A surface corrosion-resistant and heat-insulating composite material for oilfield storage equipment and pipelines

A technology for storage equipment and transportation pipelines, which is applied in pipeline protection, thermal insulation, mechanical equipment, etc., can solve the problems of difficult realization of thermal insulation layer, difficult and complex control, and thermal insulation space requirements, and achieves improved thermal insulation effect, overall strength and stability. The effect of improving the filling effect and ensuring the bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

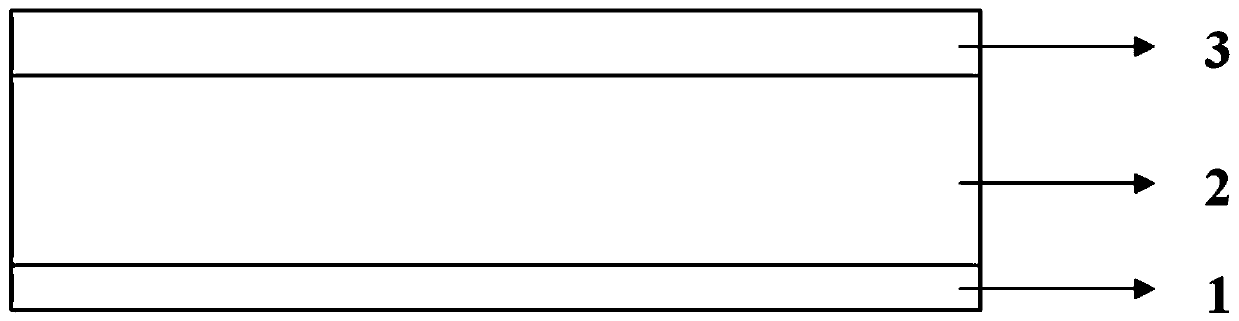

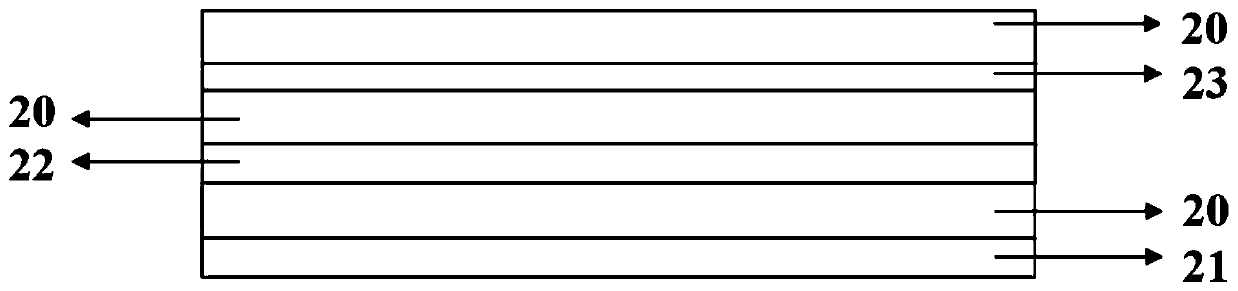

[0023] see figure 1 , a surface corrosion-resistant and heat-insulating composite material for oilfield storage equipment and transportation pipelines, comprising a bottom layer 1, an insulation middle layer 2 and an organic corrosion-resistant surface layer 3, the bottom layer 1 is directly attached to the outer surface of the oilfield storage equipment and transmission pipelines Together, the thermal insulation middle layer 2 is a multi-layer structure, the components of the thermal insulation middle layer 2 include porous silica powder, rock wool fiber and polyvinyl alcohol, and the 3 components of the organic corrosion-resistant surface layer are epoxy resin. The three functional layers of the bottom layer, the insulation middle layer and the organic anti-corrosion surface layer are responsible for each, taking into account the bonding strength, heat preservation and anti-corrosion performance.

[0024] The bottom layer 1 is a bottom rock wool layer with a thickness of 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com