Biological composite deodorizing, passivating and cleaning composition, and preparation method and application thereof

A cleaning composition, a composite technology, applied in the directions of detergent compositions, surface-active detergent compositions, chemical instruments and methods, etc., can solve the problems of not being able to carry out at the same time, one-step completion, residual reaction indicators, etc., and achieve cost Low, easy to use, environmentally friendly speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

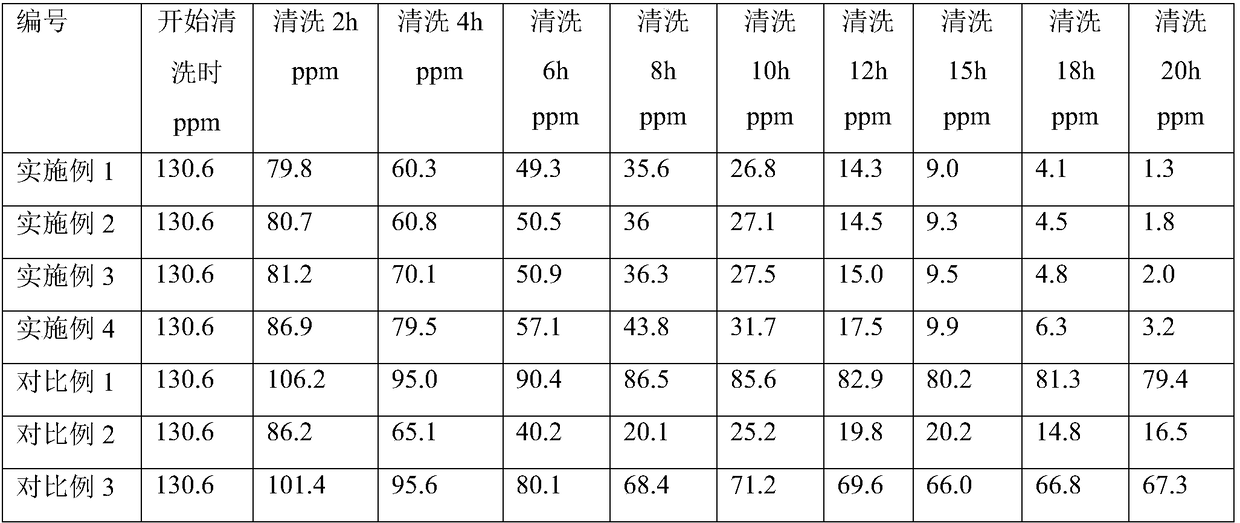

Examples

preparation example Construction

[0032] The present invention also provides a kind of preparation method of biocomposite type deodorant passivation cleaning composition, comprises the following steps:

[0033] (1) Take each raw material in proportion, and under stirring condition, slowly add citric acid into secondary deionized water until the addition ends;

[0034] (2) under stirring condition, slowly add sodium lauryl sulfate, control maximum reaction and be less than 75 ℃ (can control reaction speed by stirring intensity, feeding speed, and then regulate and control reaction temperature. For example, when reaction temperature rises faster, The temperature of reaction can be controlled by slowing down the feed rate), until the feed ends;

[0035] (3) Under stirring conditions, slowly add cinnamaldehyde, and control the maximum reaction temperature to be less than 75° C. Control the reaction temperature)) by slowing down the feed rate, until the feed ends;

[0036] (4) Slowly add sorbitol under stirring c...

Embodiment 1

[0048] 1. The formula of biological compound deodorization passivation cleaning composition

[0049] Based on the total weight of the biocomposite deodorant passivation cleaning composition, the content of sorbitol is 25% by weight, the content of citric acid is 0.8% by weight, the content of sodium lauryl sulfate is 13% by weight, and the content of cinnamaldehyde The content is 21% by weight, and the content of secondary deionized water is 40.2% by weight.

[0050] 2. Preparation of biocomposite deodorant passivation cleaning composition

[0051] (1) Take each raw material in proportion, under stirring condition, citric acid is slowly added to secondary deionized water, until the addition is finished, the required time from opening and stirring to the end of feeding is 8 minutes;

[0052] (2) Under stirring conditions, slowly add sodium lauryl sulfate, control the highest reaction to be less than 75°C until the addition is completed, and the whole process is completed in 25...

Embodiment 2

[0056] 1. The formula of biological compound deodorization passivation cleaning composition

[0057] Based on the total weight of the biocomposite deodorant passivation cleaning composition, the content of sorbitol is 28% by weight, the content of citric acid is 0.5% by weight, the content of sodium lauryl sulfate is 12% by weight, and the content of cinnamaldehyde The content is 19.5% by weight, and the content of secondary deionized water is 40% by weight

[0058] 2. Preparation of biocomposite deodorant passivation cleaning composition

[0059] The only difference from the preparation of Example 1 is that the ratio of raw materials is different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com