Patents

Literature

30results about How to "No process changes required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

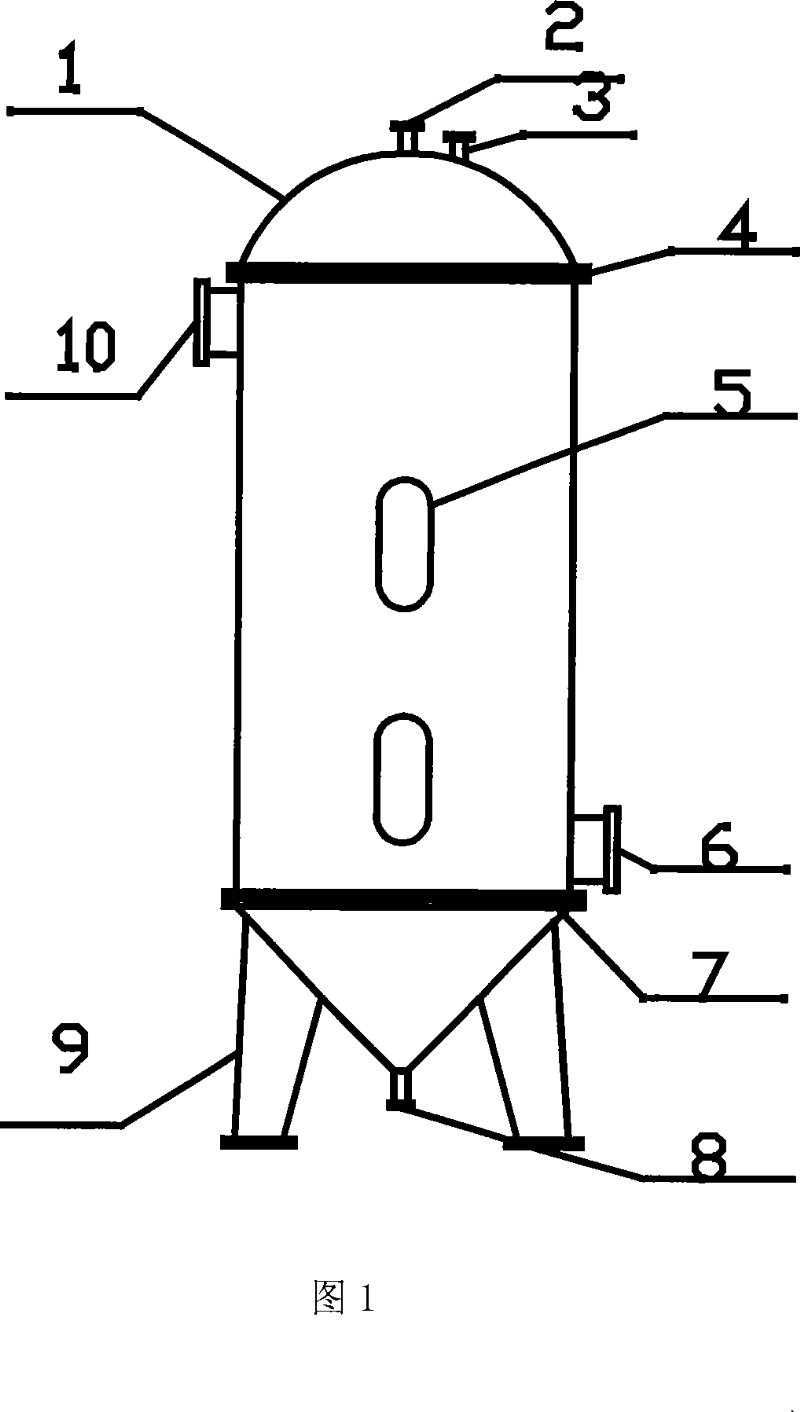

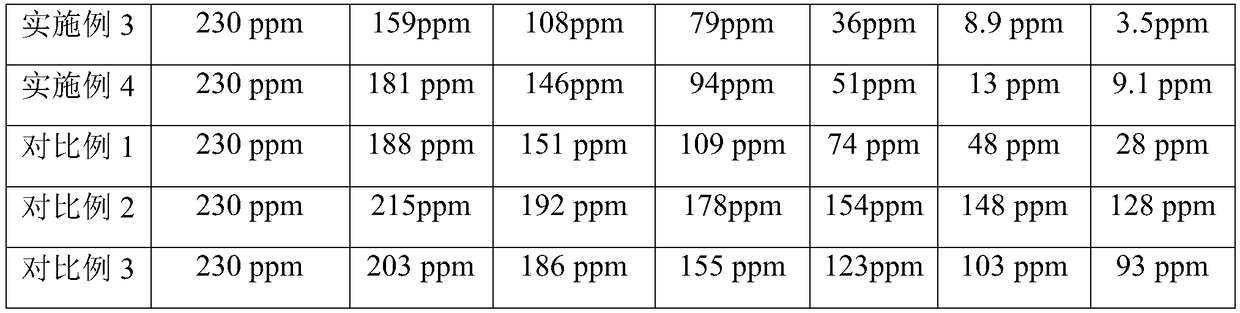

Heavy metal treatment method of electroplating wastewater

InactiveCN101037243ASolve pollutionReduce processing costsWater contaminantsWaste water treatment from metallurgical processFiltrationIon exchange

The present invention discloses a waste water treatment method, in particular to a heavy metal processing method in electroplating effluent, which comprises the steps of pretreatment, detection, filtration, adsorption, ionexchange and regeneration of filter material; wherein the filtration, adsorption and ionexchange processes are gathered to a whole, a sodium form resin serves as the filter material of the filtration, adsorption and ionexchange processes; the electroplating effluent contacts the resin sufficiently at a certain flow rate so as to be completely exchanged; and the resin is regenerated and recovered in good time according to the heavy metal content of the waste water. The present invention has the advantages of that the equipment is simple, the installation is convenient, the former waste water treatment process is not changed, the resin can be regenerated and recovered, the heavy metal ion and the suspended matter SS can be completely removed from the water, and the cost is reduced. The present invention can be widely used in the waste water treatment processes of various electroplating effluent.

Owner:陈启松

Continuous annealing and acid washing method for medium-chromium ultrapure ferrite stainless steel

ActiveCN103243339AAvoid intergranular corrosionSpeed up the formation of passivation filmHydrofluoric acidConcentration ratio

A continuous annealing and acid washing method for medium-chromium ultrapure ferrite stainless steel comprises the process flow of cold rolling, annealing heat treatment, acid washing, final water washing, drying, flattening and packaging, and is characterized in that in the acid washing process flow, the acid washing solution is prepared from 120-150g / L of 65% nitric acid, 2-4g / L of 40% hydrofluoric acid and water. According to the invention, in the chemical acid washing stage, reasonable concentration ratio of nitric acid to hydrofluoric acid is adopted and proper acid washing speed is controlled to carry out acid washing on medium-chromium ferrite stainless steel. As a result, on one hand, the performance of a medium-chromium ferrite stainless steel passivation film is obviously improved, and the corrosion resistance of the surface of a medium-chromium ferrite stainless steel 2B board is significantly improved, and on the other hand, the process flow of the existing production factory is not needed to be changed, a special passivation treatment procedure is not needed, and the production cost is significantly lowered.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

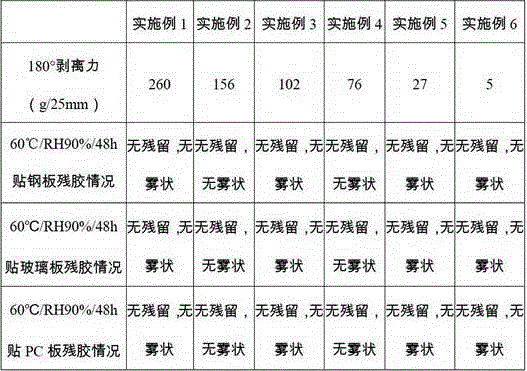

Stripping-force-controllable pressure-sensitive adhesive and preparation method thereof

ActiveCN106749874ANo need to change the structureNo process changes requiredEster polymer adhesivesPressure sensitive film/foil adhesivesEnvironmental resistanceFunctional monomer

The invention discloses a stripping-force-controllable pressure-sensitive adhesive, which is characterized by being prepared from the following raw materials in percentage by weight: 4 to 8 percent of hard monomer, 26 to 34 percent of soft monomer, 2 to 6 percent of functional monomer and 60 percent of solvent. The pressure-sensitive adhesive is controllable in stripping force and wide in adaptive range; the 180-degree stripping force is 5g to 260g per 25mm; further, the stripping force is changed little along with temperature; glue is low in viscosity and further stable; the pressure-sensitive adhesive is good in humidity and heat resistance, has no residual adhesive, has no fogginess, and has favorable environmental resistance performance; a preparation method of the pressure-sensitive adhesive is simple and effective; the pressure-sensitive adhesive is low in cost, and can be widely applied to an electronic product, a building material product, a furniture product and the like.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

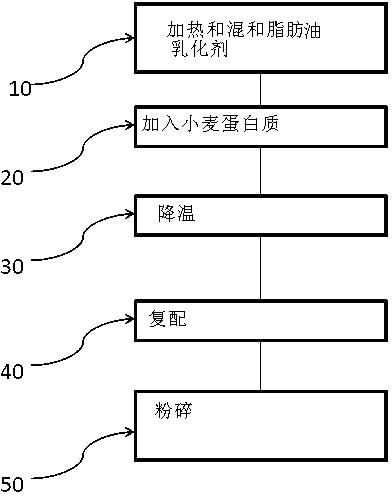

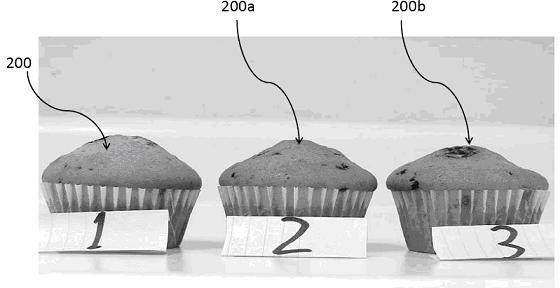

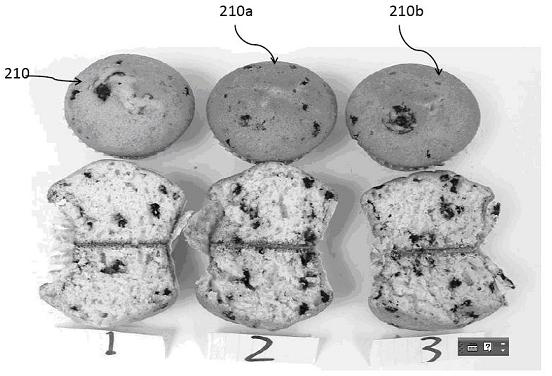

Egg substitute and preparation method thereof

InactiveCN102326795ANo need to change recipeNo process changes requiredDough treatmentFood preparationBiotechnologyAnimal science

The invention discloses an egg substitute for baked and non-baked food and a preparation method thereof. The egg substitute for the baked food contains 1 to 60 percent of wheat protein, 0 to 50 percent of other protein, 1 to 30 percent of an emulsifier, 1 to 30 percent of fat or oil, 0 to 10 percent of food gum, 0 to 3 percent of calcium salt and 5 to 30 percent of carbohydrate. The egg substitute for the non-baked food contains 40 to 90 percent of wheat protein, 0 to 30 percent of other protein, 1 to 30 percent of the emulsifier, 1 to 30 percent of fat or oil, 0 to 10 percent of food gum, 0 to 3 percent of an oxidation and reduction agent, 0 to 5 percent of calcium and ferrite and 5 to 30 percent of carbohydrate. The preparation method of the egg substitute for the baked food comprises astep of preparing a wheat protein, fat and emulsifier composite. Compared with the conventional egg substitute, the egg substitute disclosed by the invention has the advantages that: the formula and the basic process of the food do not need to be changed, and the cholesterol content of the food due to the egg is reduced or eliminated.

Owner:李伟莉

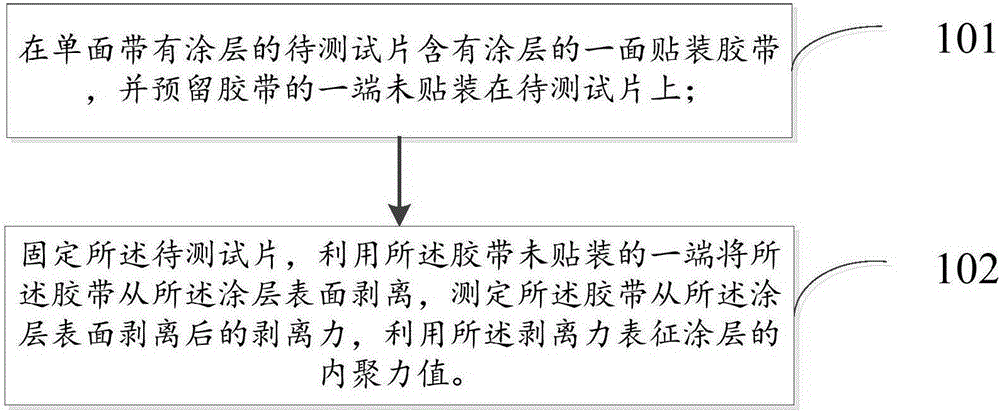

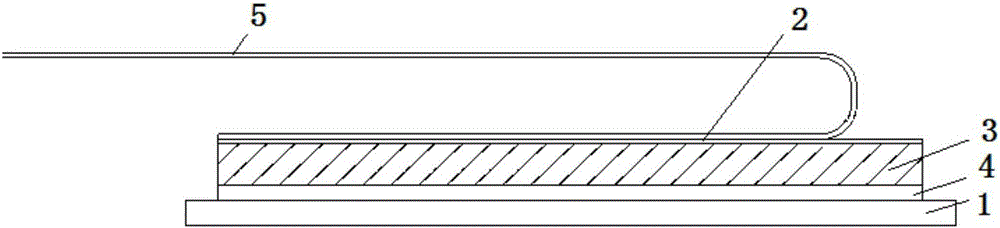

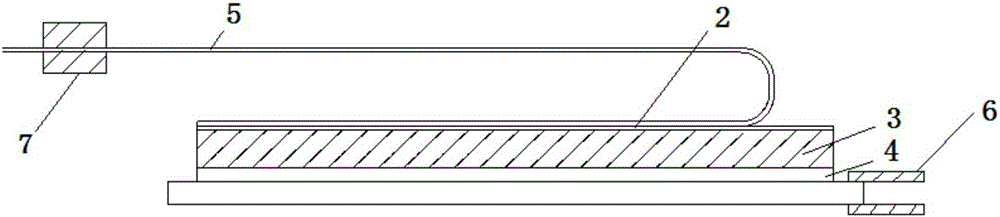

Representation method for cohesion of coating

InactiveCN105203451ANo process changes requiredCohesion test is convenientUsing mechanical meansMaterial analysisCoated surfaceEngineering

The embodiment of the invention provides a representation method for cohesion of a coating. The method includes the steps that adhesive tape is pasted to the face, provided with the coating, of a to-be-tested piece with one face provided with the coating, and one end of the adhesive tape is reserved and is not pasted to the to-be-tested piece; the to-be-tested piece is fixed, the adhesive tape is stripped from the surface of the coating through the end, not pasted to the to-be-tested piece, of the adhesive tape, stripping force generated after the adhesive tape is stripped from the surface of the coating is tested, and the cohesion value of the coating is represented through the stripping force. According to the method, the cohesion of the coating can be accurately and quantitatively represented.

Owner:BLUE OCEAN & BLACK STONE TECH CO LTD FUJIAN

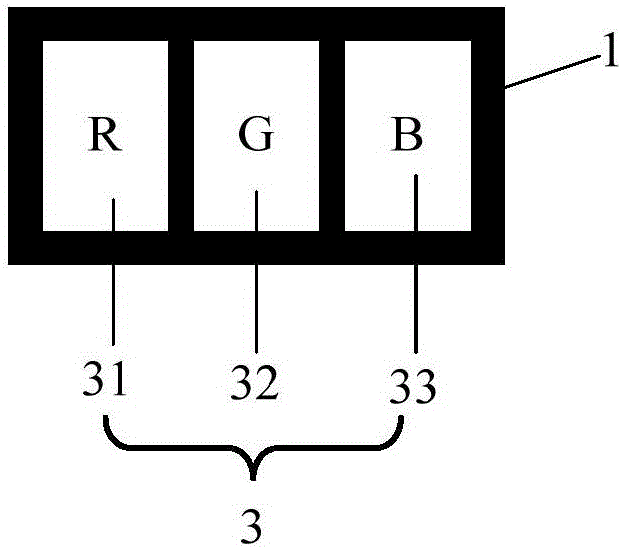

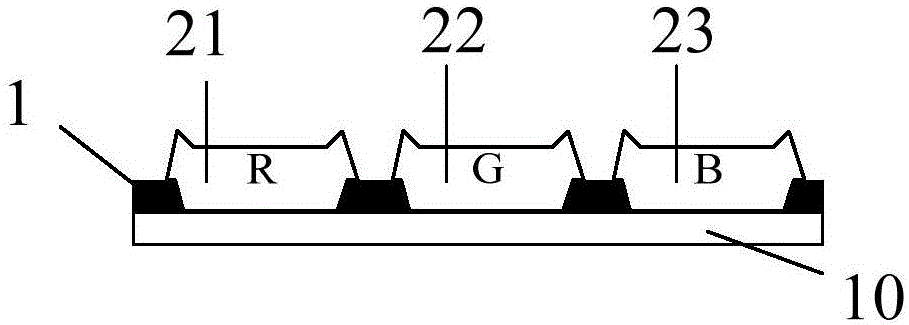

Color film substrate and manufacture method thereof, display panel and display device

The invention provides a color film substrate and a manufacture method thereof, a display panel and a display device, pertaining to the field of display technology. Therefore, the problem that purple, green and yellow fail to achieve in a color gamut due to poor color mixture. The color film substrate comprises multiple pixel units, each comprising multiple primary-color subpixels and at least one mixed-color subpixel. The mixed-color subpixel is composed of color films of different colors which are stacked in multiple layers. The mixed-color subpixel is used for supplementing and augmenting the primary-color subpixels such that high colour gamut is achieved and display is purer. The color film substrate and the manufacture method thereof, the display panel and the display device have following beneficial effects: the manufacture method is used for changing a metal pattern plate of a color film without changing technology; cost is low; volume production is achieved; and the color film substrate is suitable for all kinds of display devices.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

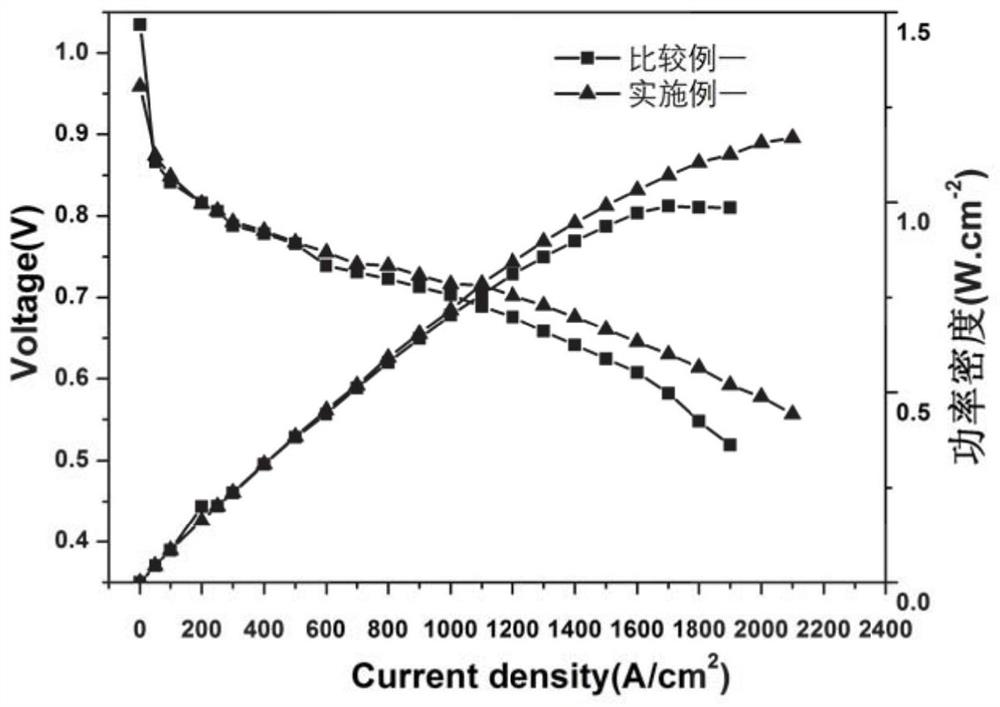

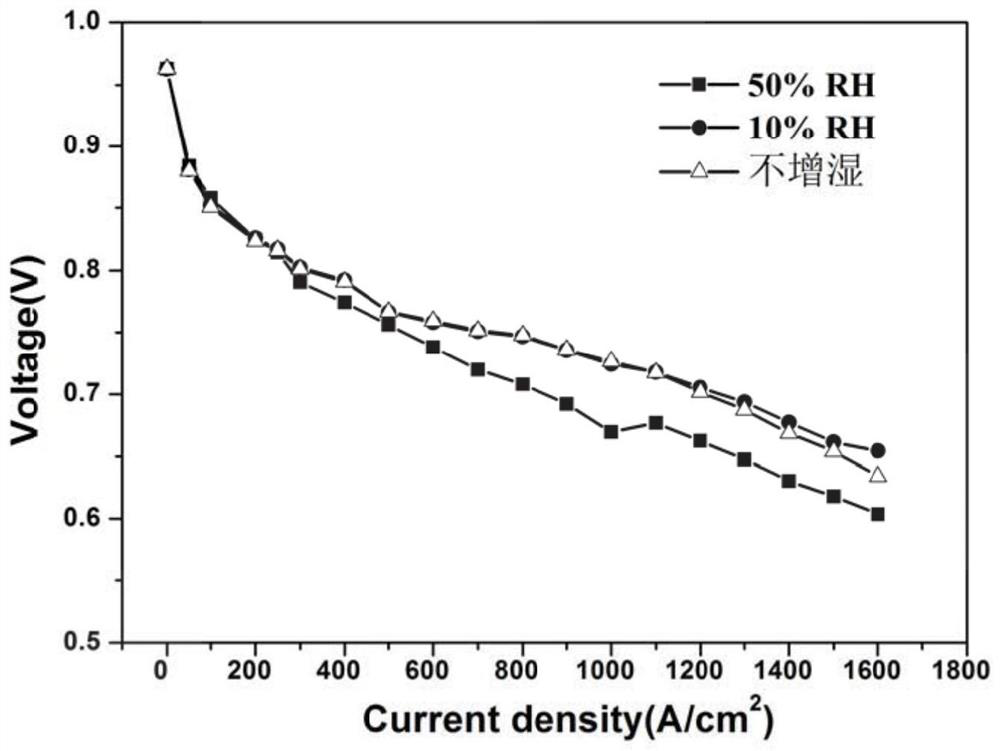

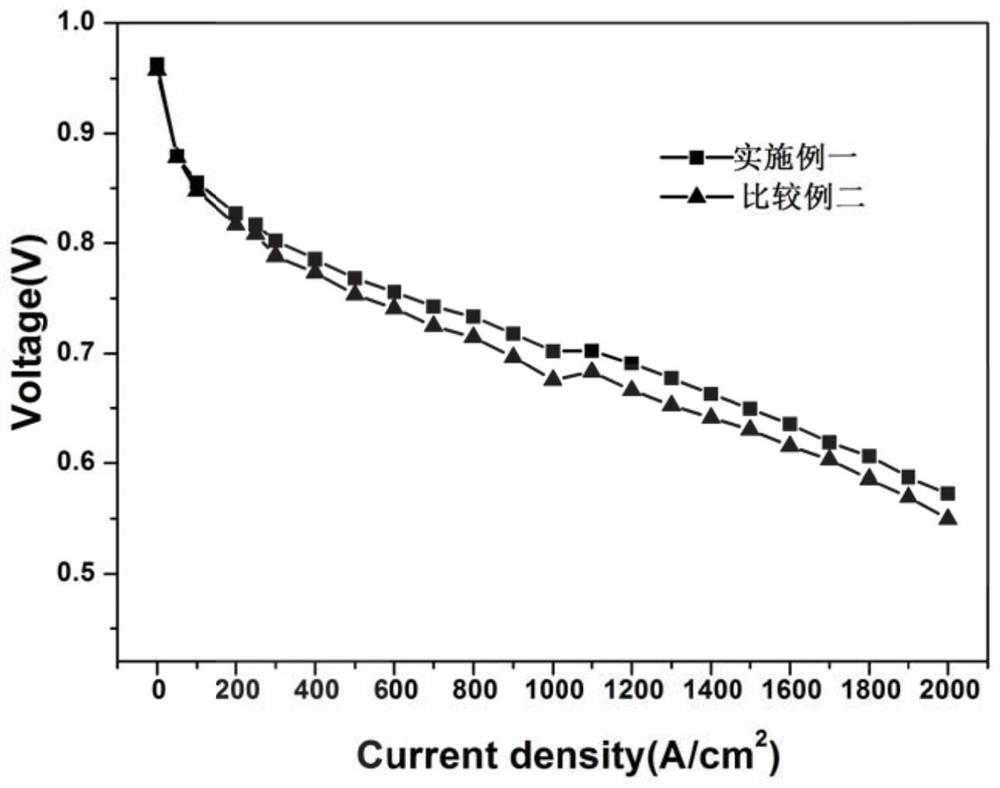

Fuel cell membrane electrode CCM with high-temperature-resistant and self-humidifying characteristics

InactiveCN112768708AAbility to achieve water balanceAdd binding sitesCell electrodesFuel cellsPtru catalystSide chain

The invention discloses a preparation method of a fuel cell membrane electrode CCM. The method comprises the following steps: preparing a hydrophilic catalyst, a perfluorosulfonic acid resin solution and a dispersing agent into a slurry with uniform components in a dispersing manner, and transferring the slurry to two sides of a proton exchange membrane to obtain the fuel cell membrane electrode CCM, wherein the EW value of the proton exchange membrane is 700 to 900; and the EW value of the perfluorinated sulfonic acid resin is 700 to 800; The hydrophilic catalyst and a short-side-chain low-EW-value resin are adopted, binding sites of water are increased so that the affinity of the catalyst layer to water is improved, a rich proton transmission network structure is constructed, the proton conduction rate of the catalyst layer is increased, the proton exchange membrane with a high water conduction capacity is adopted, the diffusion capacity of water generated by a cathode to an anode is enhanced, and a self water balance capability of the MEA under the condition that external humidification is not performed is realized. The whole preparation process does not introduce additional substances, does not need to change a membrane electrode preparation process flow, and is easy to popularize and apply.

Owner:SUNRISE POWER CO LTD

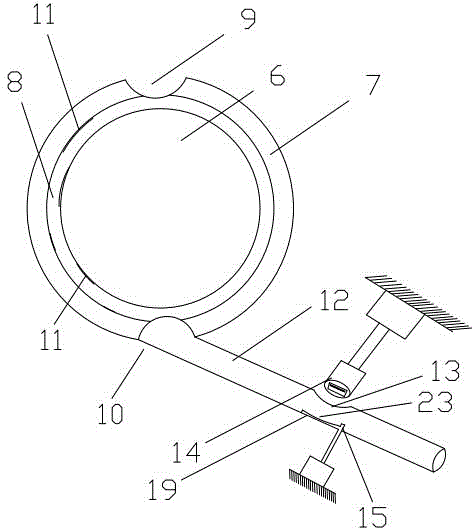

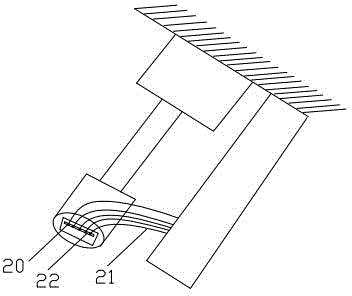

Rice dumpling rounding device for printing patterns

ActiveCN104146327AFast printNo process changes requiredFood coatingFood shapingEngineeringFood products

The invention relates to the field of food processing, particularly to a rice dumpling rounding device for printing patterns. A tapping is formed in a position above a rounding transition pipe, a supporting plate is arranged at a position below the rounding transition pipe corresponding to the tapping, a baffle plate is arranged at the front end of the supporting plate, a printing head is correspondingly arranged outside the tapping, a cylinder is arranged at one end of the printing head, a molding groove or a molding protrusion is formed in the end surface of the printing head, openings are formed in the molding groove or the molding protrusion, and the openings are connected with spray heads which are connected with an edible pigment pipe. The spray heads can spray edible pigments into groove grains in the outer surfaces of rice dumplings, which is very convenient. Even the structure can also be simplified, only the parts of the spray heads are remained, when the rice dumplings are transported here, the spray heads are directly used for spraying the edible pigments onto the outer surfaces of the rice dumplings, and the groove grains do not need to be printed in the outer surfaces of the rice dumpling first.

Owner:扬州艺缘启科技研发有限公司

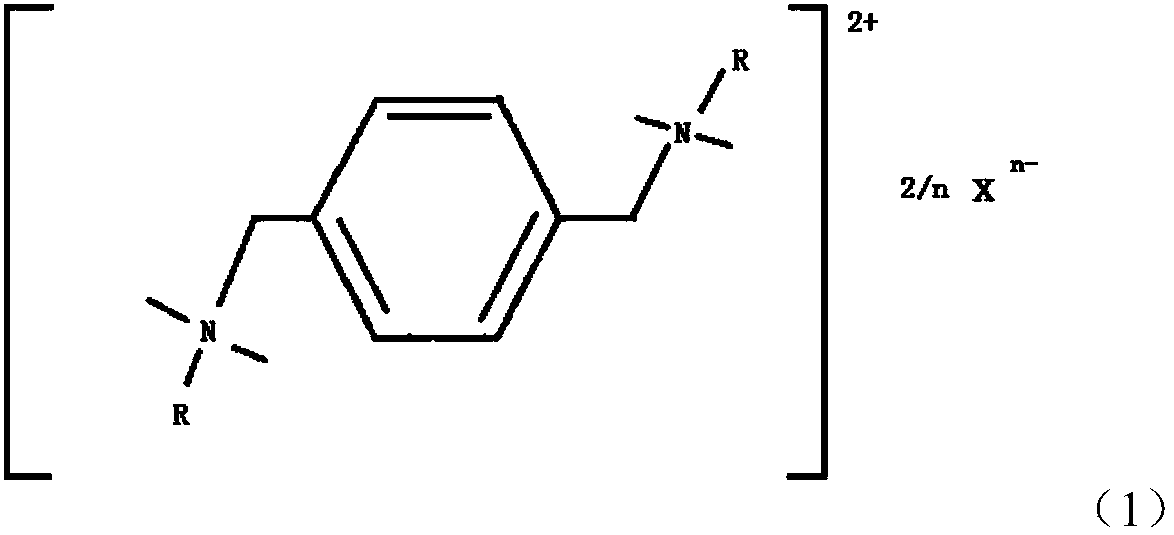

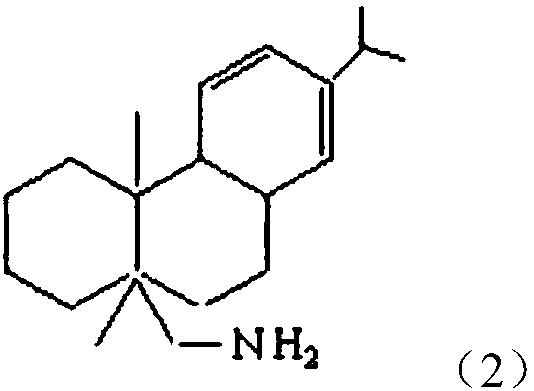

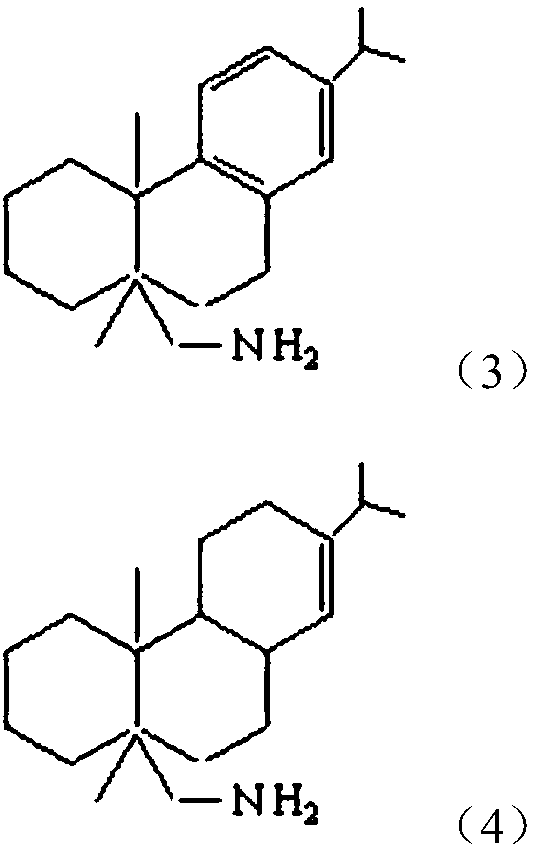

Electrostatic additive for powder coating as well as preparation method and application thereof

ActiveCN108299914AThe preparation process is highly operableImprove triboelectric performanceRosin coatingsPowdery paintsHigh pressureRosin

The invention discloses an electrostatic additive for a powder coating as well as a preparation method and application thereof. The electrostatic additive for the powder coating is a rosin-based bi-quaternary ammonium salt compound, is prepared by the steps of rosin-based dimethyl tertiary amine preparation, rosin-based dimethyl tertiary amine separation, rosin-based biquaternary ammonium salt ammonium chloride synthesis, anion replacement reaction and the like, is used for improving the triboelectric property of the powder coating or can be rapidly charged in the charge control application ofthe high-pressure powder coating and improve the amount of charges.

Owner:广西零到壹科技有限责任公司 +2

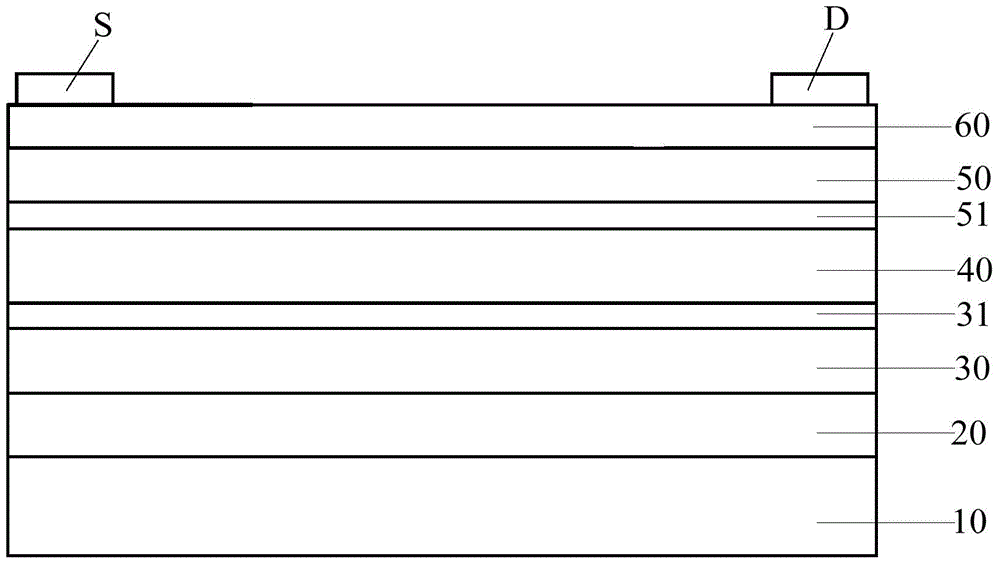

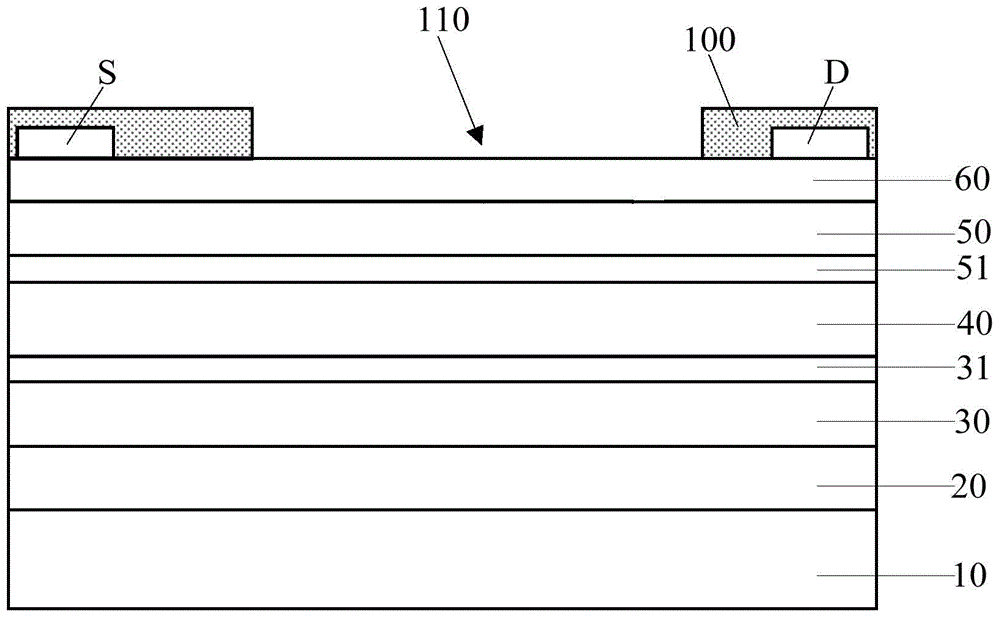

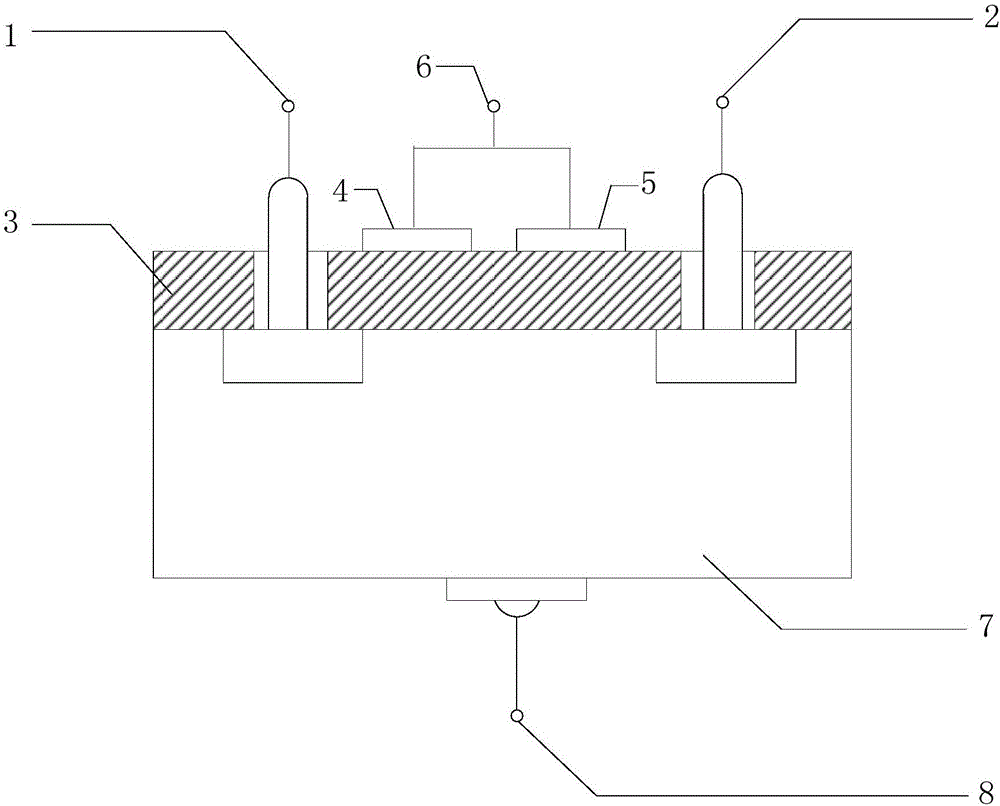

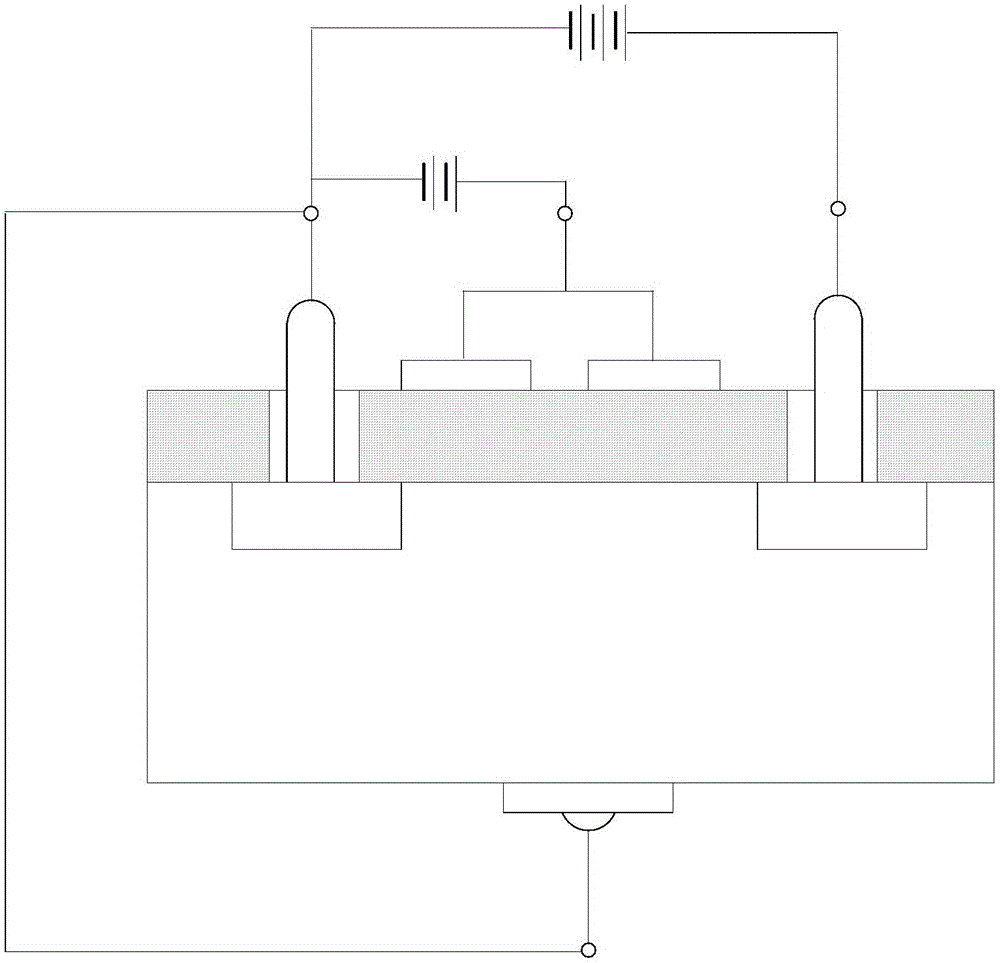

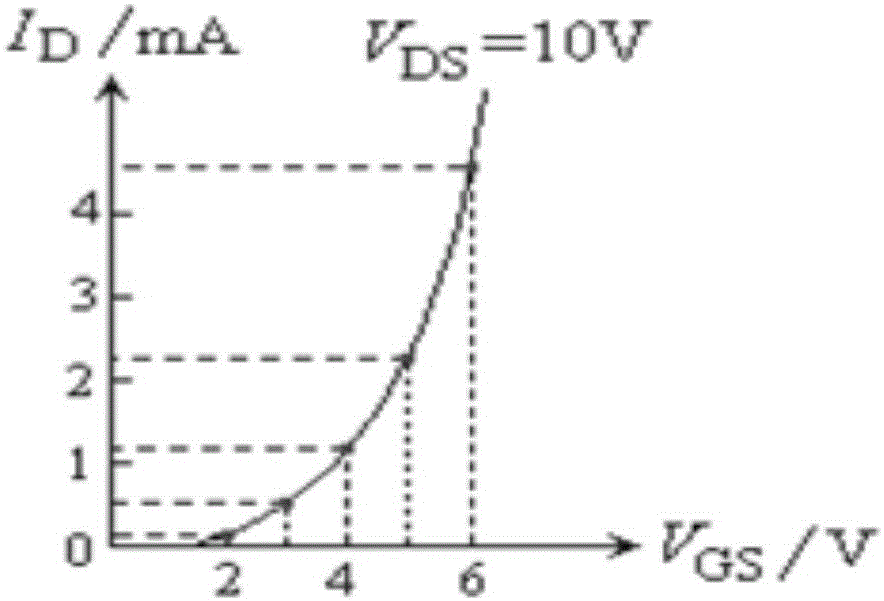

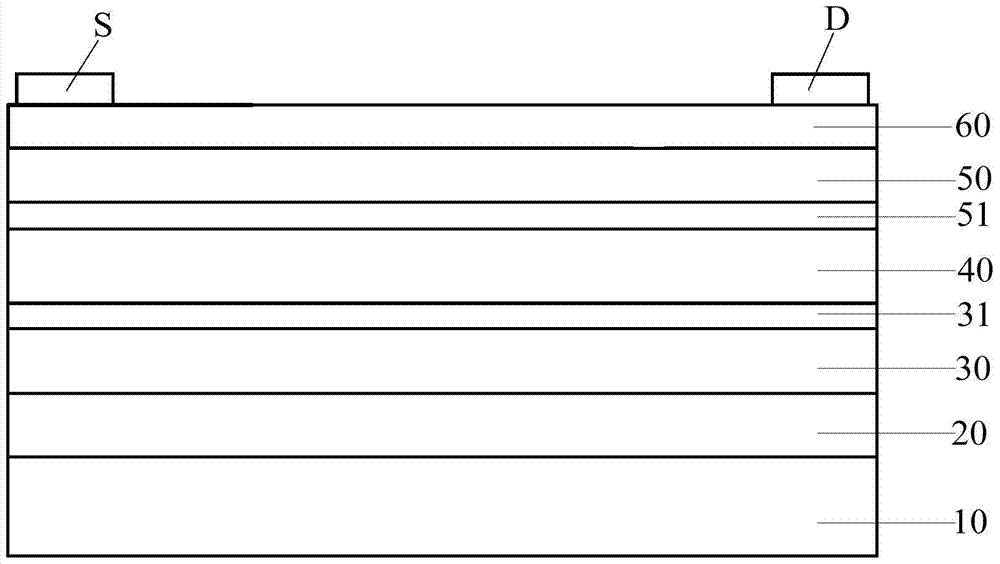

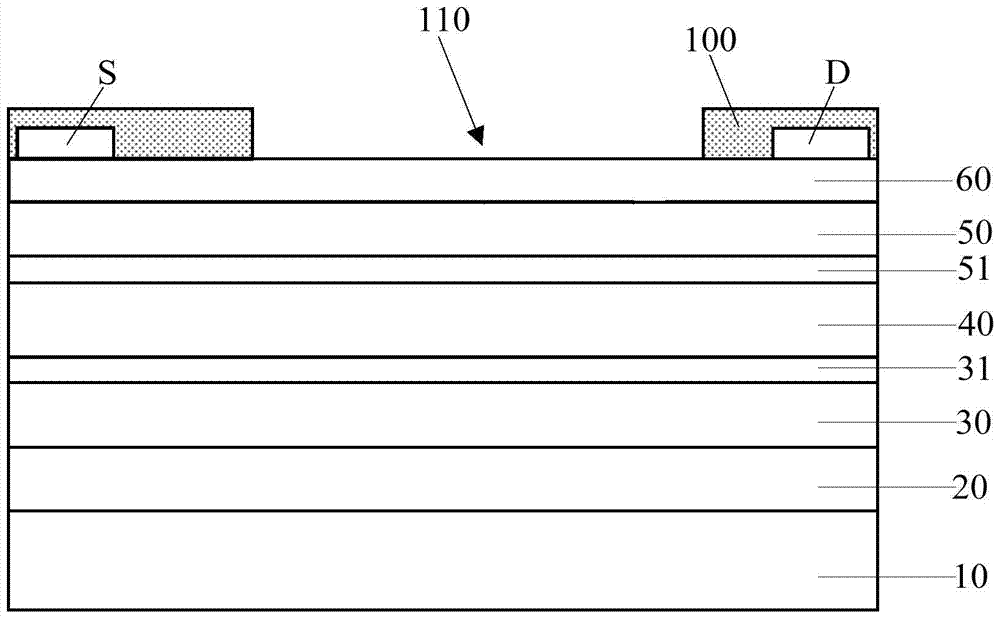

GaAs-based pHEMT device and preparation method therefor

ActiveCN104966732AImprove breakdown voltagePerformance is not affectedSemiconductor/solid-state device manufacturingSemiconductor devicesOptoelectronicsElectron

The invention provides a GaAs-based pHEMT device and a preparation method therefor. The device comprises a GaAs substrate, a buffer layer, a first AlGaAs barrier layer, an InGaAs channel layer, a second AlGaAs barrier layer and a N<+>-GaAs layer. The channel layer and two barrier layers form two-dimensional electron gases respectively. A source electrode and a drain electrode are formed on the N<+>-GaAs layer. A recessed groove exposed from the second AlGaAs barrier layer is arranged between the source electrode and the drain electrode. A grid electrode is formed in the recessed groove. A nodal region with a high dielectric constant is arranged in a recessed groove between the grid electrode and the drain electrode. The nodal region with a high dielectric constant is embedded from the upper surface of the second AlGaAs barrier layer and extends into the interior. The distance of the source electrode to the grid electrode is equal to the distance of the drain electrode to the grid electrode. The transverse width of the recessed groove between the grid electrode and the drain electrode is more than the transverse width of the recessed groove between the grid electrode and the source electrode. The grid-drain breakdown voltage can be raised under a condition that device performances are not affected.

Owner:CHENGDU HIWAFER SEMICON CO LTD

Preparation method of oxidation-biodegradable shopping bag

PendingCN107353481APerformance is not affectedSimple preparation processBag making operationsFlexible containers manufactureFiller ExcipientBiodegradable product

The invention belongs to the technical field of degradable plastic and in particular relates to a preparation method of an oxidation-biodegradable shopping bag. The oxidation-biodegradable shopping bag is prepared from the following raw material components: a resin additive, a degradable master batch and a filling agent; the oxidation-biodegradable shopping bag is prepared from the raw material components in percentage by mass: 87 percent to 96 percent of the resin additive, 3.0 percent to 10 percent of the degradable master batch and 1.0 percent to 3.0 percent of the filling agent; a preparation process is simple, and production equipment and a production process do not need to be changed; the oxidation-biodegradable shopping bag can be recycled and waste materials are not generated; toxic substances are not generated in production, storage, utilization and degradation processes; original performance of a product is not influenced; the productivity is improved; especially, the productivity of thin film and sheet material products is improved; the thickness can be properly reduced when mechanical properties are the same; the raw materials adopt conventional materials and a natural modifier; compared with energy source investment of competitive products or directly-biodegradable products, the energy source investment of the oxidation-biodegradable shopping bag is the lowest and the energy consumption of other products is 3 times as much as that of the oxidation-biodegradable shopping bag; few polymers are used so that natural resources are ensured; the waste materials are reduced; in a composting process, nutrients are easily supplemented and the value of useful humus soil is not influenced.

Owner:昆明鑫鑫大壮降解塑料技术有限公司

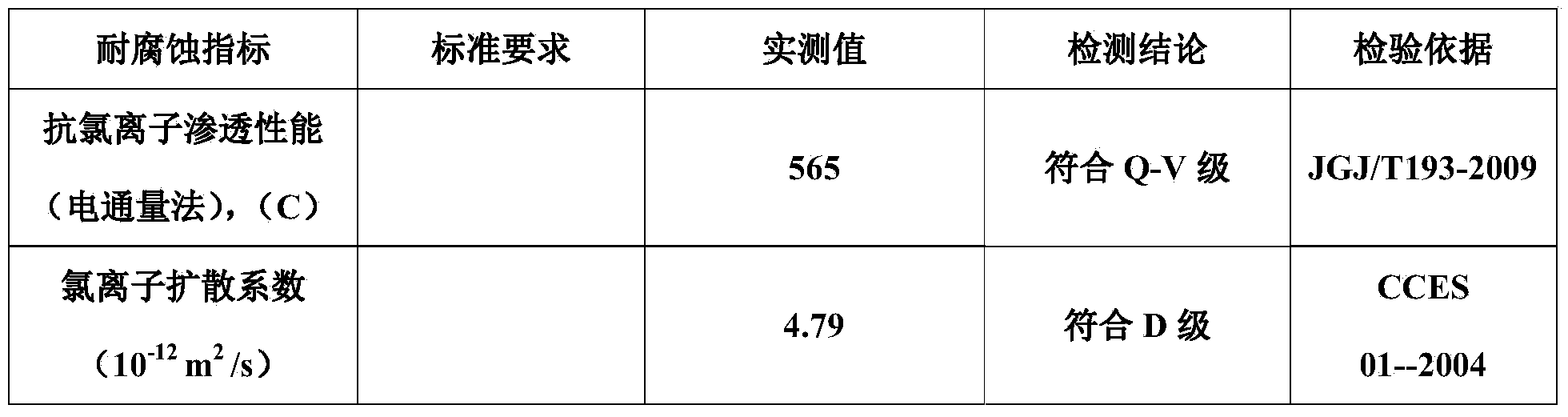

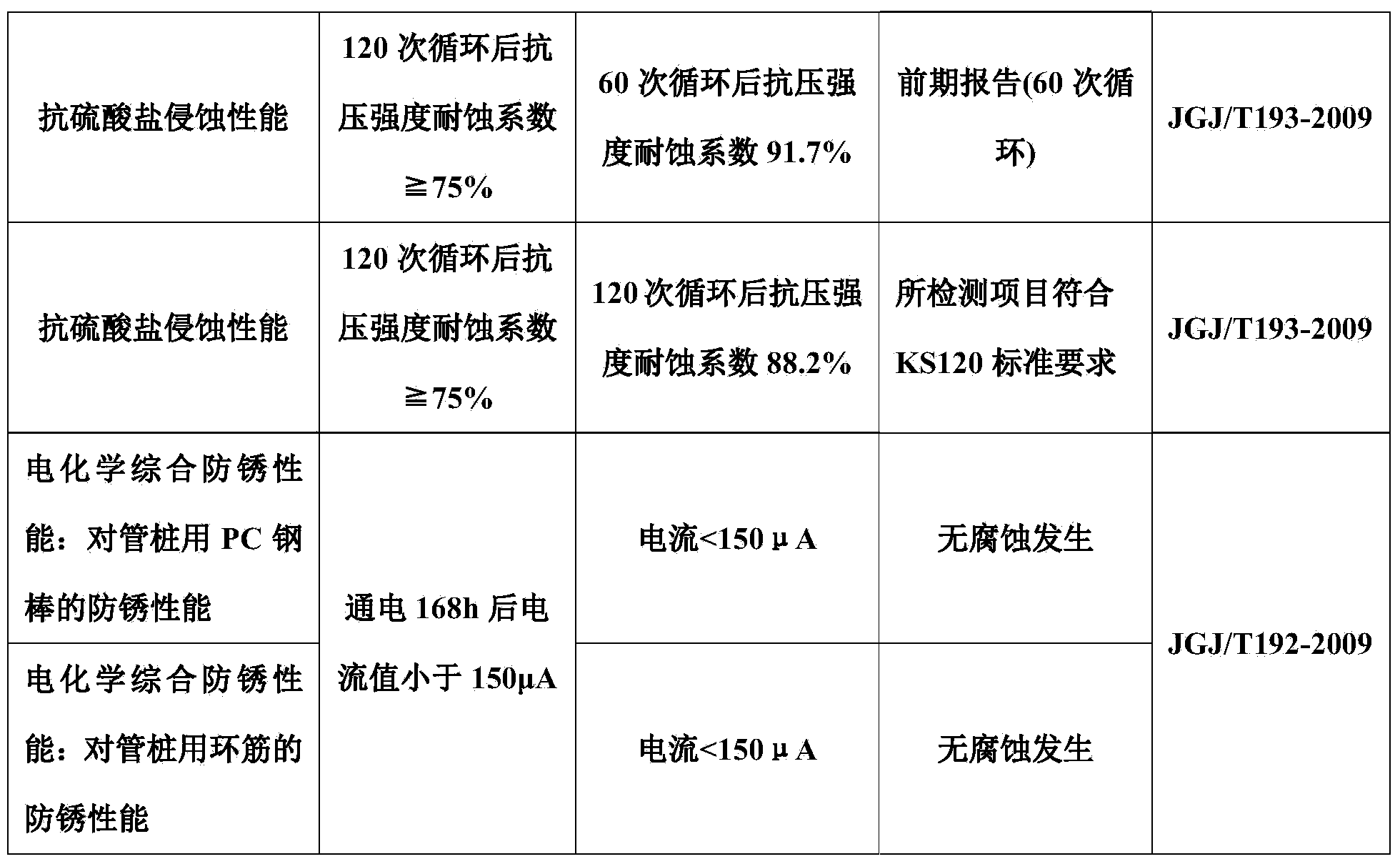

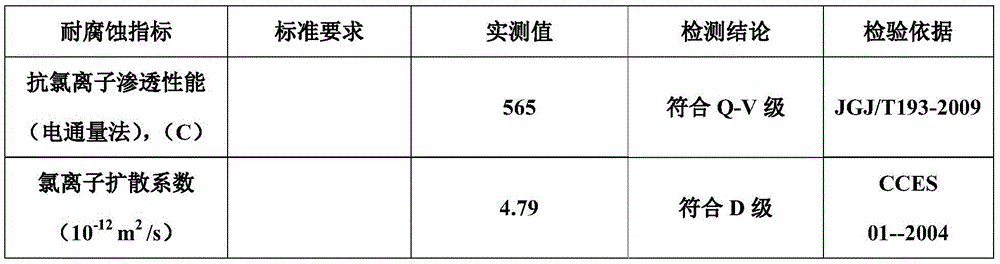

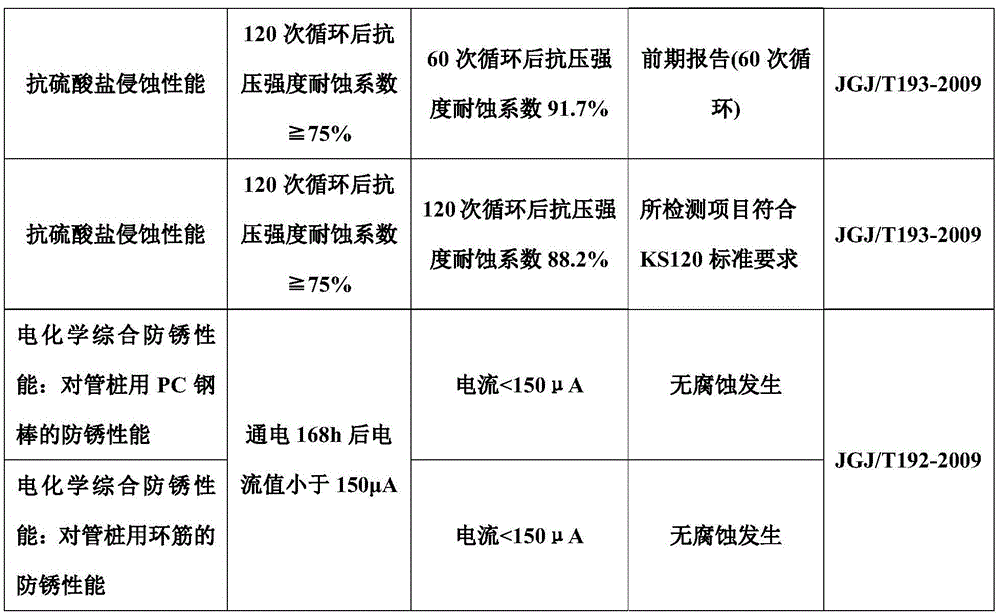

Corrosion-resistant PHC pipe pile

ActiveCN104291754ANo need to change the production process parametersNo process changes requiredProduction lineNational standard

The invention discloses a corrosion-resistant PHC pipe pile. The corrosion-resistant PHC pipe pile is characterized by comprising the following components in parts by weight: 1 part of a binding material, 0.28 part of water, 1.58 parts of sand, 2.92 parts of stones, 0.023 part of a water reducer, 0.005-0.03 part of an organic corrosion inhibitor HQ; and the organic corrosion inhibitor HQ accounts for 0.5%-3% of weight of the binding material. The corrosion-resistant PHC pipe pile has the advantages that (1) the technologic processes of an existing pipe pile do no need to be changed, and no production equipment is added; (2) production process parameters of the existing pipe pile do not need to be changed; (3) the production cost is low; and (4) an existing pipe pile production line can be used for producing national standard of PHC pipe piles, and can also be used for producing the corrosion-resistant PHC pipe pile.

Owner:广东宏基管桩有限公司

Sewage disposal agent for sanitary sewage treatment and preparation method thereof

The invention discloses a sewage disposal agent for sanitary sewage treatment. The sewage disposal agent for sanitary sewage treatment comprises, by weight, 15-20 parts of calcium aluminate, 12-16 parts of ethidene diamine tetramethylene phosphonic acid, 8-11 parts of aluminum sulfate, 17-20 parts of ferric trichloride, 33-36 parts of diatom ooze, 35-40 parts of polyethyleneimine, 21-24 parts of polyferric sulfate, 15-20 parts of imvite, 12-16 parts of zeolite and 40-45 parts of straw. The invention further discloses a preparation method of the sewage disposal agent for sanitary sewage treatment. According to the sewage disposal agent for sanitary sewage treatment, the good treatment effect on sanitary sewage is achieved, the reaction speed is quick, generation of poisonous and harmful substances is avoided in the treatment process, and secondary pollution is avoided.

Owner:余姚怡丰生态农业发展有限公司

Preparation method of oxidized biodegradable mulching film

InactiveCN107383544APerformance is not affectedSimple preparation processPolymer scienceBiodegradable product

The invention belongs to the technical field of degradable plastics, and specifically relates to a preparation method of an oxidized biodegradable mulching film. The oxidized biodegradable mulching film is prepared from a resin additive and a degradable master batch, wherein the raw material components in mass percent are as follows: 98-99.8% of the resin additive and 0.2-2.0% of the degradable master batch. According to the preparation method of the oxidized biodegradable mulching film, the preparation process is simple without the need of changing the production equipment and process; the mulching film can be recovered without generating waste; no toxic substance is generated in the processes of production, storage, use and degradation; the inherent properties of the products are unaffected; the productivity is increased especially for film and sheet products; the thickness of the film can be appropriately reduced under the condition of the same mechanics properties; the raw materials adopt general materials and natural modifiers; the energy source investment is the lowest compared with compatible products or directly biodegradable products, because the energy consumption of other products is as high as 3 times of the oxidized biodegradable mulching film; less polymers are used and natural resources are guaranteed; waste is reduced; and supplement nutrition is benefited in composting without influencing the value of available humus soil.

Owner:昆明鑫鑫大壮降解塑料技术有限公司

Black inorganic fiber and plasma preparation method thereof

The invention relates to a black inorganic fiber and a plasma preparation method thereof, and particularly discloses a black inorganic fiber. The black inorganic fiber comprises a fiber matrix and carbonized sugar attached to the fiber matrix, wherein the fiber matrix is an inorganic fiber capable of tolerating heat at the temperature of 500 DEG C, such as a basalt fiber, a ceramic fiber, a quartzfiber and a sepiolite fiber. The carbonized sugar attached to the fiber matrix is obtained by the following method: 1) pretreatment: carrying out surface modification on the fiber matrix by using wetplasma to obtain activated fibers, and soaking the activated fibers in a sugar aqueous solution under the action of tension; and 2) carbonization dyeing: carbonizing the soaked fibers obtained in thestep (1) at a high temperature to obtain the inorganic fibers with carbonized sugar attached to the fiber matrix after dyeing. The black inorganic fiber is novel and unique, simple in preparation method, environment-friendly and pollution-free.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

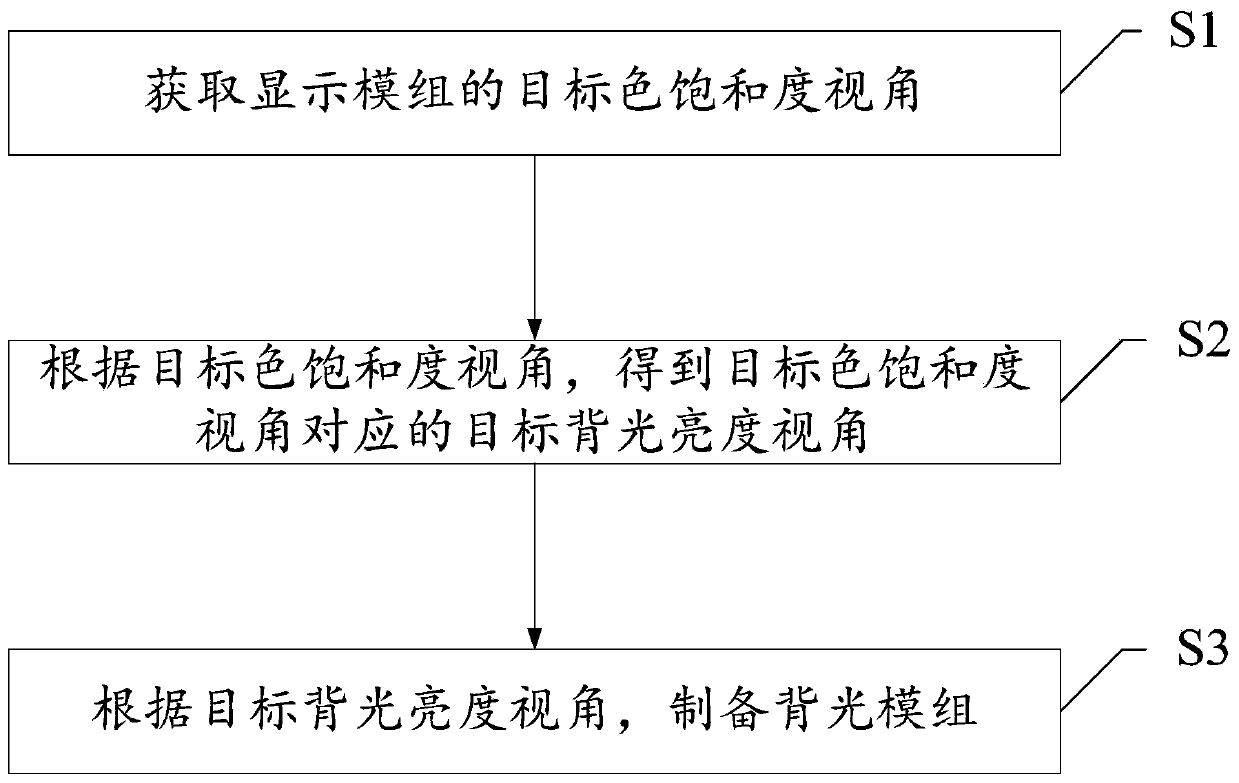

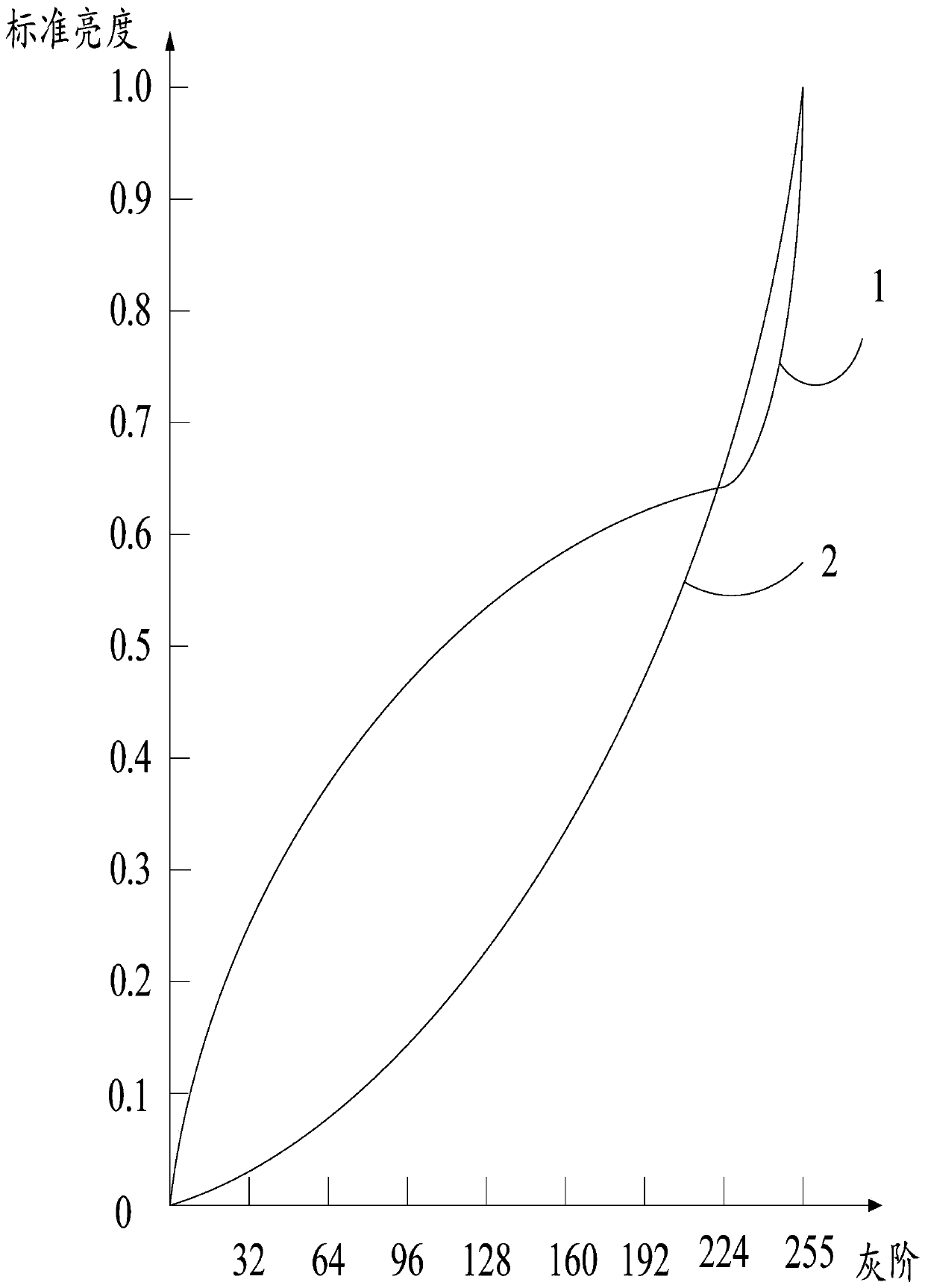

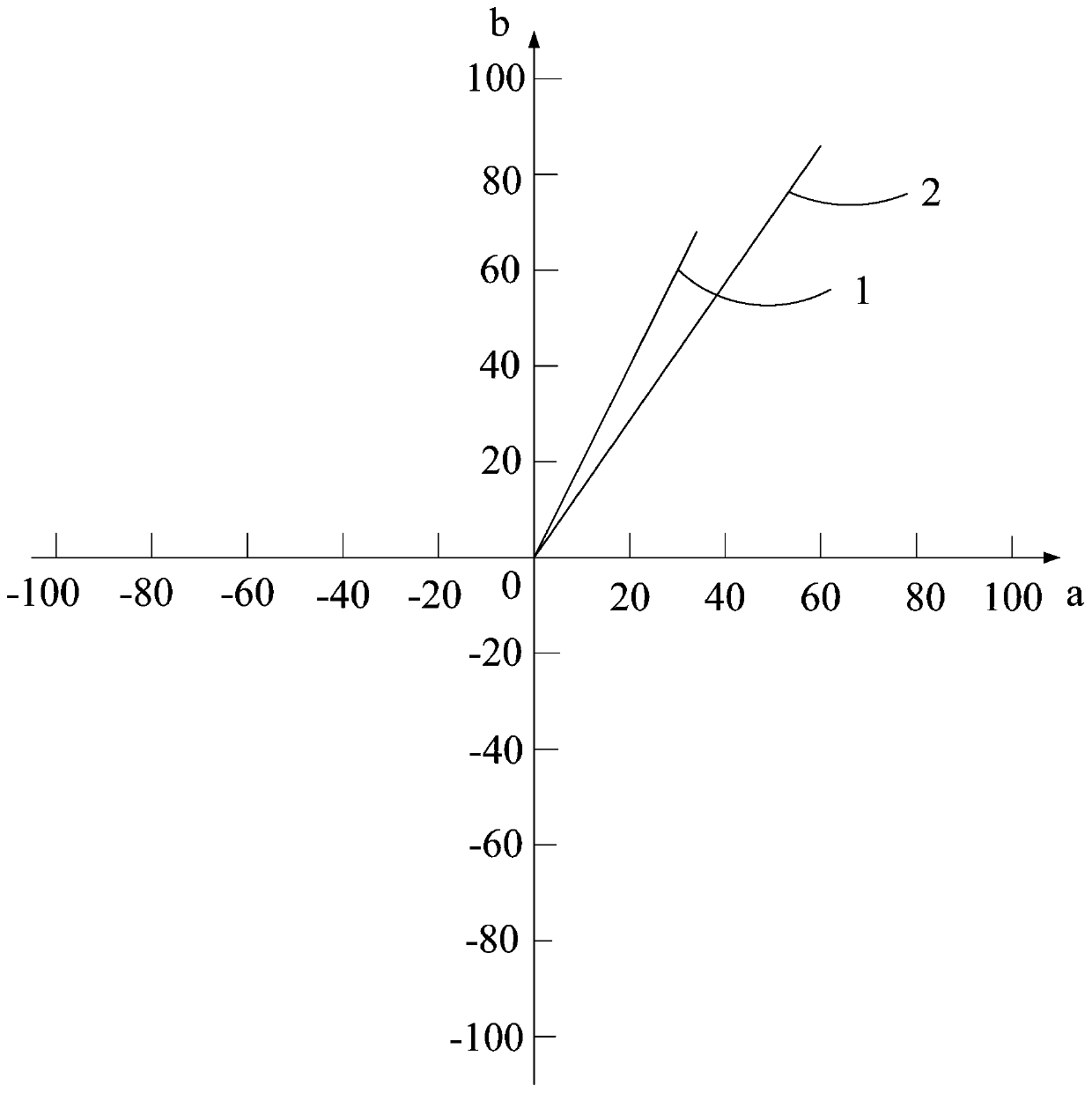

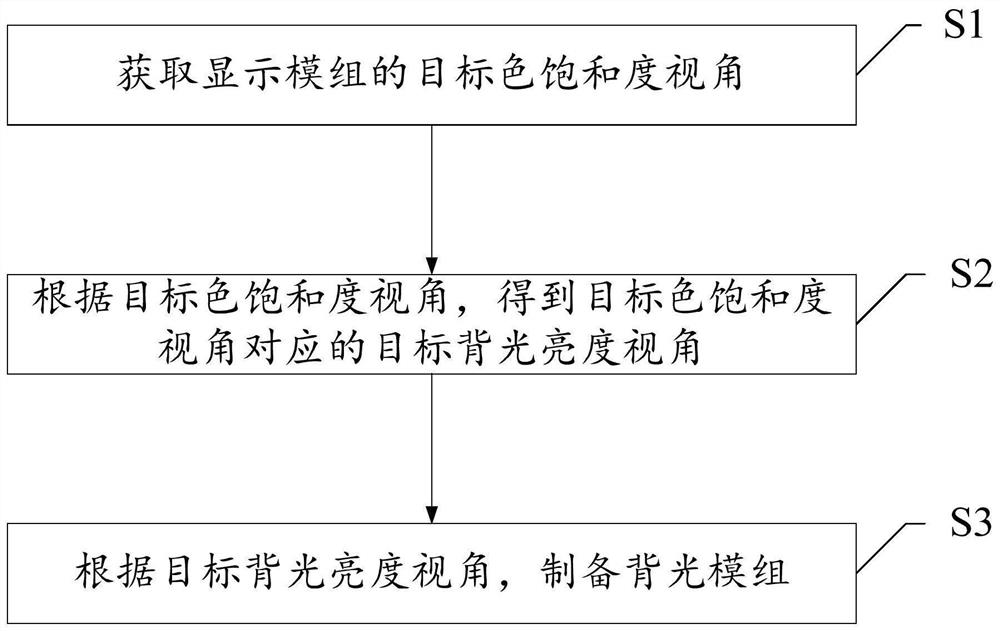

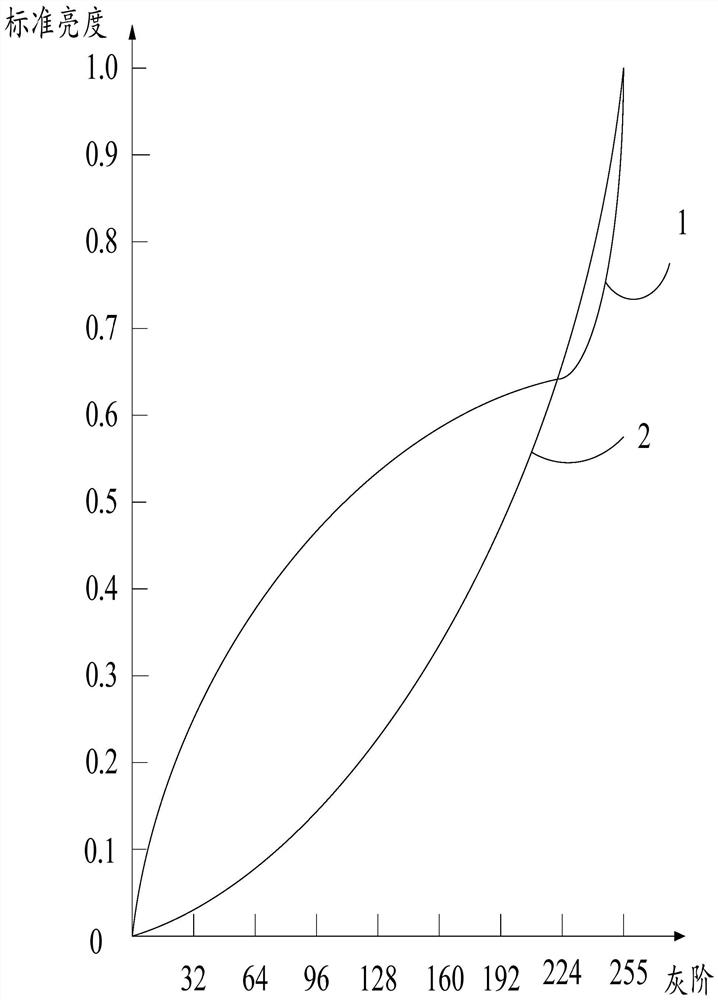

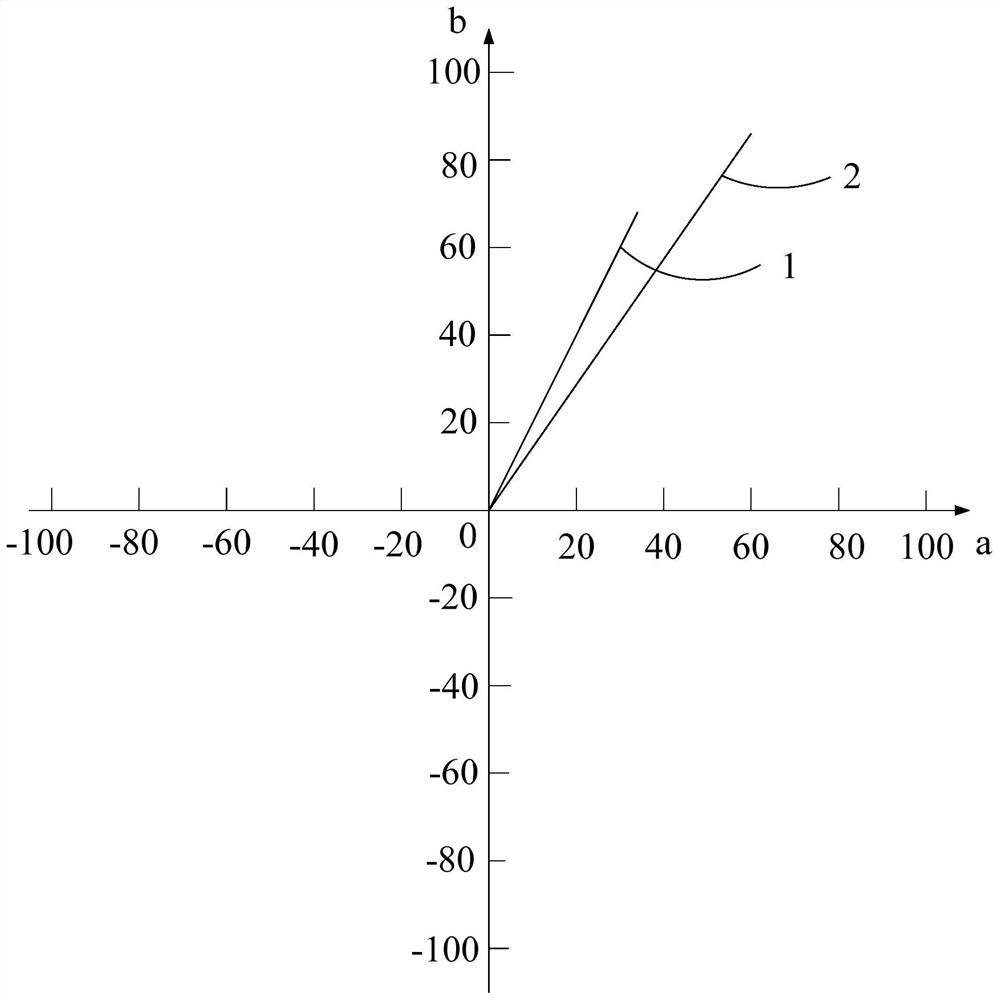

Backlight module preparation method and device

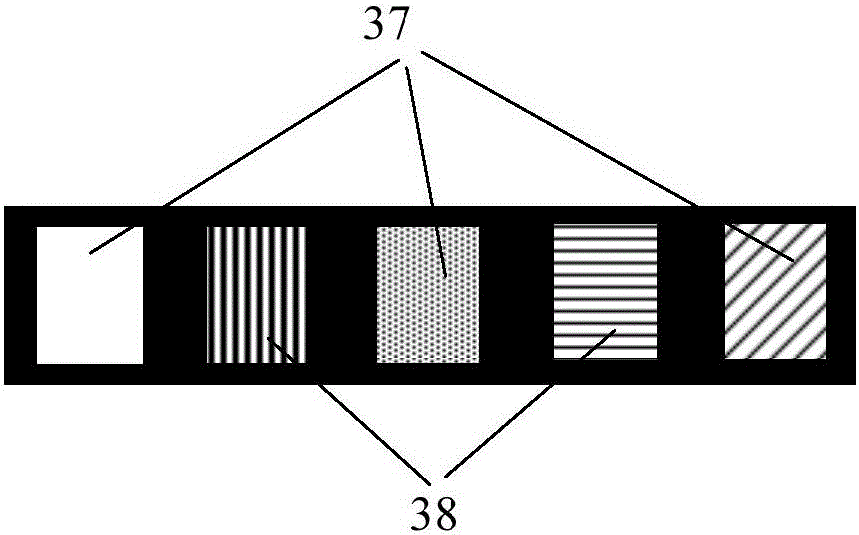

ActiveCN111583876ANo process changes requiredImprove color castStatic indicating devicesLiquid-crystal displayColor saturation

The embodiment of the invention provides a backlight module preparation method and device. The backlight module preparation method comprises the steps of acquiring a target color saturation visual angle of a display module; wherein a display module comprises a liquid crystal display panel and a backlight module; obtaining a target backlight brightness view angle corresponding to the target color saturation view angle according to the target color saturation view angle, and preparing a backlight module according to the target backlight brightness view angle; when the color saturation visual angle of the liquid crystal display panel needs to be changed; obtaining target color saturation viewing angle, obtaining a target backlight brightness visual angle according to the target color saturation visual angle. The target backlight brightness visual angle is obtained, and then the backlight module is prepared according to the target backlight brightness visual angle, so that the color saturation visual angle can be changed and the color cast can be improved by changing the backlight brightness visual angle in the backlight module, the manufacturing process of the display panel does not need to be changed, and the technical problems of complex manufacturing process and relatively low yield of an existing VA type liquid crystal display panel improvement method are solved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Hollow blade intracavitary residue detection method

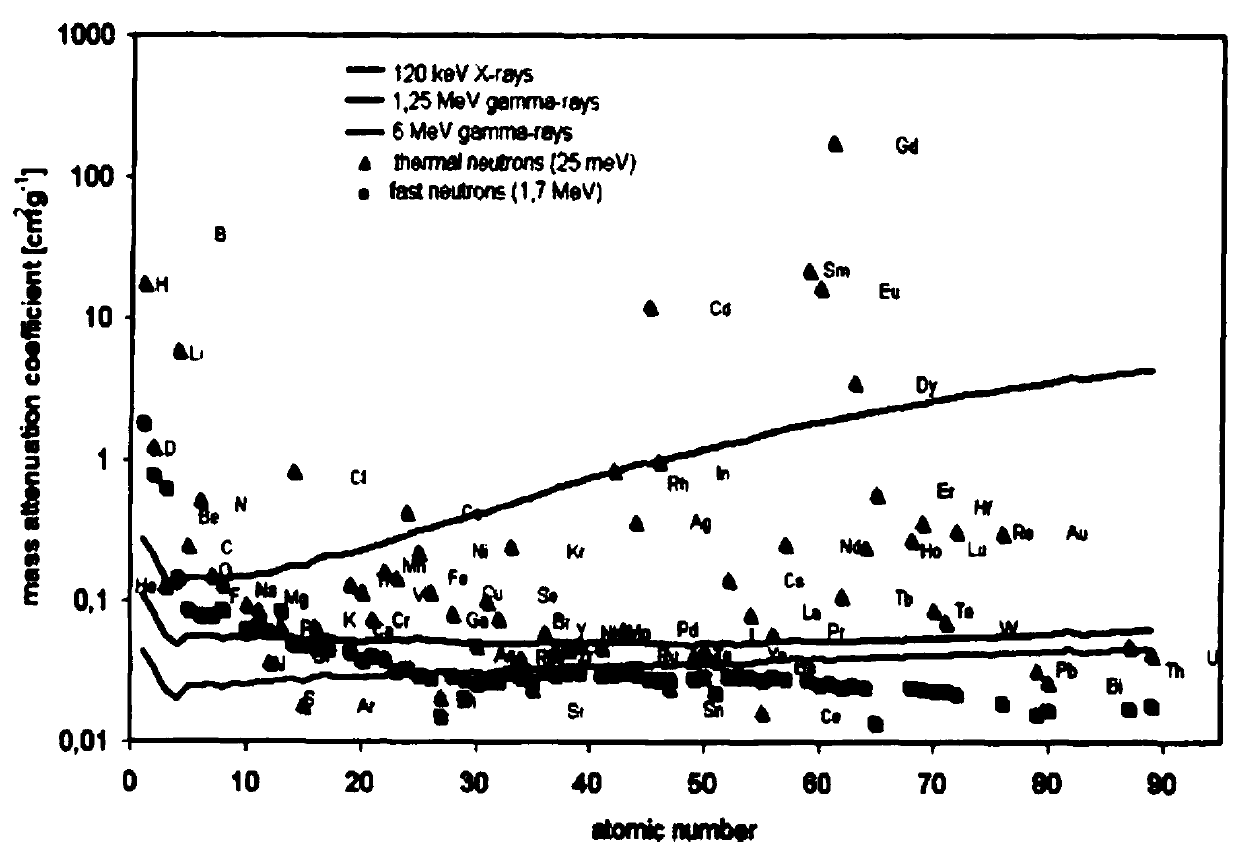

InactiveCN110426255AWide range of market applicationsLow costPreparing sample for investigationMaterial analysis by transmitting radiationIron powderGadolinium

The invention belongs to the technical field of nondestructive detection, and discloses a hollow blade intracavitary residue detection method which is applied in neutron radiography, and includes thefollowing main steps: (1) preparing 10%-20% of a gadolinium nitrate aqueous solution; (2) placing a to-be-detected hollow blade into the gadolinium nitrate aqueous solution, soaking the to-be-detectedhollow blade at a vacuum degree of 0.07-0.09 atm for 6-8 hours; (3) continuously washing the to-be-detected hollow blade in a 24-64KHZ ultrasonic tank for 5-15 minutes; and (4) drying the be-detectedhollow blade at 80-100 degrees by baking. The to-be-detected hollow blade processed by the method is subjected to neutron radiography, and intracavitary residues of the hollow blade, including a residual core, residual iron powder produced after powder filling detection, and impurities sucked by the blade after long working hours, can be removed effectively. The method is simple in process, low in cost and accurate in detection results, and avoids erroneous judgement and missed judgment caused by other detection methods.

Owner:GUIYANG AVIC POWER PRECISION CASTING

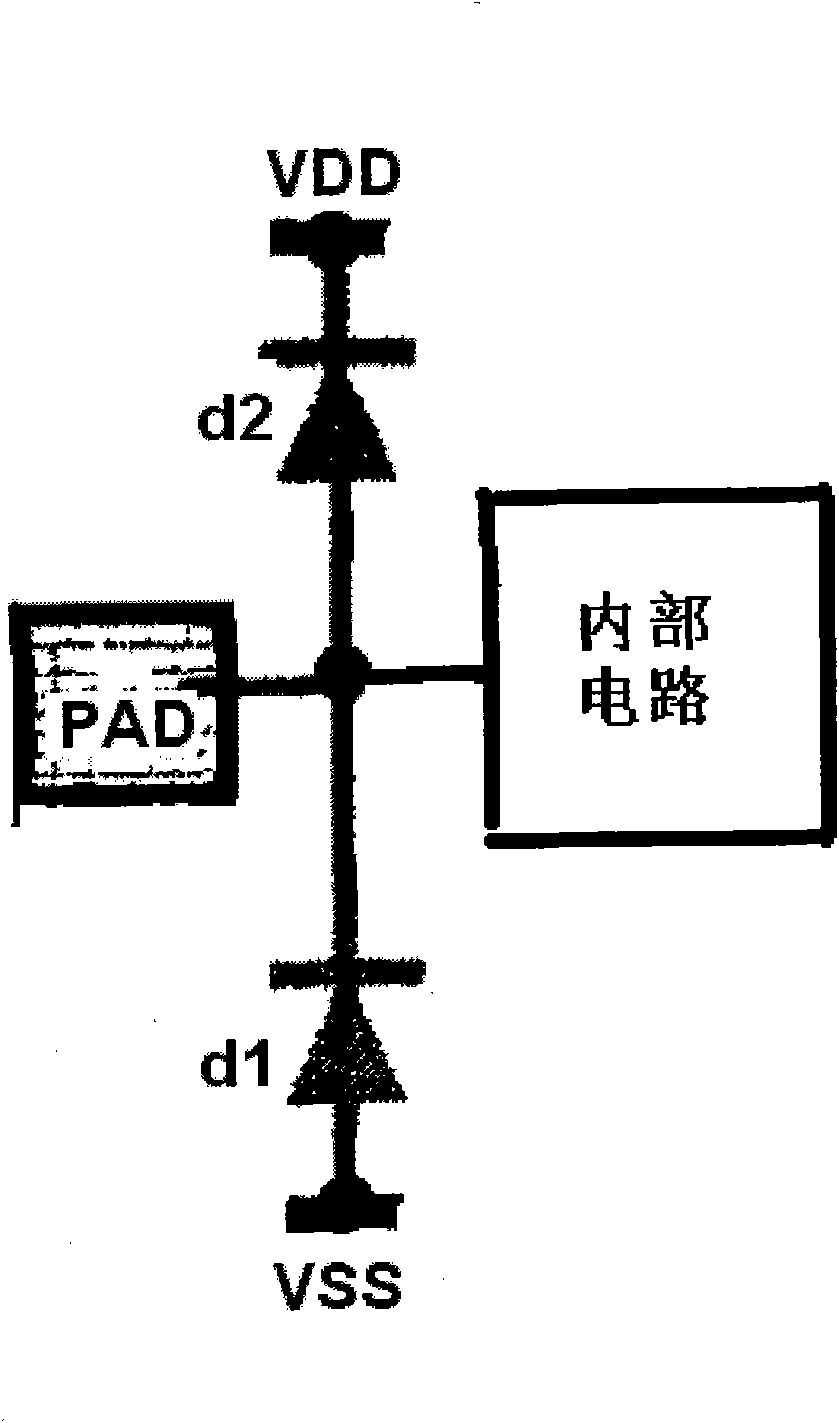

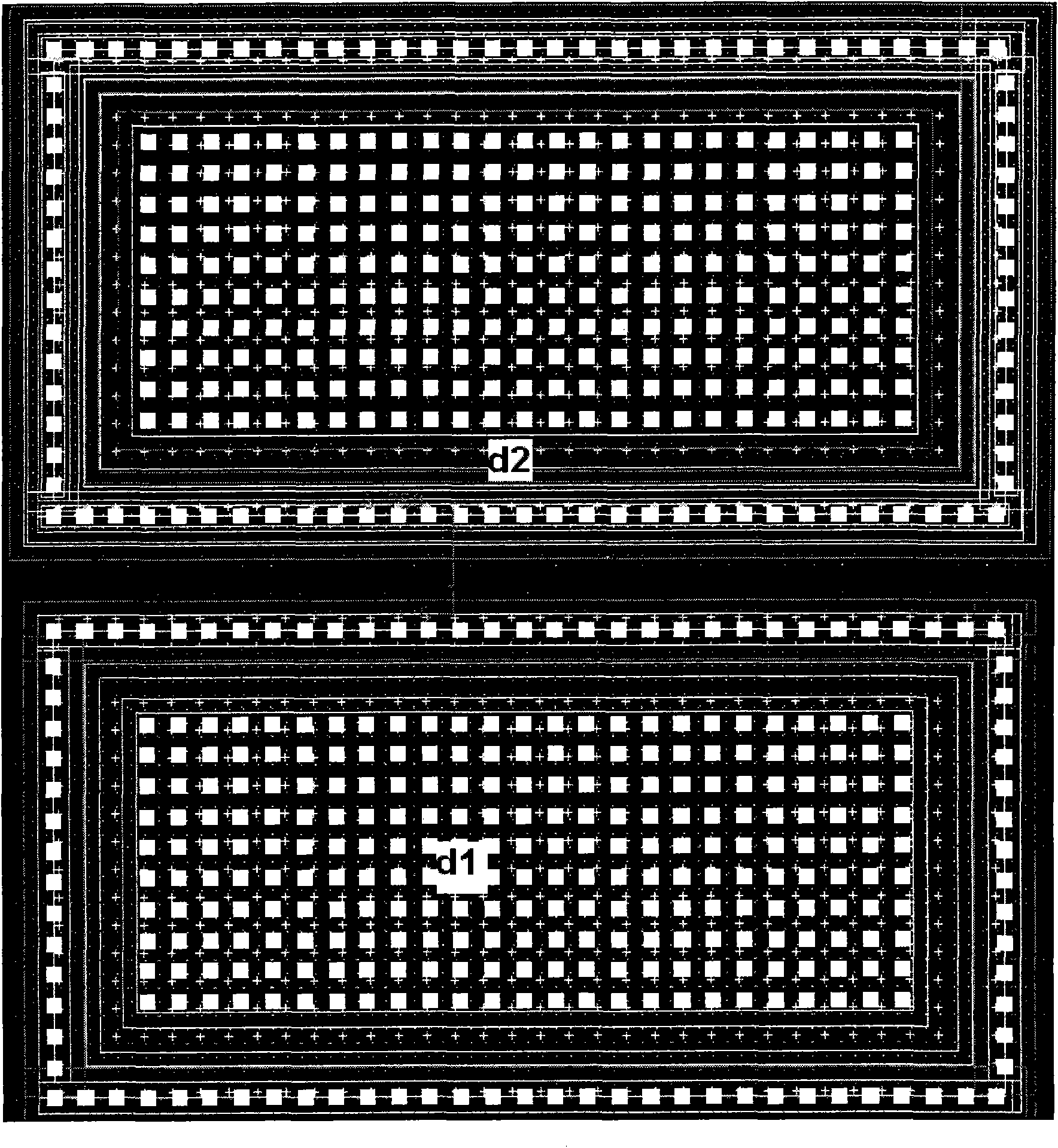

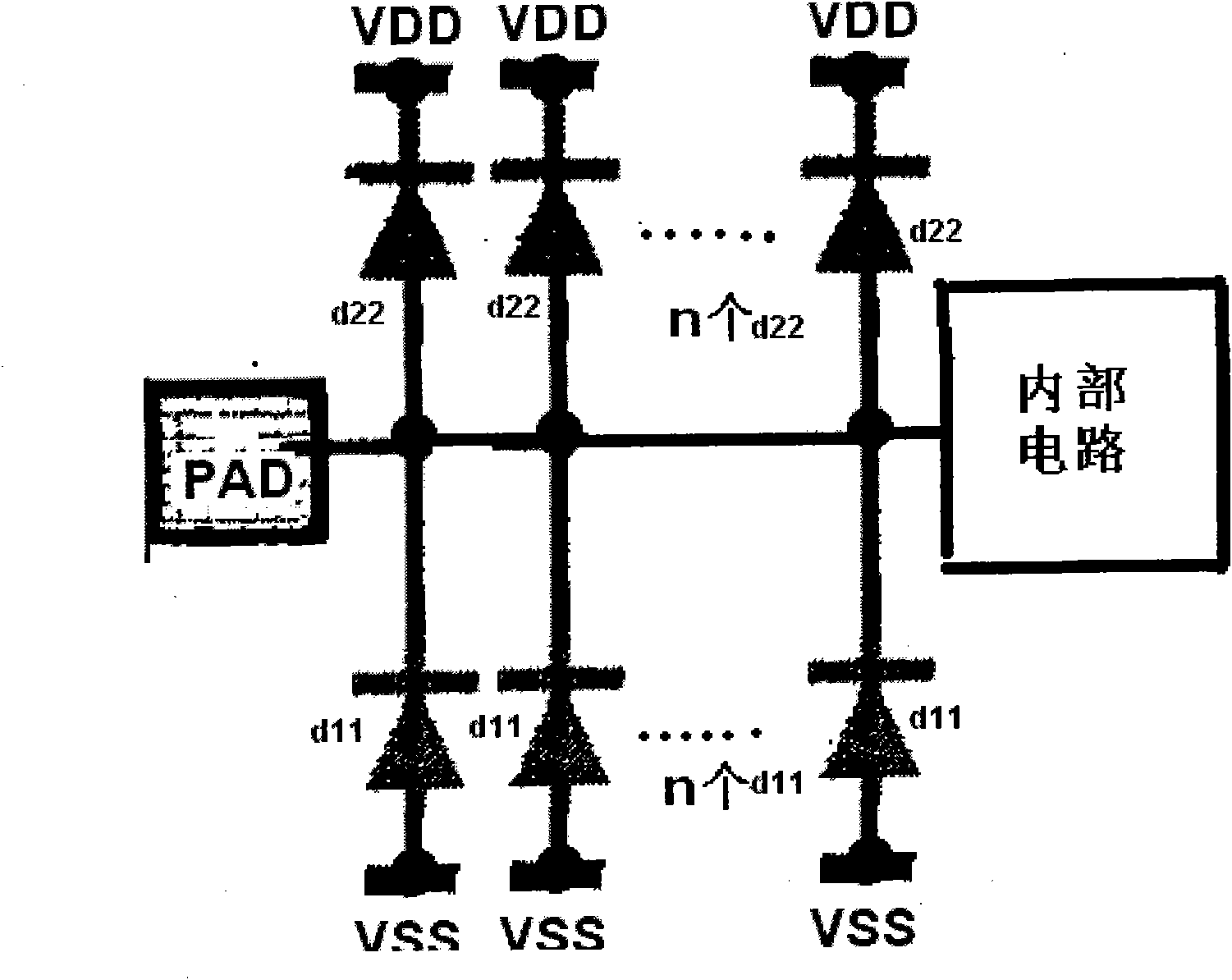

Electrostatic discharge (ESD) protection structure of integrated circuit

InactiveCN102122657AImprove performance against ESDImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesP–n junctionSilicon

The invention discloses an electrostatic discharge (ESD) protection structure of an integrated circuit. The ESD protection structure is arranged between an internal circuit and a bonding pad of the integrated circuit and consists of a PN junction which occupies a certain area of a chip of the integrated circuit, wherein the PN junction is set to be formed by parallelly connecting a plurality of small-area PN junctions on the occupied area of the chip, so that the volume of intrinsic silicon included in the PN junction is increased. In the novel ESD protection structure, the volume of the intrinsic silicon in a PN junction depletion region is increased without the increase of the occupied area on the chip, so that the influence of energy produced by an ESD event on a circuit can be more effectively reduced, and the ESD resistance of the circuit is improved.

Owner:SUZHOU HUAXIN MICROELECTRONICS

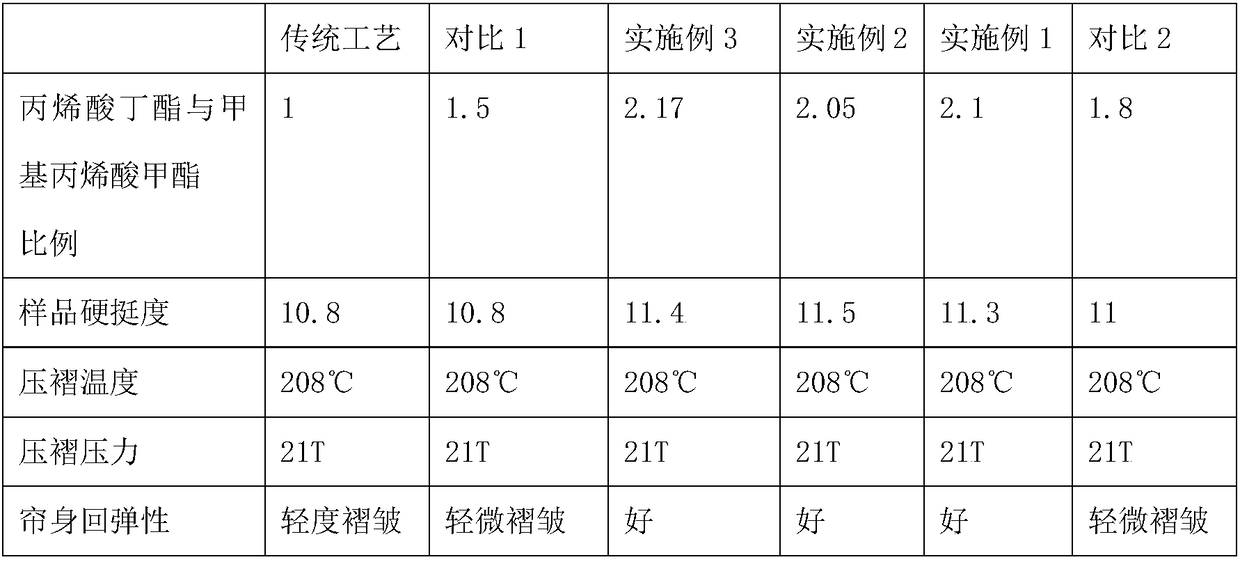

Manufacturing method of distemper silver-coated pleated blind fabric

The invention discloses a manufacturing method of a distemper silver-coated pleated blind fabric. The method includes the steps of: selecting a 100% polyester fabric as the base fabric and conductingshaping treatment; performing blade coating of a black slurry in forward direction on one side of the shaping treated base fabric, and performing drying to generate a first bladed black layer; after drying, conducting blade coating of the black slurry in reverse direction and performing drying to generate a second bladed black layer, performing blade coating of a layer of silver slurry on the surface of the second bladed black layer, and conducting drying to generate a silver coating; and performing blade coating of a layer of distemper slurry on the back of the silver coating, and conductingdrying to generate a distemper layer. No rebound of the blind body due to the blind body straightening caused by the height and weight increase of the pleated blind fabric prepared by the method provided by the invention cannot occur, the pleated shape is more stable, the rebound resilience is better, also the pleating temperature and process are not needed to change, and the energy consumption isnot increased.

Owner:CHANGZHOU TAILUN TEXTILE CO LTD

Backlight module preparation method and device

ActiveCN111583876BNo process changes requiredImprove color castStatic indicating devicesLiquid-crystal displayColor saturation

The embodiment of the present application provides a backlight module preparation method and device, the backlight module preparation method includes obtaining the target color saturation viewing angle of the display module; the display module includes a liquid crystal display panel and a backlight module; according to the Target color saturation viewing angle, obtain the target backlight brightness viewing angle corresponding to the target color saturation viewing angle, prepare a backlight module according to the target backlight brightness viewing angle; when the liquid crystal display panel needs to change the color saturation viewing angle, obtain the target color saturation degree viewing angle, and then obtain the target backlight brightness viewing angle according to the target color saturation viewing angle, and then prepare a backlight module according to the target backlight brightness viewing angle, so that by changing the backlight brightness viewing angle in the backlight module, the color saturation viewing angle can be changed, and the color saturation can be improved. It does not need to change the manufacturing process of the display panel, and solves the technical problems of complex manufacturing process and low yield rate in the existing improvement method of VA-type liquid crystal display panel.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

A continuous annealing and pickling method for medium-chromium ultra-pure ferritic stainless steel

ActiveCN103243339BImprove surface corrosion resistanceImprove surface conditionWater rinsingSS - Stainless steel

A continuous annealing and acid washing method for medium-chromium ultrapure ferrite stainless steel comprises the process flow of cold rolling, annealing heat treatment, acid washing, final water washing, drying, flattening and packaging, and is characterized in that in the acid washing process flow, the acid washing solution is prepared from 120-150g / L of 65% nitric acid, 2-4g / L of 40% hydrofluoric acid and water. According to the invention, in the chemical acid washing stage, reasonable concentration ratio of nitric acid to hydrofluoric acid is adopted and proper acid washing speed is controlled to carry out acid washing on medium-chromium ferrite stainless steel. As a result, on one hand, the performance of a medium-chromium ferrite stainless steel passivation film is obviously improved, and the corrosion resistance of the surface of a medium-chromium ferrite stainless steel 2B board is significantly improved, and on the other hand, the process flow of the existing production factory is not needed to be changed, a special passivation treatment procedure is not needed, and the production cost is significantly lowered.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for arranging in piles the tailings generated by iron ore processing

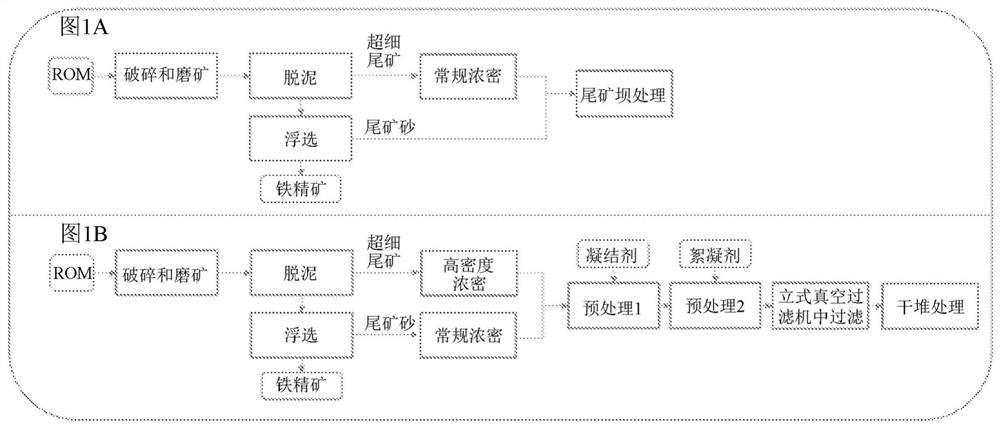

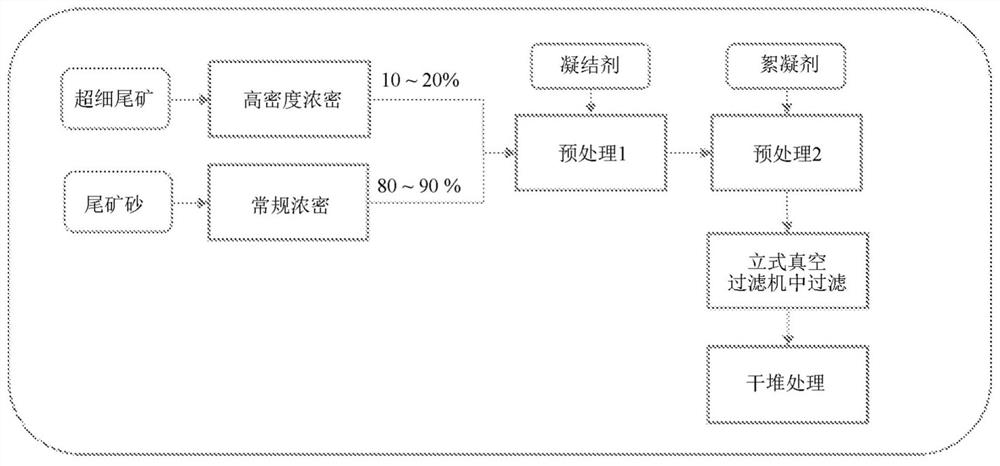

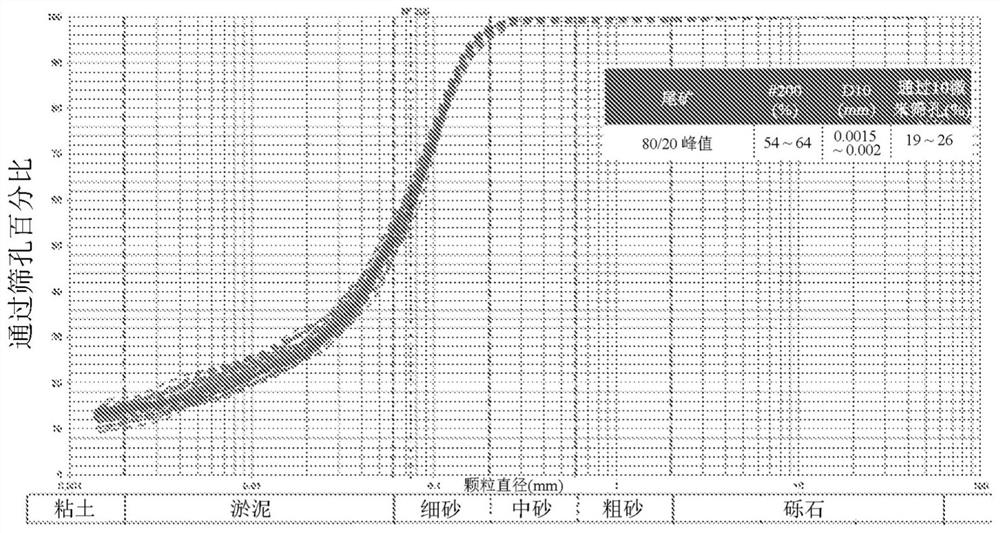

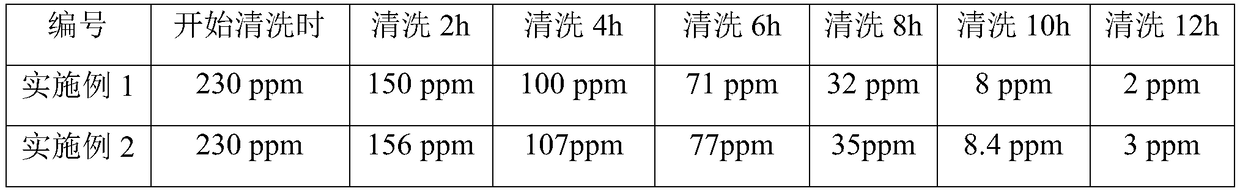

PendingCN113840808ANo process changes requiredWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningTailings damMining engineering

The present invention discloses a method for arranging in piles, instead of in dams, the tailings generated by iron ore processing, said method comprising the steps of thickening the ultrafine tailings, thickening the sandy tailings, mixing the tailings at a ratio of 80-90% sandy tailings to 10-20% ultrafine tailings by weight, adding coagulant, adding flocculent, filtering the mixture and piling the filtered tailings. Unlike the traditional methods, the present invention provides an economically and technically viable method for arranging tailings in piles, which can be used in any conventional iron ore concentration plant without having to alter the process flows in any way.

Owner:VALE LIMITED

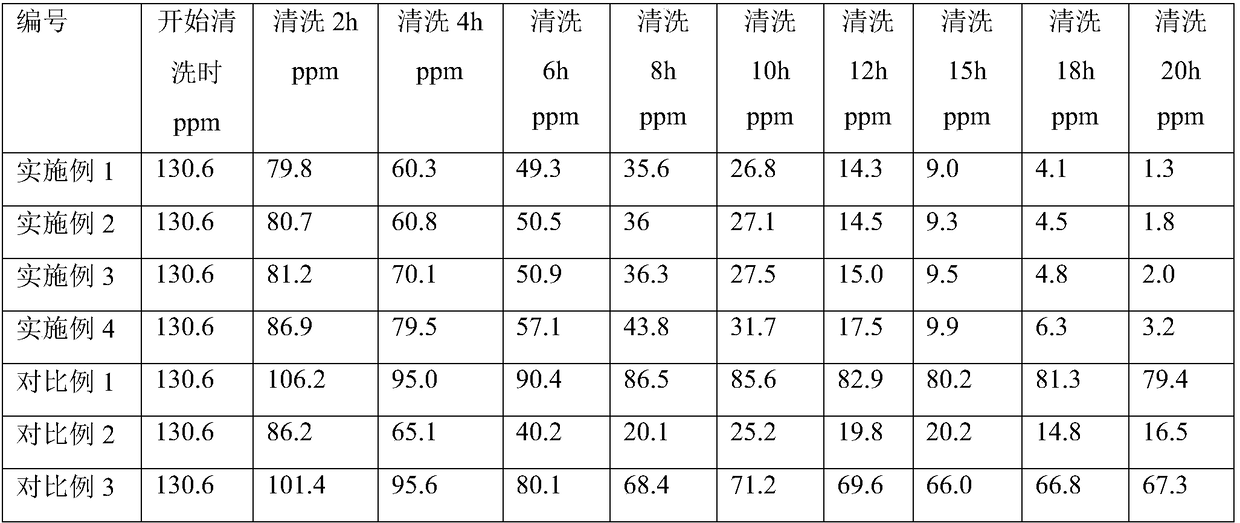

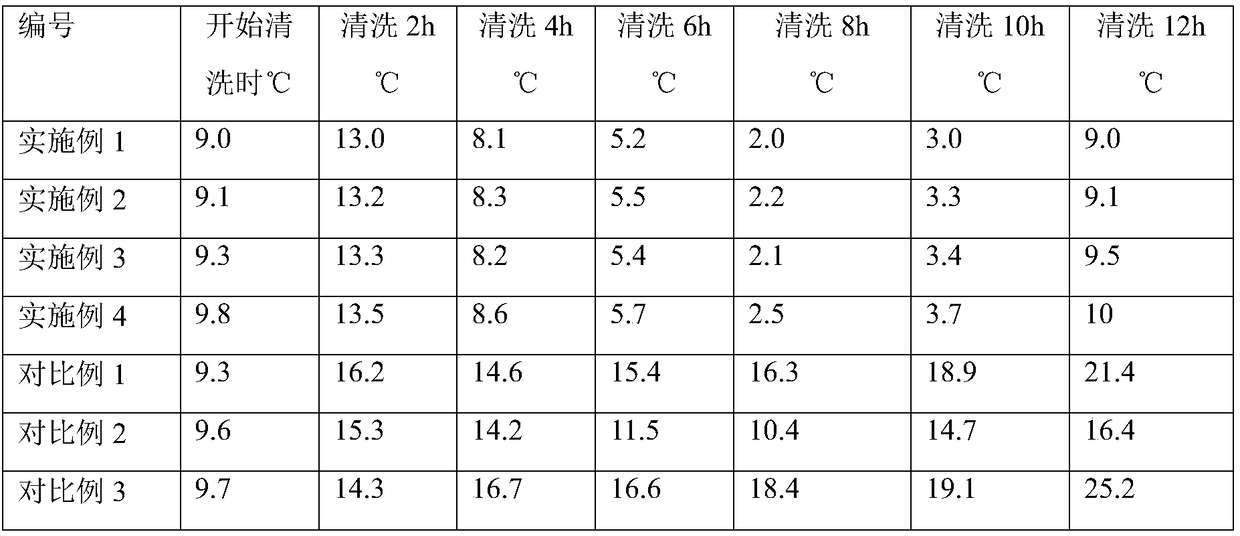

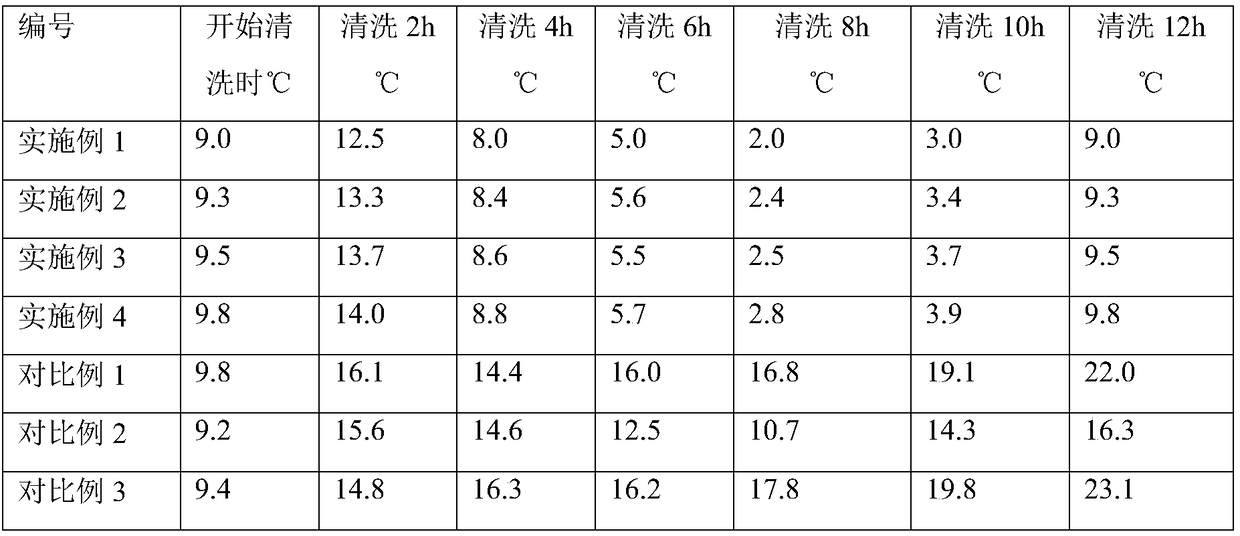

Compound environment-friendly type composition for deodorization, passivation and cleaning and preparation method and application thereof

InactiveCN108659992AReduce sewageShorten cleaning timeDetergent mixture composition preparationOrganic non-surface-active detergent compositionsCitric acidPollution

The invention relates to the technical field of deodorization, passivation and cleaning and discloses a compound environment-friendly type composition for deodorization, passivation and cleaning and apreparation method and application thereof. The compound environment-friendly type composition for deodorization, passivation and cleaning contains citric acid, urea, sodium p-hydroxybenzoate and secondary deionized water. The invention also discloses the preparation method and application of the compound environment-friendly type composition for deodorization, passivation and cleaning. The cleaning composition disclosed by the invention integrates multiple functions of cleaning and passivation, reduces pollution discharge amount, shortens cleaning time, and has the advantages of environmental friendliness, high efficiency and no corrosion to equipment; and the preparation method is simple.

Owner:JINAN RUIDONG IND

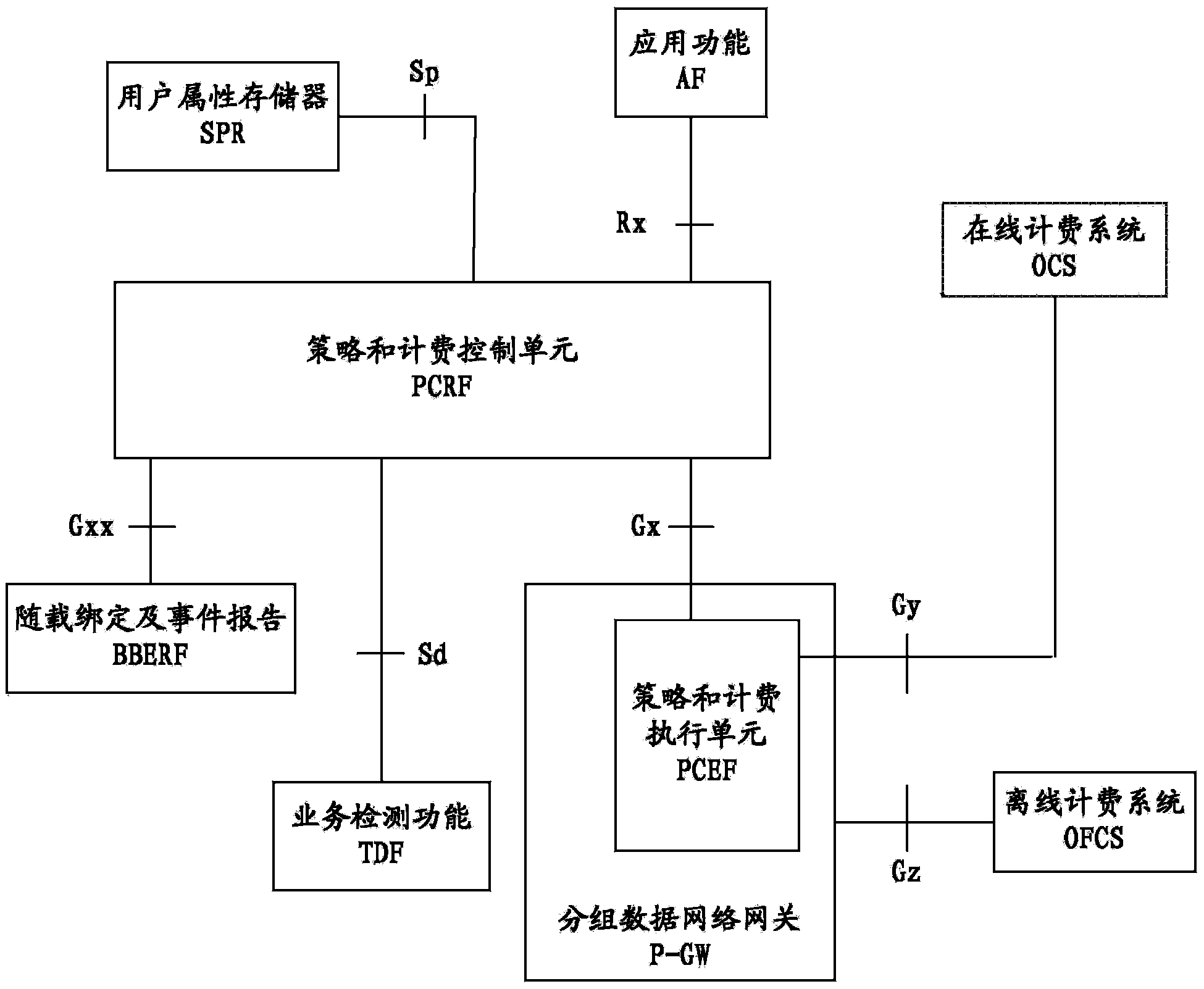

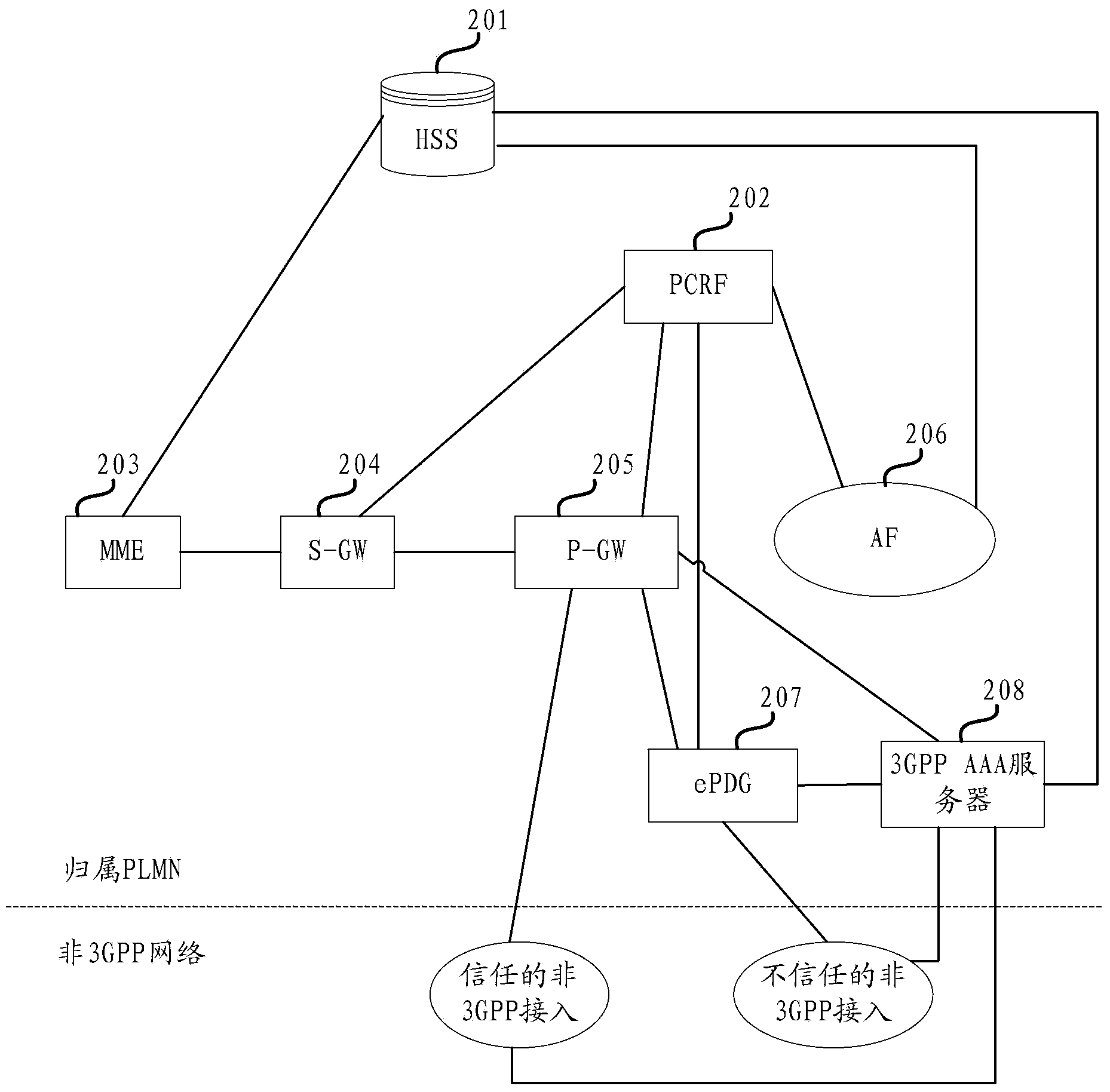

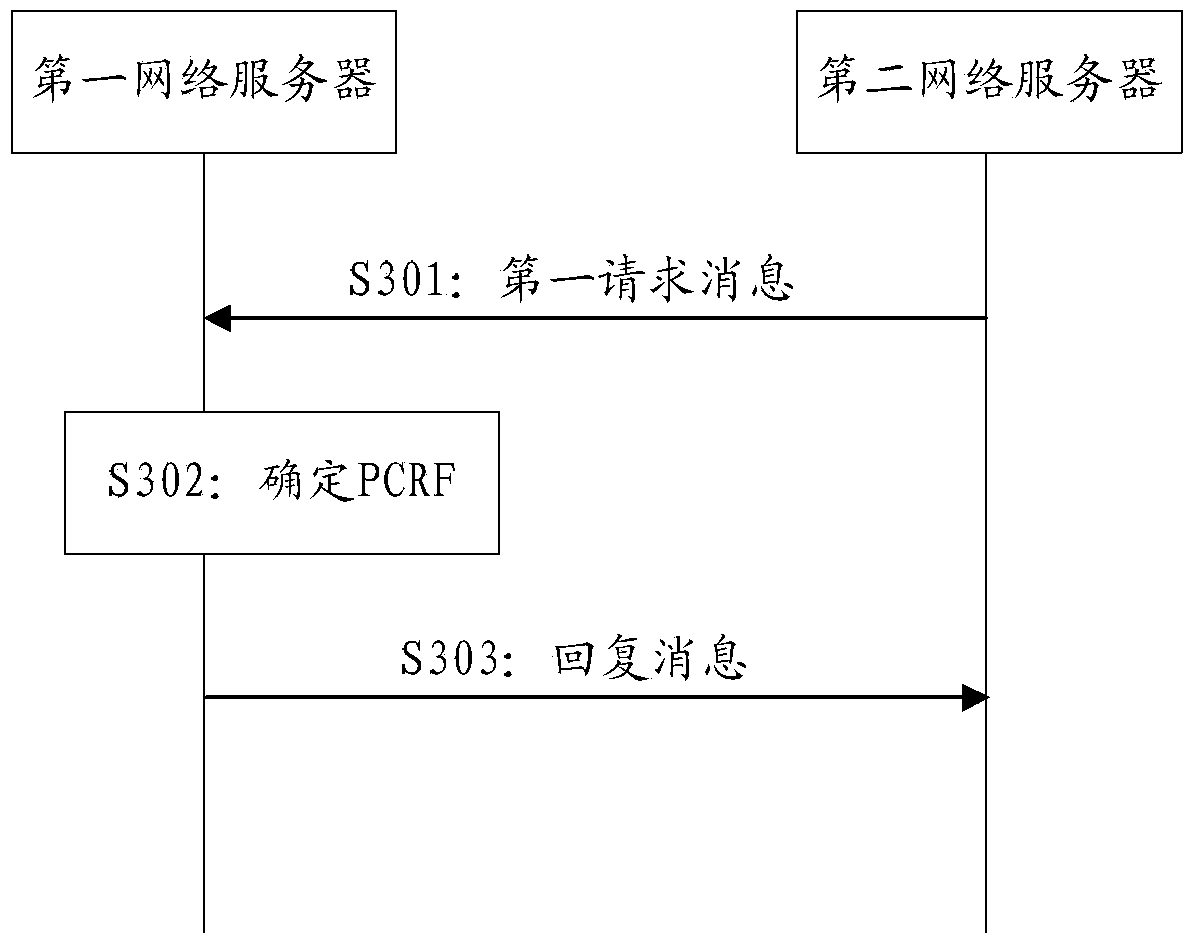

Method and device for determining PCRF

InactiveCN104244211ANo process changes requiredReduce complexityAccounting/billing servicesAssess restrictionUser groupNetwork element

The invention aims to provide a method and device for determining a PCRF; the method comprises the following steps: presetting a matched relation between a user and the PCRF in a HSS, and the same PCRF is configured for the users of a same user group; using a MME or AF or 3GPP AAA server to send a request message to the HSS so as to obtain the PCRF matched with certain user; sending the PCRF information to S-GW or P-GW or ePDG, so the S-GW or P-GW or ePDG can send the message related to the same user or same user group to the same PCRF. The method and device can enable a network element in the network to send the message, needing to be sent to the PCRF, of the same user or same user group to the same PCRF; the same PCRF can uniformly control all related conversations of the same user or same user group.

Owner:ALCATEL LUCENT SAS

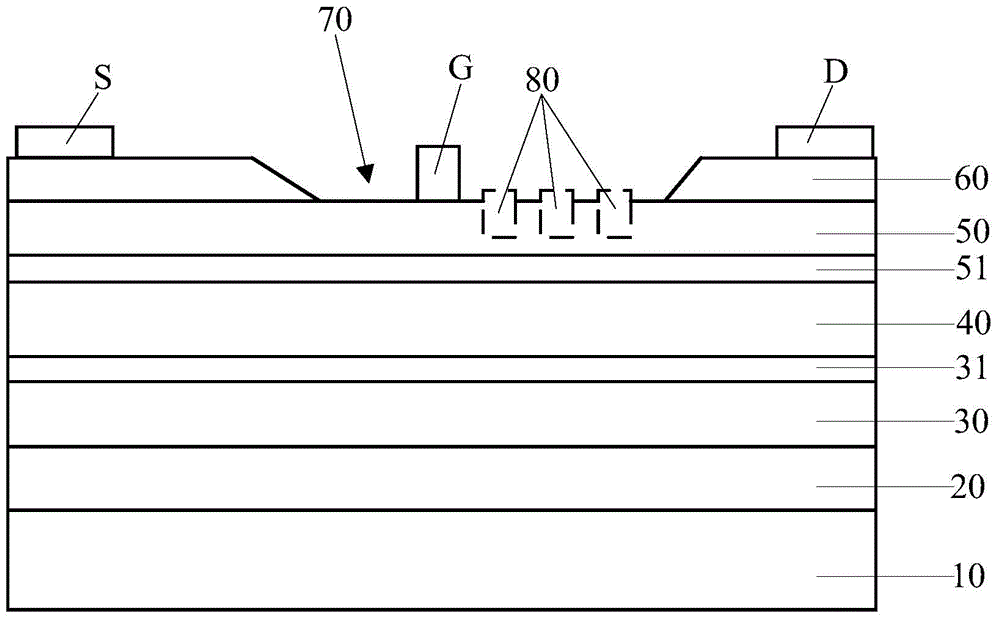

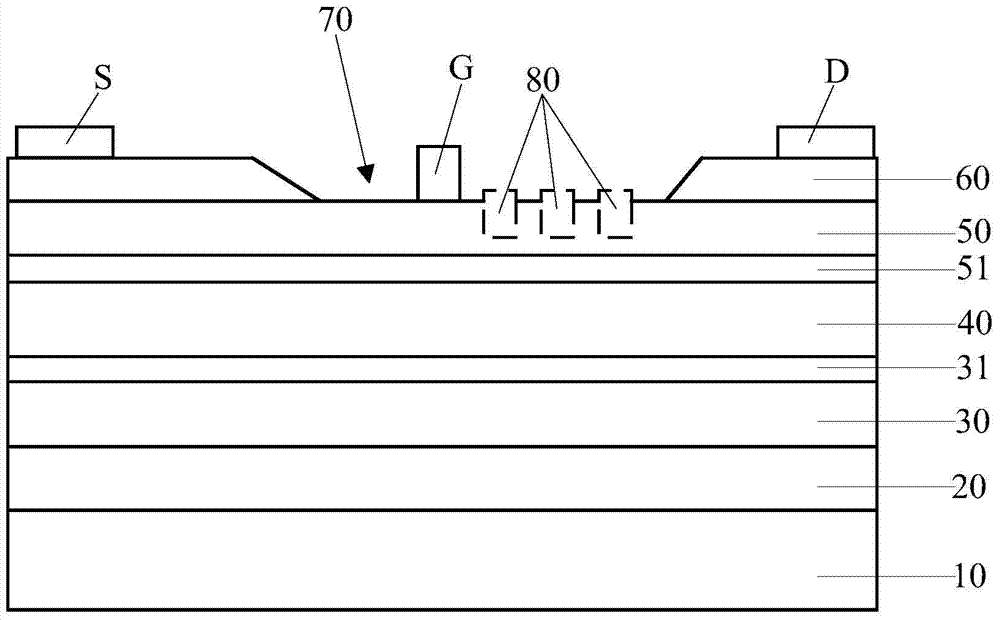

Thin-film transistor and display unit

InactiveCN106409882ALower resistanceIncrease the on-state currentSolid-state devicesSemiconductor devicesMetallurgySemiconductor

The invention provides a thin-film transistor, which comprises a source electrode, a drain electrode, a substrate and a semiconductor thin-film layer coated on the substrate, and is characterized in that the semiconductor thin-film layer is plated with a first metal layer and a second metal layer which are not mutually contacted, the first metal layer is connected to a first metal lead, the second metal layer is connected to a second metal lead, and the first metal lead and the second metal lead are connected to form a grid electrode. The invention further provides a display unit. According to the invention, an original metal layer of the grid electrode is separated into the first metal layer and the second metal layer, thereby enabling the resistance of an equivalent resistor to be smaller, and being capable of effectively increasing on-state current and reducing leakage current. In addition, the thin-film transistor does not need to change manufacturing procedures of a console, thereby being easy to improve and use.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

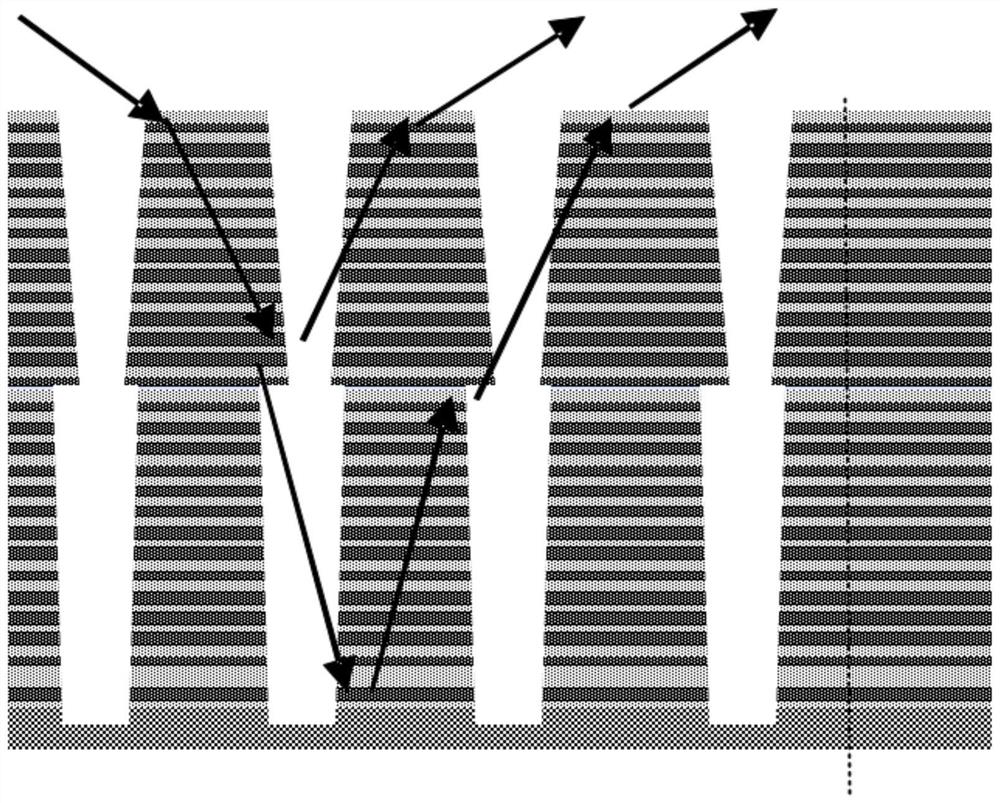

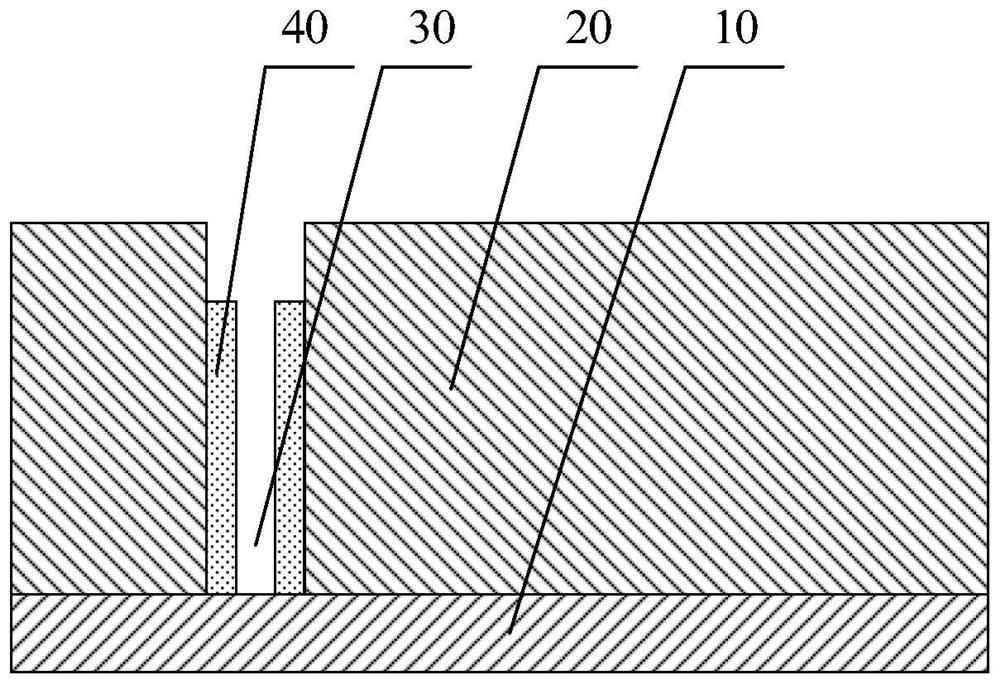

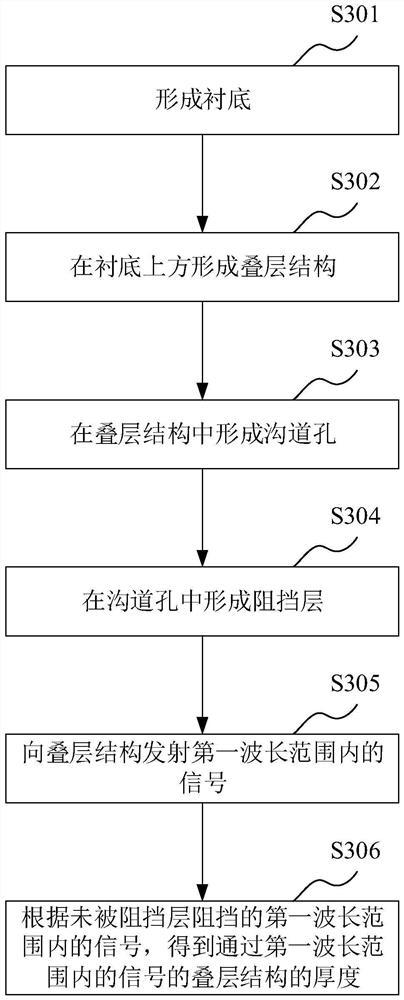

3D storage device and its measurement method, thin film measurement device

ActiveCN112786603BAchieve isolationNo process changes requiredSemiconductor/solid-state device testing/measurementSolid-state devicesThin membraneEngineering

The invention discloses a 3D storage device, a measurement method thereof, and a thin film measurement device. A 3D memory device according to an embodiment of the present invention includes a substrate; a stacked structure located above the substrate for forming a memory array; a channel hole disposed on the stacked structure; and a barrier layer disposed on the stacked structure. In the channel hole, it is used to block signals with a wavelength in the first range. The stacked structure includes a first stacked structure located above the substrate and used to form a memory array; a second stacked structure, Located above the first stacked structure for forming a memory array; the channel hole includes: a first channel hole set in the first stacked structure, wherein the barrier layer is set on the in the first channel hole. According to the 3D memory device, its measuring method, and thin film measuring device according to the embodiments of the present invention, it is possible to accurately measure the film thickness of the 3D memory device.

Owner:YANGTZE MEMORY TECH CO LTD

A corrosion-resistant phc pipe pile

ActiveCN104291754BNo need to change the production process parametersNo process changes requiredProduction lineNational standard

The invention discloses a corrosion-resistant PHC pipe pile. The corrosion-resistant PHC pipe pile is characterized by comprising the following components in parts by weight: 1 part of a binding material, 0.28 part of water, 1.58 parts of sand, 2.92 parts of stones, 0.023 part of a water reducer, 0.005-0.03 part of an organic corrosion inhibitor HQ; and the organic corrosion inhibitor HQ accounts for 0.5%-3% of weight of the binding material. The corrosion-resistant PHC pipe pile has the advantages that (1) the technologic processes of an existing pipe pile do no need to be changed, and no production equipment is added; (2) production process parameters of the existing pipe pile do not need to be changed; (3) the production cost is low; and (4) an existing pipe pile production line can be used for producing national standard of PHC pipe piles, and can also be used for producing the corrosion-resistant PHC pipe pile.

Owner:广东宏基管桩有限公司

Gasoline upgrading additive for reducing olefin and cleaning gasoline

The invention relates to a petroleum grade improving agent by using manganese based metallorganics as initiating agent for reducing olefin and boosting the octane substantially to 180-220. The grade improving agent comprises ethers 100%, manganese based metallorganics 0.002%-0.01%, low carbon alcohol 0.5-5%, protective agent 0.5-1%, ketones 1-5%, cross linking agent 10-20%, and auxiliary agent 1-5%.

Owner:王方茂

Biological composite deodorizing, passivating and cleaning composition, and preparation method and application thereof

InactiveCN108611201AEnvironmental speedLow costNon-ionic surface-active compoundsDetergent compounding agentsIonChemistry

The invention discloses a biological composite deodorizing, passivating and cleaning composition, and a preparation method and application thereof, belonging to the field of deodorization, passivationand cleaning technology. The biological composite deodorizing, passivating and cleaning composition comprises, on the basis of the total weight of the composition, 20 to 30% of sorbitol, 0.3 to 1% ofcitric acid, 10 to 15% of the surfactant sodium dodecyl sulfate, 10 to 25% of cinnamaldehyde and 30 to 45% of secondary deionized water. The invention also comprises the preparation method and application of the biological composite deodorizing, passivating and cleaning composition. The composition provided by the invention integrates cleaning and passivation functions into one, and is reduced inblowdown flow rate, shortened in cleaning time, friendly to environment, highly efficient, free of color and odor and noncorrosive to equipment; and the preparation method is simple.

Owner:JINAN RUIDONG IND

Gaas-based phemt device and preparation method thereof

ActiveCN104966732BImprove breakdown voltagePerformance is not affectedSemiconductor/solid-state device manufacturingSemiconductor devicesOptoelectronicsElectron

Owner:CHENGDU HIWAFER SEMICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com