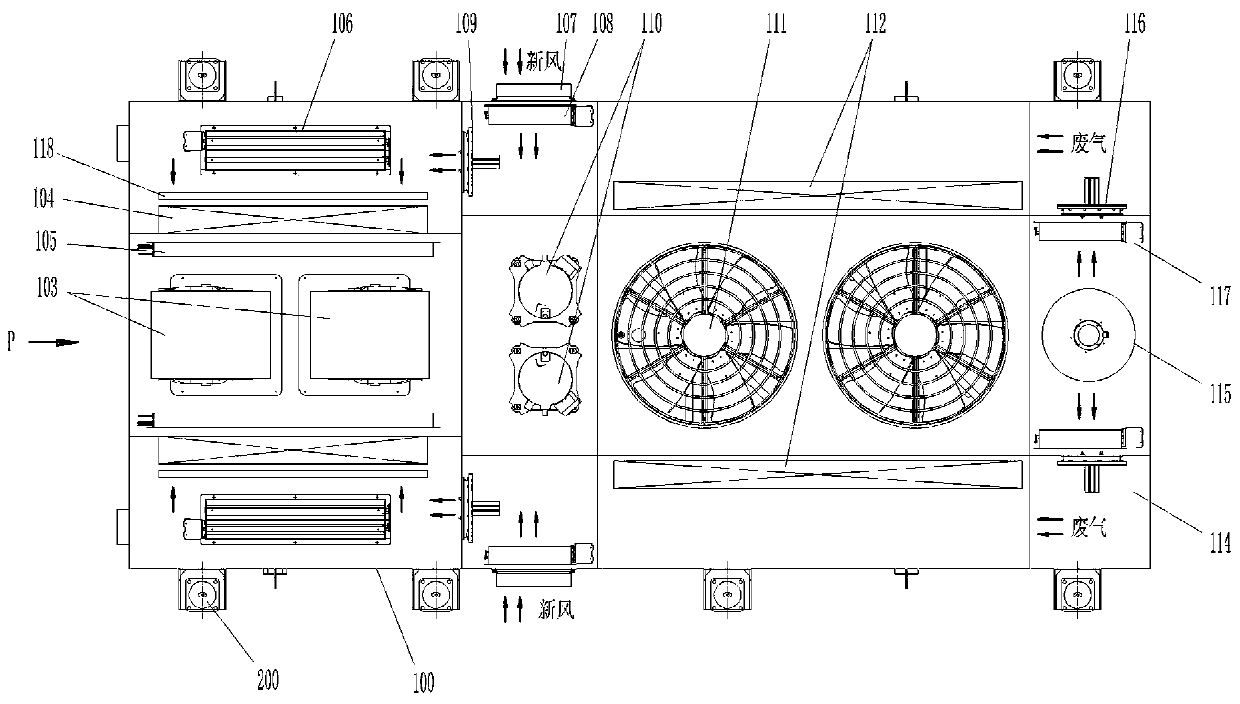

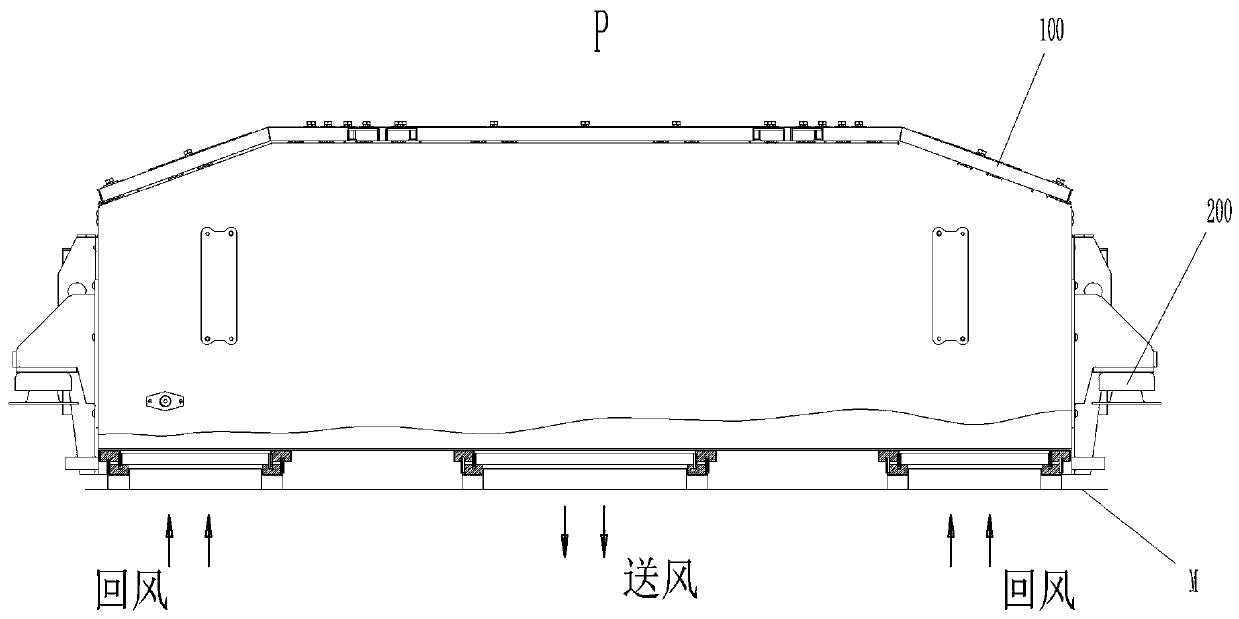

Air conditioning unit for EMU multiple unit train

A technology for air-conditioning units and EMUs, which is applied in railway car body parts, railway vehicle heating/cooling, transportation and packaging, etc., can solve the problems of unfavorable modification, the need for mold opening, and high cost, and can reduce weight and eliminate mold opening. Cost, cycle time reduction and cost effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

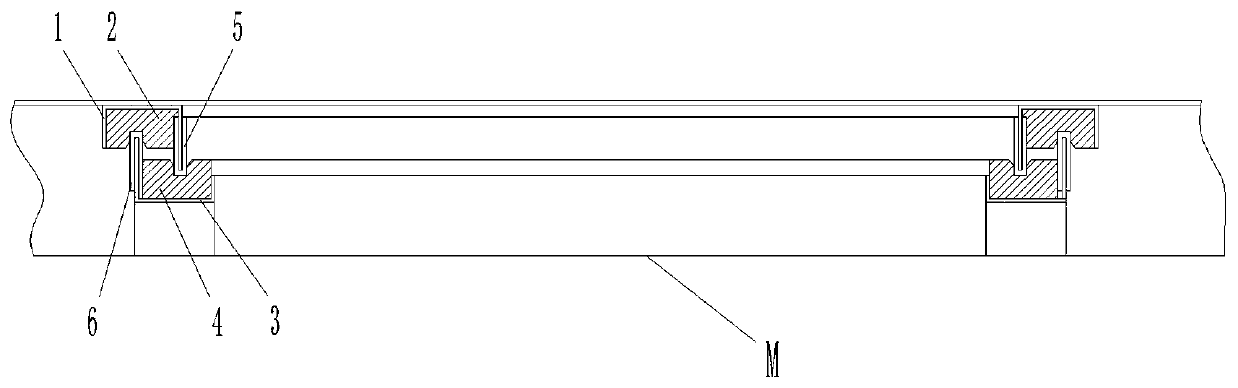

[0030] In this embodiment, the first sealing assembly includes a first annular sealing flange 1 arranged at the outer edge of the tuyere and a first sealing rubber strip 2 arranged in the annular groove of the first annular sealing flange 1 . Through the installation of the air-conditioning unit and the top of the compartment, the first sealing rubber strip 2 is closely attached to the top of the compartment to achieve sealing.

[0031] See attached Image 6 , the above-mentioned first annular sealing flange 1 is formed by a bending process, which saves the mold opening cost of the mold, and is also conducive to the modification of the design scheme. The bent annular groove facilitates the installation of the sealing strip.

Embodiment 2

[0033] Different from Embodiment 1, the first seal between the air outlet and the roof of the compartment can be realized through the first sealing assembly. Further, a second sealing assembly forming a second seal is also provided between the top of the compartment and the above-mentioned tuyere. The second sealing assembly includes a second annular sealing flange 3 arranged on the top of the compartment and a second annular sealing flange arranged on the second annular sealing flange. The second sealing strip 4 in the annular groove of 3.

[0034] The second annular sealing flange 3 is the same as the first annular sealing flange 1 and is formed by bending process, the difference lies in the height and size of the inner and outer edges.

[0035] The height of the inner annular edge of the above-mentioned first annular sealing flange 1 is greater than the height of the outer annular edge and extends into the groove of the second sealing strip 4 to compress the bottom of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com