Probe frame of supersonic inspection device for weld joint at safe end of nuclear reactor pressure vessel

A technology for ultrasonic inspection of pressure vessels, which is applied in the field of ultrasonic probe holders, can solve problems such as limitations, increased time for ultrasonic inspection of weld seams at the safety end of pressure vessels, and missing scans, and achieve accurate and reliable results, prevent scratches on the inner wall of the nozzle, and achieve good results. coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, illustrate in detail the specific content of the preferred implementation of the probe holder of the present invention:

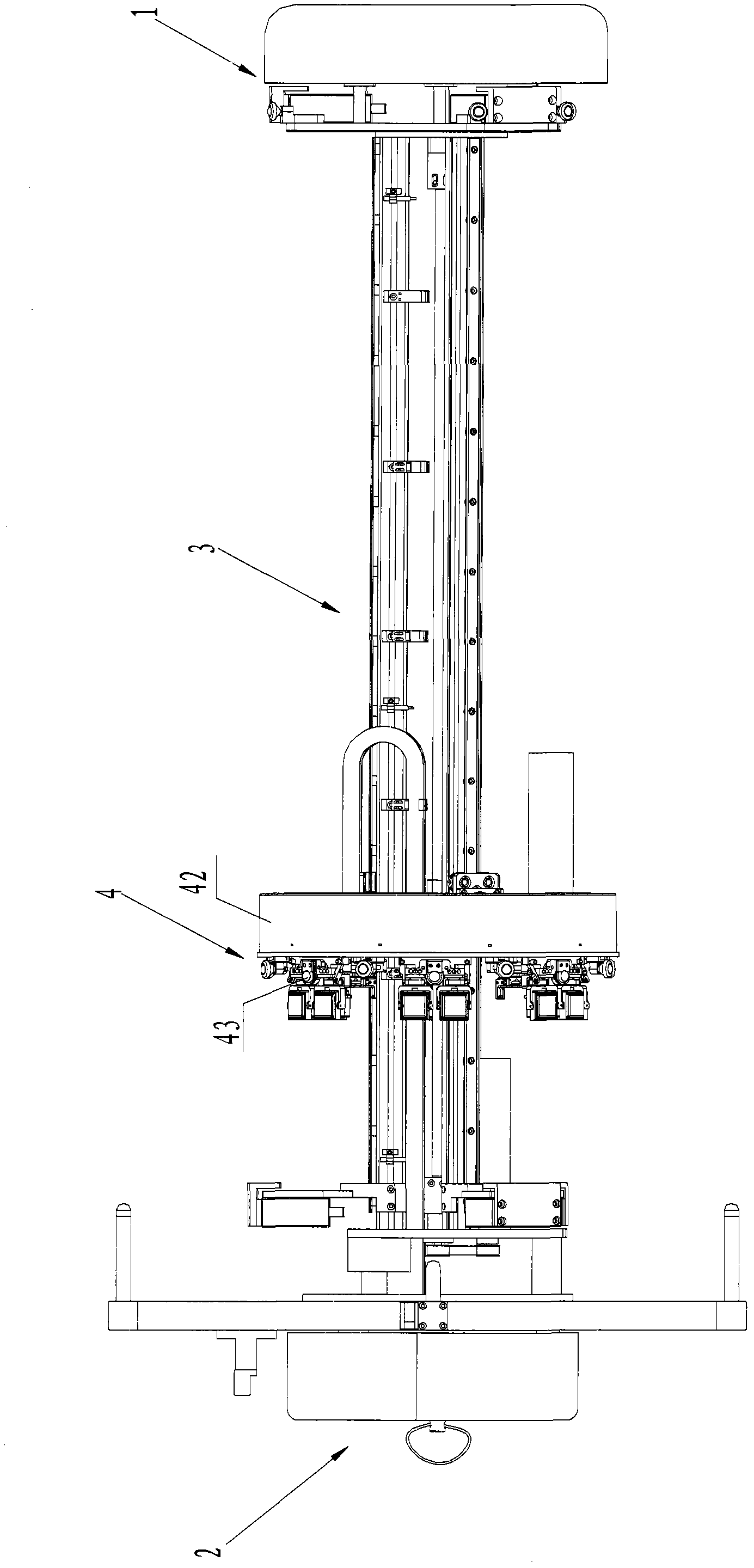

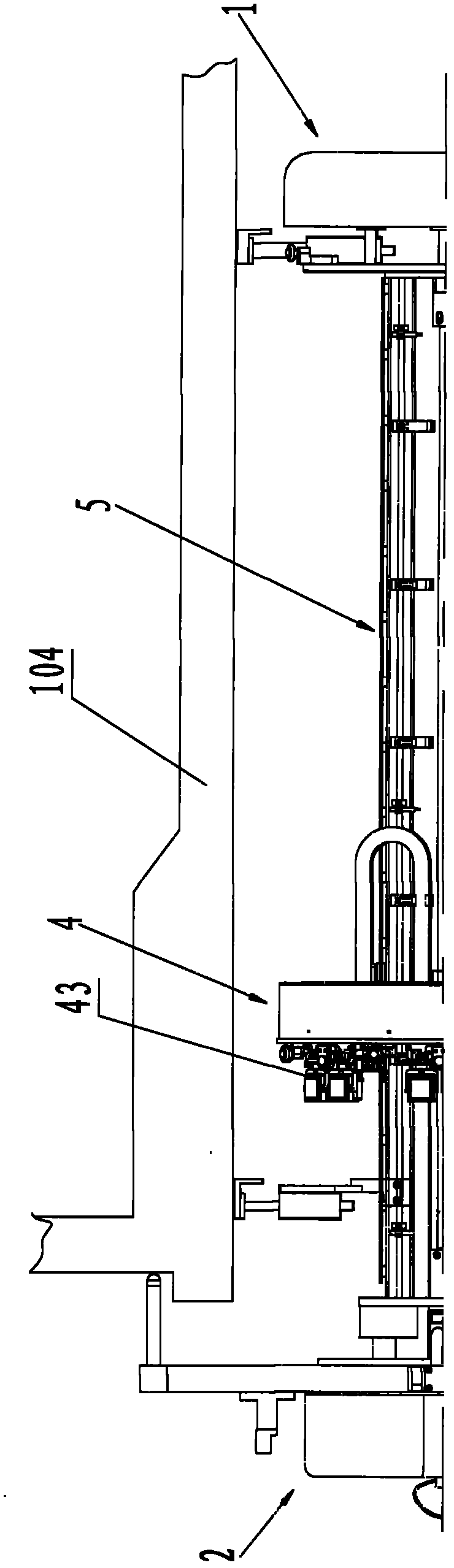

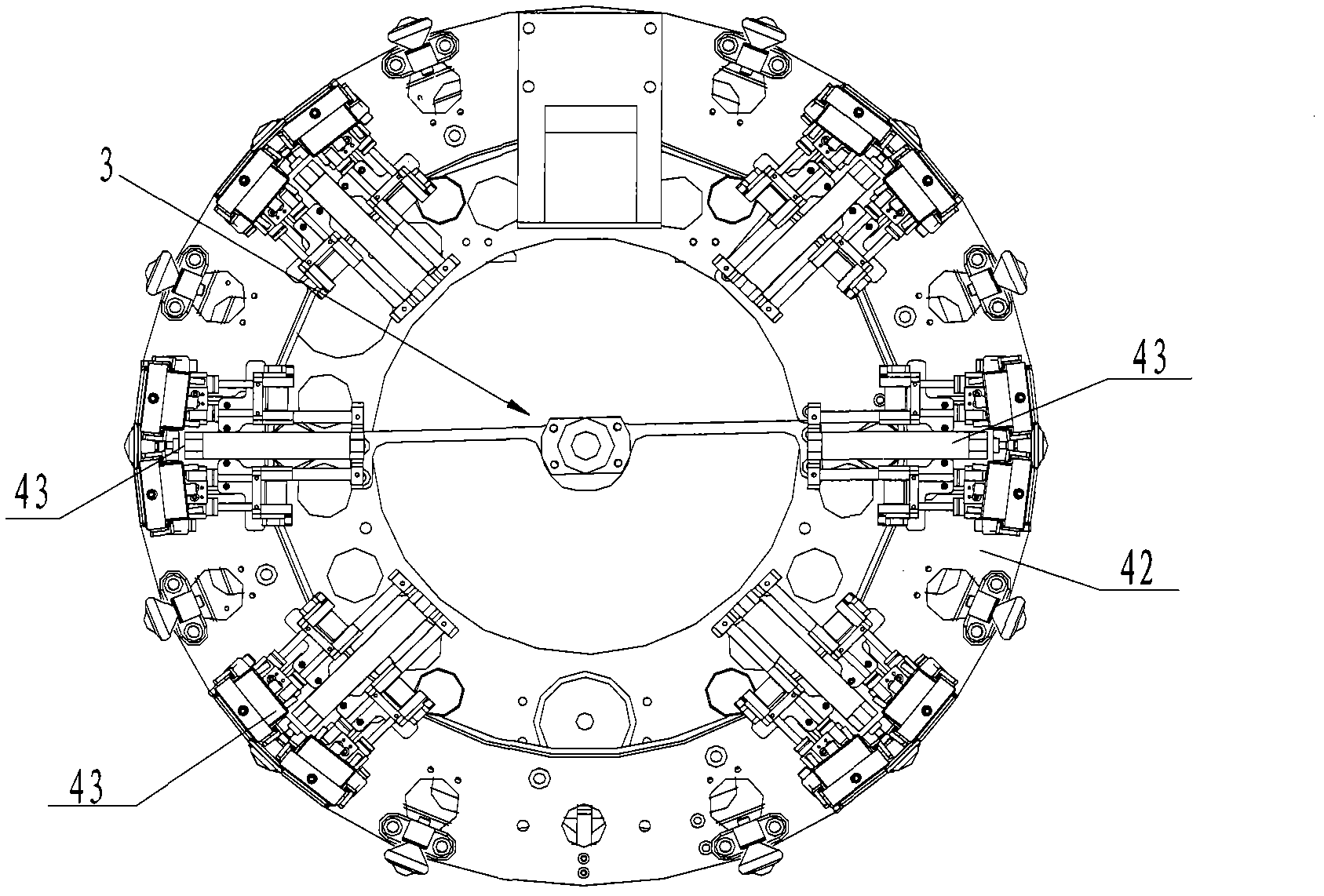

[0022] figure 1 and figure 2 The ultrasonic inspection equipment shown mainly consists of a front-end support module 1, a rear-end support module 2, a guide rail assembly 3 detachably connected between the front-end support module 1 and the rear-end support module 2, and a guide rail assembly 3 arranged on the relative The guide rail assembly 3 is composed of an ultrasonic probe scanning module 4 that performs axial linear movement and circumferential rotation. Among them, the front-end support module 1 mainly plays the role of guiding and radial positioning in the nozzle, the rear-end support module 2 is mainly used to realize the positioning of the equipment on the wall of the pressure vessel cylinder and along the axial direction of the nozzle, and the guide rail assembly 3 Mainly play the role o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com