Molybdenum base nitride composite ganoine thin film and preparation thereof

A nitride and film technology, applied in the field of molybdenum-based nitride composite hard film and its preparation, can solve the problems of film hardness, low anti-oxidation temperature, high process temperature requirements, and decreased material flexural strength, etc. The process is clean and pollution-free, the process is simple and easy to operate, and the temperature of film formation is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

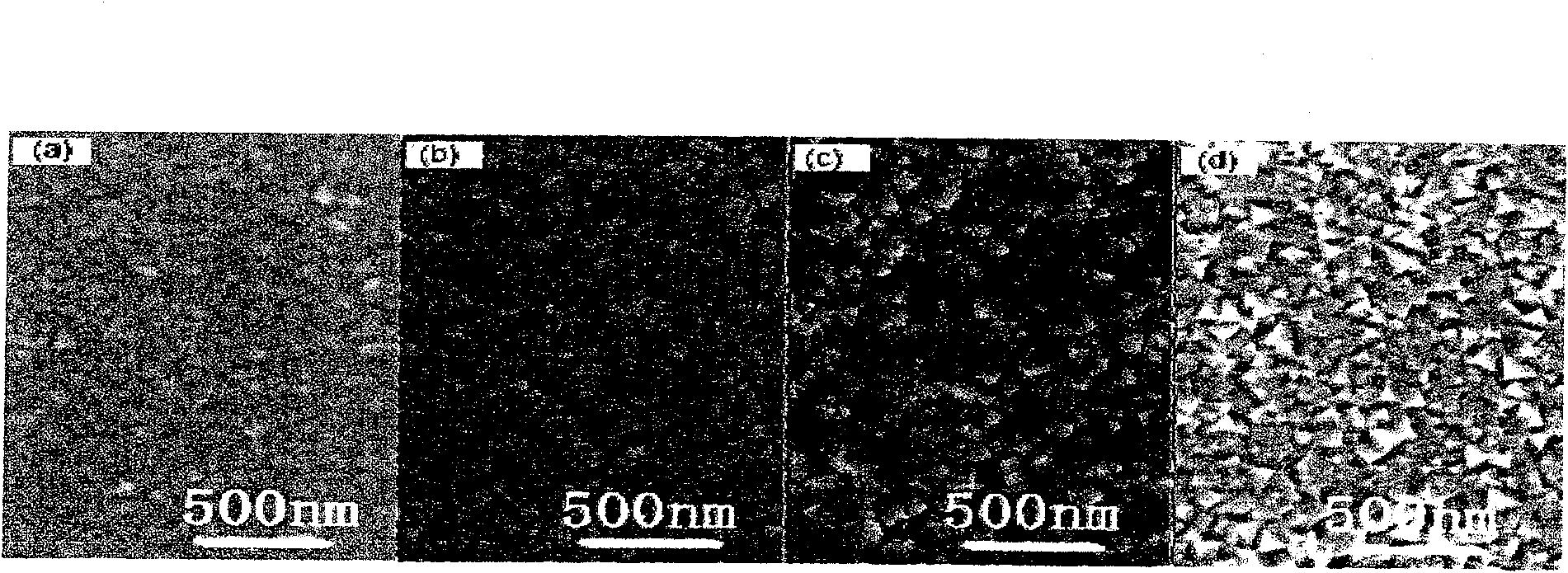

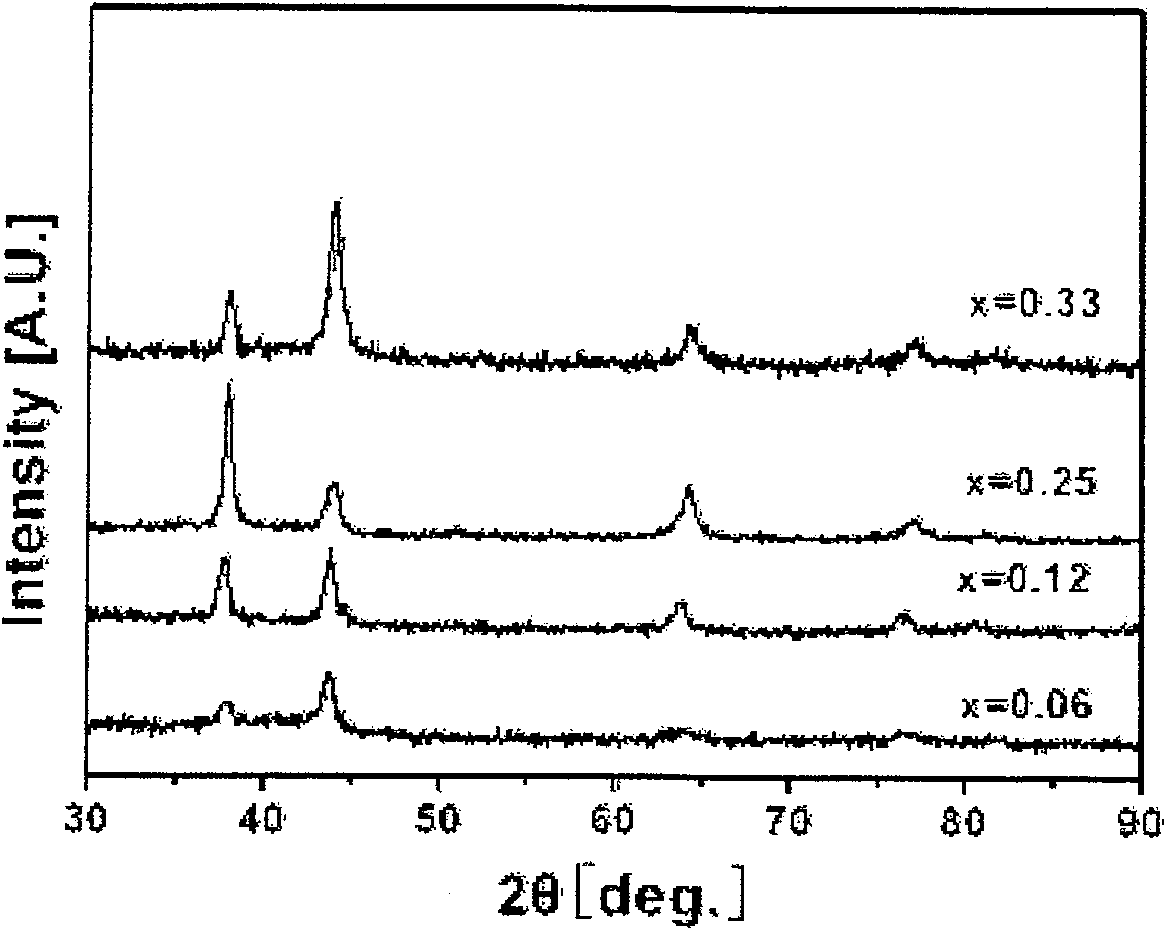

Embodiment 1

[0027] Embodiment 1: The preparation is completed in sequence according to the following steps: a) Before placing the substrate in the sample stage in the vacuum chamber of the magnetron sputtering equipment, it is firstly polished and cleaned. Afterwards, the target and the substrate composed of metal molybdenum and the substituent are respectively placed on the cathode and the sample stage in the vacuum chamber of the magnetron sputtering equipment; wherein the substituent is metal aluminum, and the substrate is a metal substrate. The area ratio between the metal molybdenum in the target and the substitute metal aluminum is 1:8, and the distance between the target and the substrate is 40mm. b) The vacuum degree of the vacuum chamber is 8×10 -4 Pa, after the substrate temperature reaches 300°C, put the vacuum chamber in the argon-nitrogen mixed atmosphere, and sputter for 120 minutes; wherein, the argon-nitrogen mixed atmosphere is that the flow ratio between argon and nitrog...

Embodiment 2

[0028] Embodiment 2: The preparation is completed in sequence according to the following steps: a) Before placing the substrate in the sample stage in the vacuum chamber of the magnetron sputtering equipment, it is firstly polished and cleaned. Afterwards, the target and the substrate composed of metal molybdenum and the substituent are respectively placed on the cathode and the sample stage in the vacuum chamber of the magnetron sputtering equipment; wherein the substituent is metal aluminum, and the substrate is a metal substrate. The area ratio between the metal molybdenum in the target and the substitute metal aluminum is 3:7, and the distance between the target and the substrate is 50mm. b) The vacuum degree of the vacuum chamber is 7×10 -4 Pa, after the substrate temperature reaches 350°C, put the vacuum chamber in the argon-nitrogen mixed atmosphere, and sputter for 95 minutes; wherein, the argon-nitrogen mixed atmosphere is the flow ratio between argon and nitrogen is ...

Embodiment 3

[0029] Embodiment 3: The preparation is completed in sequence according to the following steps: a) Before placing the substrate in the sample stage in the vacuum chamber of the magnetron sputtering equipment, it is firstly polished and cleaned. Afterwards, the target and the substrate composed of metal molybdenum and the substituent are respectively placed on the cathode and the sample stage in the vacuum chamber of the magnetron sputtering equipment; wherein the substituent is metal aluminum, and the substrate is a metal substrate. The area ratio between the metal molybdenum in the target and the metal aluminum as the substitute is 5:5, and the distance between the target and the substrate is 60mm. b) The vacuum degree of the vacuum chamber is 5×10 -4 Pa, after the substrate temperature reaches 400°C, put the vacuum chamber in an argon-nitrogen mixed atmosphere, and sputter for 75 minutes. The transmitting power is 130W. Stop heating the substrate after sputtering, turn off...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| anti-oxidation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com