Evaluation method for defects of CPR1000 unit reactor pressure vessel core cylindrical shell zones

A technology for pressure vessels and reactors, applied in reactors, nuclear reactor monitoring, reduction of greenhouse gases, etc., can solve problems such as the impact on the safe operation of nuclear power plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

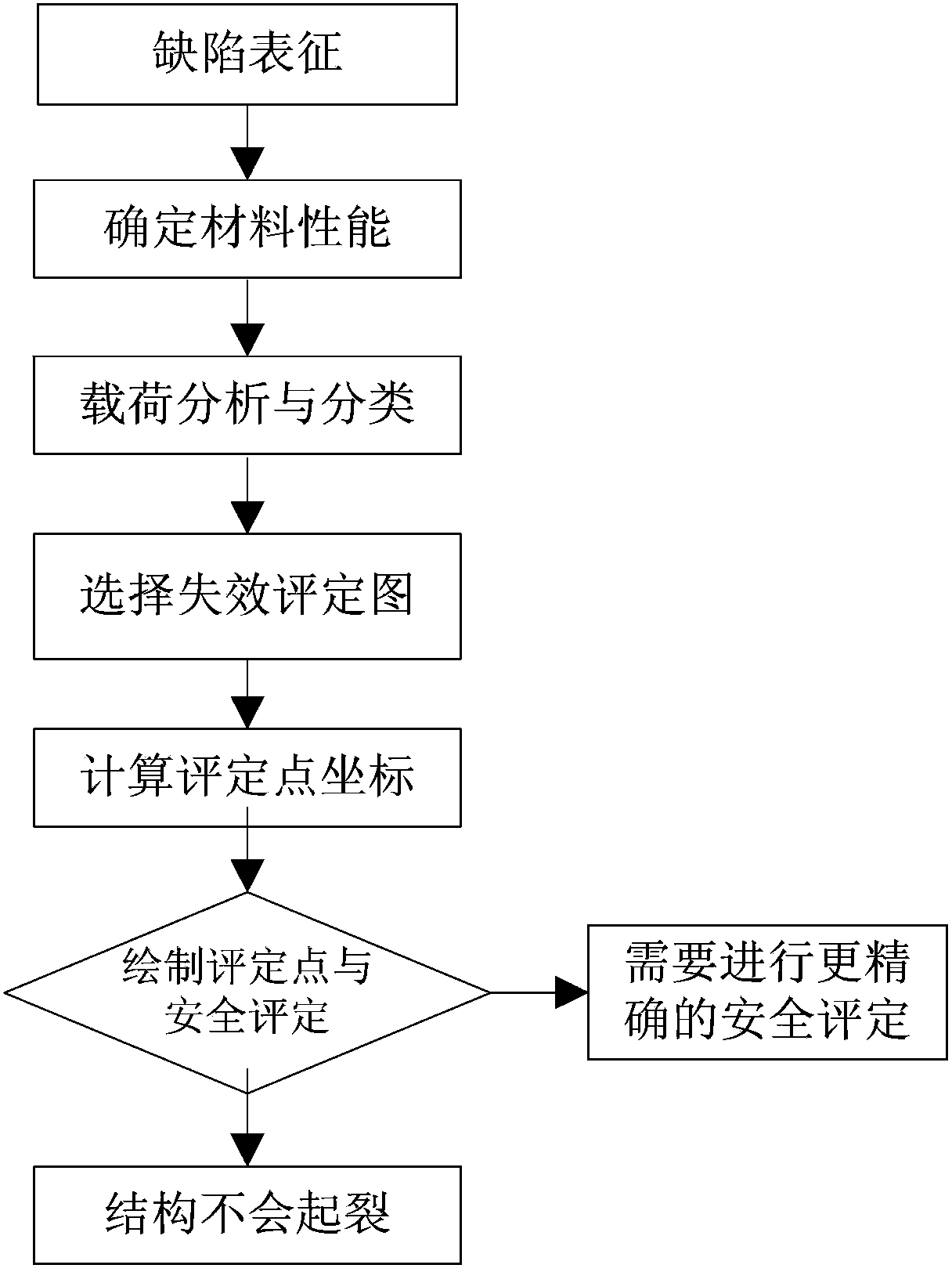

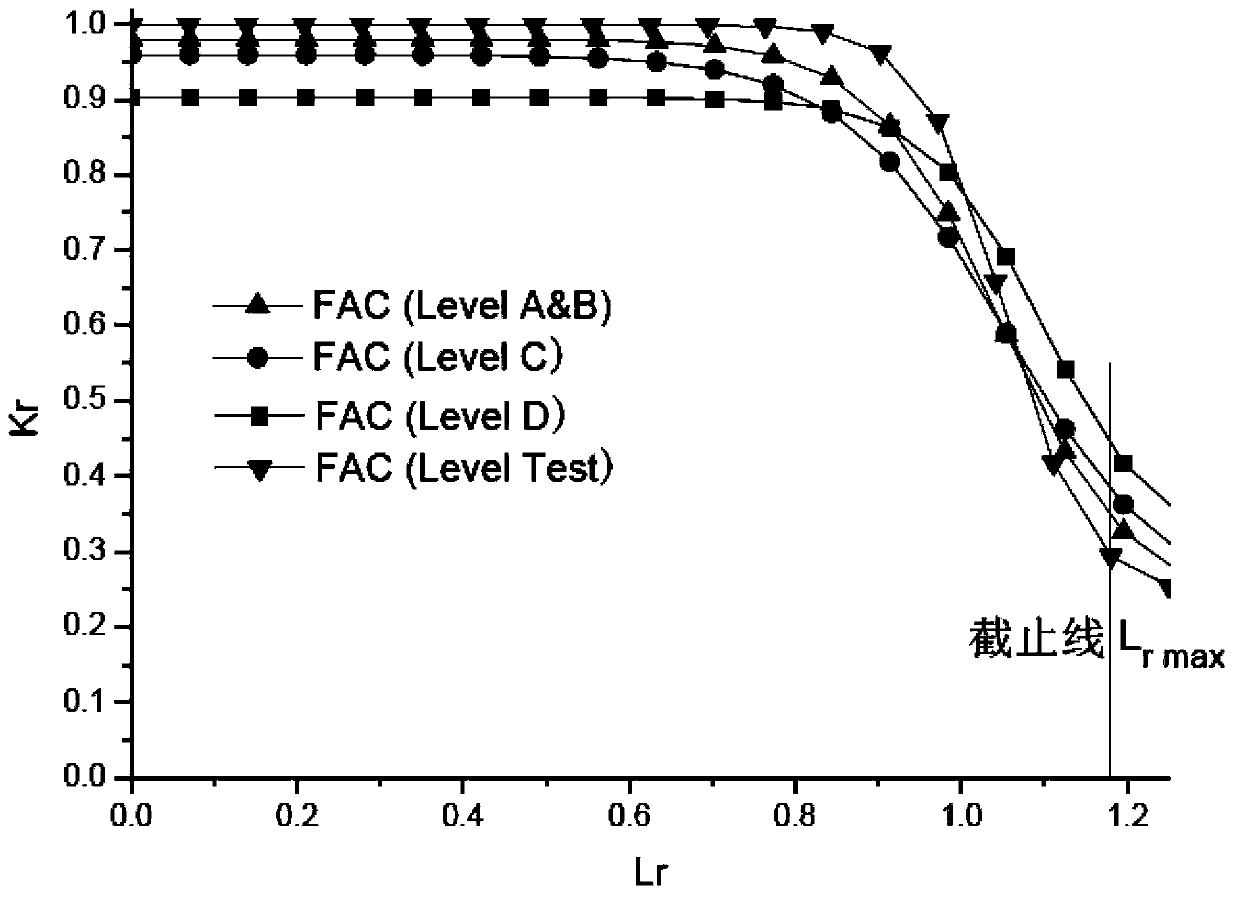

Method used

Image

Examples

Embodiment 1

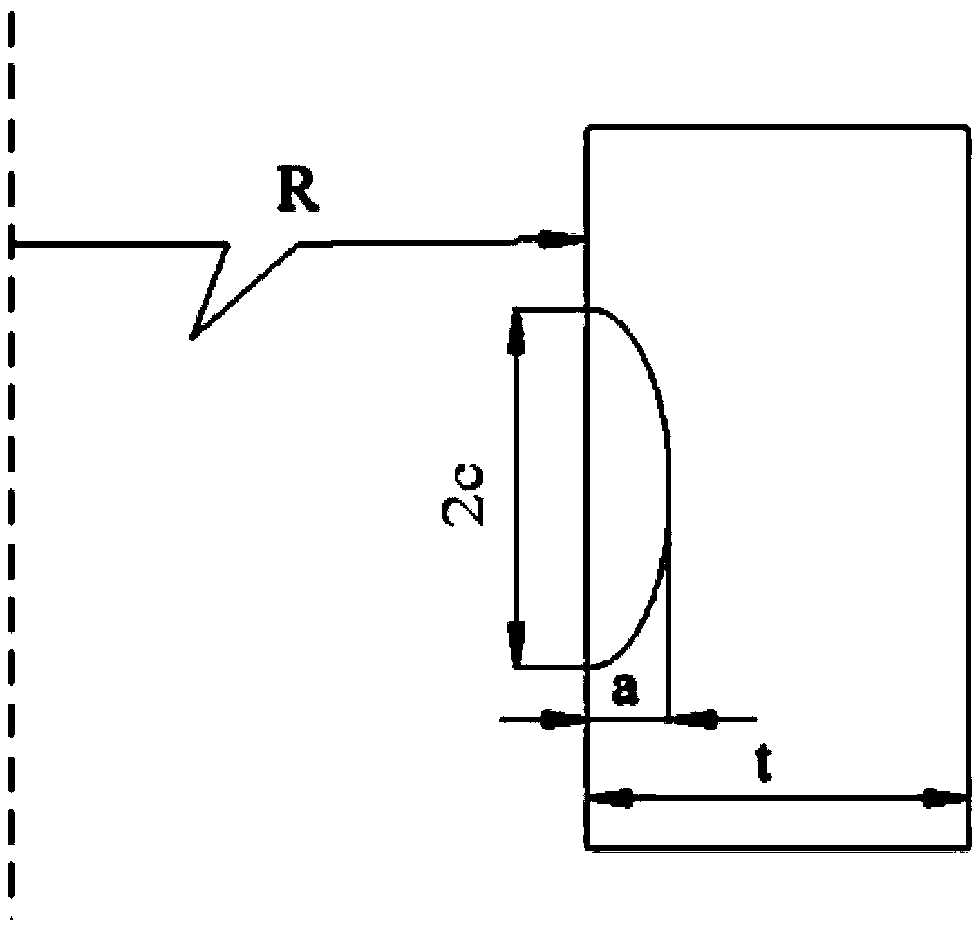

[0068] (1) Defect characterization

[0069] There are axial cracks on the axial inner surface of the RPV core barrel, the crack depth a=19.945mm, and the defect length 2c=119.67mm.

[0070] (2) Determine material properties

[0071] RPV material is steel 16MND5. See RCCM specification for material properties. The fracture toughness of the material is taken as the fracture toughness value of the material given in Appendix ZG of the RCCM Code, and the ductile-brittle transition temperature NDT RT is taken as 20°C.

[0072] (3) Load analysis and classification

[0073] Assuming that the evaluated transient is a cold shutdown transient, the pressure and temperature in the RPV change with time as shown in Table 1. The RPV core barrel bears the internal pressure load and the thermal stress load caused by the cooling process, where the internal pressure load It belongs to the primary load, and the thermal stress load is the secondary stress load.

[0074] Table 1 Pressure and te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com