Automatic spraying system of galvanized pipe passivation liquid

A technology of automatic spraying and passivation liquid, applied in the direction of metal material coating process, etc., can solve the problems of uneven adhesion of passivation liquid on the surface, affecting the aesthetics of steel pipes, and less adhesion of passivation liquid, etc., to increase the scope of use , Improve passivation quality and increase the effect of adhesion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

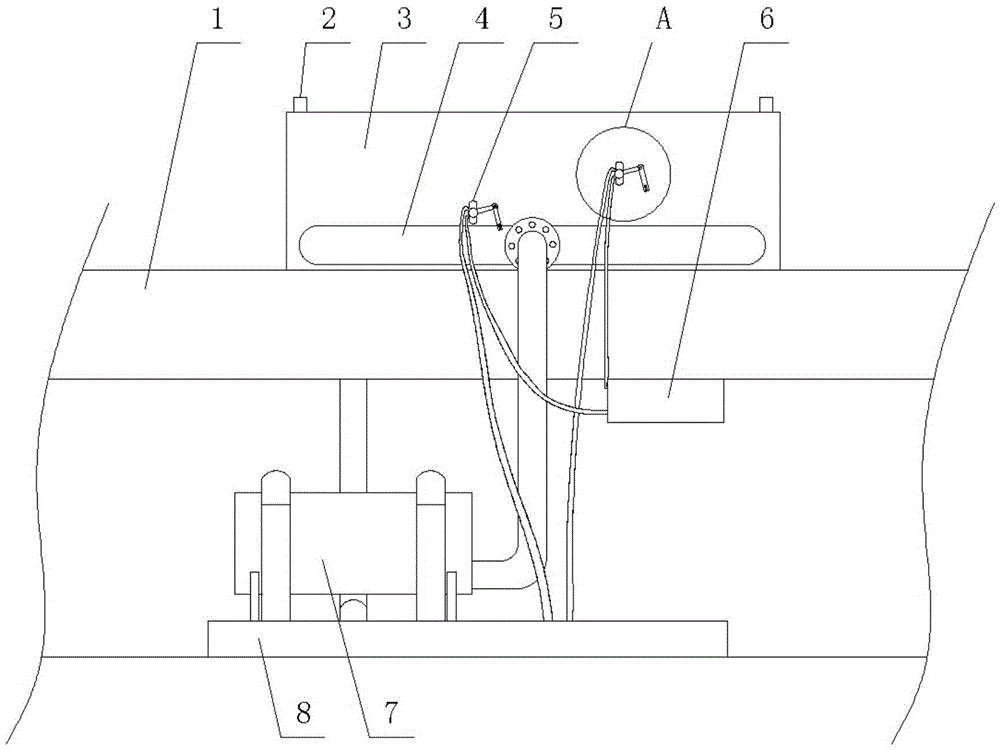

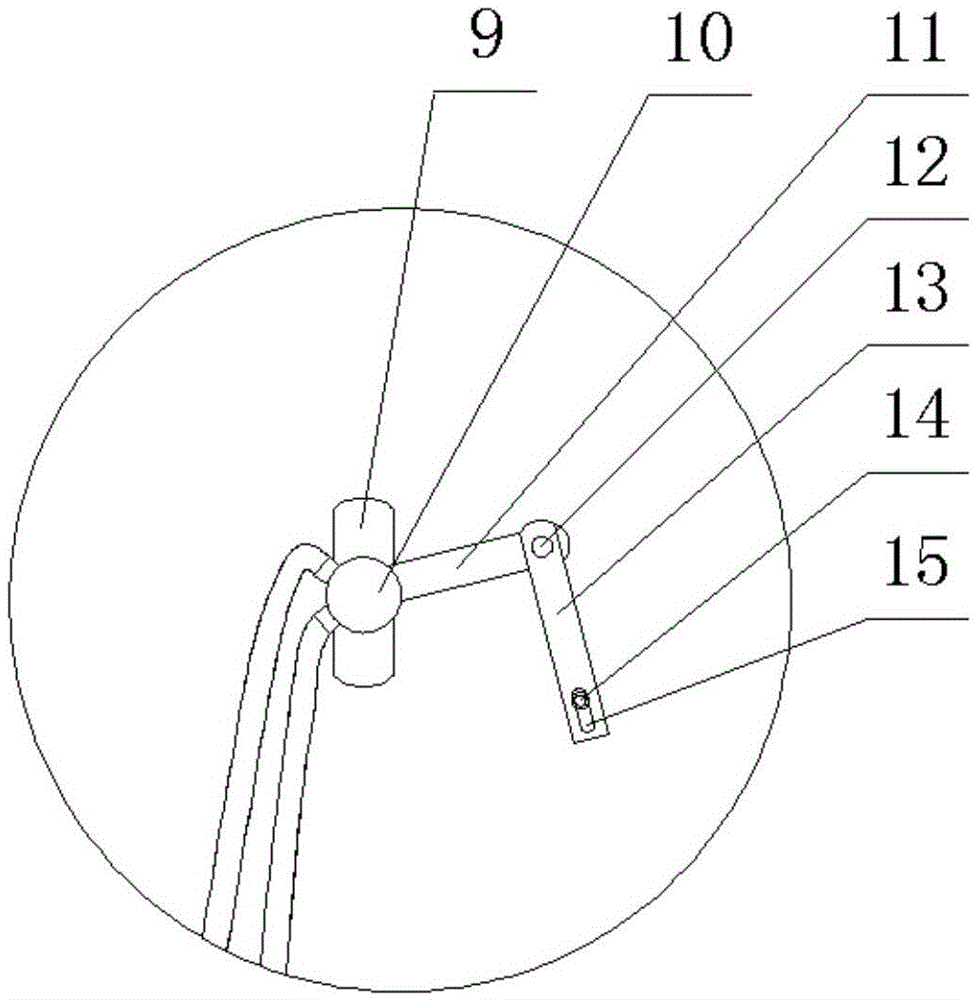

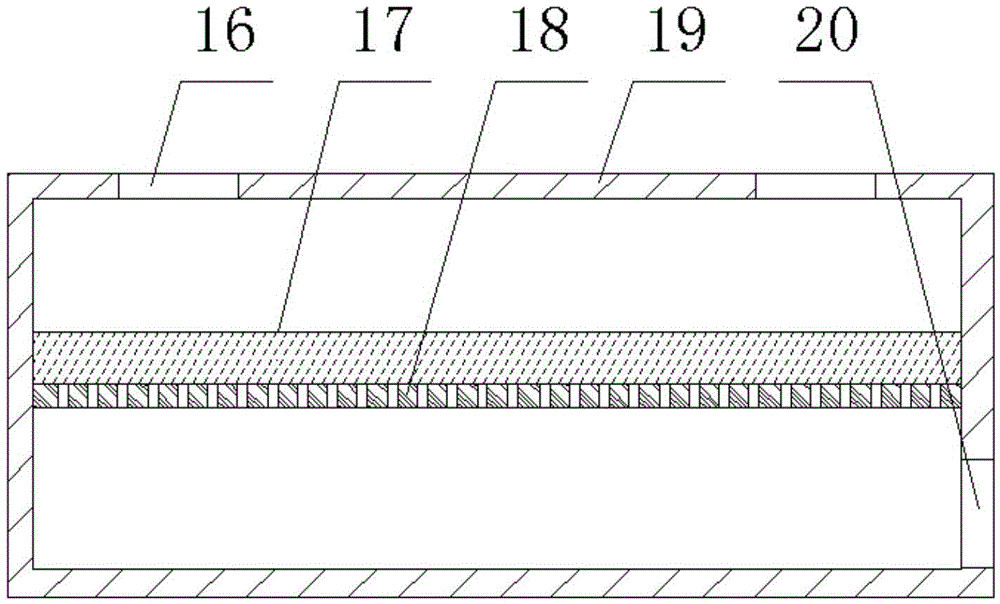

[0023] A galvanized pipe passivation liquid automatic spraying system, its innovation lies in: it is composed of a passivation liquid storage tank 8, a filter tank 7, a spraying base 1, a spraying cover 3 and an atomized spraying mechanism 5, the spraying cover The cover is installed on the upper part of the spraying base, and there are openings for pipelines to pass through at the left and right ends of the spraying cover, and atomization spraying mechanisms arranged up and down are installed on the front and rear walls of the spraying cover. The end is provided with a steam outlet, which is connected with the inlet 20 of the filter tank through a three-way pipeline 4, and the outlet 16 of the filter tank is connected to the passivation liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com