Heavy metal treatment method of electroplating wastewater

A technology for electroplating wastewater and metal treatment, which is used in metallurgical wastewater treatment, neutralization water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high impact of treatment facilities, excessive electroplating wastewater effluent, and high operating costs. , to solve the problem of heavy metal pollution, reduce COD, and achieve the effect of long-term regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

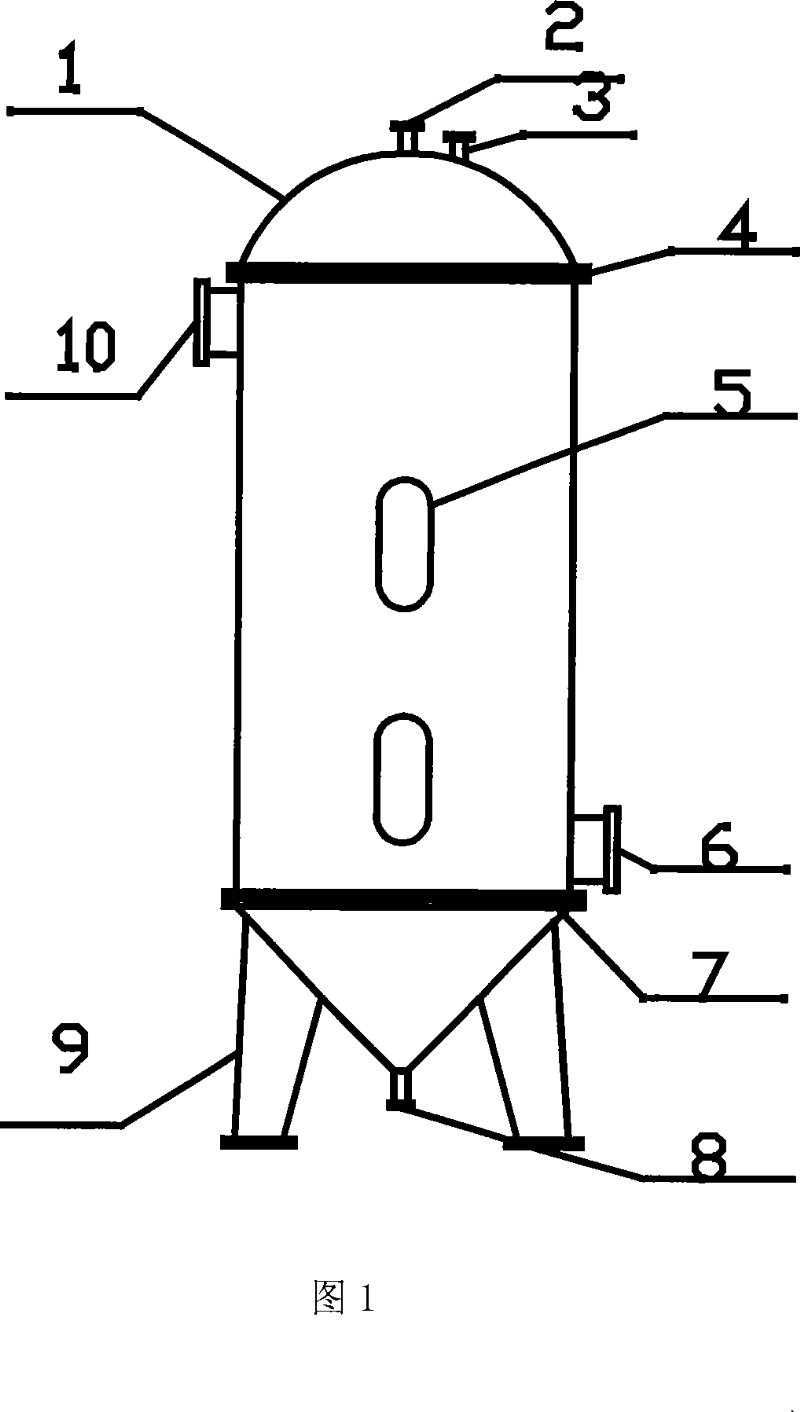

[0019] Embodiment 1: The embodiment of the present invention is reproduced in the form of a device of a mechanical filter, and accompanying drawing 1 is a device for realizing the present invention. The nickel, chromium and copper in the electroplating wastewater are 5mg / L, adjust the pH to 6, and input it from the water inlet 2. At the beginning, because there is a lot of air in the shell 1, the electroplating wastewater can be discharged from the exhaust port 3. The air is sent in and out. The setting of the upper water distribution device 4 can make the electroplating wastewater more evenly distributed on the filter material 5, and can make the electroplating wastewater fully contact with the filter material, which is beneficial to the removal of heavy metals. In this implementation, D001 is the macroporous benzene Vinyl sodium type resin is the filter material 5. Then flow through the filter material 5 at a speed of 30m / h for processing. After being treated, it is discha...

Embodiment 2

[0020] Embodiment two: under the situation that does not change filter material, be 15mg / L with nickel, chromium, copper, PH is 7, and flow velocity is 20m / h, carry out treatment, and the testing result of final effluent contains nickel, chromium, copper is 0.18 mg / L.

Embodiment 3

[0021] Embodiment three: under the situation of not changing filter material, be 25mg / L with nickel, chromium, copper, PH is 7.5, and flow velocity is 20m / h, carry out treatment, and the testing result of final effluent contains nickel, chromium, copper is 0.18 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com