Forecast evaluation method of radiation embrittlement of reactor pressure vessel

A technology of pressure vessels and reactors, which is applied in the direction of instruments, special data processing applications, electrical digital data processing, etc., and can solve problems such as poor stability and inaccurate data collection model parameter settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

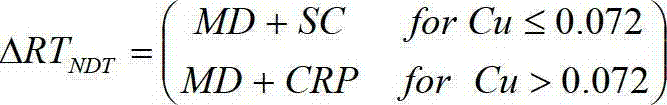

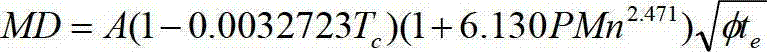

Method used

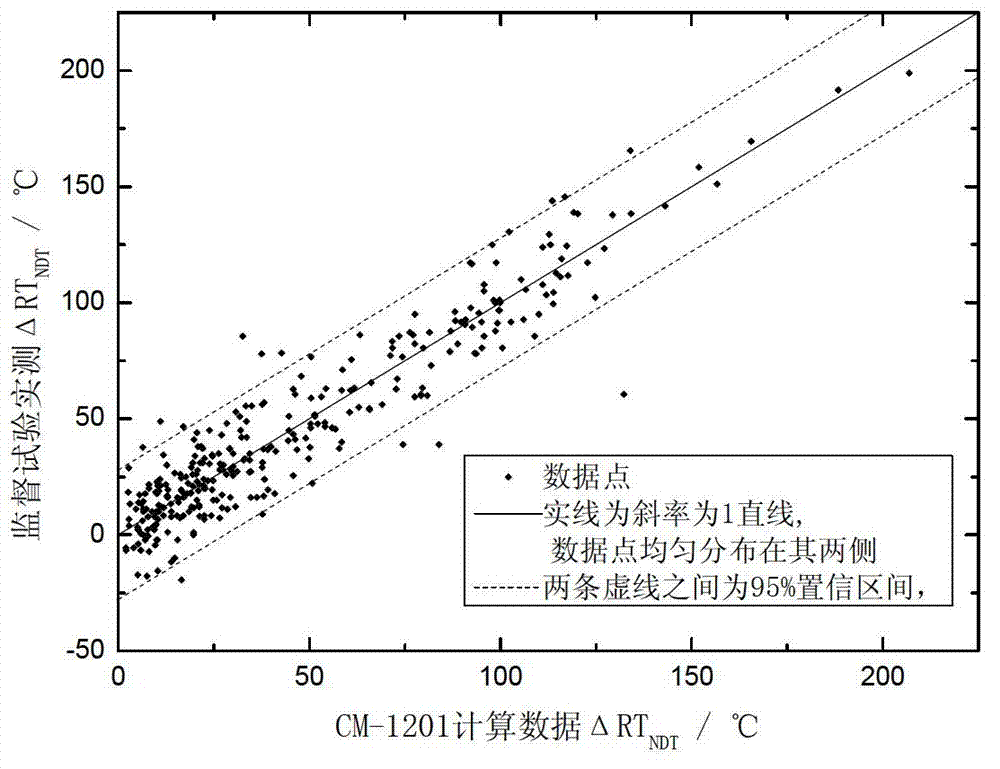

Image

Examples

Embodiment

[0058] The nuclear power plant uses A508-III material as the reactor pressure vessel material, the design service life is 40 full power years, and the allowable adjustment reference temperature ART at the end of the service life is 85°C. The specific chemical compositions of the materials are listed in Table 1. The T measured by the Charpy impact test of the unirradiated A508-III base metal 41J -47°C, RT NDT =-20°C, RT NDT The measurement accuracy is σ I =7°C, after the pressure vessel has operated with the stack for a long time, T 41J The temperature became -20°C. The manufacturing process of pressure vessels is forging. The average operating temperature of the reactor at full power is 290°C. After 20 years of full power operation, the fast neutron fluence at the 1 / 4 wall thickness of the pressure vessel from the inner surface was determined to be 2.99×10 19 n / cm 2 , the neutron fluence rate is 3.95×10 10 n / (cm 2 .s ec), the T measured by the Charpy impact test of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com