Manufacturing method of distemper silver-coated pleated blind fabric

A manufacturing method and technology of pleated blinds, which are applied in coatings, window decorations, textiles and papermaking, etc., can solve the problems of cloth surface cracking, unstable fabric quality, poor fold shape, etc., and achieve good resilience , Stable pleated shape, and increased energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

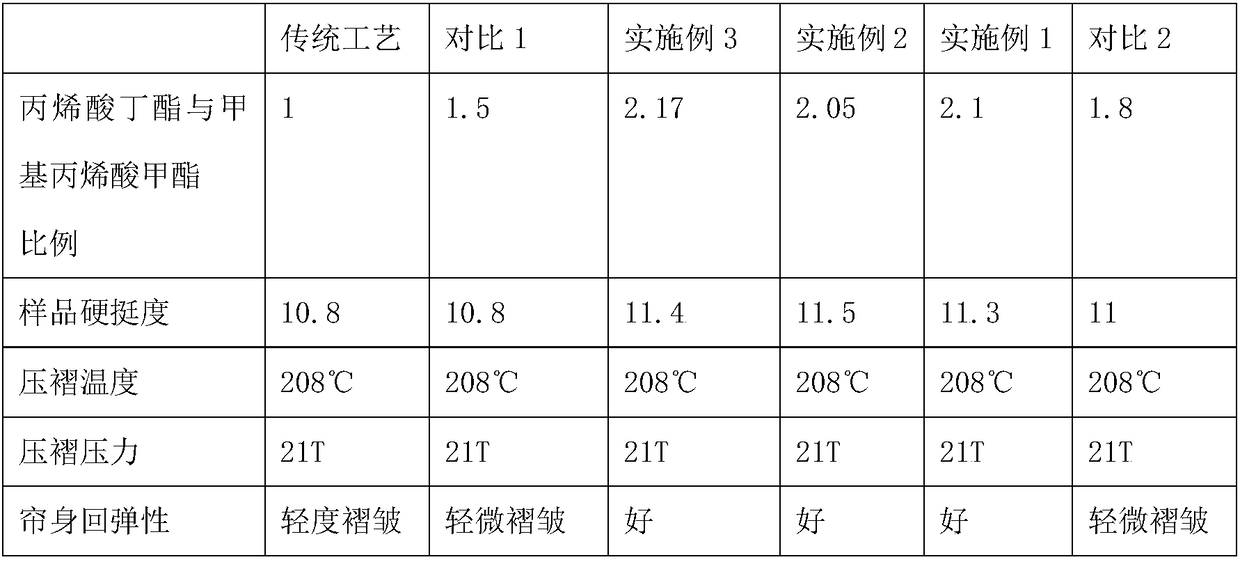

Embodiment 1

[0022] A kind of manufacture method of color glue coating silver pleated curtain fabric, comprises the following steps:

[0023] S1, setting treatment: choose 100% polyester fabric as the base fabric, and send the base fabric to the setting machine for setting treatment;

[0024] S2, the first black scraping treatment: one side of the base cloth after the sizing treatment is scraped with a knife black slurry, and then the first drying treatment is performed to form the first black scraping layer on the surface of the base cloth;

[0025] S3, the second black scraping treatment: scrape a black slurry on the surface of the first black scraping layer in reverse, and then perform the second drying treatment to form a second scraping on the surface of the first black scraping layer black layer;

[0026] S4, silver-coating treatment: scraping a layer of silver paste on the surface of the second black-scraping layer, and then performing a third drying treatment to form a silver-coat...

Embodiment 2

[0031] Embodiment 2: compared with embodiment 1, the difference is: the setting of slurry formula and parameters, specifically as follows:

[0032] The black slurry is prepared by mixing 22 parts by weight of methyl methacrylate, 45 parts of butyl acrylate, 40 parts of titanium dioxide dispersion and 5 parts of carbon black. The silver paste is made by mixing 80 parts by weight of acrylic emulsion and 20 parts of silver powder, and stirring evenly. The color glue slurry is prepared by mixing 55 parts by weight of acrylic emulsion, 32 parts of titanium dioxide dispersion and 3 parts of pigment, and stirring evenly.

[0033] Among them, the drying temperature of the first drying treatment, the second drying treatment, the third drying treatment and the fourth drying treatment are all set to 160°C, and the drying time is all set to 43 seconds . The temperature of the setting treatment was set at 180°C.

Embodiment 3

[0034] Embodiment 3: Compared with Embodiment 1 and 2, the difference is: the setting of the slurry formula and parameters, specifically as follows:

[0035] The black slurry is prepared by mixing 23 parts by weight of methyl methacrylate, 50 parts by butyl acrylate, 34 parts of titanium dioxide dispersion and 2 parts of carbon black. The silver paste is made by mixing 85 parts by weight of acrylic emulsion and 15 parts by weight of silver powder, and stirring evenly. The color glue slurry is prepared by mixing 60 parts by weight of acrylic emulsion, 35 parts of titanium dioxide dispersion and 5 parts of pigment, and stirring evenly.

[0036] Among them, the drying temperature of the first drying treatment, the second drying treatment, the third drying treatment and the fourth drying treatment are all set to 165°C, and the drying time is all set to 40 seconds . The temperature of the setting treatment was set at 185°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com