Corrosion resistant steel for cargo oil tanks and application thereof

A technology for corrosion-resistant steel and cargo oil tanks, which is applied to corrosion-resistant steel and corrosion-resistant steel for cargo oil tanks. In the field, it can solve problems such as difficult effects, achieve extended time, reduce repair painting operations, and meet the effects of corrosion resistance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

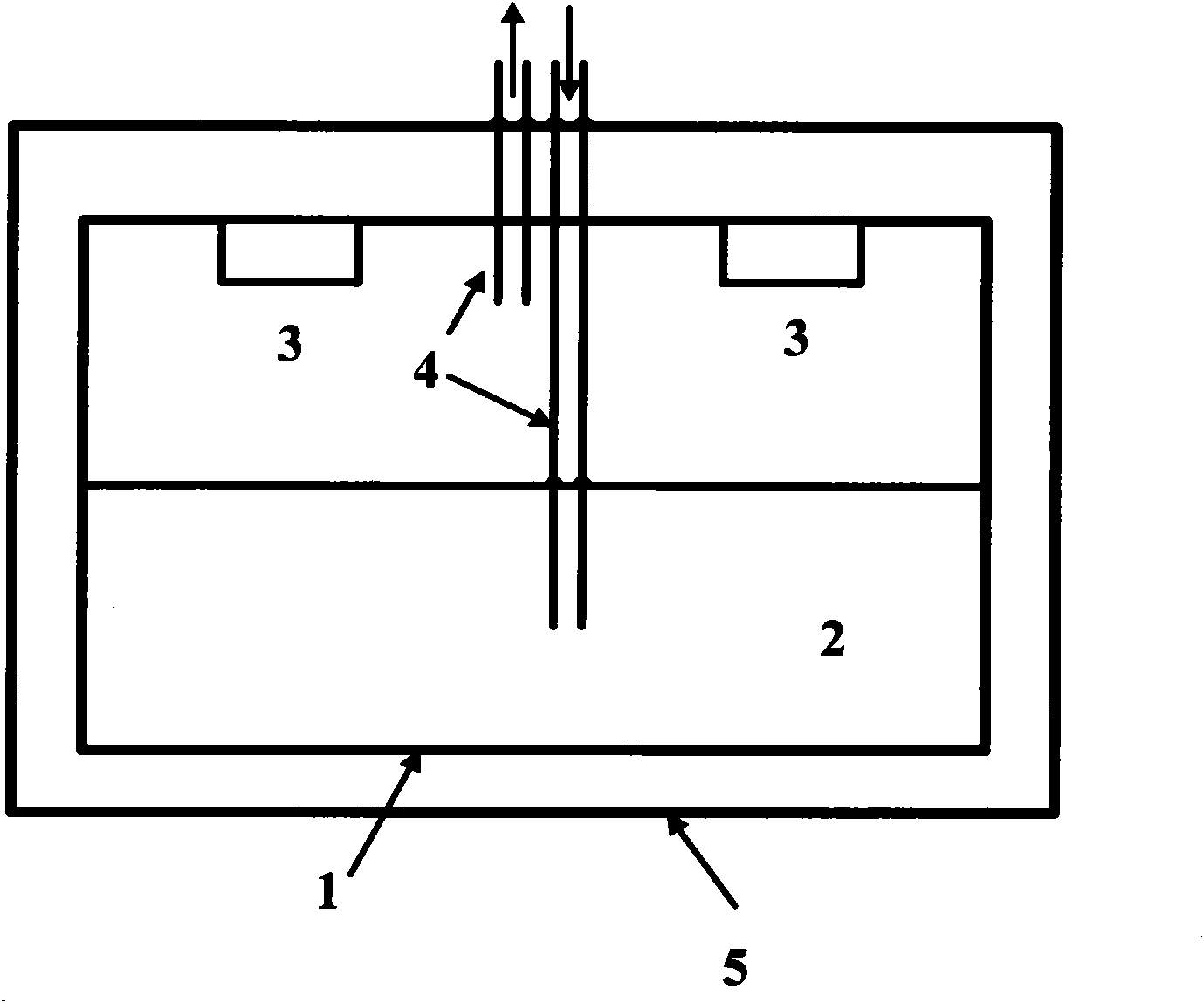

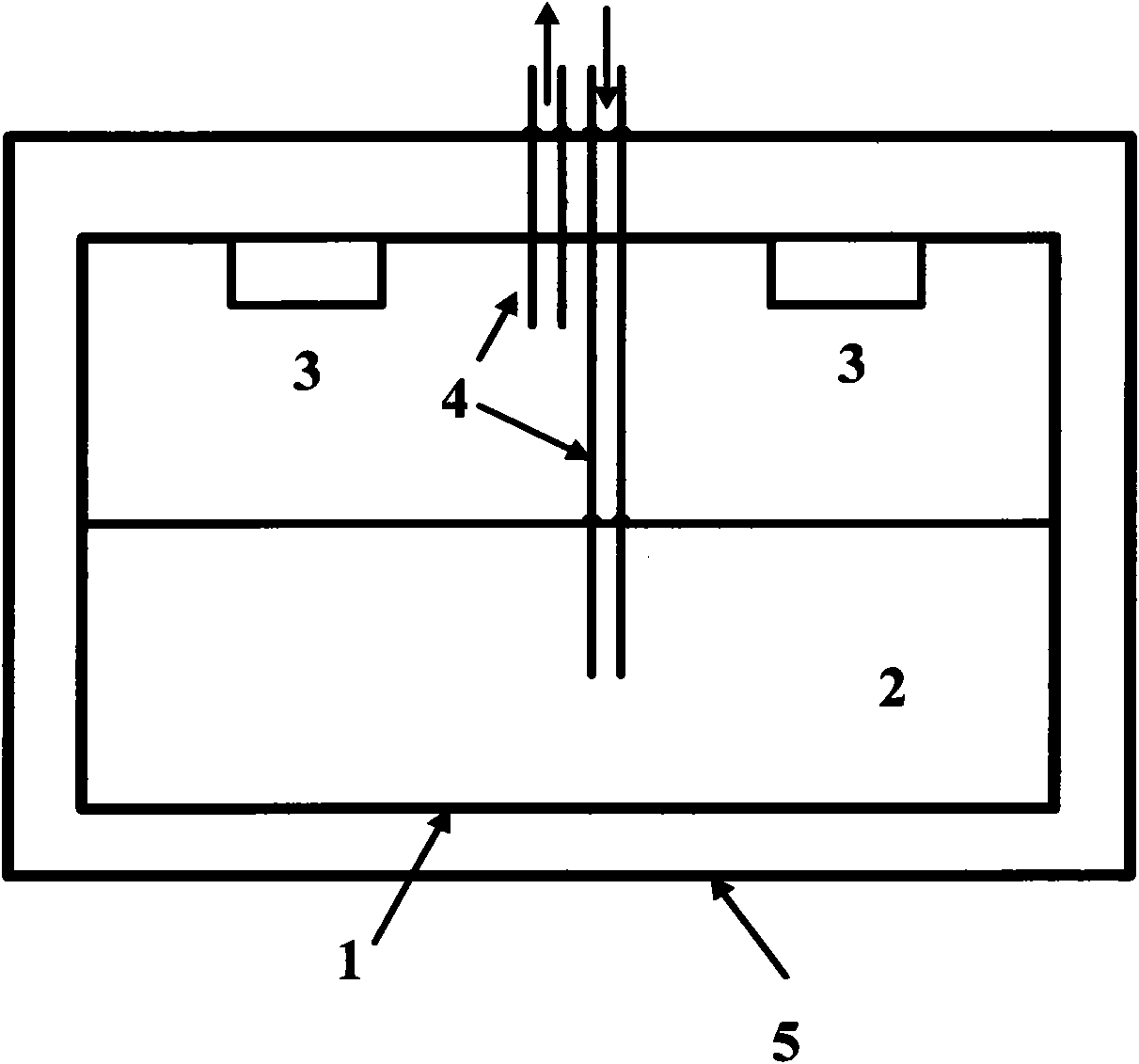

[0035] A corrosion-resistant steel for cargo oil tanks according to the present invention, the alloy composition of the steel is shown in Table 1. The experimental samples were wire-cut into rectangular samples of 50mm×30mm×4.5mm to simulate the corrosion test of the backside environment of the actual oil tanker deck. Such as figure 1 as shown, figure 1It is a schematic diagram of the present invention simulating the corrosion environment on the back of the deck of an actual oil tanker. Among them, 1 is a glass container, 2 is a 0.3% NaCl aqueous solution, 3 is a steel sample to be tested, 4 is a ventilation pipe, and 5 is a constant temperature bath. A glass container is used to simulate cargo oil tank, and a part of 0.3% NaCl aqueous solution is injected inside, and there are vent holes on the upper part, one gas supply port and one exhaust port, and the sample is fixed on the upper part of the glass container. Place the sealed glass container in a constant temperature ba...

Embodiment 2

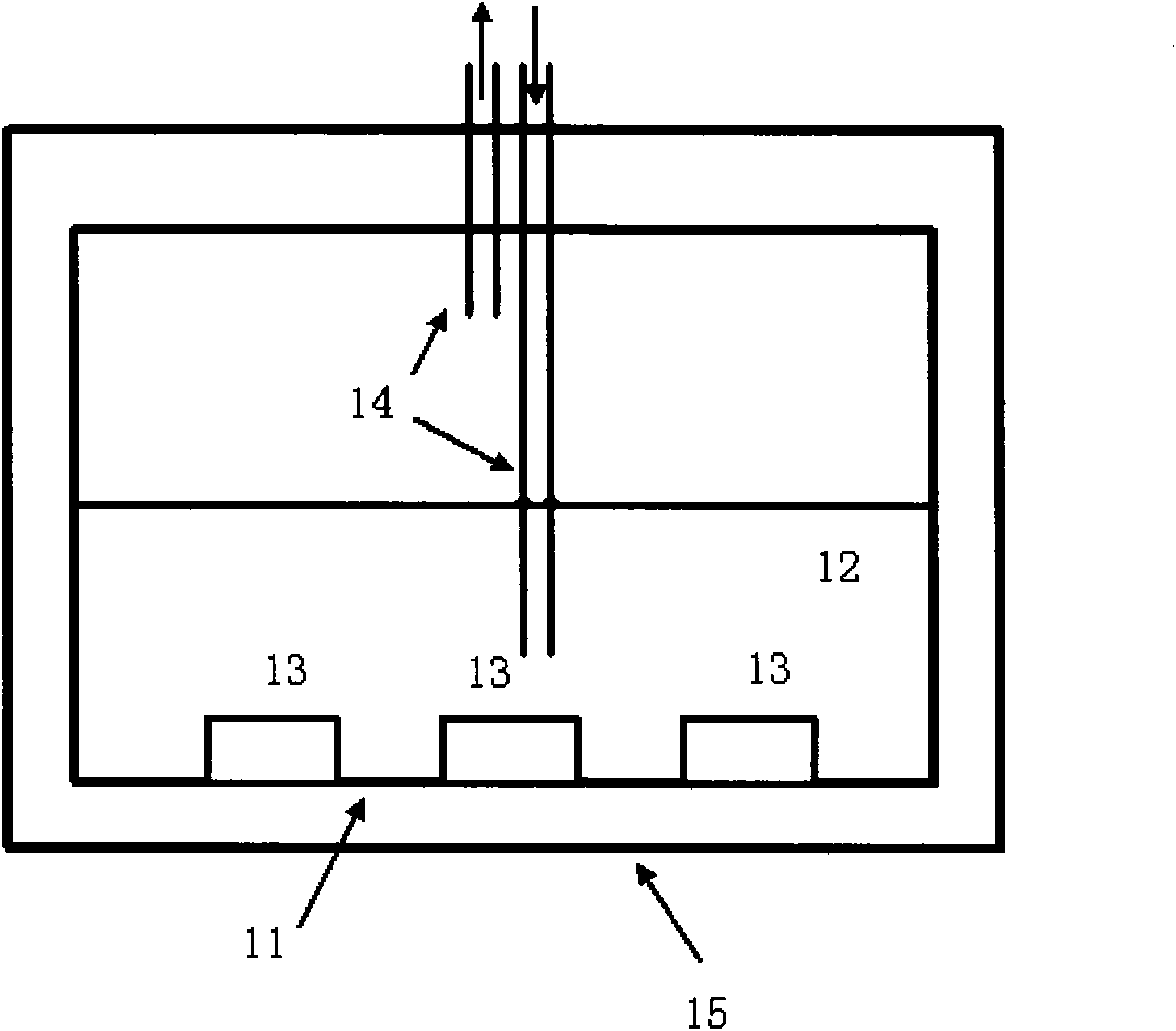

[0046] The experimental material was manufactured according to the alloy composition described in the summary of the invention, and the alloy composition of the material is shown in Table 1. The experimental sample is wire-cut into a rectangular sample of 50mm×30mm×4.5mm to simulate the corrosion test of the steel used in the bottom plate of the cargo oil tank of an actual oil tanker. figure 2 The present invention simulates the schematic diagram of the corrosion environment of the cargo oil tank bottom plate of the actual oil tanker, 11 is a glass container, 12 is an artificial seawater solution, 13 is a steel sample for testing, 14 is a vent pipe, and 15 is a constant temperature tank.

[0047] Use a glass container to simulate a cargo oil tank, inject a part of artificial seawater into it, and leave a vent hole on the upper part, one gas supply port and one exhaust port. The sample is fixed at the bottom of the glass container and immersed in the artificial seawater solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com