Method and device for monitoring irradiation damage of reactor pressure vessel in nuclear power plant

A pressure vessel, radiation damage technology, applied in the fields of nuclear reactor monitoring, reactor, nuclear power generation, etc., can solve the problems of large amount of three wastes, high cost, limited number of radiation supervision tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

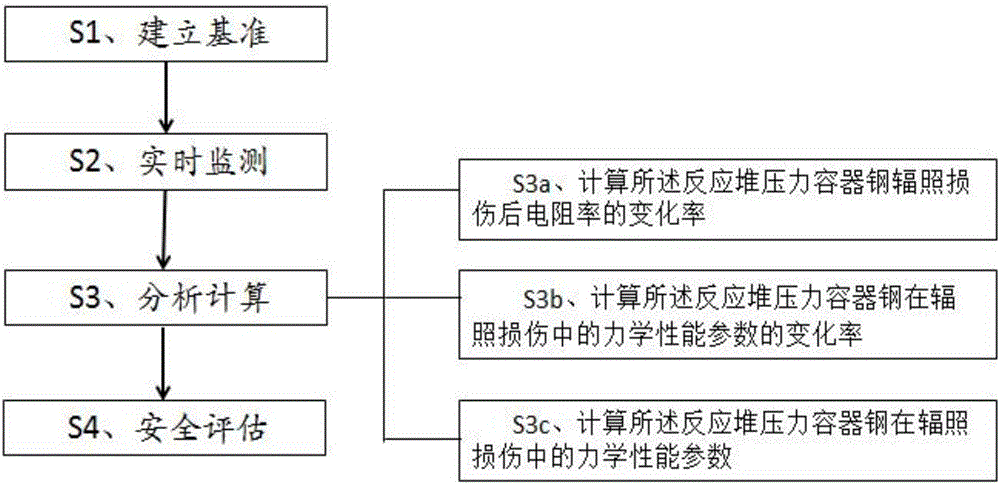

[0080] figure 1 It shows the steps of a method for real-time monitoring of the radiation damage of the reactor pressure vessel:

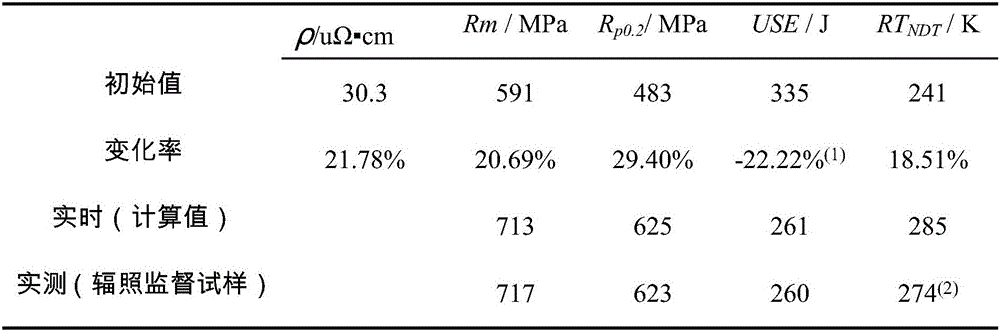

[0081] S1. Establish a benchmark: measure the initial resistivity ρ of the reactor pressure vessel steel 0 Specifically, the "four-lead method (also known as four-point method or four-terminal method)" can be used to measure the initial resistivity ρ of the steel in the core area of the reactor pressure vessel 0 is 30.3μΩ·cm, and other conventional methods can also be used to measure the initial resistivity ρ0 of the reactor pressure vessel.

[0082] S2. Real-time monitoring: During the normal operation of the nuclear power plant, the resistivity ρ of the reactor pressure vessel steel after irradiation damage at a specific time point is obtained in real time; specifically, the "four-lead method (also known as the four-point method or Four-terminal method)" to measure the real-time resistivity ρ of the same position after the radiation damage of ...

Embodiment 2

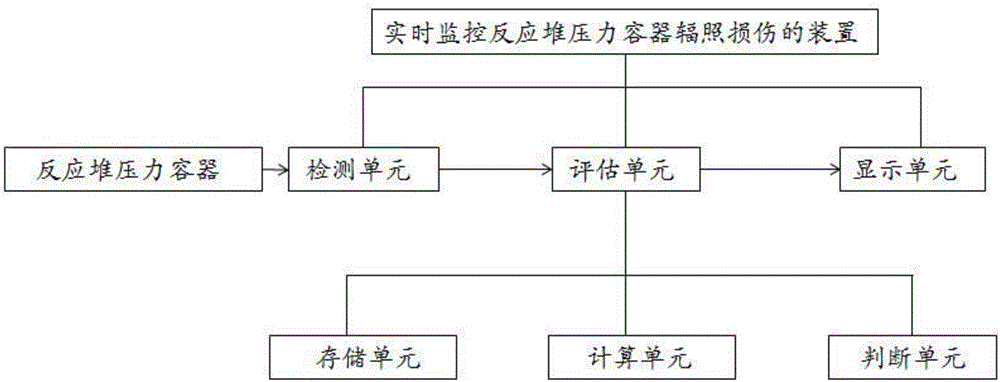

[0120] see figure 2 , which shows a device for real-time monitoring of reactor pressure vessel radiation damage by monitoring resistivity changes, including:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com