Plating solution for hot-dip galvanizing, aluminum and magnesium on surface of steel and plating method using plating solution

A hot-dip galvanizing and steel technology, applied in hot-dip galvanizing process, metal material coating process, coating, etc., can solve the problems of reducing the strength of steel wire, affecting the use, and deteriorating corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Bath atomic percentage of each element Al: 20%, Mg: 0.8%, Si: 3%, Ti: 1%, B: 2.2%, Ce: 0.45%, the balance being Zn.

[0022] Coating preparation process comprises the steps of: preparing an alloy ingot obtained preform ratio of each element in accordance with the content of the bath. Prefabricated sufficiently melted alloy ingot, a zinc pot zinc was incubated stand 510 ℃. Selection of packaging steel wire, steel wire elemental composition by weight percent: C: 0.10-0.40%, Si: 0.1-0.3%, Mn: 1.0-2.0%, P≤0.025%, S≤0.015% and Al: 0.015- 0.1%, Ti: 0.11-0.16%, Nb: 0.1-0.13% and V: 0.2-0.25%, the balance being iron (Fe) and unavoidable impurities. Cold rolled steel wire prepared, drawn to a diameter of 3mm. Steel wire degreasing, brushing, rinsing, drying process. Purpose is to remove the plate surface residual grease, stains. Steel wire heated, cooled, and 350 deg.] C incubation, into the zinc pot, dip time 5min, the protective gas atmosphere furnace volume percentage of H 2 / N ...

Embodiment 2-12

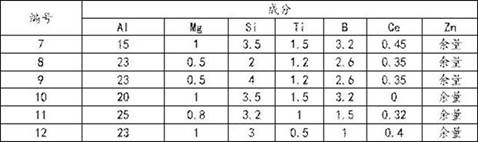

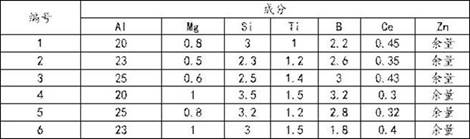

[0025] In various embodiments, the bath composition in Table 1 and Table 3, in Example 1 was prepared DETAILED embodiment, only the adjustment of the bath composition. Example corrosion resistance test and bending test results in Table 2 and Table 4 for each embodiment.

[0026] Examples 1-6 using the bath composition of the present application, does not significantly red rust after 2000h salt spray test, repeated bending of the visible surface of the coating cracks was not observed. Example 6 is not employed preferably Ti, B atomic ratio range, the coating surface appears red rust after 2000h portion hours of salt spray testing, 5cm bend radius of 10 times the rear surface cracks were observed. Example 7 Al atomic ratio ranges reduction, in Examples 8-9 to change the range of the atomic ratio of Si, not added in Example 10 rare earth Ce, embodiments bath Ti, reducing the addition amount of B 11-12, wherein Example 7, 11 the corrosion resistance decreased to different degrees, cra...

Embodiment 13

[0036] The percentage of each element of the plating solution is Al: 20%, Mg: 0.8%, Si: 3%, Ti: 1%, B: 2.2%, CE: 0.45%, the margin is Zn. The preparation process of the plating includes the following steps: Pre-forming alloy ingots were prepared according to each element content ratio in the plating solution. The prefabricated alloy ingot is fully melted, and zinc liquid in zinc pot is maintained from 430-480 ° C for use. Packaging steel wire, the components of the steel wires are: 0.1-0.40%, Si: 0.1-0.3%, MN: 1.0-2.0%, P ≤ 0.025%, s ≤ 0.015% and Al: 0.015- 0.1%, Ti: 0.1-0.16%, NB: 0.1-0.13% and V: 0.2-0.25%, the rest is iron Fe and inevitable impurities. The steel wire is prepared by cold rolling, draws to 3 mm in diameter. Stermanement, brush, rinse, drying treatment of steel wires. The purpose is to remove the panel residual oil and stains. After the steel wire is heated, cooled and incubated 350 ° C, it enters zinc pot, dip plating time 50s, and the percentage of protective ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com