Rice dumpling rounding device for printing patterns

A pattern and printing head technology, applied in the field of dumpling rounding devices, can solve the problems of low production efficiency, complex process, incompatibility with dumpling production lines, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

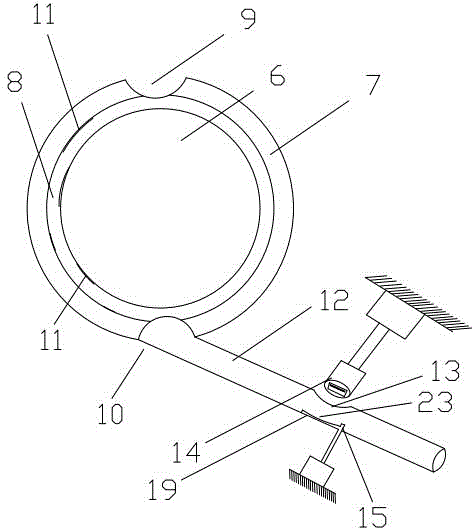

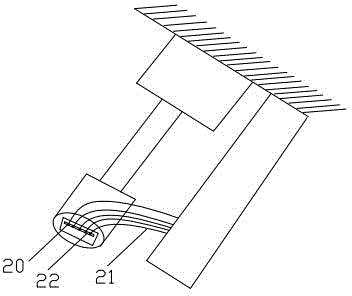

[0027] A kind of glutinous rice ball rubbing device of printing pattern comprises rubbing inner core 6 and rubbing outer cover 7, and described rubbing outer cover 7 is arranged on the outside of rubbing inner core 6, and described rubbing outer cover 7 and rubbing inner core The annular space between 6 forms the rounding channel 8, the outer surface of the rounding inner core 6 is provided with groove lines 11, the groove lines 11 are arranged along the circumference of the rounding inner core 6, and the top of the rounding outer cover 7 The rounding entrance 9 is provided, and the rounding outlet 10 is arranged at the bottom of the rounding cover 7, and groove lines 11 are respectively arranged on the inner surface of the rounding cover 7 and the groove of the rounding inner core 6. The outlet 10 is also provided with a rounding transition tube 12, the rounding transition tube 12 is a strip tube arranged obliquely, and an opening 13 is arranged above the rounding transition t...

Embodiment 2

[0031] A kind of glutinous rice ball rubbing device of printing pattern comprises rubbing inner core 6 and rubbing outer cover 7, and described rubbing outer cover 7 is arranged on the outside of rubbing inner core 6, and described rubbing outer cover 7 and rubbing inner core 6 The annular space between constitutes the rounding channel 8, the outer surface of the rounding inner core 6 is provided with groove lines 11, the groove lines 11 are arranged along the circumference of the rounding inner core 6, and the top of the rounding outer cover 7 is arranged There is a rounding entrance 9, and the bottom of the rounding cover 7 is provided with a rounding outlet 10, and the inner surface of the rounding cover 7 and the groove of the inner core 6 are respectively provided with groove lines 11, and at the rounding outlet 10 places are also provided with a rounding transition tube 12, the rounding transition tube 12 is a strip tube arranged obliquely, and an opening 13 is arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com