Monitoring method for irradiation embrittlement of reactor pressure vessel in nuclear power plant

A technology for nuclear power plant reactors and pressure vessels, applied in the field of nuclear power, can solve problems such as high security requirements, high transportation costs, and limited number of irradiation supervision samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

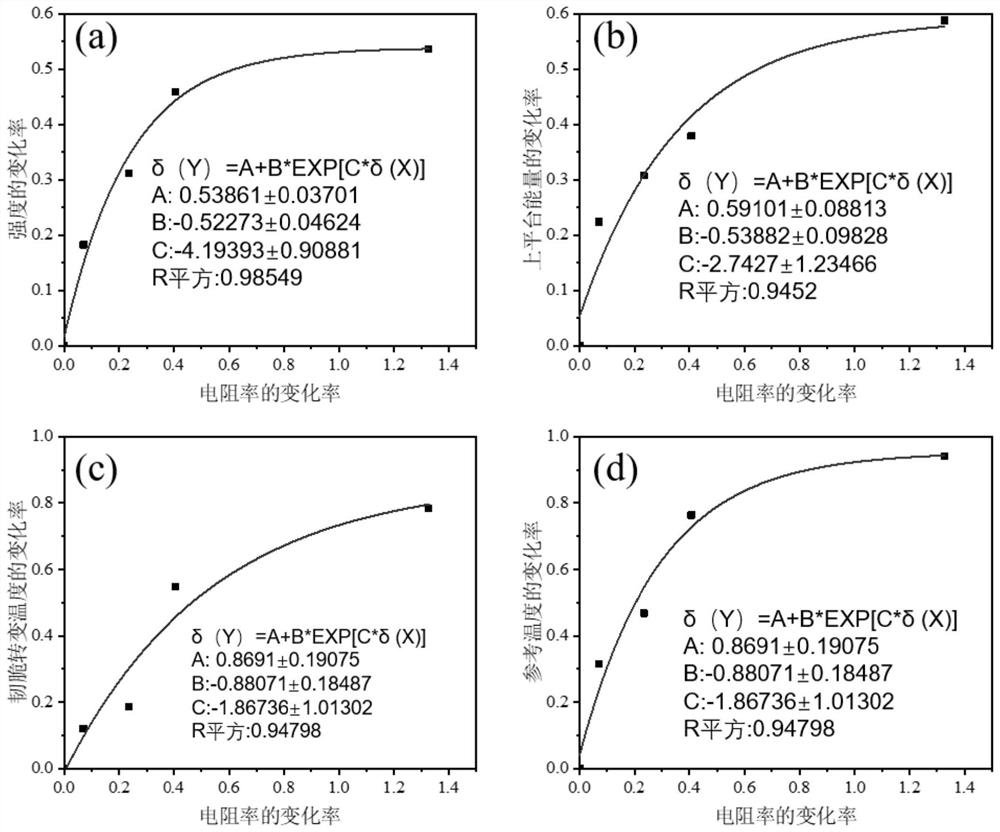

[0047] Embodiment 1: upper platform energy-resistivity

[0048] Depend on figure 1 (b) It can be seen that:

[0049] ΔUSE / USE 0 =0.59-0.54exp(-2.74Δρ / ρ 0 ) (4.1)

[0050] Where: ΔUSE = USE 0 -USE; Δρ = ρ - ρ 0

[0051] Explanation: During the irradiation embrittlement process of RPV steel, the platform energy of the material decreases gradually, so here define ΔUSE=USE 0 -USE.

[0052] The unit of USE is Joule, and the unit of ρ is ×10 -7 ohm meter.

[0053] For this research object RPV steel, USE 0 is 335J, ρ 0 is 3.03×10 -7 Ω·m, USE=137.01+2803.03exp(-0.90ρ) after being substituted into the above formula for calculation.

Embodiment 2

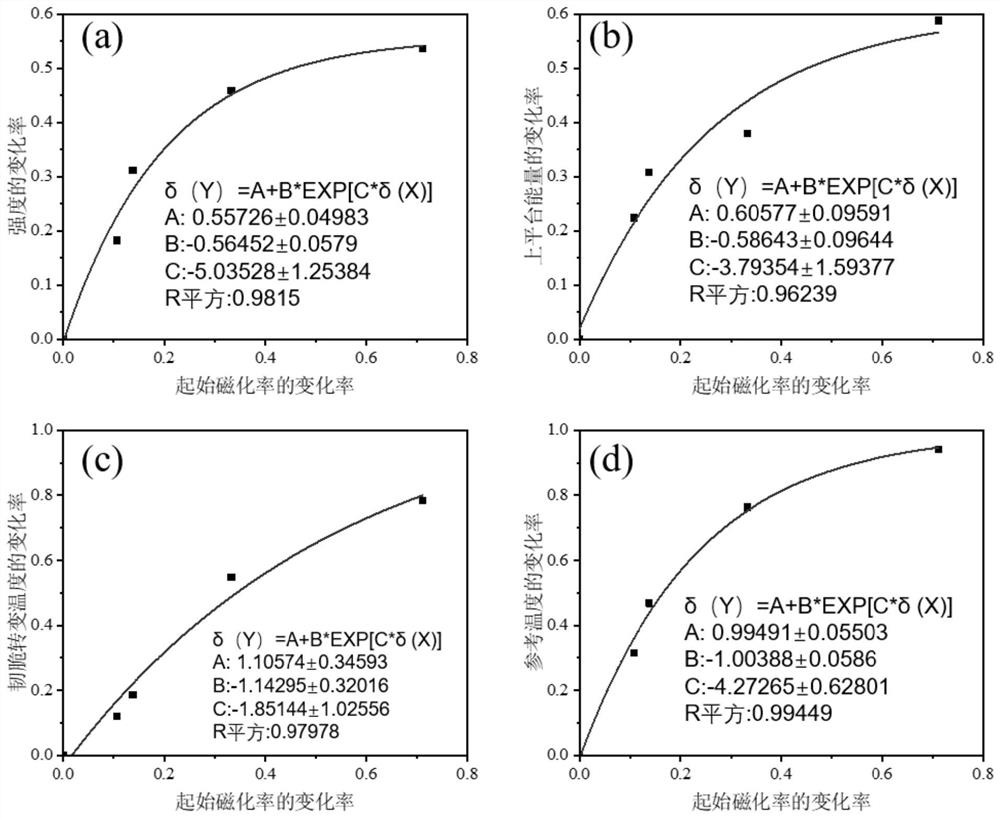

[0054] Example 2: Reference temperature - initial magnetic susceptibility

[0055] Depend on figure 2 (d) know that:

[0056] ΔT 0 / T 00 =0.99-1.00exp(-4.27Δχ / χ 0 ) (4.2)

[0057] where: ΔT 0 =T 0 –T 00 ;Δχ=χ 0 -χ.

[0058] Explanation: The material reference temperature increases gradually during the irradiation embrittlement process of RPV steel, so ΔT is defined here 0 =T 0 –T 00 ; while the initial magnetic susceptibility is gradually reduced, so define Δχ=χ 0 -χ.

[0059] T 0 The unit of is absolute temperature, and χ is dimensionless.

[0060] For the RPV steel of this research object, T 00 is 203K, χ 0 is 11.406, after substituting into the above formula to calculate T 0 =404.97-2.84exp(0.37χ).

Embodiment 3

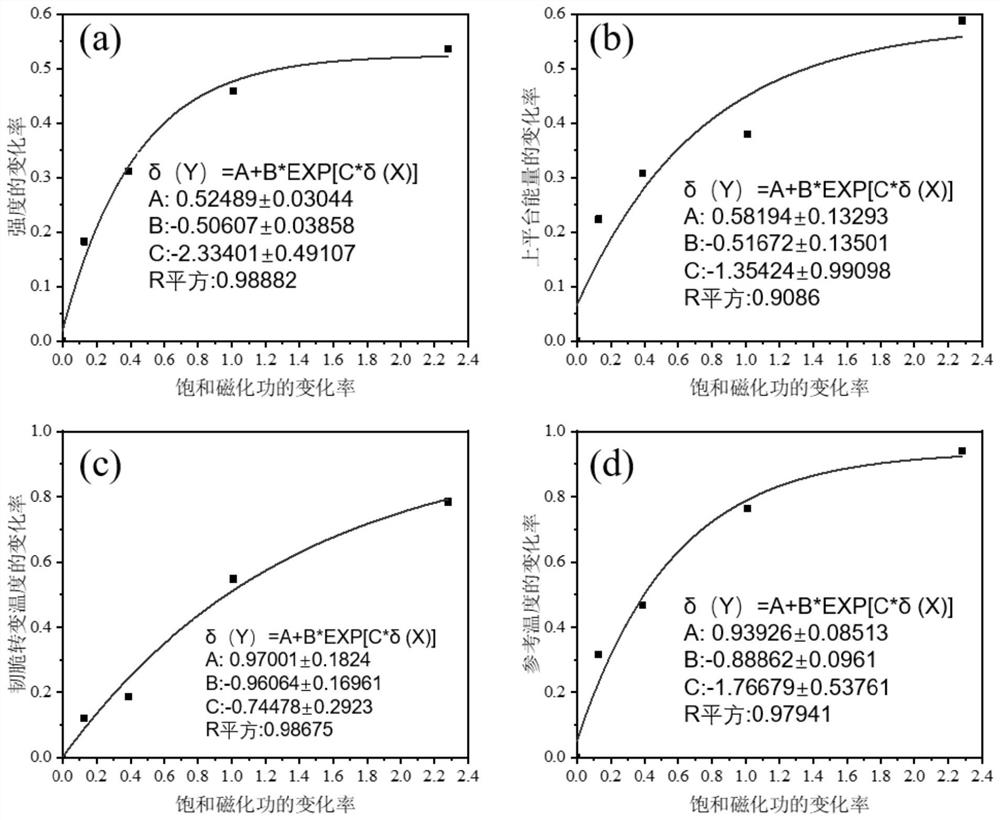

[0061] Example 3: Ductile-brittle transition temperature-saturation magnetization work

[0062] Depend on image 3 (c) know:

[0063] ΔRT NDT / RT NDT0 =0.94-0.89exp(-1.77ΔW / W 0 ) (4.3)

[0064] Where: ΔRT NDT =RT NDT -RT NDT0 ;ΔW=W-W 0 .

[0065] Explanation: During the irradiation embrittlement process of RPV steel, the ductile-brittle transition temperature of the material increases gradually, so here the definition of ΔRT NDT =RT NDT -RT NDT0 .

[0066] RT NDT The unit of is absolute temperature, and the unit of W is kilojoules / cubic meter.

[0067] For this research object RPV steel, RT NDT0 241K, W 0 246.3KJ / m 3 , after substituting into the above formula to calculate RT NDT =474.77-492.13exp(-0.0030W).

[0068] Table 4.1 Using the predictive unified model to characterize the fitting accuracy of the relationship model between the rate of change of mechanical properties and the rate of change of electromagnetic properties of reactor pressure vessel steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com