Patents

Literature

41results about How to "Meet corrosion resistance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion resistant steel for cargo oil tanks and application thereof

InactiveCN101928886AImprove corrosion resistanceExtension of timeRare-earth elementChemical composition

The invention discloses corrosion resistant steel for cargo oil tanks and application thereof. The corrosion resistant steel for cargo oil tanks comprises the following chemical components in percentage by weight: 0.01-0.2% of C, 0.05-1.0% of Si, 0.1-2.0% of Mn, being more than or equal to 0.020% of P, being more than or equal to 0.020% of S, 0.1-1.5% of Cu, being more than or equal to 1.0% of Cr, 0.01-1.0% of Ni, being more than or equal to 0.1% of Al, being more than or equal to 0.010% of Ti and the balance of Fe. The corrosion resistant steel also comprises one or more than two of 0.05-1.0% of W, 0.01-0.5% of Mo, 0.05-1.0% of Co, 0.01-0.3% of Sb and 0.01-0.3% of Sn, or one or more than two of 0.01-0.5% of Nb, 0.005-0.1% of V and 0.0005-0.005% of B, or one or two rare-earth elements of being more than or equal to 0.50% of La and being more than or equal to 0.50% of Ce. The corrosion resistant steel is used in a cargo oil tank of a crude oil tanker, and has excellent general corrosion resistance and local corrosion resistance.

Owner:NANJING IRON & STEEL CO LTD

Phosphor molybdenum heteropolyacid inactivating treatment liquid used for heat zinc coating plate

InactiveCN101168840AMeet corrosion resistance requirementsTo achieve the effect of passivation treatmentMetallic material coating processesHeteropoly acidSodium phosphates

The invention relates to a phosphorus-molybdenum heteropolyacid passivation treatment solution and a preparation method for hot-dip galvanized sheets. The passivation treatment solution consists of 15000-23000 ppm of molybdate, 7300-11000 ppm of sodium phosphate, and 2000-5000 ppm of nitrate , 5000-15000ppm of at least one water-soluble polymer compound, 1000-4000ppm of at least one non-ionic surfactant, the solution pH value is 2-3; the preparation method is to mix molybdate and sodium phosphate first, Then add nitrate; add non-ionic surfactant into the water-soluble polymer compound, then add it into the solution prepared above, adjust the pH value to 2-3, and set the volume to 1000ml. For the hot-dip galvanized sheet, the treatment temperature is 30-50°C, the time is 30-60s, and the drying temperature is 50-70°C, and the time is 5-25min. The treated hot-dip galvanized sheet has a salt spray corrosion resistance of more than 72 hours.

Owner:NORTHEASTERN UNIV

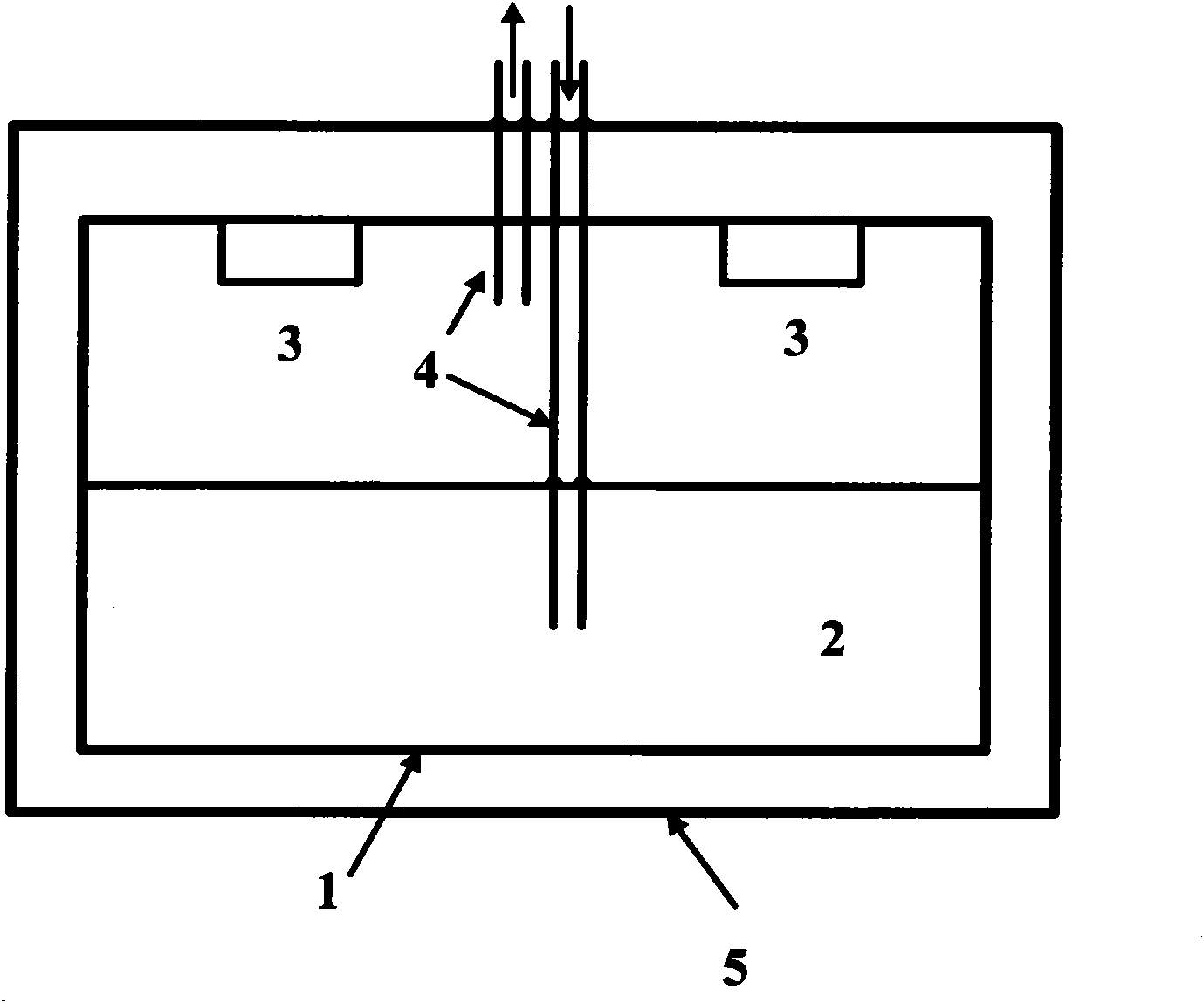

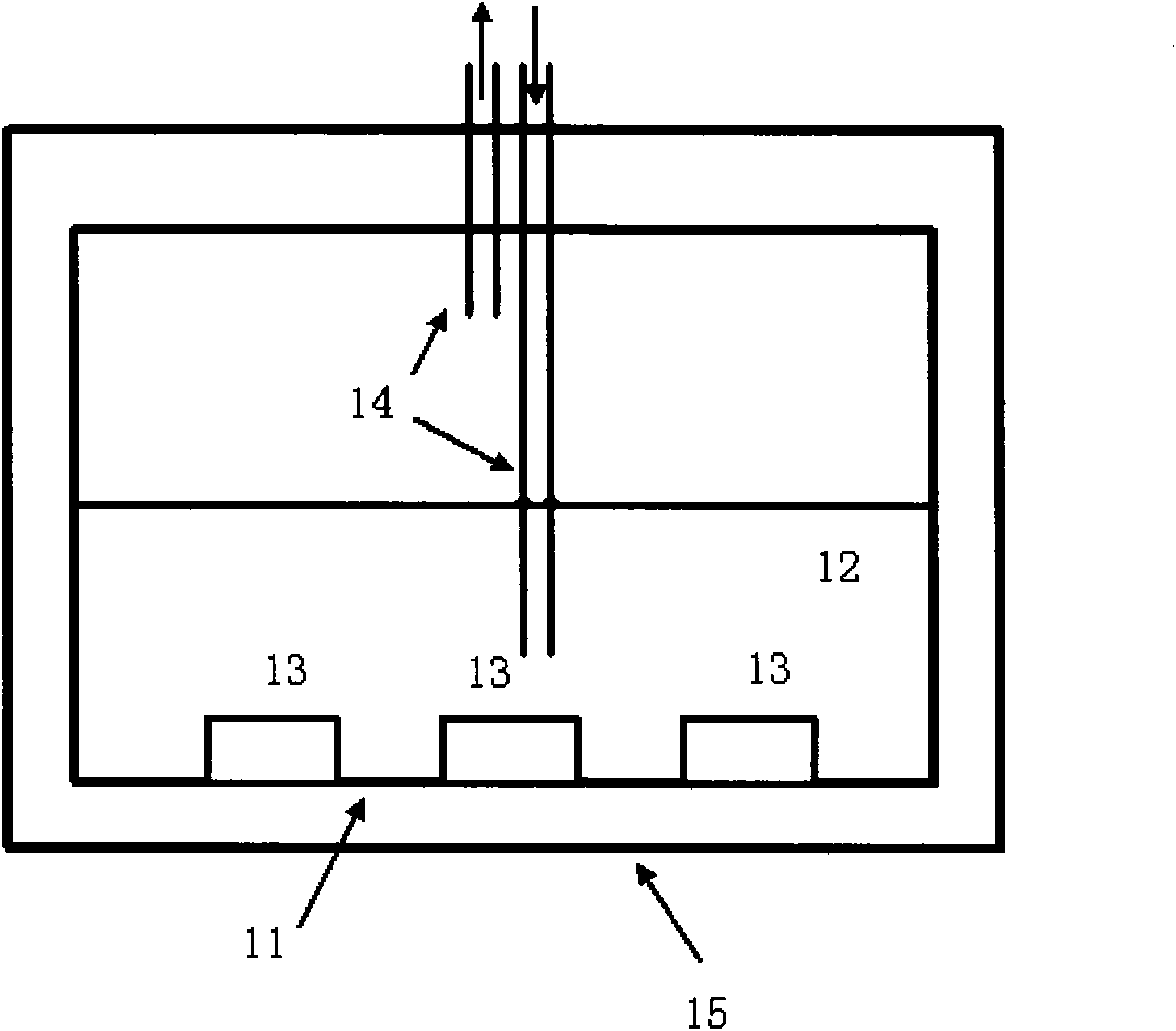

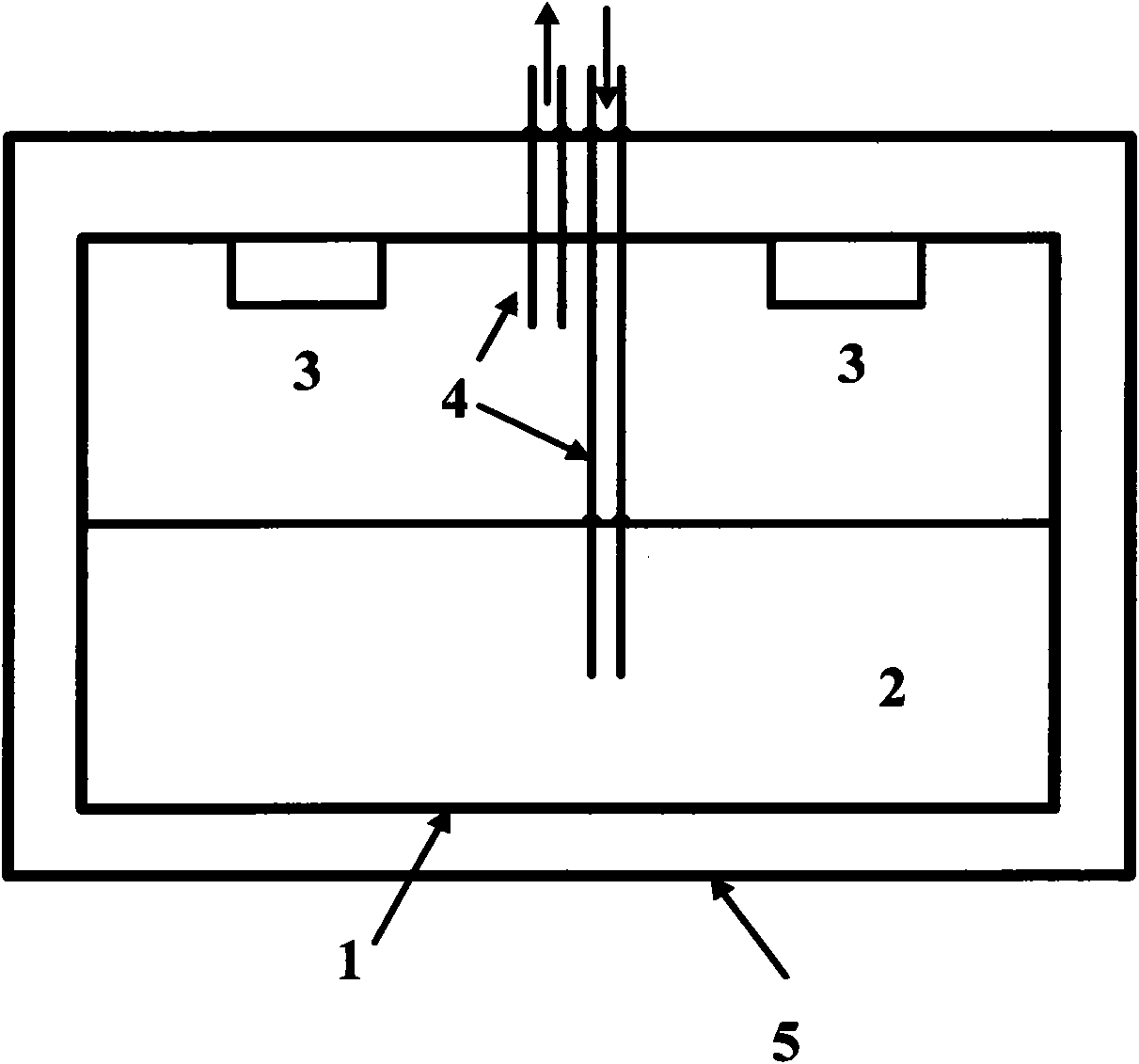

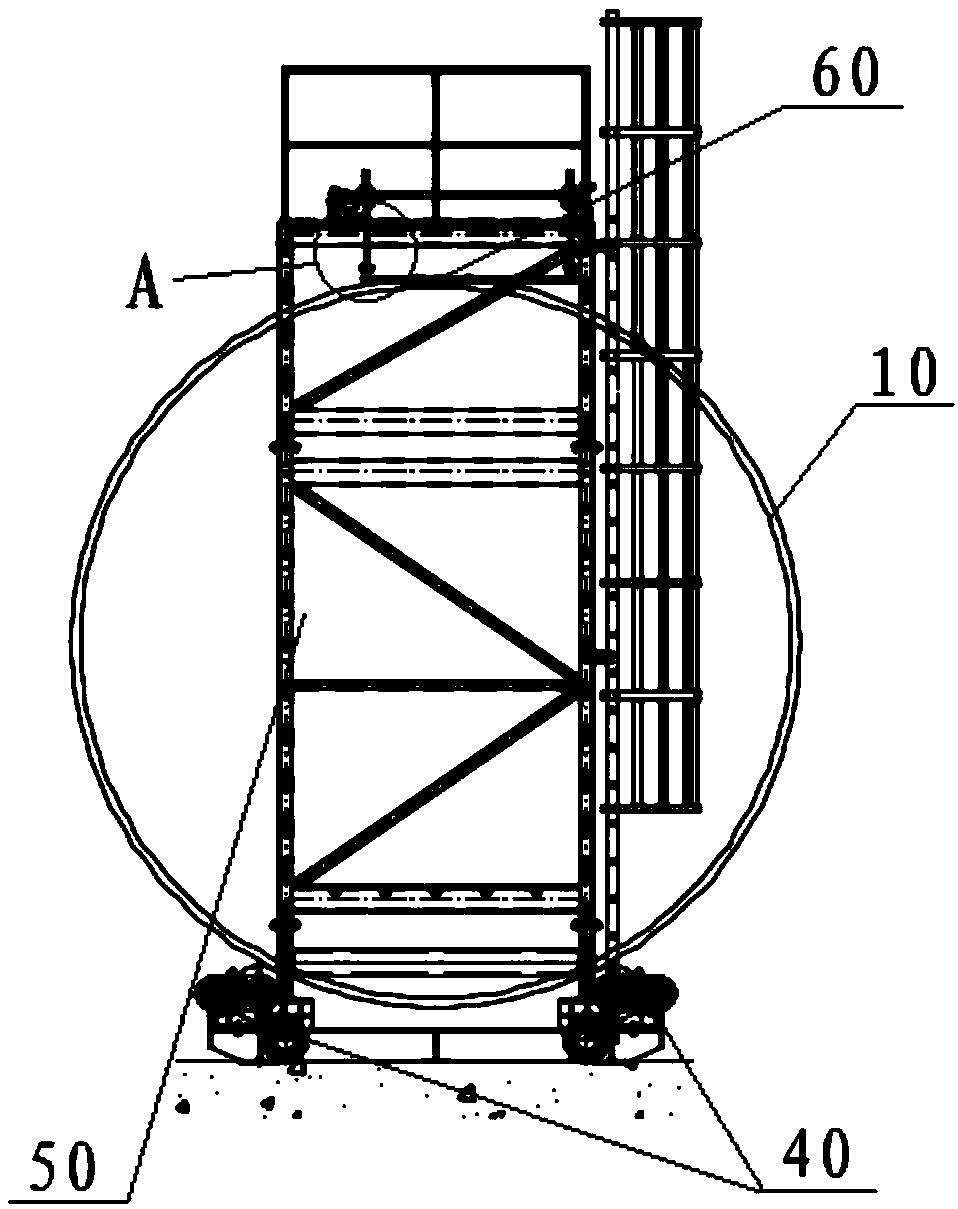

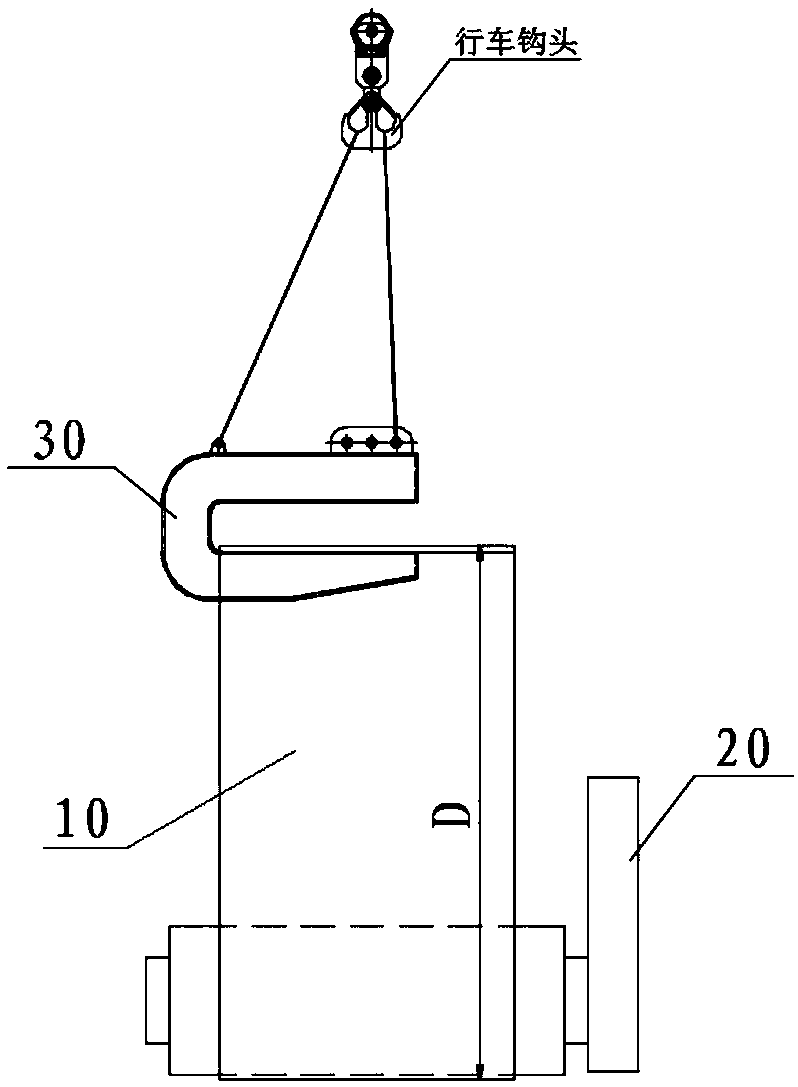

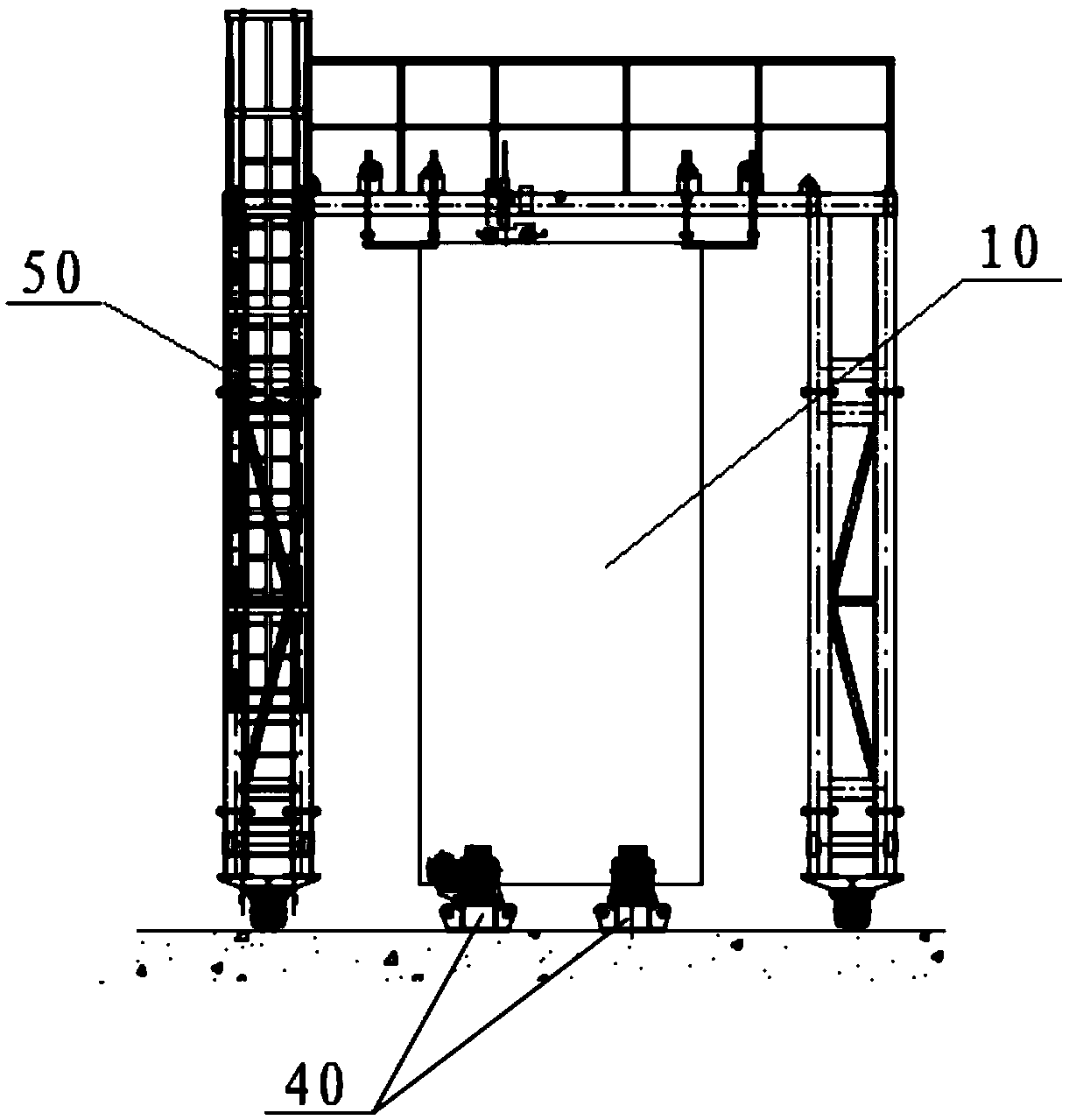

Manufacturing process for offshore wind power foundation steel pipe pile

InactiveCN108867623AImprove impact resistanceMeet corrosion resistance requirementsBulkheads/pilesElectricityEngineering

The invention discloses a manufacturing process for an offshore wind power foundation steel pipe pile. The manufacturing process comprises the following steps of pipe joint blanking, pipe joint grooveprocessing, pipe joint rolling formation, pile body top flange assembling, pipe joint splicing and anticorrosive coating painting. According to the manufacturing process, from material selection, blanking to manufacturing process of steel plates for the steel pipe pile, the roundness and straightness of a pile body are detected and adjusted at any time, and the welding materials and welding processes are strictly controlled. In addition, the coating process of an anticorrosive coating is strictly carried out, so the impact resistance of the steel pipe pile can be effectively improved, it is guaranteed that a pile foundation is driven into a soil layer smoothly, and the corrosion resistance requirement of the steel pipe pile can be met.

Owner:CCCC THIRD HARBOR ENG +1

Continuous annealing and acid washing method for medium-chromium ultrapure ferrite stainless steel

ActiveCN103243339AAvoid intergranular corrosionSpeed up the formation of passivation filmHydrofluoric acidConcentration ratio

A continuous annealing and acid washing method for medium-chromium ultrapure ferrite stainless steel comprises the process flow of cold rolling, annealing heat treatment, acid washing, final water washing, drying, flattening and packaging, and is characterized in that in the acid washing process flow, the acid washing solution is prepared from 120-150g / L of 65% nitric acid, 2-4g / L of 40% hydrofluoric acid and water. According to the invention, in the chemical acid washing stage, reasonable concentration ratio of nitric acid to hydrofluoric acid is adopted and proper acid washing speed is controlled to carry out acid washing on medium-chromium ferrite stainless steel. As a result, on one hand, the performance of a medium-chromium ferrite stainless steel passivation film is obviously improved, and the corrosion resistance of the surface of a medium-chromium ferrite stainless steel 2B board is significantly improved, and on the other hand, the process flow of the existing production factory is not needed to be changed, a special passivation treatment procedure is not needed, and the production cost is significantly lowered.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

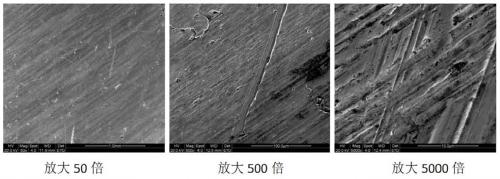

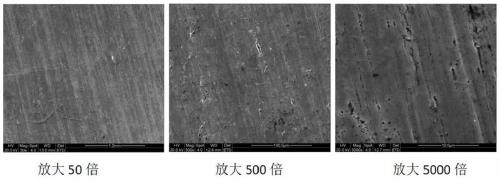

Stainless steel surface processing method

ActiveCN105386030AQuality improvementImprove corrosion resistanceMetallic material coating processesAcid washingImpurity

The invention provides a stainless steel surface processing method. The stainless steel surface processing method includes the processing steps of acid washing, alkali washing, passivation and sealing of stainless steel workpieces, wherein in the passivation and / or sealing process, ultrasonic processing is conducted on a passivation solution and a sealing solution at the same time. By means of the stainless steel surface processing method, the roughness of the surfaces of the stainless steel workpieces can be reduced, the metal glossiness is excellent, oxides or other impurities on the surfaces can be removed thoroughly, passivation films can cover the surfaces of the workpieces evenly and completely, and the corrosion resistance of stainless steel is greatly improved.

Owner:AEROSPACE PRECISION PROD INC LTD

Processing method for wrapping side surface of printed-circuit connector product with nickel gold

ActiveCN106132108ANo copper exposureImprove corrosion resistancePrinted circuit aspectsConductive pattern reinforcementResistEngineering

The invention discloses a processing method for wrapping a side surface of a printed-circuit connector product with nickel gold. The processing method comprises the following steps of A, addition of gold-plated leads: adding leads on the corner of a square bonding pad and at a welding ring position of a solder resist covering via hole in a mode of adding the leads on the two sides; B, prevention of gold-plating permeation: adopting processes of using a photosensitive wet film as the base, and performing one-time exposure pattern transferring after photosensitive dry film protection is carried out so as to realize the prevention of gold-plating permeation; and C, performing protection while etching the leads: choosing a Dupont GMP220 thick dry film with the thickness of 2mil, and adopting an alkali etching process so as to prevent circuit corrosion and oxidization caused by attack of liquid medicine on the inlet surface.

Owner:XIAN KING BROTHER CIRCUIT TECH +2

Surface coating structure of engineering plastic and preparation method thereof

ActiveCN103818047AAvoid harmEmission reductionSuperimposed coating processMetal layered productsCorrosion resistant alloyEngineering plastic

The invention relates to engineering plastic surface treatment, and particularly relates to a surface coating structure of engineering plastic and a preparation method thereof. The surface coating structure of the engineering plastic comprises, in sequence, a vacuum coating conductive metal layer, a nickel electroplated coating, a PVD corrosion-resistant alloy layer and a PVD color layer. The method includes a step of subjecting the engineering plastic to hydrocarbon vacuum oil removal and drying, transferring and hanging the engineering plastic into a PVD furnace, and subjecting the conductive metal layer to vacuum plating; a step of transferring and hanging the processed engineering plastic product to an electroplating hanger to perform nickel electroplating, performing Watt's nickel electroplating, then performing semi-bright nickel electroplating, subjecting the engineering plastic product to wiredrawing processing, and subjecting the engineering plastic product after the wiredrawing processing to hydrocarbon vacuum oil removal and drying; or a step of transferring and hanging the processed engineering plastic product to an electroplating hanger to perform nickel electroplating, performing Watt's nickel electroplating first, then performing semi-bright nickel electroplating, then performing bright nickel electroplating, and finally performing microporous nickel electroplating; and a step of plating the processed engineering plastic product with the PVD corrosion-resistant alloy layer and the PVD color layer.

Owner:XIAMEN RUNNER IND CORP

Chromium-aluminum alloy target as well as preparation method and application thereof

InactiveCN103981487AUniform tissue sizeAppearance color is easy to controlVacuum evaporation coatingSputtering coatingMixed materialsHeat treated

The invention discloses a chromium-aluminum alloy target as well as a preparation method and an application thereof and relates to an intermetallic compound alloy target. The chromium-aluminum alloy target comprises the following components in percentage by weight: 50-80% of chromium and 20-50% of aluminum. The preparation method comprises the following steps: mixing chromium powder with aluminum powder to obtain a chromium-aluminum mixed material; putting the chromium-aluminum mixed material in a nitrogen protective atmosphere to be pressed to n electrodes; welding every two electrodes pressed to chromium-aluminum smelting electrodes; smelting the chromium-aluminum smelting electrodes for the first time to a chromium-aluminum first ingots; de-heading and removing tail of the chromium-aluminum first ingots, and welding every two chromium-aluminum first ingots to chromium-aluminum secondary smelting electrodes; smelting the chromium-aluminum secondary smelting electrodes for the second time to obtain chromium-aluminum secondary ingots; carrying out hot forging on the chromium-aluminum secondary ingots; thermally treating the hot-forged chromium-aluminum secondary ingot, and then air-cooling and cooling, and processing the required chromium-aluminum alloy target according to dimension of the target. The chromium-aluminum alloy target can be applied to manufacturing products in the fields of bathrooms, household appliances, automobiles and the like.

Owner:XIAMEN RUNNER IND CORP

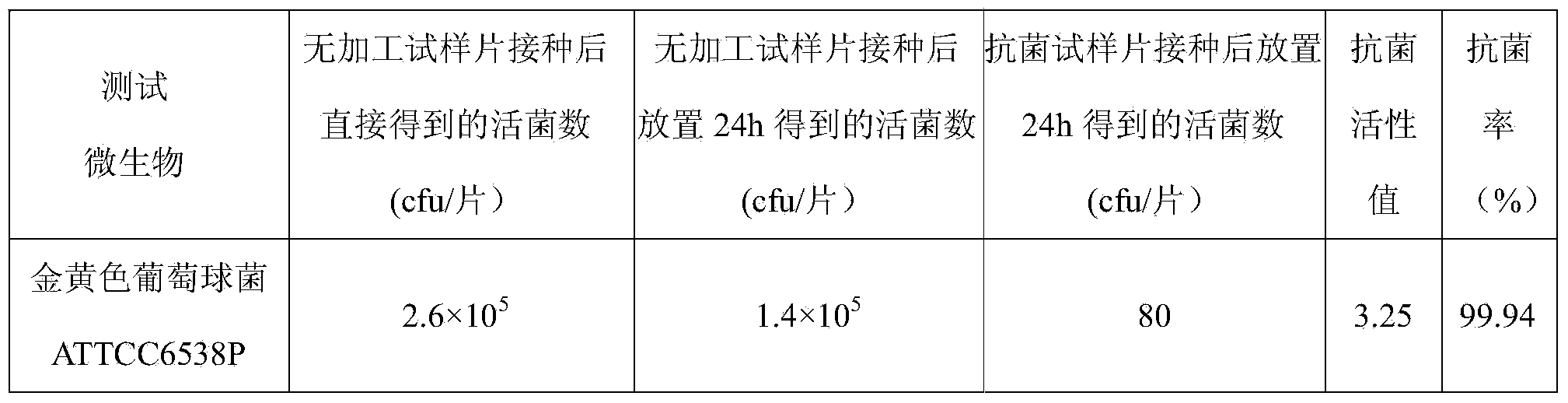

Zirconium-silver alloy target and preparation method and application thereof

ActiveCN103924122AUniform tissue sizeSimple processVacuum evaporation coatingSputtering coatingNitrogen atmosphereIngot

The invention provides a zirconium-silver alloy target and a preparation method and an application thereof, and relates to alloy targets. The zirconium-silver alloy target is composed of 97-99.5% of zirconium and 0.5-3% of silver according to mass percent. The preparation method includes the following steps: mixing nuclear grade sponge stage metal zirconium with silver chips to obtain a zirconium and silver mixture; pressing the zirconium and silver mixture into electrodes, placing the electrodes in a nitrogen atmosphere environment to prevent dampness and oxidation of the material; welding each two electrodes into a melting electrode; melting the melting electrode to obtain primary zirconium-silver ingots; deheading and smoothing the tails of the primary zirconium-silver ingots, welding each two primary zirconium-silver ingots into a secondary zirconium-silver melting electrode; melting the secondary zirconium-silver melting electrode to obtain secondary zirconium-silver ingots; hot forging the secondary zirconium-silver ingots to eliminate coarse-grain generated in the melting process and homogenize the tissues, carrying out a heat treatment and cooling, and processing the necessary zirconium-silver alloy target according to the size specification of the target. The prepared zirconium-silver alloy target is free of such defects as obvious pore, segregation and the like, and is uniform in tissue size.

Owner:XIAMEN RUNNER IND CORP

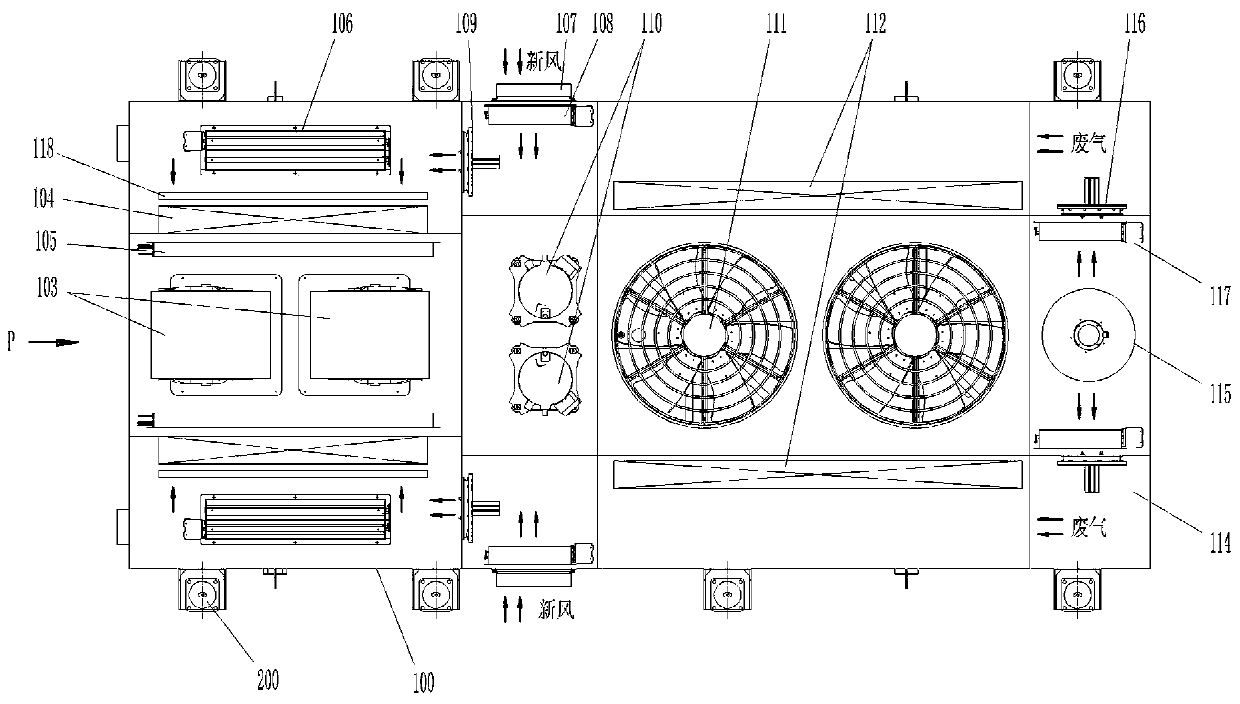

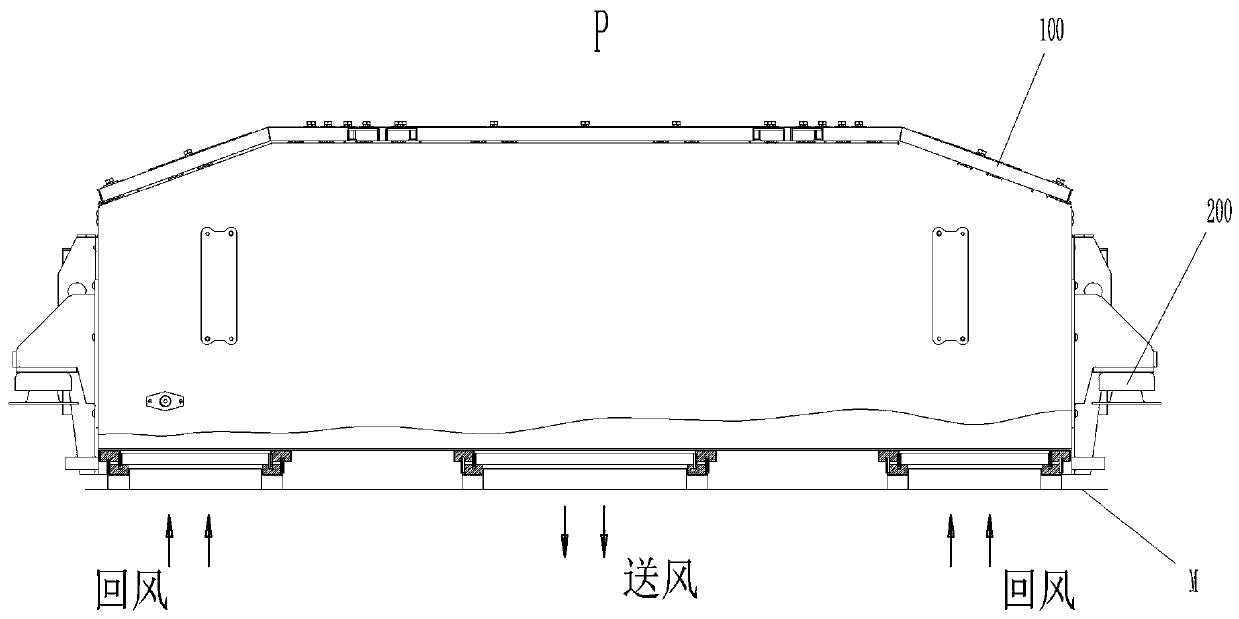

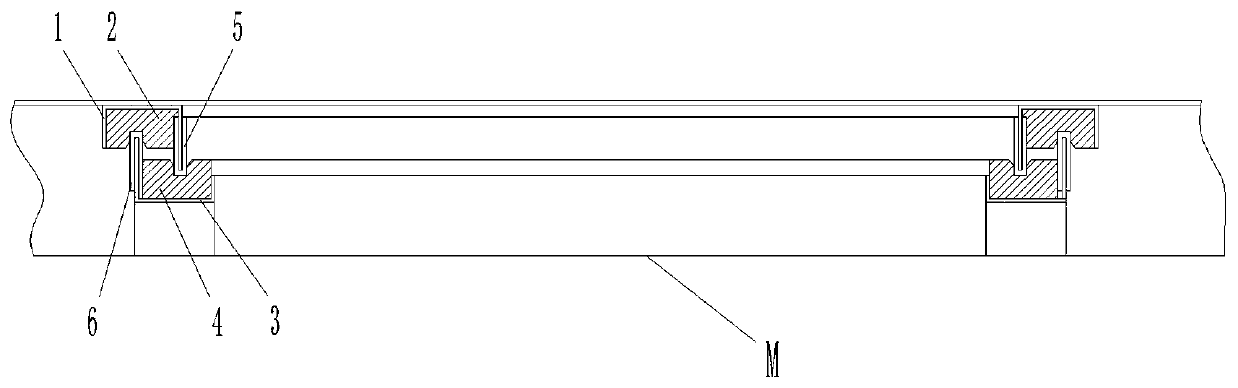

Air conditioning unit for EMU multiple unit train

The invention discloses an air conditioning unit for an EMU multiple unit train and belongs to the technical field of air conditioning equipment of rail vehicles. The air conditioning unit comprises an air conditioning unit body which is characterized in that a first sealing assembly is arranged between an air port in the bottom of the air conditioning unit body and the top of a car; the first sealing assembly comprises a first annular sealing flange arranged at the outer edge of the air port and a first sealing rubber strip arranged in an annular groove of the first annular sealing flange. The air conditioning unit disclosed by the invention has the beneficial effects that 1, the sealing flange at the air port and the car is a bended formed metal sheet part, so that an existing section bar is replaced and a die opening cost is cancelled while the sealing effect is guaranteed, and meanwhile, a design scheme is modified favorably, and the design cost and the product cost are reduced greatly; and 2, the air port and the car are of a double-layered sealing structure, and meanwhile, the double-layered sealing structure is of a labyrinth seal, so that the sealing property of the positions of the air ports is guaranteed, and the airtightness of the unit is achieved by means of a pressure wave protecting valve arranged in the unit.

Owner:石家庄国祥运输设备有限公司

Rare-earth multi-element alloy coating and hot-dip galvanizing method thereof

The invention discloses a rare-earth multi-element alloy coating and a hot-dip galvanizing method thereof. The rare-earth multi-element alloy coating comprises the following main components: rare earth, aluminum, nickel, magnesium and zinc. The hot-dip galvanizing method comprises the following steps: (1) mix-melting intermediate alloys, namely Al-RE-Mg and Zn-Ni; (2) mix-melting a multi-element rare-earth alloy; (3) dredging slag; (4) casting; and (5) applying. The rare-earth multi-element alloy coating and the hot-dip galvanizing method thereof have the advantages that: firstly, difficulty of directly adding multiple elements with different melting points into a zinc liquid to melt and the impossibility problem of adding high-melting-point elemental metal elements into the zinc liquid to melt are solved; secondly, the multiple elements can be completely and quickly molten and dispersed, so that the hot-dop galvanizing method is easy to operate and control in a practical production process; thirdly, the dilution capability, the dispersive capacity, the mobility and the uniformity of the zinc liquid are strengthened, so that the zinc consumption is reduced by 5%-15%, the cost is reduced and the benefits are increased; and fourthly, the corrosion resistance of the rare-earth multi-element alloy coating is doubled in comparison with that of a conventional hot dip galvanized coating.

Owner:江苏中远稀土新材料有限公司

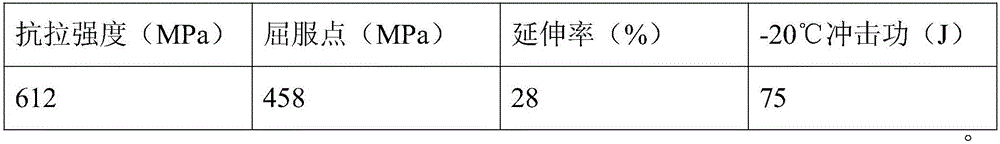

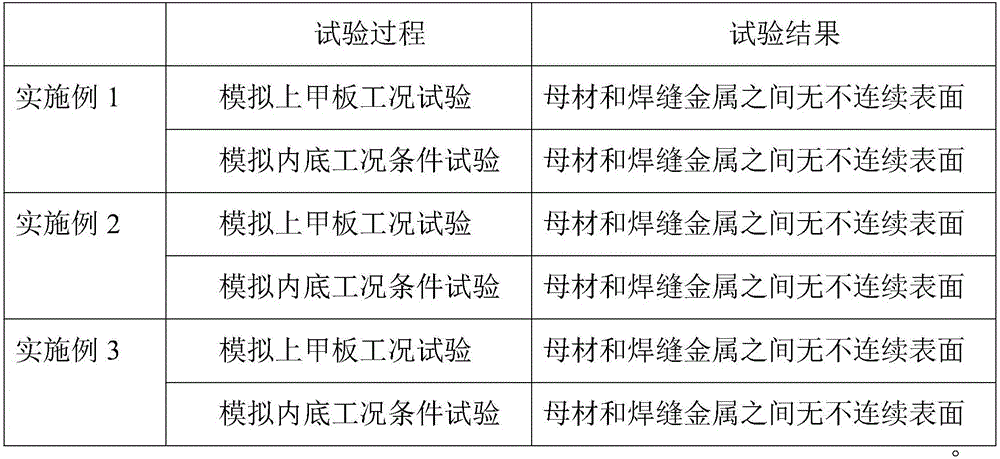

Flux-cored wire for corrosion-resistant steel

InactiveCN106624445AGood welding performanceGood arc stabilityWelding/cutting media/materialsSoldering mediaSeawaterCorrosion resistant

The invention provides a flux-cored wire for corrosion-resistant steel. The flux-cored wire for corrosion-resistant steel comprises a low carbon steel sheath and a core, and based on the total weight of the core, the components of the core include, by weight, 15-25% of TiO2, 2-6% of KF, 4-10% of silicon dioxide, 0.4-0.8% of zirconium dioxide, 3-6% of ferro-titanium, 5-10% of graphite, 3-7% of boron carbide, 2-8% of siliconmanganese alloy, 6-10% of nickel, 2-6% of alumina, 0.5-1.5% of ferric oxide, 0.5-2.5% copper, and the balance iron powder; the filling rate of the core is 30-40%. The flux-cored wire has the advantages of good arc stability, little splash, small smoke and easy slag removing, and is suitable for welding the corrosion-resistant steel serving in environment with hydrogen sulfide corrosion and seawater corrosion.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

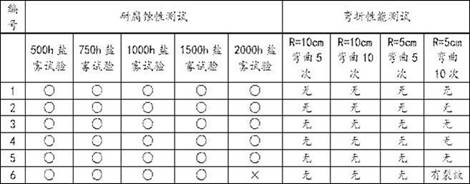

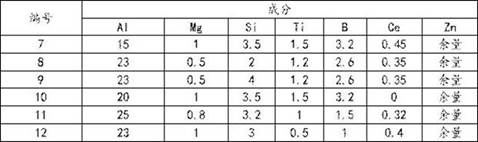

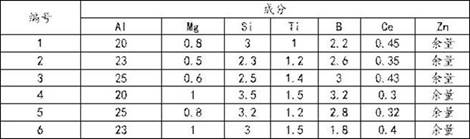

Plating solution for hot-dip galvanizing, aluminum and magnesium on surface of steel and plating method using plating solution

ActiveCN113388796AIncrease grain boundary densitySatisfy repeated use problemsHot-dipping/immersion processesMaterials scienceCorrosion resistant

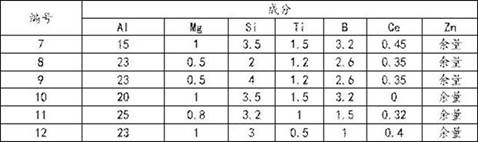

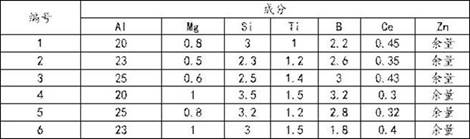

The invention provides a plating solution for hot-dip galvanizing, aluminum and magnesium on the surface of steel. The plating solution is used for relieving the risk of cracks on the surface of a plating layer of the steel under the working condition of repeated bending in the prior art. The plating solution comprises the following components of, in percentage by atom, 20%-25% of Al, 0.5%-1% of Mg, 2.3%-3.5% of Si, 1%-1.5% of Ti, 1.8%-3.2% of B, 0.3%-0.45% of Ce and the balance Zn and inevitable impurities. The corrosion resistance is improved by adding the alloy element Mg; in order to restrain the risk that the cracks appear on the surfaces of the steel and the plating layer of the steel due to repeated bending, a certain amount of Ti and B are added, so that the corrosion resistance is improved, and meanwhile, an intermediate phase is separated out at the grain boundary to restrain generation and expansion of the cracks; finally, the galvanized steel adopts a cooling mode of combining air cooling with water cooling to further refine grains, so that the corrosion resistance is improved, and the crack propagation inhibition performance is improved; and the service life of the zinc-plated aluminum-magnesium steel is prolonged by the final product.

Owner:天津市新宇彩板有限公司

A zirconium-silver alloy target material and its preparation method and application

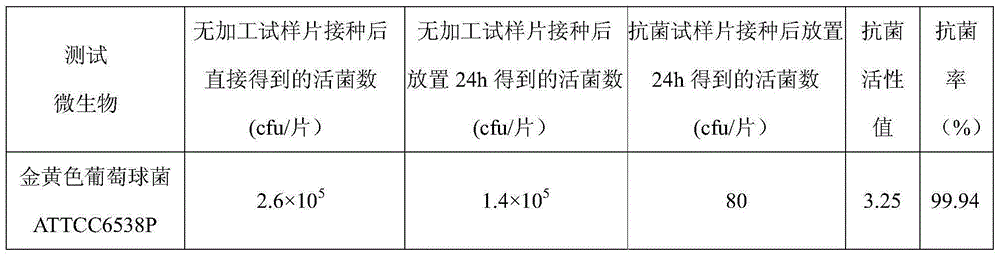

ActiveCN103924122BHas antibacterial functionUniform tissue sizeVacuum evaporation coatingSputtering coatingNuclear gradeNitrogen atmosphere

The invention provides a zirconium-silver alloy target and a preparation method and an application thereof, and relates to alloy targets. The zirconium-silver alloy target is composed of 97-99.5% of zirconium and 0.5-3% of silver according to mass percent. The preparation method includes the following steps: mixing nuclear grade sponge stage metal zirconium with silver chips to obtain a zirconium and silver mixture; pressing the zirconium and silver mixture into electrodes, placing the electrodes in a nitrogen atmosphere environment to prevent dampness and oxidation of the material; welding each two electrodes into a melting electrode; melting the melting electrode to obtain primary zirconium-silver ingots; deheading and smoothing the tails of the primary zirconium-silver ingots, welding each two primary zirconium-silver ingots into a secondary zirconium-silver melting electrode; melting the secondary zirconium-silver melting electrode to obtain secondary zirconium-silver ingots; hot forging the secondary zirconium-silver ingots to eliminate coarse-grain generated in the melting process and homogenize the tissues, carrying out a heat treatment and cooling, and processing the necessary zirconium-silver alloy target according to the size specification of the target. The prepared zirconium-silver alloy target is free of such defects as obvious pore, segregation and the like, and is uniform in tissue size.

Owner:XIAMEN RUNNER IND CORP

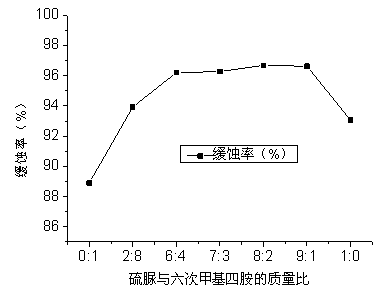

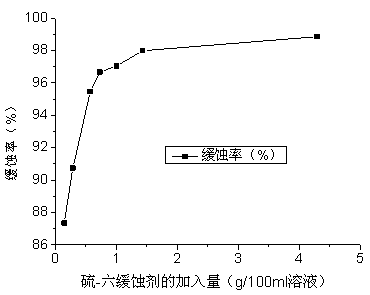

Acidic oil extraction medium corrosion inhibitor

InactiveCN103806003AHigh corrosion inhibition rateMeet corrosion resistance requirementsHexamethylenetetramineThiourea

The invention discloses an acidic oil extraction medium corrosion inhibitor, which contains thiourea and hexamethylenetetramine, wherein the mass ratio of thiourea to hexamethylenetetramine is 1:4-10:1. The acidic oil extraction medium corrosion inhibitor disclosed by the invention is high in corrosion inhibition, especially applicable to the corrosion prevention of N80 steel in an acidic oil extraction medium, namely, an ammonium persulfate solution, in an oilfield, wherein the mass concentration of ammonium persulfate is 2-10% (wt.), and the corrosion temperature is set at 10-80 DEG C; the acidic oil extraction medium corrosion inhibitor is low in toxicity, and especially suitable for the occasions with high environmental requirements.

Owner:NORTHWEST UNIV

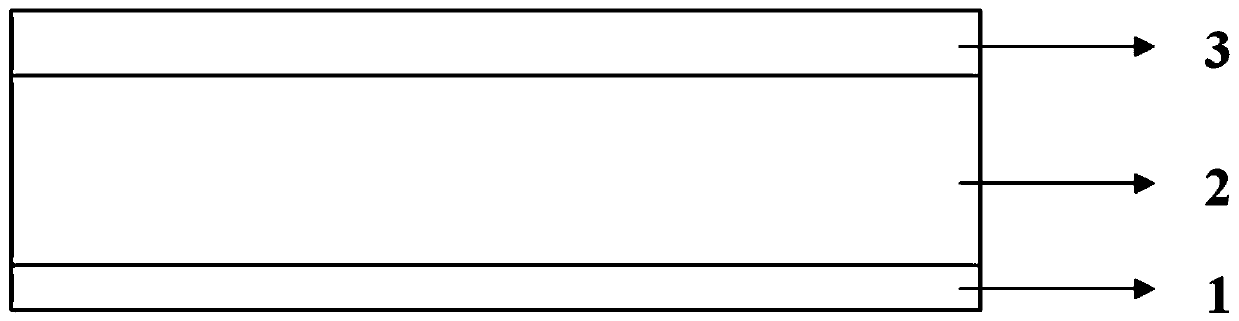

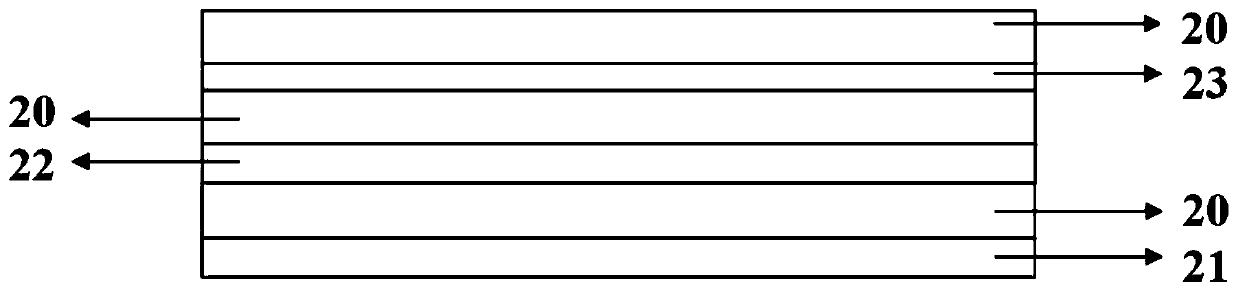

Surface corrosion-resistant thermal insulation composite material for oil field storage equipment and conveying pipeline

ActiveCN109707953AImprove toughnessMeet corrosion resistance requirementsThermal insulationPipe protection by thermal insulationEpoxyThermal insulation

The invention provides a surface corrosion-resistant thermal insulation composite material for oil field storage equipment and a conveying pipeline. The material comprises a bottom layer, a thermal insulation middle layer and an organic corrosion-resistant surface layer, wherein the bottom layer is directly attached to the outer surfaces of the oil field storage equipment and the conveying pipeline, the thermal insulation middle layer is of a multi-layer structure, and the organic corrosion-resistant surface layer is composed of epoxy resin. A composite structure is used as a minimum unit group, multiple composite structures are repeatedly stacked to form the thermal insulation middle layer, each composite structure comprises a three-stage thermal insulation unit layer, the first-stage thermal insulation unit layer is a coarse particle silicon dioxide porous powder layer / rock wool layer, the third-stage thermal insulation unit layer is a fine particle silicon dioxide porous powder layer / rock wool layer, and the second-stage thermal insulation unit layer is a mixed-particle-size silicon dioxide porous powder layer / rock wool layer. The corrosion-resistant thermal insulation compositematerial can be used for thermal insulation on the outer surfaces of an oil-gas storage equipment and an oil-gas conveying pipeline, the effect of the material is excellent, and the construction method is simple and convenient.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY +1

Chemical corrosion-resistant glass bead for reflecting film and preparation method thereof

InactiveCN104950363AGood chemical resistanceExtended service lifeOptical elementsCorrosion resistantScrap

The invention discloses a chemical corrosion-resistant glass bead for a reflecting film and a preparation method thereof. The chemical corrosion-resistant glass bead is prepared from the following raw materials in parts by weight: 27-39 parts of granite wastes, 22-34 parts of fluorapatite, 18-26 parts of spodumene, 14-22 parts of calcium carbonate heavy, 25-35 parts of kieselguhr, 4-7 parts of ammonia alum, 16-28 parts of waste porcelain powder, 12-18 parts of plant ash, 5-10 parts of basic zirconium carbonate, 3-6 parts of potassium acetate, 4-8 parts of magnesium fluoride and 6-9 parts of additive. The glass bead prepared by combining raw materials such as the granite waste, fluorapatite, spodumene, calcium carbonate heavy, kieselguhr, waste porcelain powder, plant ash and basic zirconium carbonate in a certain proportion not only has excellent chemical corrosion resistance performance, especially is capable of resisting a strong acidic environment and a strong caustic environment, is long in service life, but also has relatively high refractive index, can meet the corrosion resistant requirements of different reflecting films and has a relatively wide application range.

Owner:安徽环泰新材料科技有限公司

Corrosion-resistant glass micro-beads for maritime reflective cloth and preparation method thereof

InactiveCN105060707AImprove corrosion resistanceHigh strengthGlass shaping apparatusGlaucophaneAntimony trioxide

The invention discloses corrosion-resistant glass micro-beads for maritime reflective cloth and a preparation method thereof. The glass micro-beads are prepared from the following raw materials in parts by weight: 29-47 parts of quartz stone, 17-31 parts of a stibnite powder, 23-36 parts of peridotite, 26-42 parts of dolomite, 19-33 parts of glaucophane, 14-27 parts of kyanite, 8-12 parts of antimony trioxide, 10-15 parts of titanium dioxide, 5-10 parts of lithium tetraborate, and 8-12 parts of an additive. The prepared glass micro-beads have excellent corrosion resistance, also have the characteristics of high strength, good light reflective effect, good weather resistance, long service life and good application prospects, are especially suitable for production of the maritime reflective cloth, and fully satisfy the requirement of the maritime reflective cloth on corrosion resistance.

Owner:BENGBU GAOHUA ELECTRONICS

Corrosion-resistant plastics

The invention discloses corrosion-resistant plastics comprising the following components by weight: 70-90 parts of polytetrafluoroethylene, 5-10 parts of a polyester alloy powder, 5-10 parts of molybdenum disulfide, and 10-20 parts of a lubricant. The corrosion-resistant plastics are low in production cost, have a good corrosion-resistant property, can meet corrosion-resistant requirements of different devices, and have wider application prospects.

Owner:JIAOZHOU FUTIAN CHEM ENG

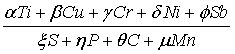

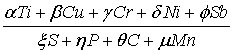

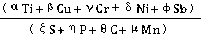

Method for measuring and calculating sulfuric acid corrosion resisting equivalent of steel material

ActiveCN102998251ATimely and effective objective evaluationProtect interestsWeather/light/corrosion resistanceSocial benefitsEconomic benefits

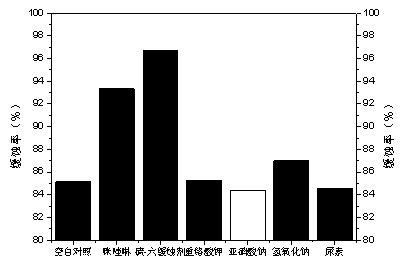

The invention discloses a method for measuring and calculating sulfuric acid corrosion resisting equivalent of a steel material. The corrosion resisting equivalent is measured and calculated according to the following corrosion resisting equivalent model, wherein the corrosion resisting equivalent is described in the specification, wherein Ti, Cu, Cr, Ni, Sb, S, P, C and Mn respectively represent percent contents of corresponding elements in the steel material, and alpha, beta, gamma, delta, phi, zeta, eta, theta and mu respectively represent corrosion coefficients of corresponding elements. The method has the advantages of avoiding the problem of incapability of judging whether the corrosion resisting property of the steel material reaches the standard after the steel material is produced according to the component control range formulated by all factories, being short in detection period, lowering production cost, reducing resource and energy consumption, being capable of meeting the requirement of corrosion resistance of a tobacco oven, and achieving remarkable economic benefit and social benefit.

Owner:WUKUN STEEL +1

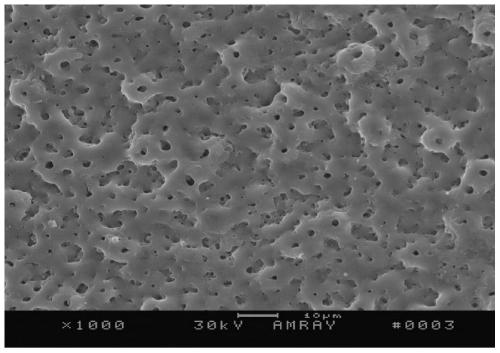

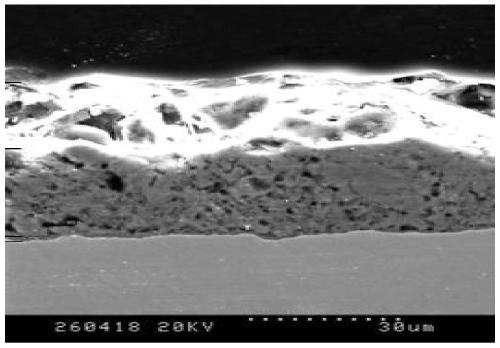

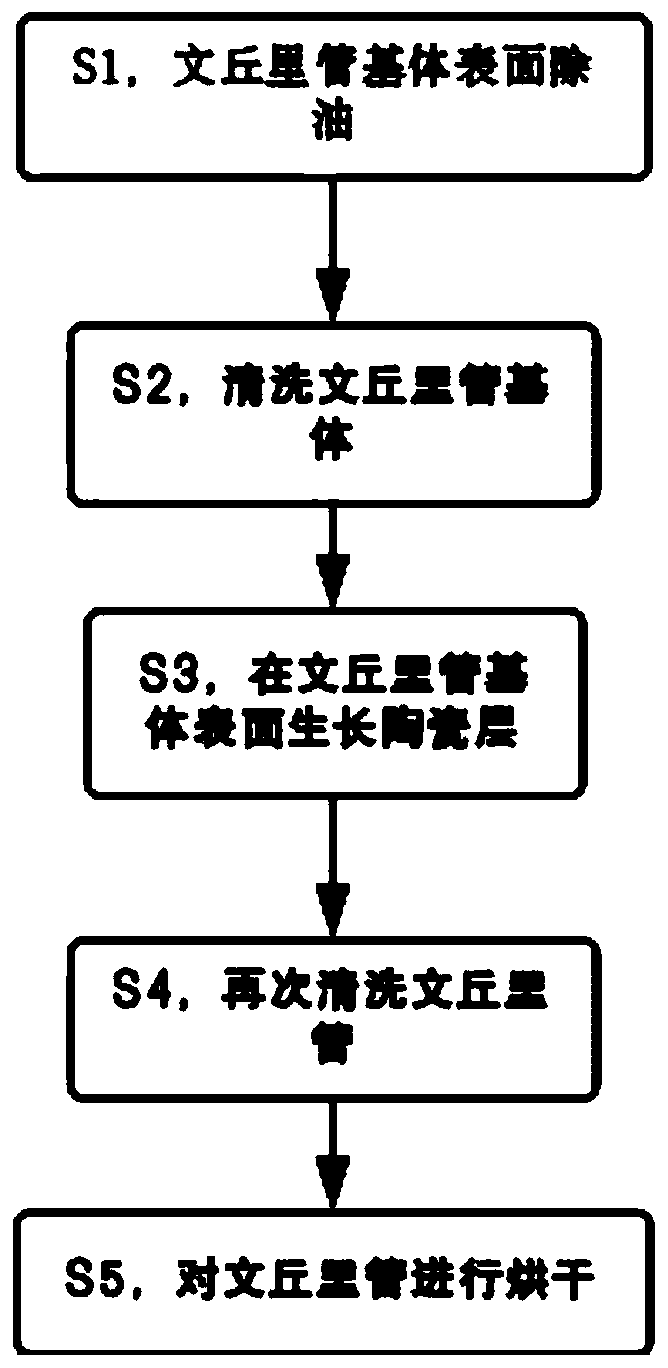

Ceramic layer for improving antifriction and corrosion resistance of inner wall of venturi tube and preparation method thereof

ActiveCN110184637AImprove anti-friction and anti-corrosion propertiesImprove wear resistanceAnodisationMicrometerAluminum silicate

The invention relates to the technical field of engine tail gas detection systems, in particular to a ceramic layer for improving antifriction and corrosion resistance of the inner wall of a venturi tube and a preparation method of the ceramic layer. The ceramic layer is grown on the surface of a venturi tube substrate, and the ceramic layer is prepare from aluminum oxide and aluminum silicate andhas the thickness of 5-15 micrometers. The preparation method of the ceramic layer comprises the following processes of S1, deoiling the surface of the venturi tube substrate, S2, cleaning the venturi tube substrate, S3, growing the ceramic layer on the surface of the venturi tube substrate, S4, cleaning the venturi tube again, and S5, drying the venturi tube. The ceramic layer obtained by the novel surface treatment technology has the advantages of being high in hardness, strong in corrosion resistance, uniform in thickness, good in bonding force, resistant to high temperature, high in flameretardance and free of six harmful substances, the antifriction an corrosion resistance of the inner wall of the venturi tube can be improved, and therefre the service life of the venturi tube is greatly prolonged.

Owner:文晓斌

Stainless steel electrolytic passivator, preparation method and application thereof

ActiveCN109957826AEnvironmentally friendly ingredientsReduce consumptionAnodisationSurface finishingSulfuric acid

The invention relates to the technical field of stainless steel surface treatment, in particular to a stainless steel electrolytic passivator, a preparation method and application thereof. The stainless steel electrolytic passivator is prepared from the following raw materials: sulfuric acid, manganese sulfate, a corrosion inhibitor, a wetting agent and water. Compared with an existing passivator,the stainless steel electrolytic passivator is more environment-friendly in components, faster in electrolytic passivation efficiency under the action of a specific current and thicker in passivationfilms on the surface of stainless steel after passivation, higher corrosion resistance requirements are met, and the service life of stainless steel products is prolonged.

Owner:Dongguan Kaimeng Chemical Co Ltd

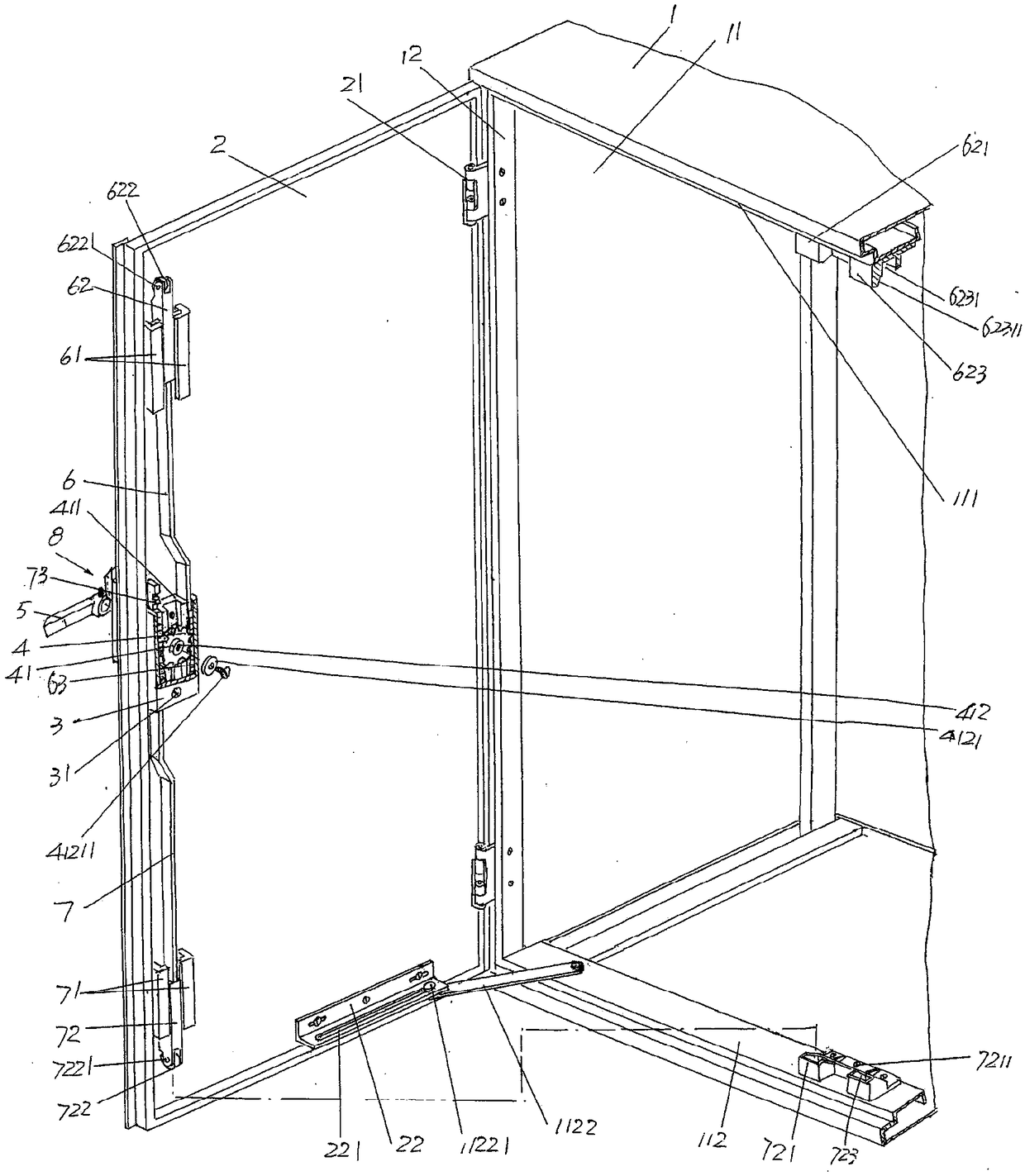

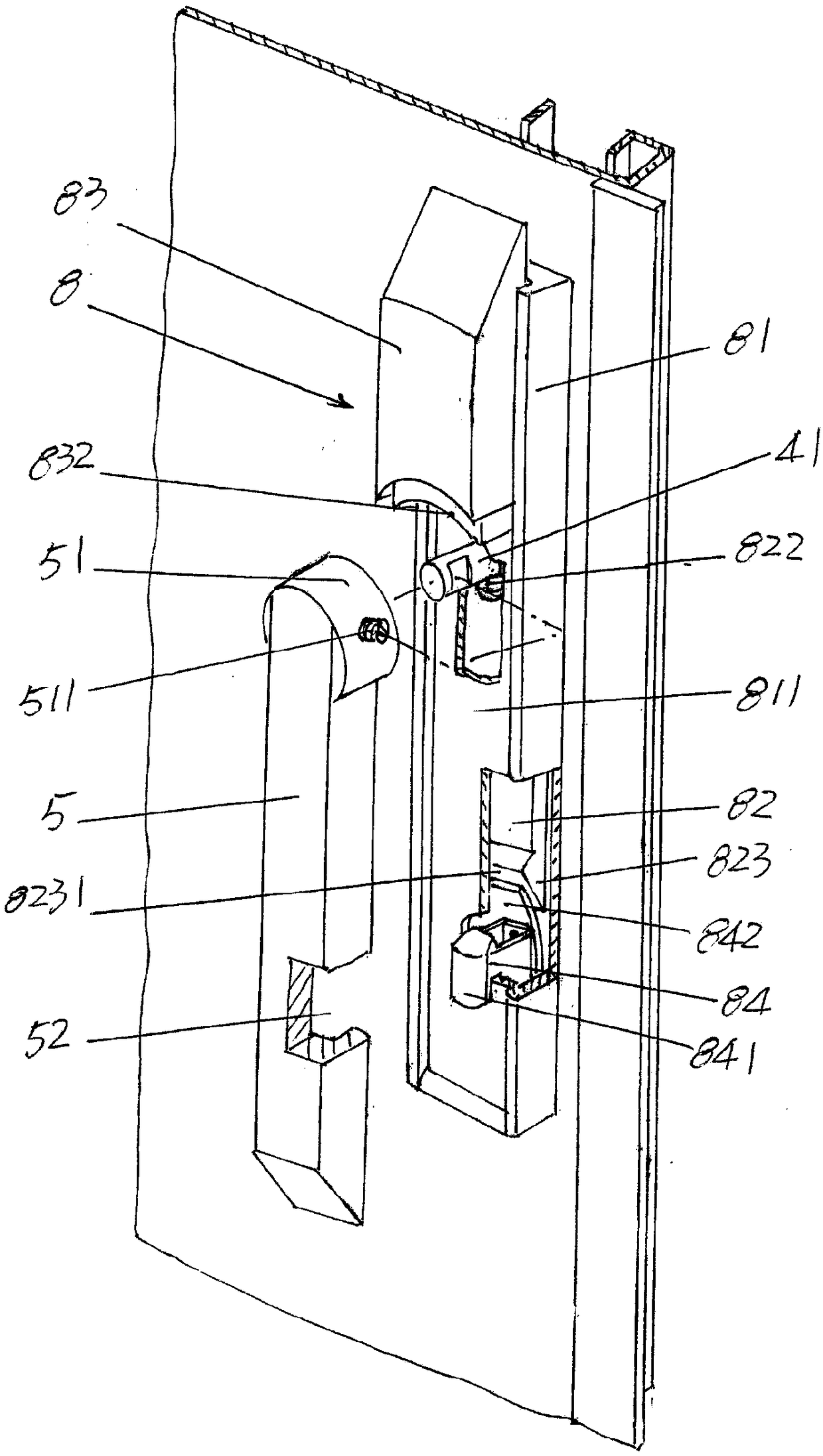

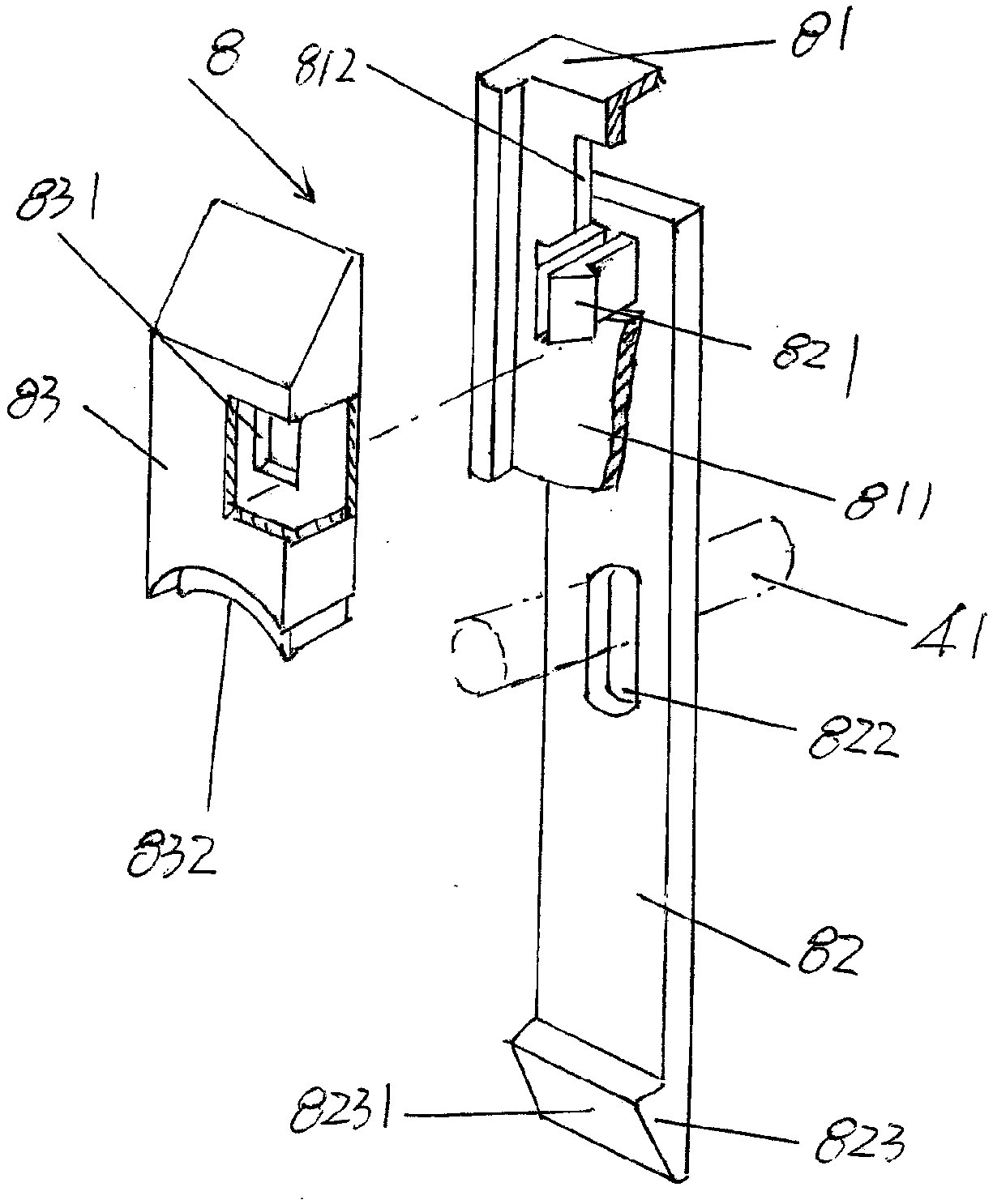

Cabinet door locking device for ship electrical cabinet

ActiveCN106285236BOpen quicklyMeet corrosion resistance requirementsWing handlesWing knobsEngineeringMechanical engineering

The invention discloses a cabinet door locking device for a marine electrical cabinet. The marine electrical cabinet comprises a cabinet body and a cabinet door. The marine electrical cabinet comprises a lock box, a gear, an operating handle, an upper lock rod, a lower lock rod and an operating handle control mechanism, the lock box is fixed in the middle of one side of the cabinet door far away from a longitudinal frame of the cabinet body, the gear is positioned in the lock box and fixed onto a gear shaft, the gear shaft is supported on a gear shaft seat, one end of the gear shaft facing the operating handle penetrates one side of the cabinet door backing a cabinet body cavity, the operating handle is fixed to one end of the gear shaft, the upper lock rod is matched with a pair of upper lock rod guide rails, an upper cylinder is arranged at the upper end of the upper lock rod, an upper lock rod rack is arranged at the lower end of the upper lock rod, the lower lock rod is matched with a pair of lower lock rod guide rails, a lower cylinder is arranged at the lower end of the lower lock rod and matched with a lower latch in a bolted manner, the lower latch is fixed to a lower frame of a cavity opening, a lower lock rod rack is arranged at the upper end of the lower lock rod, and the operating handle control mechanism is arranged on the cabinet door and matched with the operating handle. Anti-corrosion requirements are met, the cabinet door locking device is durable in use, reliable, good in safety and convenient to operate in a bare-handed manner, and the structure is simplified.

Owner:CHANGSHU ZHONGYUAN ELECTRIC POWER EQUIP

A continuous annealing and pickling method for medium-chromium ultra-pure ferritic stainless steel

ActiveCN103243339BImprove surface corrosion resistanceImprove surface conditionWater rinsingSS - Stainless steel

A continuous annealing and acid washing method for medium-chromium ultrapure ferrite stainless steel comprises the process flow of cold rolling, annealing heat treatment, acid washing, final water washing, drying, flattening and packaging, and is characterized in that in the acid washing process flow, the acid washing solution is prepared from 120-150g / L of 65% nitric acid, 2-4g / L of 40% hydrofluoric acid and water. According to the invention, in the chemical acid washing stage, reasonable concentration ratio of nitric acid to hydrofluoric acid is adopted and proper acid washing speed is controlled to carry out acid washing on medium-chromium ferrite stainless steel. As a result, on one hand, the performance of a medium-chromium ferrite stainless steel passivation film is obviously improved, and the corrosion resistance of the surface of a medium-chromium ferrite stainless steel 2B board is significantly improved, and on the other hand, the process flow of the existing production factory is not needed to be changed, a special passivation treatment procedure is not needed, and the production cost is significantly lowered.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Hot-dip galvanized aluminum-magnesium plating solution for steel surface and plating method using the same

ActiveCN113388796BIncrease grain boundary densitySatisfy repeated use problemsHot-dipping/immersion processesCorrosion resistantMagnesium

The invention provides a hot-dip galvanized aluminum-magnesium plating solution on the surface of steel to alleviate the risk of cracks on the coating surface of steel under repeated bending conditions in the prior art. The present invention improves corrosion resistance by adding alloy element Mg. In order to suppress the risk of cracks on the surface of the steel and its coating produced by repeated bending, a certain amount of Ti and B is added to improve the corrosion resistance and at the same time precipitate an intermediate phase at the grain boundary to inhibit the generation and expansion of cracks. The final galvanized steel adopts air cooling combined with water cooling to further refine the grains, improve corrosion resistance and inhibit crack growth. The final product extends the service life of galvanized aluminum-magnesium steel.

Owner:天津市新宇彩板有限公司

Phosphor molybdenum heteropolyacid inactivating treatment liquid used for heat zinc coating plate

InactiveCN101168840BMeet corrosion resistance requirementsTo achieve the effect of passivation treatmentMetallic material coating processesMolybdatePhosphor

The invention relates to phosphomolybdie heteropolyacid passivation treating liquid used for a hot galvanized plate and the preparation method thereof. The passivation treating liquid consists of 15000 to 23000 ppm of molyadate, 7300 to 11000 ppm of sodium phosphate, 2000 to 5000 ppm of nitrate radical, at least one of 5000 to 15000 ppm of water soluble high molecular compounds, at least one of 1000 to 4000 ppm of nonionic surface active agent, and the pH value of the solution is 2 to 3. The invention has the preparation method that the molyadate and the sodium phosphate are mixed, and then the nitrate radical is added; the nonionic surface active agent is added in the water soluble high molecular compound, then the water soluble high molecular compound is added into the prepared solution,the pH value is 2 to 3, and the constant volume reaches 1000 ml. The treating temperature to the hot galvanized plate is 30 to 50 DEG C, the treating time is 30 to 60 seconds, the drying temperatureis 50 to 70 DEG C, the drying time is 5 to 25 minutes. The salt atmosphere resistant ability of the treated hot galvanized plate is above 72 hours.

Owner:NORTHEASTERN UNIV LIAONING

A surface corrosion-resistant and heat-insulating composite material for oilfield storage equipment and pipelines

ActiveCN109707953BImprove toughnessMeet corrosion resistance requirementsThermal insulationPipe protection by thermal insulationEpoxyThermal insulation

The invention provides a surface corrosion-resistant thermal insulation composite material for oil field storage equipment and a conveying pipeline. The material comprises a bottom layer, a thermal insulation middle layer and an organic corrosion-resistant surface layer, wherein the bottom layer is directly attached to the outer surfaces of the oil field storage equipment and the conveying pipeline, the thermal insulation middle layer is of a multi-layer structure, and the organic corrosion-resistant surface layer is composed of epoxy resin. A composite structure is used as a minimum unit group, multiple composite structures are repeatedly stacked to form the thermal insulation middle layer, each composite structure comprises a three-stage thermal insulation unit layer, the first-stage thermal insulation unit layer is a coarse particle silicon dioxide porous powder layer / rock wool layer, the third-stage thermal insulation unit layer is a fine particle silicon dioxide porous powder layer / rock wool layer, and the second-stage thermal insulation unit layer is a mixed-particle-size silicon dioxide porous powder layer / rock wool layer. The corrosion-resistant thermal insulation compositematerial can be used for thermal insulation on the outer surfaces of an oil-gas storage equipment and an oil-gas conveying pipeline, the effect of the material is excellent, and the construction method is simple and convenient.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY +1

A kind of chromium aluminum alloy target material and its preparation method and application

InactiveCN103981487BAppearance color is easy to controlMeet corrosion resistance requirementsVacuum evaporation coatingSputtering coatingMixed materialsNitrogen gas

The invention discloses a chromium-aluminum alloy target as well as a preparation method and an application thereof and relates to an intermetallic compound alloy target. The chromium-aluminum alloy target comprises the following components in percentage by weight: 50-80% of chromium and 20-50% of aluminum. The preparation method comprises the following steps: mixing chromium powder with aluminum powder to obtain a chromium-aluminum mixed material; putting the chromium-aluminum mixed material in a nitrogen protective atmosphere to be pressed to n electrodes; welding every two electrodes pressed to chromium-aluminum smelting electrodes; smelting the chromium-aluminum smelting electrodes for the first time to a chromium-aluminum first ingots; de-heading and removing tail of the chromium-aluminum first ingots, and welding every two chromium-aluminum first ingots to chromium-aluminum secondary smelting electrodes; smelting the chromium-aluminum secondary smelting electrodes for the second time to obtain chromium-aluminum secondary ingots; carrying out hot forging on the chromium-aluminum secondary ingots; thermally treating the hot-forged chromium-aluminum secondary ingot, and then air-cooling and cooling, and processing the required chromium-aluminum alloy target according to dimension of the target. The chromium-aluminum alloy target can be applied to manufacturing products in the fields of bathrooms, household appliances, automobiles and the like.

Owner:XIAMEN RUNNER IND CORP

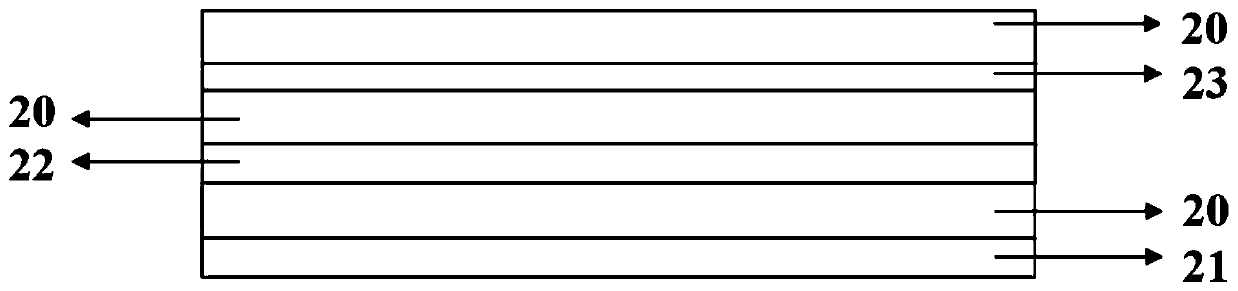

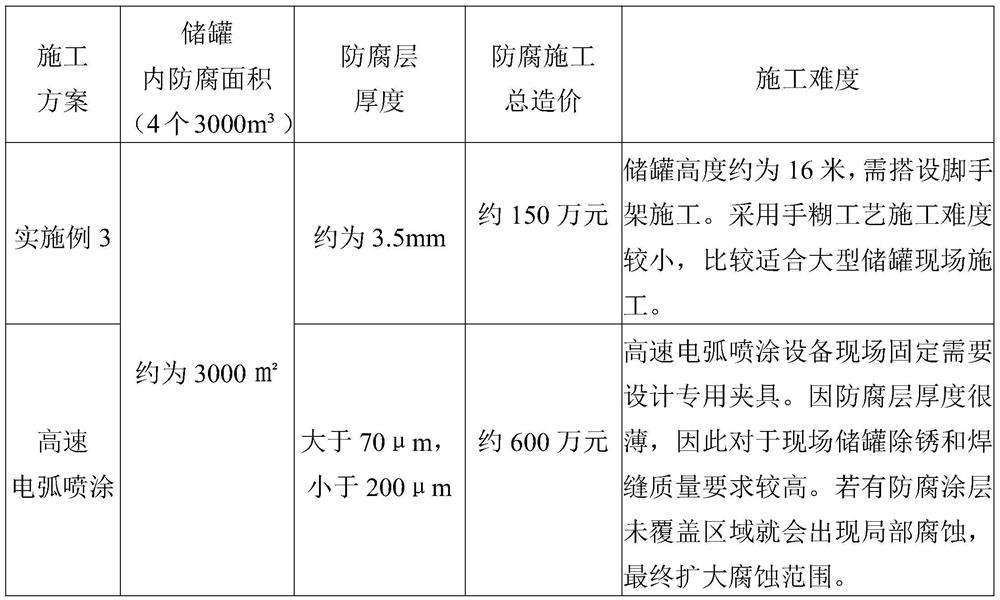

Method for preventing corrosion in large waste animal and vegetable oil carbon steel storage tank

PendingCN113954398AMeet corrosion resistance requirementsExtended service lifeNon-macromolecular adhesive additivesAnti-corrosive paintsCarbon steelCorrosion resistant

The invention relates to the technical field of tank body corrosion prevention, in particular to a method for preventing corrosion in a large waste animal and vegetable oil carbon steel storage tank. According to the method, sand blasting and derusting treatment is carried out on the inner wall of the storage tank and a bottom plate; the derusted tank wall and the derusted bottom plate are coated with a priming coat, and after the priming coat is hardened, uneven parts of concave-convex holes and internal and external corners are repaired by the adoption of resin mortar; a chopped strand mat and a surfacing mat are continuously laid on the priming coat, and the internal and external corners and weld joints are repaired with the resin mortar; and after all paved mat layers are naturally cured for 24 h, cover layer construction is conducted, and after the hardness of a cover layer is larger than or equal to 30 HBa, using can be conducted. Compared with the prior art, an FRP lining is formed on the inner wall of the carbon steel storage tank, the requirement for corrosion resistance can be met, the service life of the large carbon steel storage tank can be prolonged, and compared with various anti-corrosion schemes such as lining polytetrafluoroethylene, supersonic electric arc spraying and lining rubber, the FRP lining has the advantages of small construction difficulty and low production cost.

Owner:江西尊创新能源有限公司

A kind of engineering plastic surface coating structure and preparation method thereof

ActiveCN103818047BAvoid harmEmission reductionSuperimposed coating processMetal layered productsCorrosion resistant alloySurface layer

The invention relates to engineering plastic surface treatment, and particularly relates to a surface coating structure of engineering plastic and a preparation method thereof. The surface coating structure of the engineering plastic comprises, in sequence, a vacuum coating conductive metal layer, a nickel electroplated coating, a PVD corrosion-resistant alloy layer and a PVD color layer. The method includes a step of subjecting the engineering plastic to hydrocarbon vacuum oil removal and drying, transferring and hanging the engineering plastic into a PVD furnace, and subjecting the conductive metal layer to vacuum plating; a step of transferring and hanging the processed engineering plastic product to an electroplating hanger to perform nickel electroplating, performing Watt's nickel electroplating, then performing semi-bright nickel electroplating, subjecting the engineering plastic product to wiredrawing processing, and subjecting the engineering plastic product after the wiredrawing processing to hydrocarbon vacuum oil removal and drying; or a step of transferring and hanging the processed engineering plastic product to an electroplating hanger to perform nickel electroplating, performing Watt's nickel electroplating first, then performing semi-bright nickel electroplating, then performing bright nickel electroplating, and finally performing microporous nickel electroplating; and a step of plating the processed engineering plastic product with the PVD corrosion-resistant alloy layer and the PVD color layer.

Owner:XIAMEN RUNNER IND CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com