Roller coater liquid throwing prevention device for improving hot galvanizing passivation quality and liquid throwing prevention method

A roll coater, hot-dip galvanizing technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of splash, passivation liquid splash, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples.

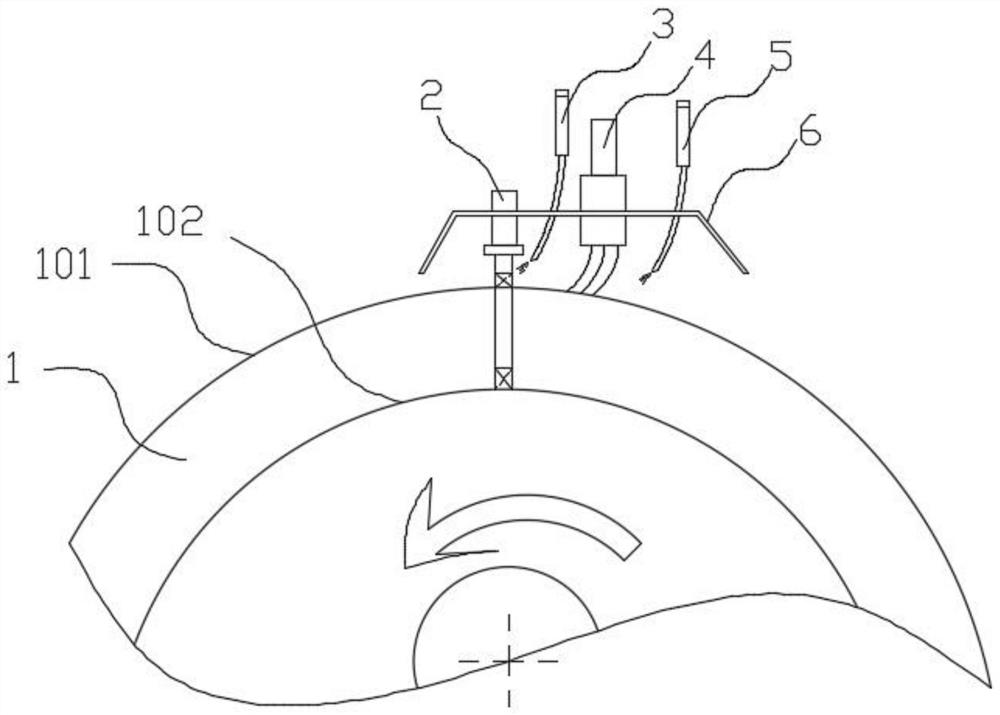

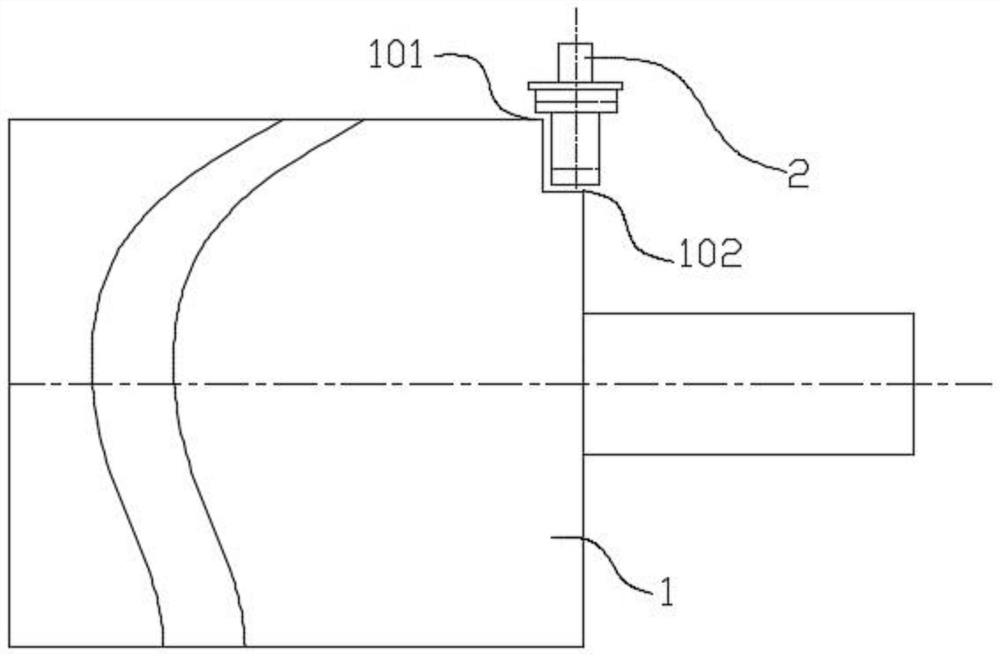

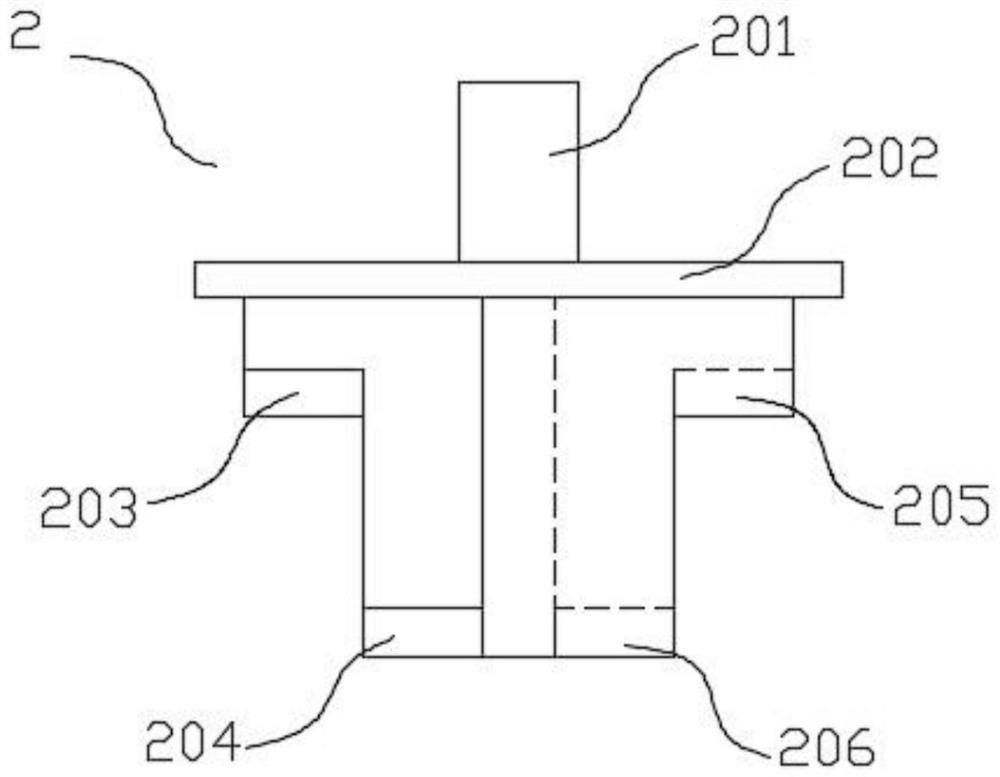

[0031] Examples such as Figure 1 to Figure 6Shown: a roll coater anti-swing liquid device for improving passivation quality by hot-dip galvanizing. The body of the anti-swing liquid device includes a slag scraping and grinding plate 2, a flushing mechanism, a liquid blocking brush 4, and a diversion shield 6. The slag scraping and grinding plate 2 is rotatably arranged on the step of the coating roller On the upper part of the edge 102, a liquid blocking brush 4 is arranged on one side of the slag scraping and grinding plate 2, and a diversion protective cover 6 is arranged on the upper part of the slag scraping and grinding plate 2 and the liquid blocking brush 4. The two sides of the liquid blocking brush 4 are equipped with flushing mechanisms respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com