preferably a permeable rockfill dam, or an earth-rockfill dam with seepage drainage facilities on the inner slope of the dam, which can guide the seepage water from the tailings slurry to the outside of the dam, speed up the consolidation of the tailings, and increase the stability of the dam body.

[0046] Flood drainage system 3 is arranged according to terrain and geological conditions, and generally adopts other types such as drainage well-drainage pipe type, drainage well-drainage tunnel type or dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com