Method for improving soluble expression quantity of beta-cyclodextrin glucosyltransferase

A glucose-based and cyclodextrin technology, applied in the field of enzyme engineering and fermentation engineering, can solve the problems of difficulty in improving, low soluble expression of exogenous proteins, and limited large-scale production and application, and achieves increased bacterial concentration and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]Embodiment 1: Containing the construction of the genetically engineered bacteria expressing the β-cyclodextrin glucosyltransferase gene of the present invention

[0039] Specific steps are as follows:

[0040] The construction of the engineering bacteria containing the β-cyclodextrin glucosyltransferase gene is carried out according to the following methods:

[0041] (1) Obtain the target gene by PCR (the nucleotide sequence of β-cyclodextrin glucosyltransferase is shown in SEQ ID NO.1), and the PCR reaction system is: TaKaRa Ex Taq (5U / μL) 0.25μL, 10× Ex Taq Buffer (mg2+plus) 20mM 5μL, Dntp Mixture (2.5mM each) 4μL, Template 1μL, Primer 1 (1μM) 1μL, Primer 2 (1μM) 1μL, sterile water 37μL. Reaction steps: 98°C for 10s, 55°C for 30s, 72°C for 3min 30s, and 30 cycles.

[0042] (2) Perform double enzyme digestion on the PCR product and the extracted plasmid pET-20b(+). The double enzyme digestion system is: 2×10×Buffer Y 20 μL, Nco I / Nde I 0.5 μL, Bam HI 0.5 μL, Plasmid ...

Embodiment 2

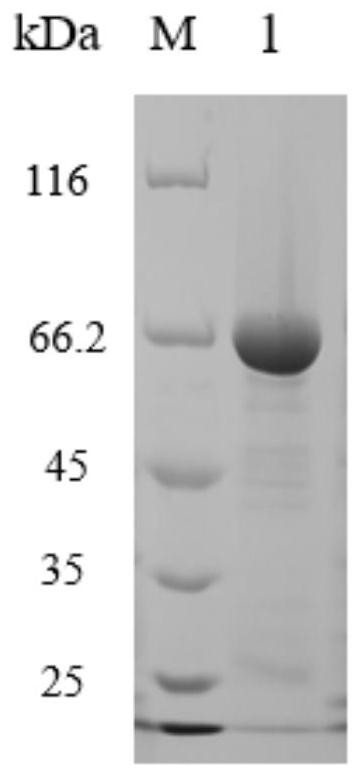

[0045] Example 2: Expression of β-cyclodextrin glucosyltransferase

[0046] Specific steps are as follows:

[0047] (1) Configure fermentation medium: yeast powder 24g / L, tryptone 12g / L, KH 2 PO 4 2.32g / L,K 2 HPO 4 ·3H 2 O16.43g / L, glycerin 5g / L.

[0048] (2) Host bacteria activation culture:

[0049] The E.coli BL 21(DE3) / pET-20b(+)-cgt recombinant strain constructed in Example 1 was streaked and isolated on LB solid medium, cultured in a constant temperature incubator at 37°C for 12 hours, and picked The positive single colony was inoculated into a 250mL Erlenmeyer flask containing 50mL of LB liquid medium, placed in a rotary shaker at 200r / min, and cultured at 37°C for 12h; the seed solution was prepared.

[0050] (3) Fermentation culture:

[0051] The seed solution prepared in step (1) was inoculated in the fermentation medium at an inoculation amount of 4% (v / v), and placed in a rotary shaker at a rate of 200r / min, and induced at 30°C for 96h .

[0052] Ampicil...

Embodiment 3

[0054] Embodiment 3: Optimization of fermentation medium

[0055] Specific steps are as follows:

[0056] details as follows:

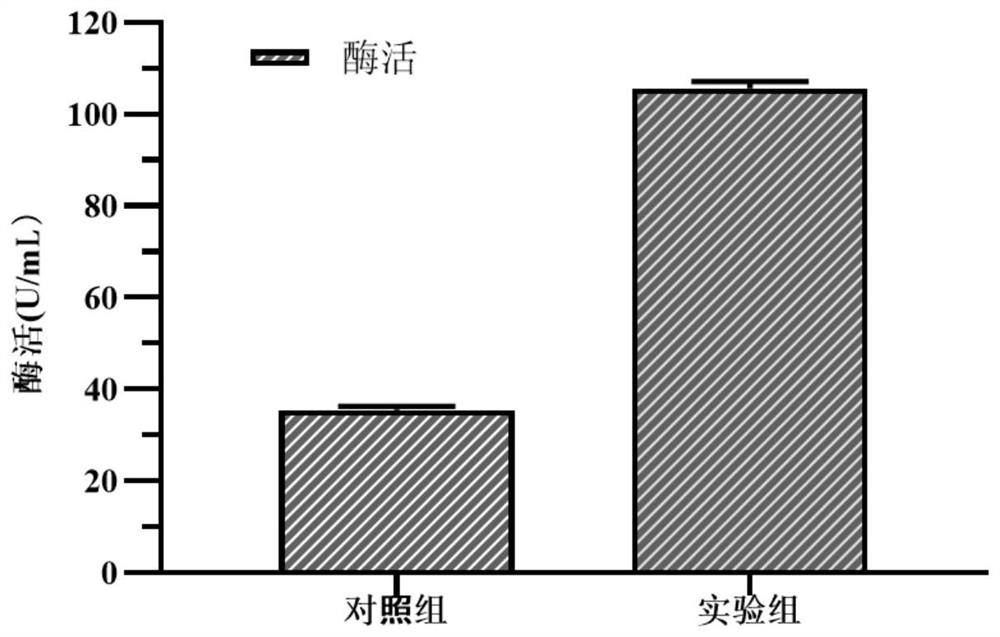

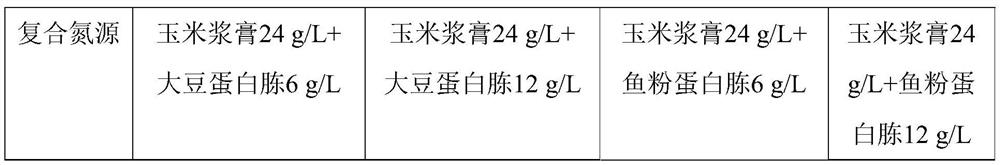

[0057] (1) Choice of nitrogen source

[0058] The specific embodiment is the same as Example 2, the difference is that the nitrogen source (yeast powder, tryptone) in the fermentation medium is replaced by: corn steep liquor, yeast powder, tryptone, soybean peptone, fish powder peptone, the concentration is: 36g / L , after the end of the fermentation, the enzyme activity was detected respectively, and the results are shown in Table 1:

[0059] Table 1 Enzyme activity under different nitrogen source conditions

[0060] Type of nitrogen source corn syrup yeast tryptone soy peptone Fish Meal Peptone Enzyme activity (U / mL) 15.95 4.48 4.48 11.79 4.96

[0061] The results showed that when corn steep liquor and soybean peptone were used as nitrogen sources, it was beneficial to increase the soluble expression of β-cyclode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com