Color film substrate and manufacture method thereof, display panel and display device

A color film substrate and color film technology, applied in the fields of instruments, nonlinear optics, optics, etc., can solve problems such as difficult to achieve high color gamut and poor color display performance, and achieve mass production, low cost, and high color gamut Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

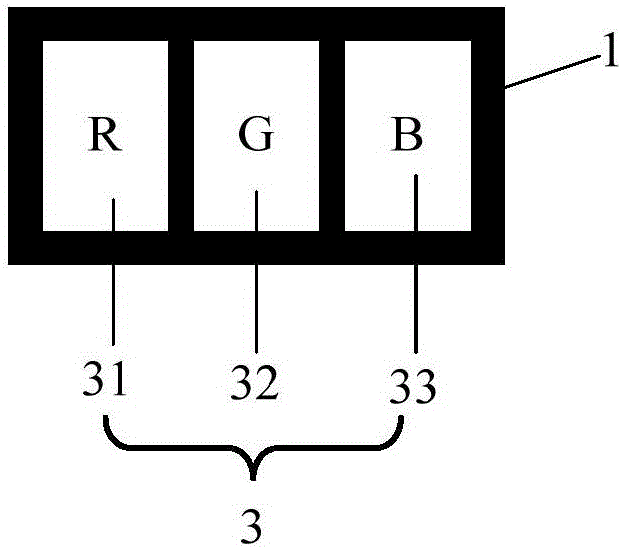

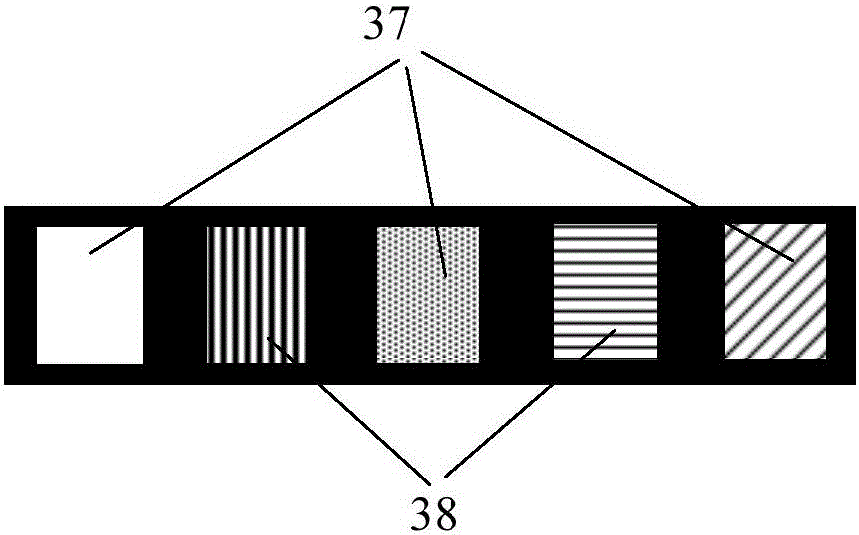

[0028] This embodiment provides a color filter substrate, such as image 3 As shown, a plurality of pixel units 3 are included, and each pixel unit 3 includes a plurality of primary color sub-pixels 37 and at least one color-mixing sub-pixel 38, and the color-mixing sub-pixel 38 is composed of multi-layered color filters of different colors.

[0029] Specifically, such as Figure 4 As shown, the red color film 21, the blue color film 22, and the green color film 23 respectively form the primary color sub-pixel 37; in addition, the blue color film 22 and the green color film 23 are stacked to form the cyan sub-pixel 35, and similarly, the red color film 21 It overlaps with the green color filter 23 to form a yellow sub-pixel 36 .

[0030] Among them, the color mixing sub-pixel 38 composed of multi-layered color filters of different colors supplements and enhances the primary color sub-pixel 37 to achieve a high color gamut and make the display more pure. The preparation metho...

Embodiment 2

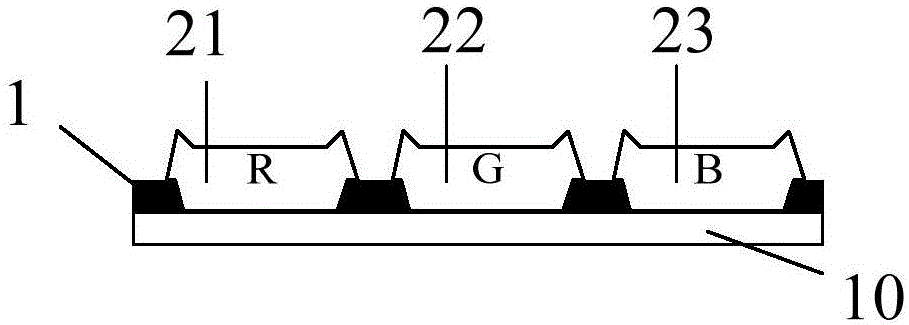

[0032] This embodiment provides a color filter substrate, the color filter substrate includes a substrate 10, such as Figure 5 , Image 6 As shown, a plurality of pixel units 3 are included, and each pixel unit 3 includes a plurality of primary color sub-pixels 37 and at least one color-mixing sub-pixel 38, and the color-mixing sub-pixel 38 is composed of multi-layered color filters of different colors; wherein A black matrix area 12 is arranged around the primary color sub-pixels and mixed color sub-pixels, and the black matrix area 12 is composed of multi-layered color filters of different colors.

[0033] Specifically, such as Image 6 As shown, the black matrix region 12 is composed of a red color film 21 , a blue color film 22 , and a green color film 23 stacked together.

[0034] Preferably, the color filters of each layer in the black matrix area 12 are formed synchronously with the color filters of the same color as the pixel unit 3 . That is to say, in this embodi...

Embodiment 3

[0045] This embodiment provides a method for preparing a color filter substrate, including the step of forming color filters of different colors, wherein the color filters at some positions form primary color sub-pixels, and the color filters of different colors at some positions are stacked in multiple layers to form mixed colors sub-pixel.

[0046] by Image 6 The color filter substrate shown as an example, such as Figure 9 As shown, it specifically includes the following steps:

[0047] (1) Form a red color film 21 on the substrate 10, and use the first mask plate 4 to expose and develop;

[0048] (2) Form a green color film 23 on the red color film 21, and use the second mask plate 4 to expose and develop;

[0049] (3) Form the color blue color film 22 on the green color film 23, and adopt the third mask plate 4 to expose and develop, to obtain Image 6 The color filter substrate shown.

[0050] Among them, from Image 6 and Figure 9 It can be seen from the figure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com