Method for leaching chalcopyrite through reinforced iron oxidized culture

A technology of bacterial leaching and chalcopyrite, applied in the direction of improving process efficiency, can solve the problems of aggravating the passivation effect of jarosite, hindering continuous adhesion, low cell culture efficiency, etc., and achieves shortening passivation time, The effect of reducing carry-in and increasing cell concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

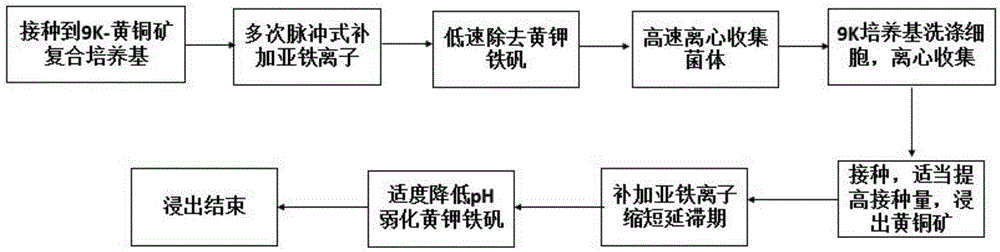

Method used

Image

Examples

Embodiment 1

[0020] Example 1 High-density cultivation of Thiobacillus ferrooxidans and cell collection without jarosite

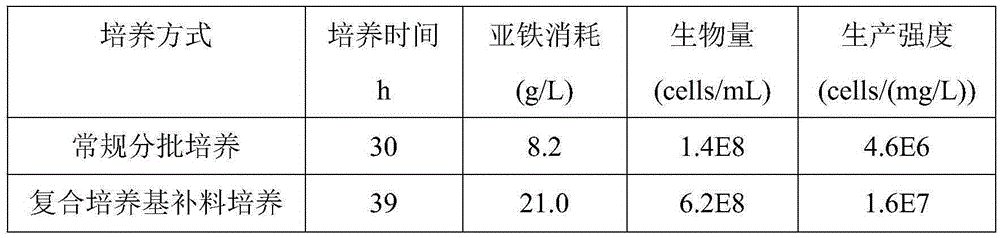

[0021] 9K-chalcopyrite compound basal medium: (NH 4 ) 2 SO 4 3.0g, KCl0.1g, K 2 HPO 4 0.5g, MgSO 4 ·7H 2 O0.5g, Ca(NO 3 ) 2 0.01g, H 2 O700mL; Part II: Fe 2 (SO 4 ) 3 ·7H 2 O44.3g, H 2 O300mL. The third part is 0.1% (w / v) lean chalcopyrite. The ore samples were taken from the Tonglingshan mining area in Anhui Province. After preliminary crushing and filtration with steel sieves, the ore particle size is about 2+ When it is lower than 5g / L, add ferrous sulfate and add 2mL of 9K basal medium at the same time to control the Fe 2+ Maintained at about 7g / L, after 8 feedings, the culture process ended when the bacterial concentration showed a downward trend again. The main parameters of this culture method compared with the control system are shown in Table 1. Biomass from conventional batch culture of 1.4 × 10 8 Individuals / mL increased to 6.2×10 8per mL,...

Embodiment 2

[0024] Embodiment 2 inoculates cells that do not contain jarosite precipitation, and appropriately increases the inoculum size

[0025] Using 9K basal medium (recipe: (NH 4 ) 2 SO 4 3.0g, KCl0.1g, K 2 HPO 4 0.5g, MgSO 4 ·7H 2 O0.5g, Ca(NO 3 ) 2 0.01g, H 2 (21000mL), control pulp concentration is 3.0%, 30 ℃ of temperature, shaker rotating speed 170rpm, control initial cell approximately 5.0 * 10 by inoculation 7 individual / mL. After leaching for 30 days, the leaching results are shown in Table 2. The concentration of copper ions in the leaching system without accessing jarosite-containing cells and appropriately increasing the inoculation amount increased from 32.5 mg / L to 37.1 mg / L. Continue to increase the inoculation amount, and the final leaching rate does not change much. Considering the saving of cell amount, 5.0×10 cells without jarosite were used. 7 individual / mL. Because jarosite covers the surface of the ore, it hinders the adhesion of the attached cells ...

Embodiment 3

[0028] Example 3 Appropriate supplementation of ferrous ions in the early stage of leaching shortens the lag period

[0029] During the inoculation process of the leaching system, 1.0 g / L of ferrous ions were added (the inoculum size was 5.0×10 7 Individual / mL, other steps are consistent with embodiment 2), the key parameter and the leaching result of the thalline growth of leaching process are as shown in table 3. Maximum specific growth rate changed from 0.45d -1 Improve to 0.53d -1 , and the time required to reach the maximum value is reduced from 10.0d to 8.5d. The final copper ion concentration has also been improved to a certain extent (as shown in Table 3). The results indicated that due to the low ore dissolution efficiency in the early stage of leaching, the strains were not adapted to the relatively poor nutrient environment in the environment after inoculation, and the lag period was relatively long. Adding an appropriate amount of ferrous ions can accelerate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com