Patents

Literature

66results about How to "Cleaning preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

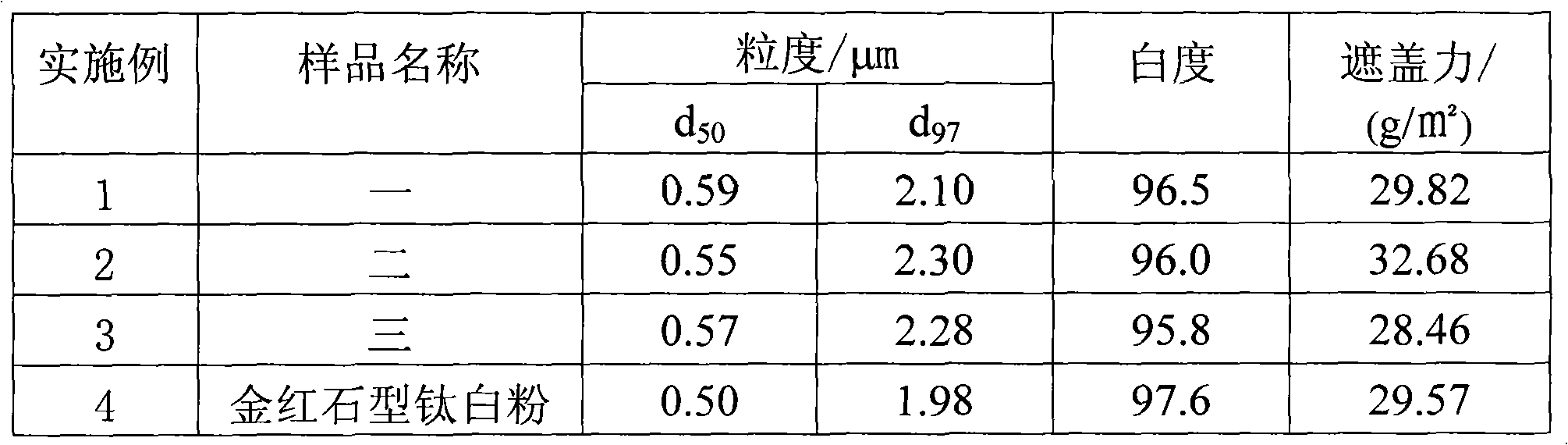

Preparation method of inorganic composite white pigment with high covering power

InactiveCN101775239AEfficient use ofReduce manufacturing costPigment physical treatmentColored whiteWhite powder

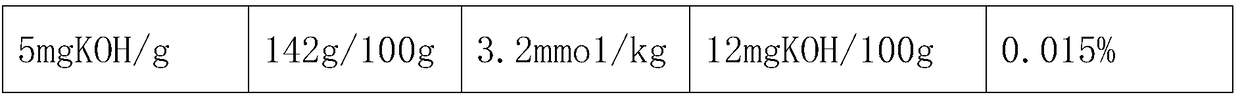

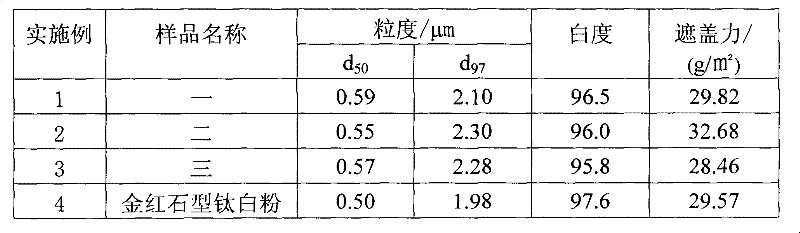

The invention relates to a preparation method of an inorganic composite white pigment with high covering power. The method comprises the steps of: taking titanium white powder and white mineral powder or composite white mineral powder as raw materials; taking a wet ultrafine stirring grinder or a sand miller as a compound device; performing segmented wet ultrafine grinding and compounding to the titanium white powder and the white mineral powder by adding a certain quantity of pH adjusting agent and dispersing agent; and drying and mechanically dispersing and depolymerizing size after ultrafine grinding and compounding to prepare the inorganic composite white pigment which can be used by replacing the titanium white powder, wherein the performance indexes such as the granularity, the whiteness and the covering power, and the like, of the inorganic composite white pigment are as the same as or similar with the granularity, the whiteness and the covering power of the titanium white powder. The method has simple preparation technology, lower preparation cost and cleaning preparation process.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

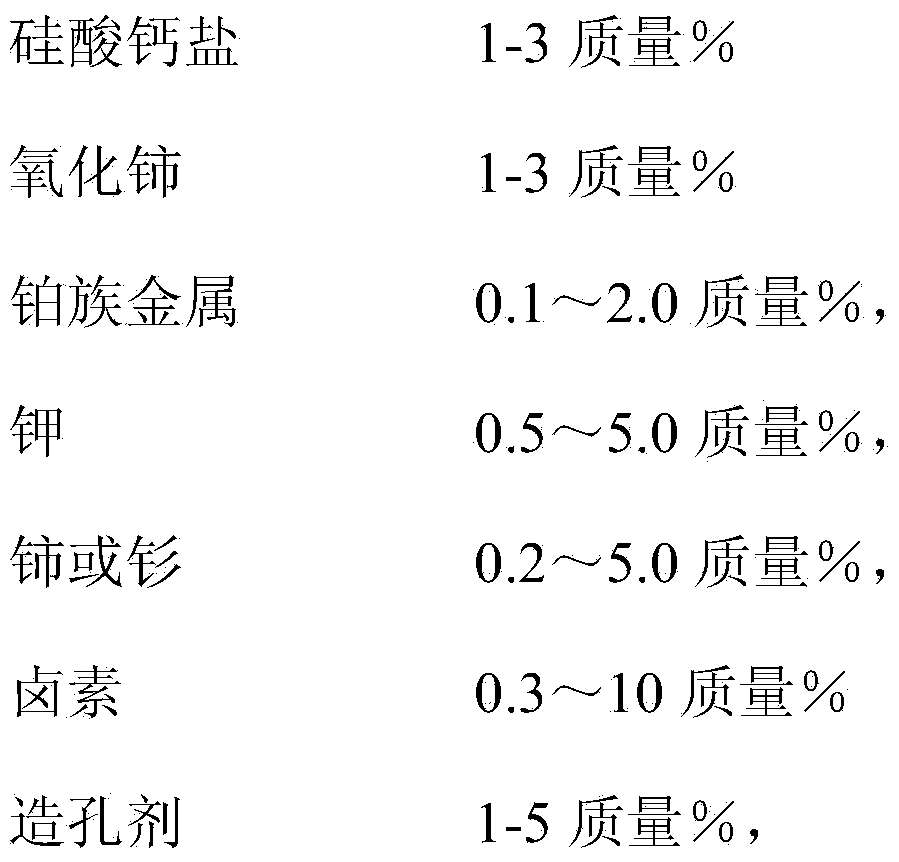

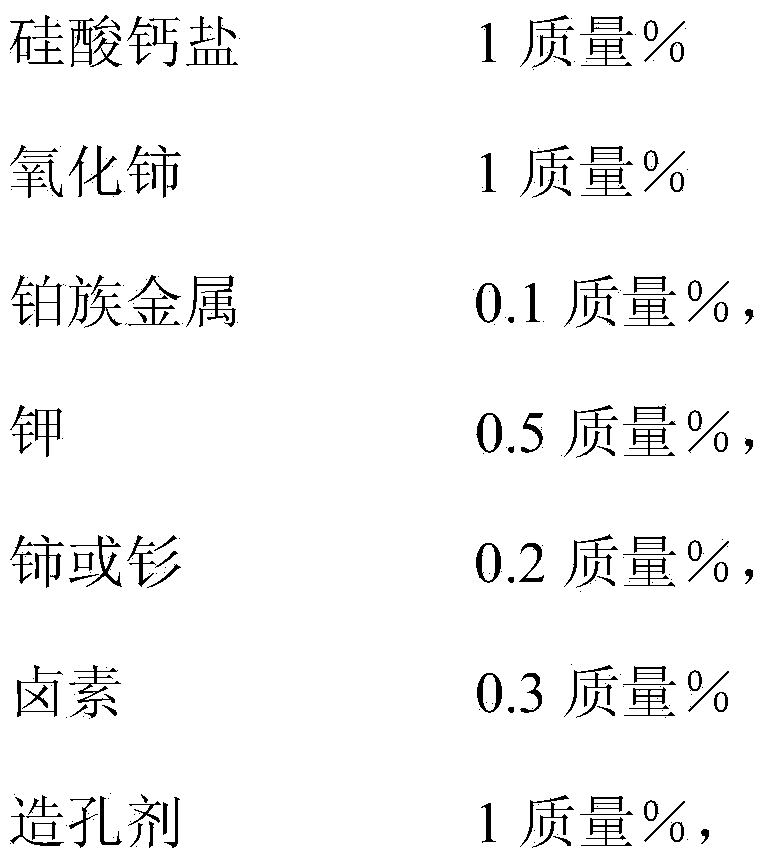

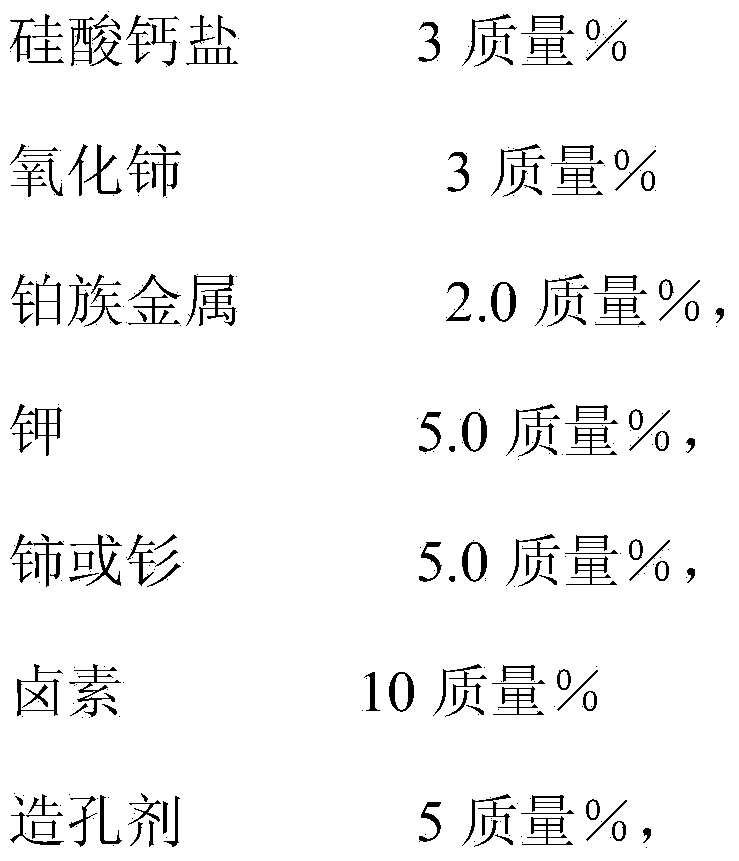

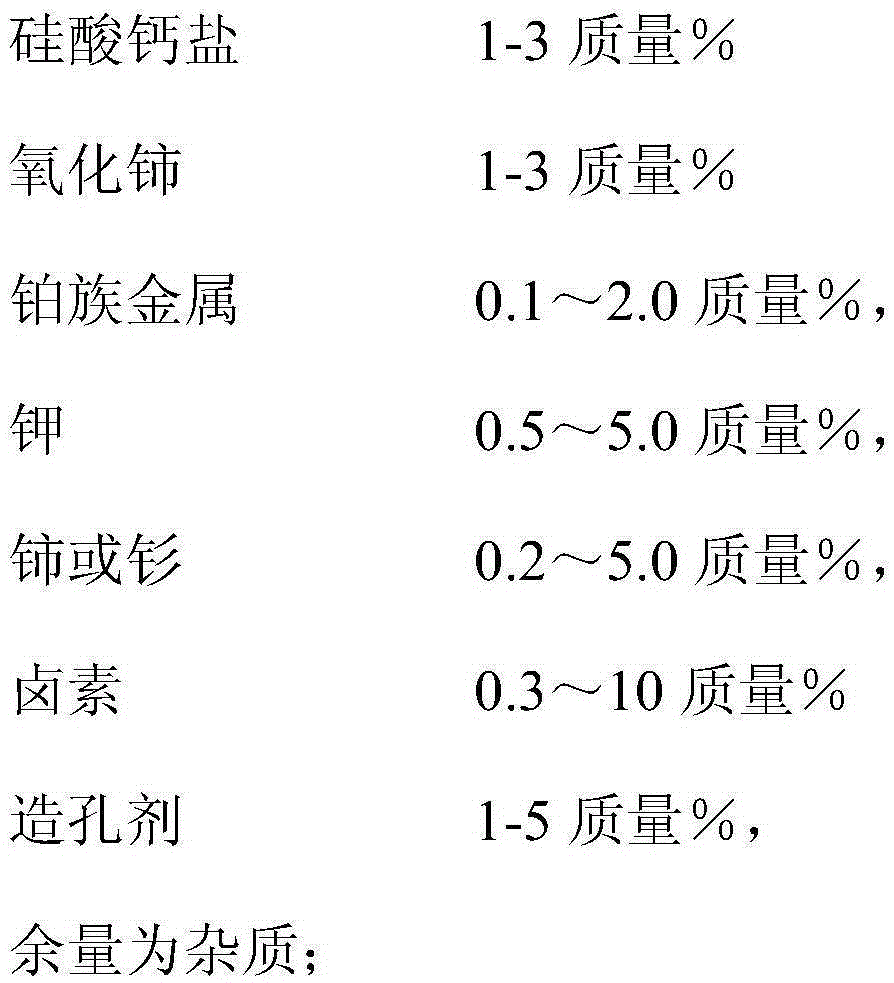

Preparation method of catalyst for preparing propylene by virtue of propane dehydrogenation

InactiveCN104368364AAvoid it happening againAvoid Contaminated SituationsPhysical/chemical process catalystsHydrocarbonsCalcium silicateHydrogen halide

The invention discloses a preparation method of a catalyst for preparing propylene by virtue of propane dehydrogenation. The catalyst comprises an aluminum oxide carrier and active components with the following contents in percentage by mass calculated based on the carrier: 1-3% of calcium silicate salt, 1-3% of cerium oxide, 0.1-2.0% of a platinum group metal, 0.5-5.0% of potassium, 0.2-5.0% of cerium or samarium, 0.3-10% of halogen, 1-5% of a pore forming agent and the balance of impurities, wherein the molar ratio of cerium or samarium to the platinum group metal is 7:8; the platinum group metal is platinum; and halogen is chlorine. The preparation method comprises the following steps: soaking, drying and roasting the aluminum oxide carrier by using a soluble compound solution of cerium or samarium and a calcium silicate salt solution, then soaking, drying and roasting by using a solution containing compounds of the platinum group metal and hydrogen halide, and then soaking, drying and roasting by using a potassium salt solution; and then mixing cerium oxide and the pore forming agent with corresponding amounts, and roasting for 3 hours at 600 DEG C to obtain the catalyst for preparing propylene by virtue of propane dehydrogenation.

Owner:华玉叶

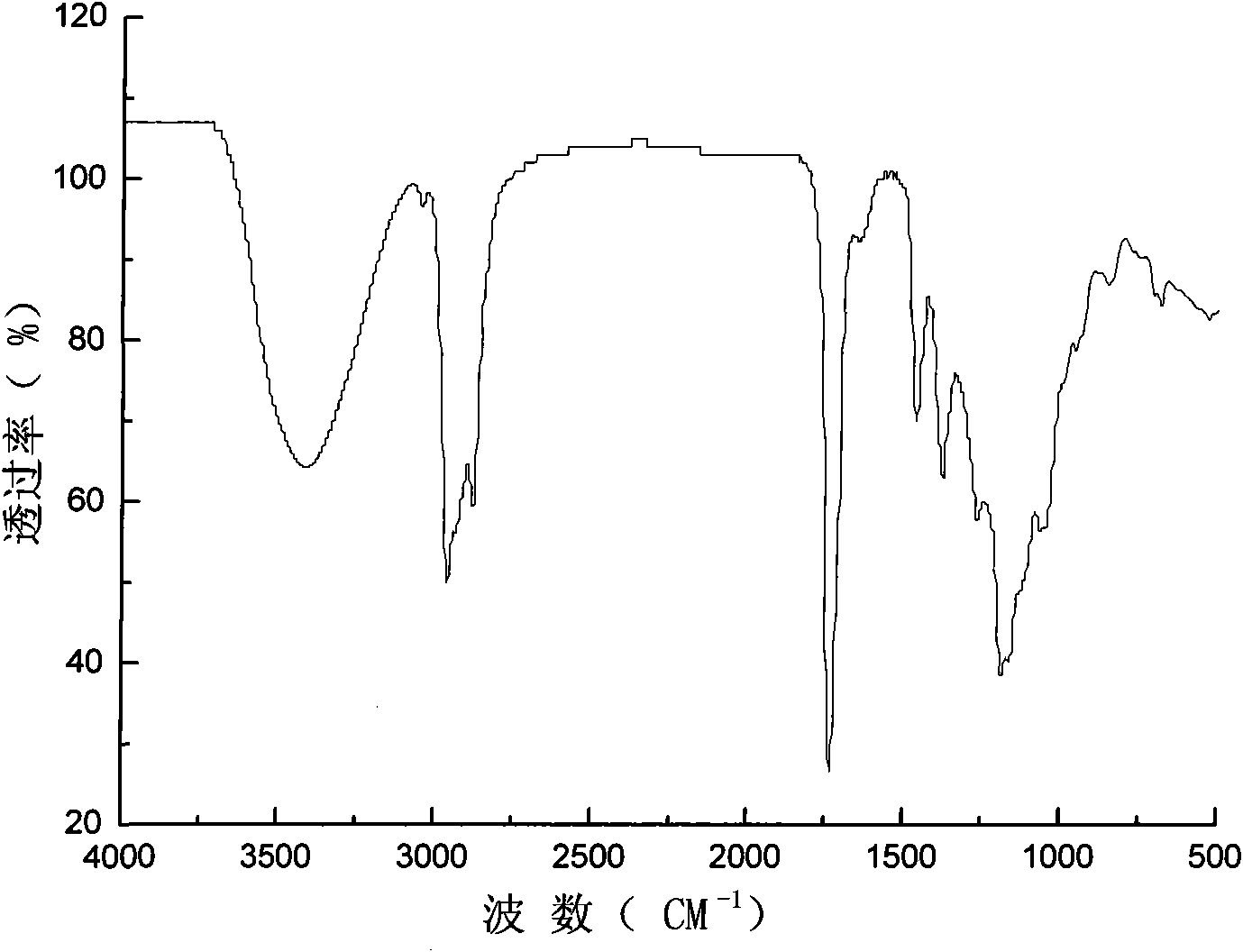

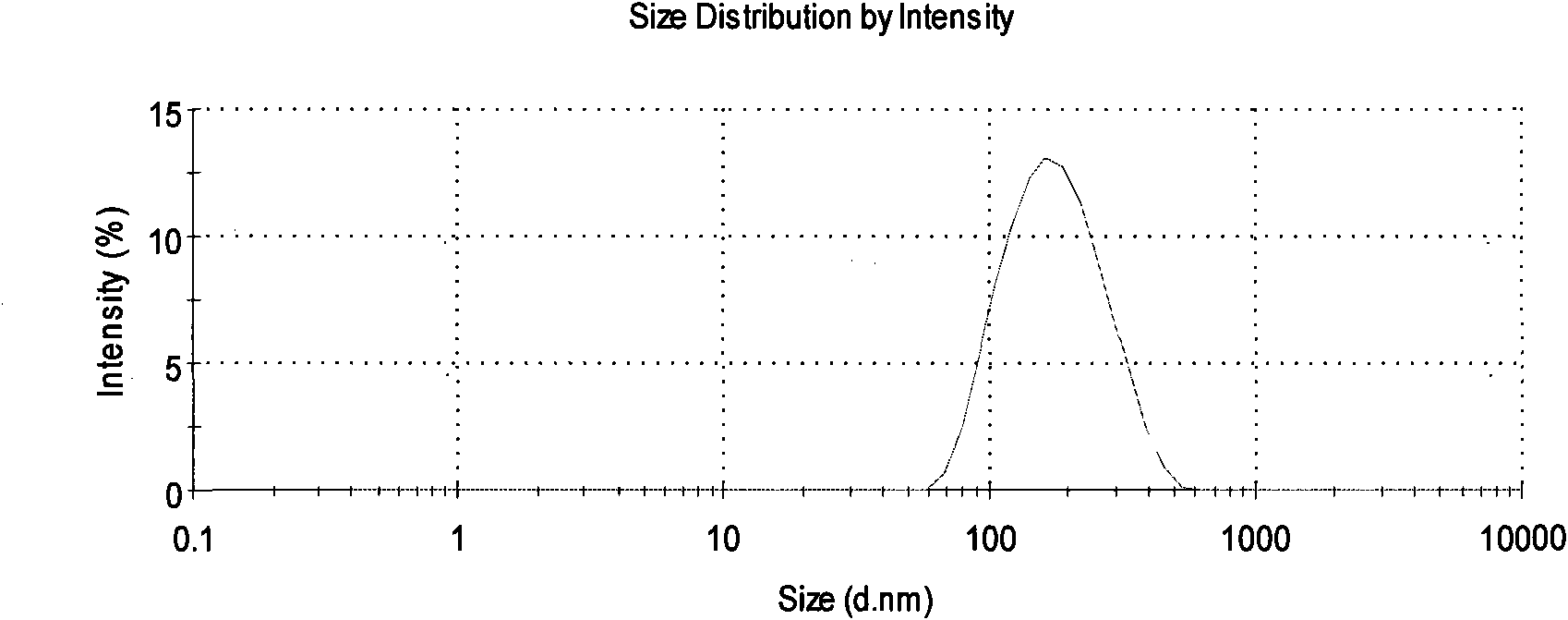

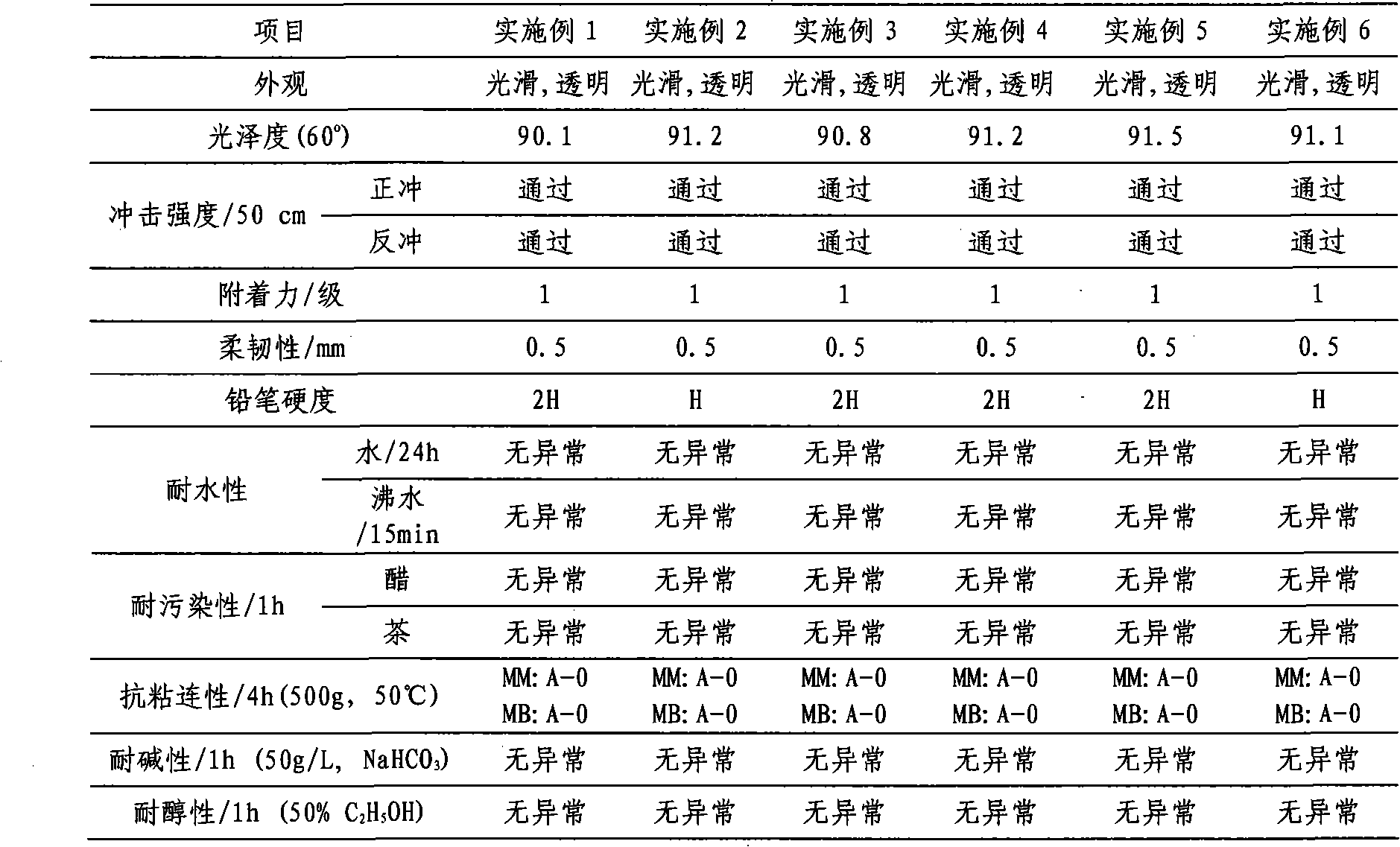

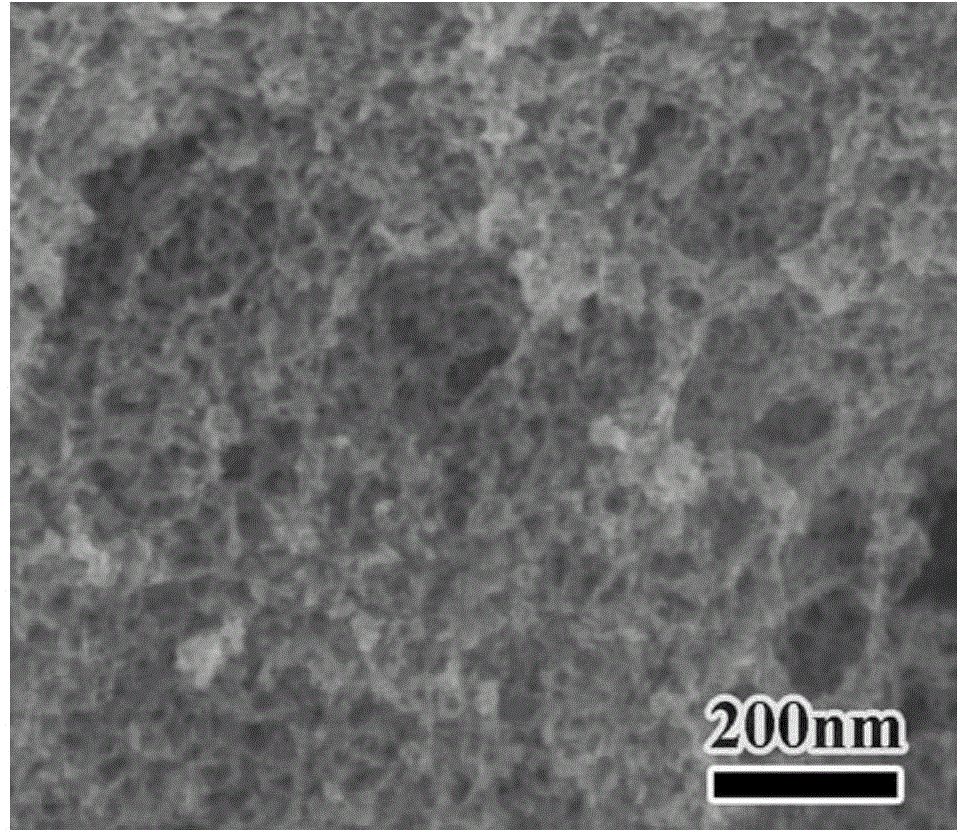

Preparation method of cationic terpenyl epoxy resin polyalcohol water dispersoid and application thereof

InactiveCN101701059AEasy to prepareCleaning preparationPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsEpoxySolvent

The invention discloses a preparation method of cationic terpenyl epoxy resin polyalcohol water dispersoid and an application thereof. In the method, terpenyl maleic anhydride epoxy resin of glycidyl ester or hydrogenated terpenyl maleic anhydride epoxy resin of glycidyl ester is utilized to react with diethanol amine and micromolecule hydroxy chain extender under the action of catalyst to obtain the polyalcohol product, the polyalcohol product is neutralized with acid and directly disperses in water to obtain self-emulsifying cationic terpenyl epoxy resin polyalcohol water dispersoid. The polyalcohol water dispersoid is a bicomponent aqueous polyurethane system which is combined by hydroxyl component and polyisocyanate and can be widely applied to water paint, binding agent and polymer materials. The preparation method is simple and convenient, the preparation process is clean, the reaction process has no solvent, and stable self-emulsifying water dispersoid can be obtained with no need of stirring at a high speed; the hydroxyl value and the glass transition temperature of the polyalcohol resin can be adjusted along with the type and use level of the micromolecule chain extender; and the prepared bicomponent aqueous polyurethane paint film has excellent ultraviolet resistance and anti-yellowing performances.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

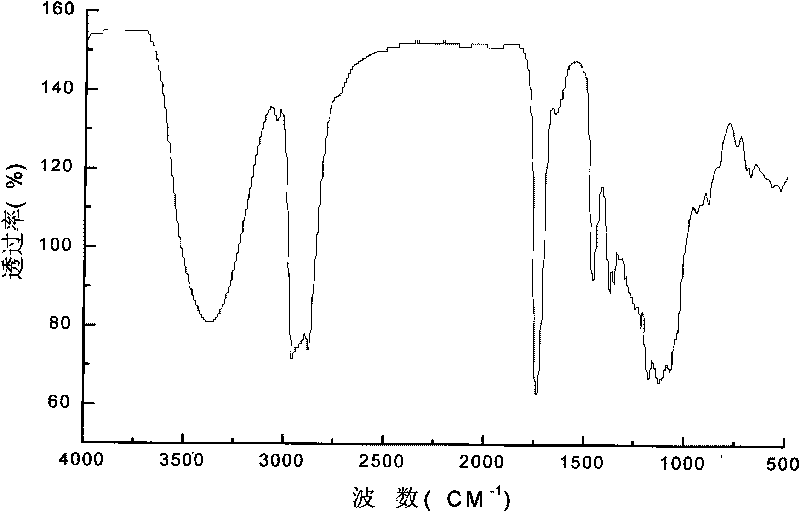

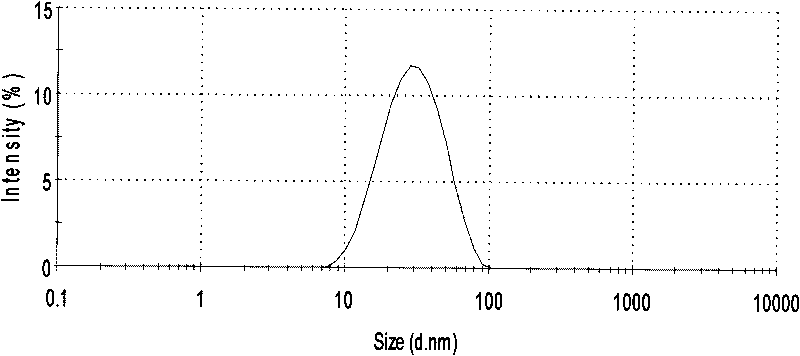

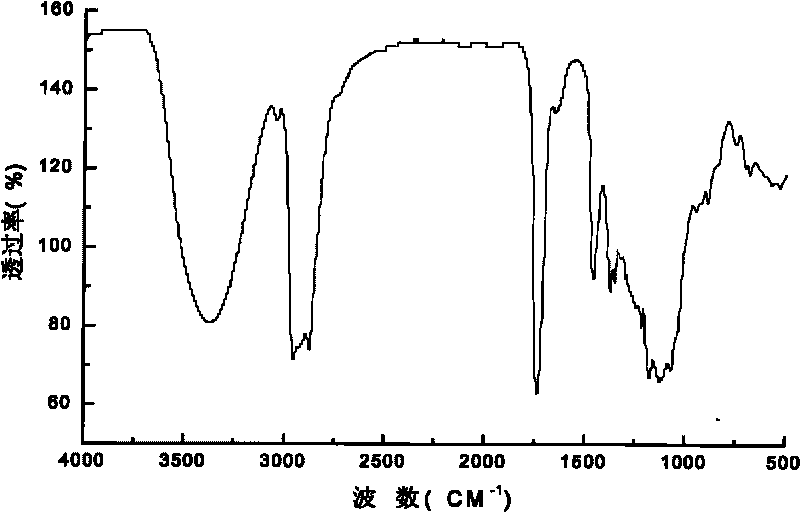

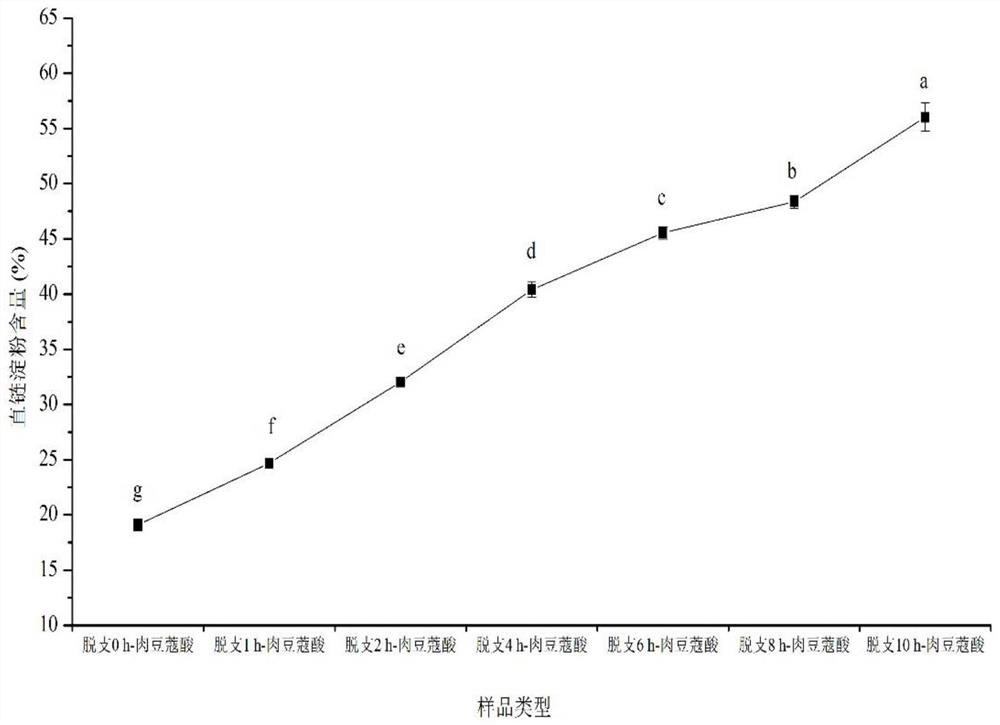

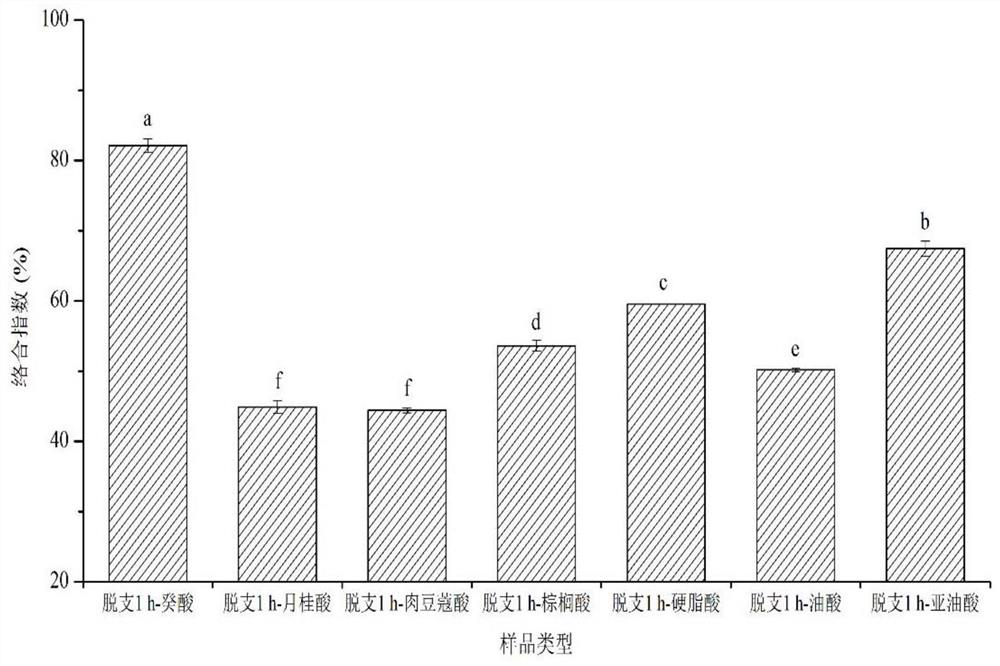

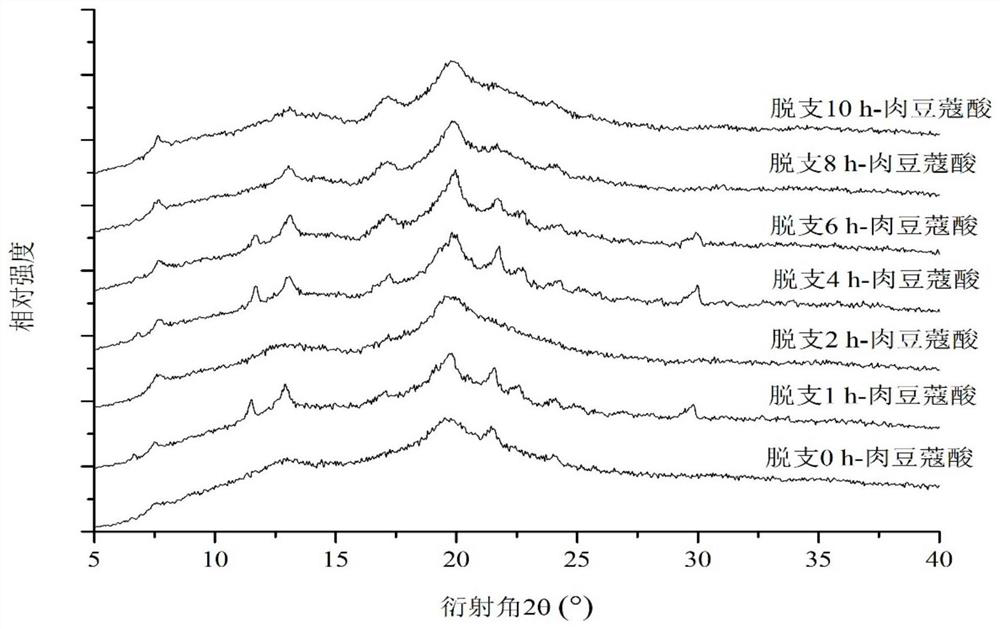

Preparation method of debranched starch-lipid compound

ActiveCN111675830AComplexation index controllableFully develop application potentialMetabolism disorderDigestive systemPolymer scienceEnzymatic hydrolysis

The invention discloses a preparation method of a debranched starch-lipid compound, and belongs to the technical field of modified starch processing. The method comprises the following steps: taking starch as a raw material, carrying out de-branching modification on the starch by adopting a de-branching enzyme, carrying out structural modification on the starch so as to improve the complexing capacity of the starch, and preparing the debranched starch-lipid compound in a water phase system by taking lipid as a ligand. Ordinary starch is used as a raw material; the debranched starch-lipid compound is prepared through enzymatic hydrolysis, de-branching modification and lipid complexing, the debranched starch-lipid compound and common starch interact with each other, the content of digestion-resistant starch in the product is greatly increased and can reach 39% at most, and the debranched starch-lipid compound has good effects of reducing blood sugar and benefiting intestinal tracts, hasa higher resistant starch content compared with that of a high-amylose corn starch-lipid compound, and is lower in cost.

Owner:JIANGNAN UNIV

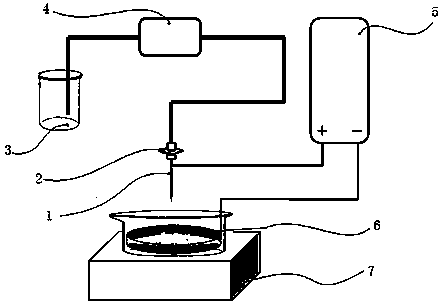

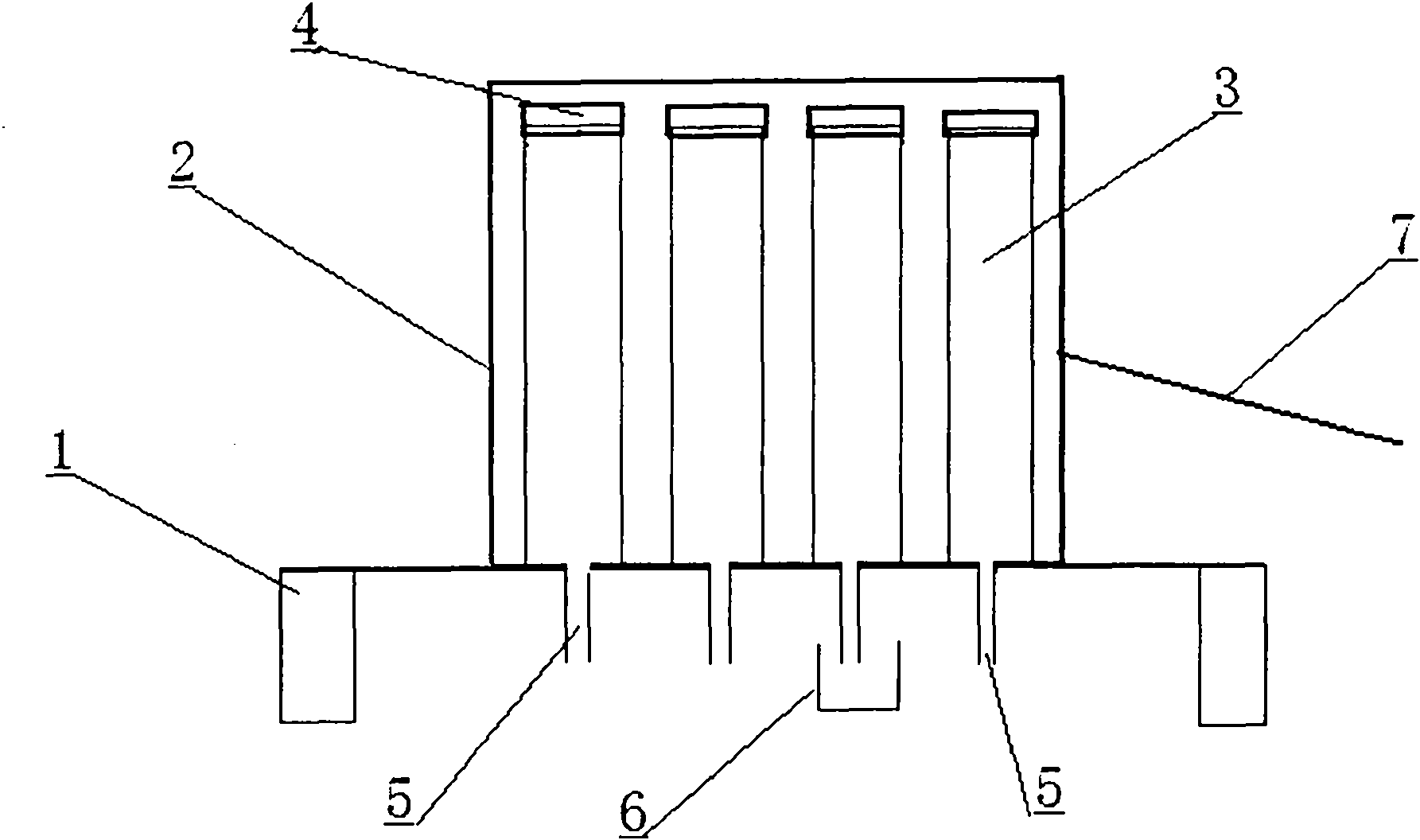

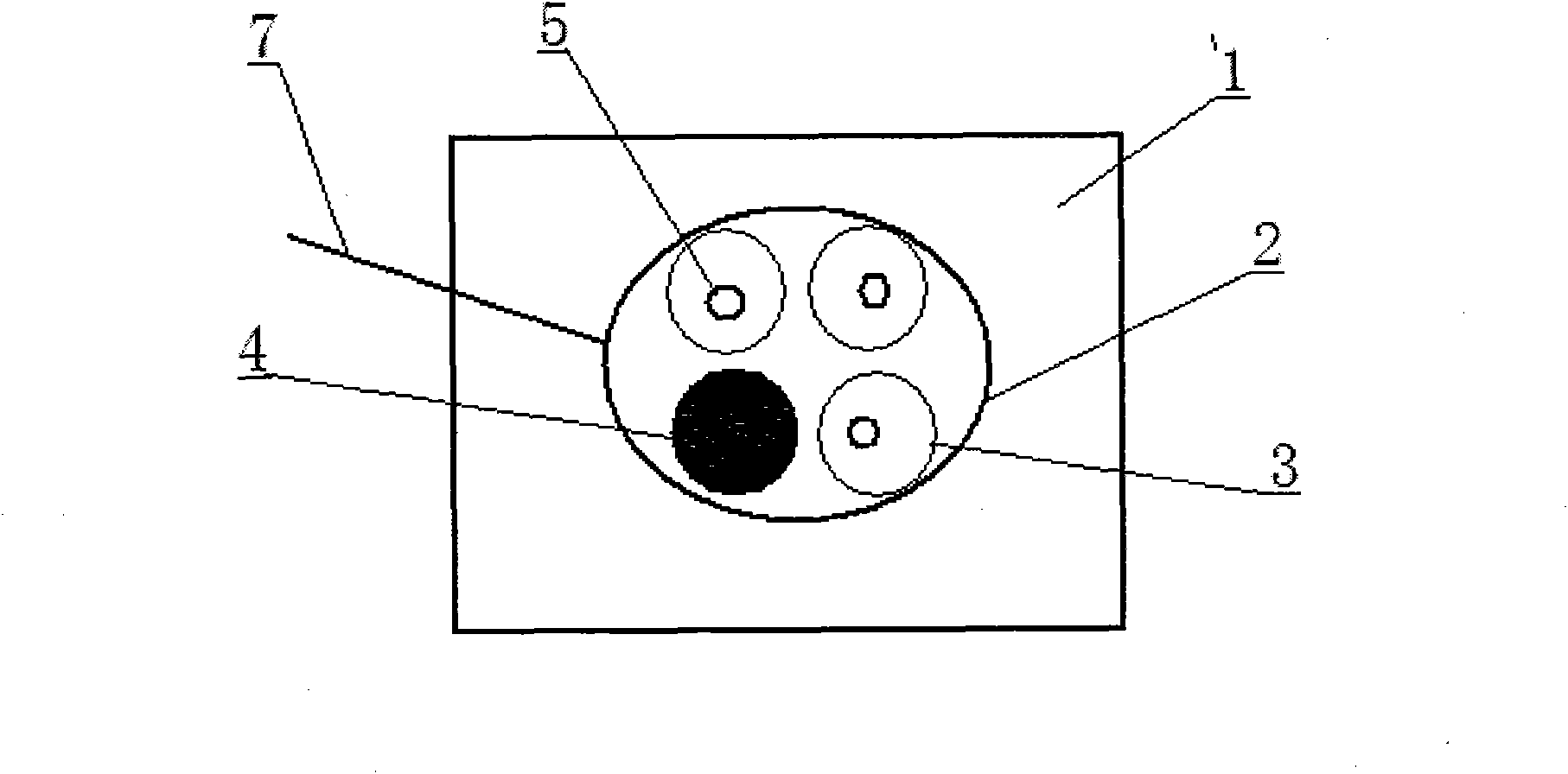

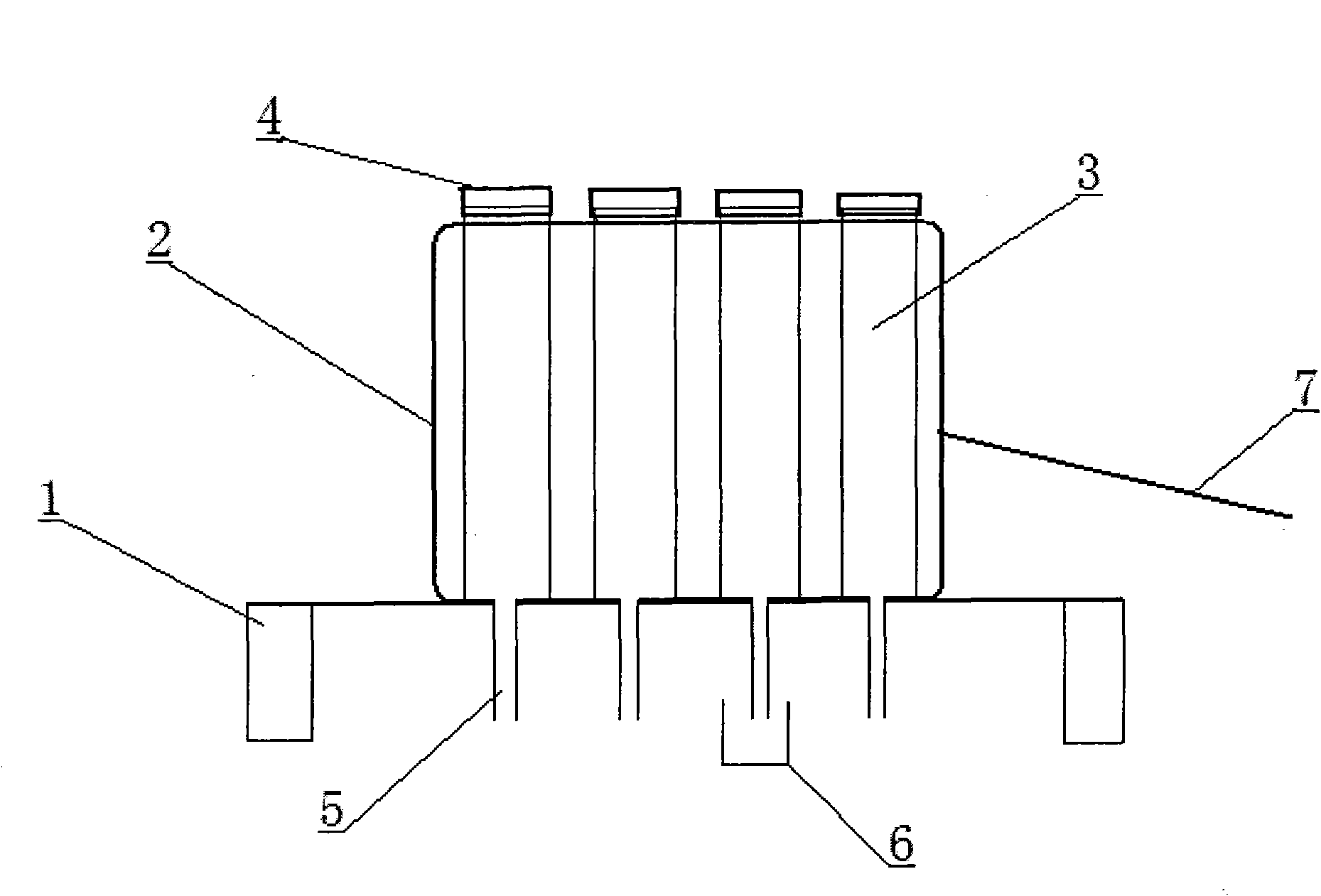

Preparation method and apparatus of chitosan beads

The invention relates to a preparation method and apparatus of chitosan beads. Chitosan beads are prepared by using chitosan as a raw material. The preparation method comprises the steps: preparing a chitosan solution and a coagulation bath solution, coagulating chitosan into beads, washing the chitosan beads and storing the chitosan beads. The preparation apparatus is provided with a rack, wherein a chitosan bead forming container is arranged on a base, a dropper is arranged at the middle of the rack, a constant-flow pump, a direct current power supply and a chitosan solution bead stirrer are arranged on the rack, one electrode of the direct current power supply is connected with the dropper, and the other electrode of the direct current power supply is connected with a conductive ring in the coagulation bath solution, or is connected with the metal chitosan bead forming container. The preparation method has the advantages of stable process conditions, high efficiency, good quality of the chitosan beads, and is easy to operate and continuous in operation; the preparation method is clean in preparation process, and is a safe preparation method of the chitosan beads without generating toxic pollutants; the preparation apparatus of the chitosan beads is simple, small in occupation area, high in efficiency, low in energy consumption and capable of realizing industrialized scale production.

Owner:HUAZHONG AGRI UNIV

Self-emulsified nonionic terpenyl epoxy resin polyalcohol emulsion and preparation method and application

ActiveCN101914194AImprove dispersion stabilityEasy to preparePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsDispersion stabilityEpoxy

The invention discloses self-emulsified nonionic terpenyl epoxy resin polyalcohol emulsion and a preparation method and application. The method comprises the following steps of: reacting hydroxyl and an epoxy group under the action of a catalyst by using a terpinene-maleic eater (TME) or a hydrogenated terpinene-maleic eater (HTME), polyethylene glycol (PEG) and a micro-molecule hydroxy chain extender; introducing a hydrophilic chain section polyethylene glycol (PEG) into a product to obtain a polyalcohol pre-polymer; and directly dispersing the polyalcohol pre-polymer with water to obtain the self-emulsified nonionic terpenyl epoxy resin polyalcohol emulsion. The polyalcohol emulsion is a bi-component waterborne polyurethane system consisting of a hydroxy component and polyisocyanate and can be widely applied to waterborne polymer systems such as paint, an adhesive and the like. The emulsion has the advantages of simple and convenient preparation method, clean preparation process, no solvent in a reaction process and high dispersion stability. The hydroxyl value of a polyalcohol resin is adjustable along with the adding amount of the micro-molecule chain extender. A prepared bi-component waterborne polyurethane paint film has high heat resistance and mechanical property.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

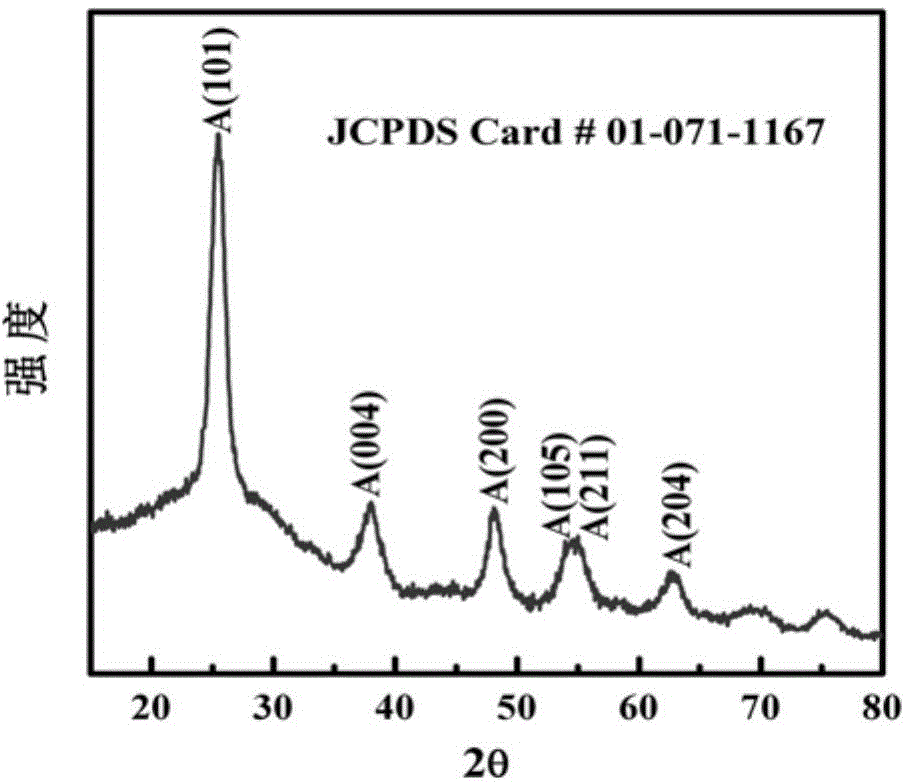

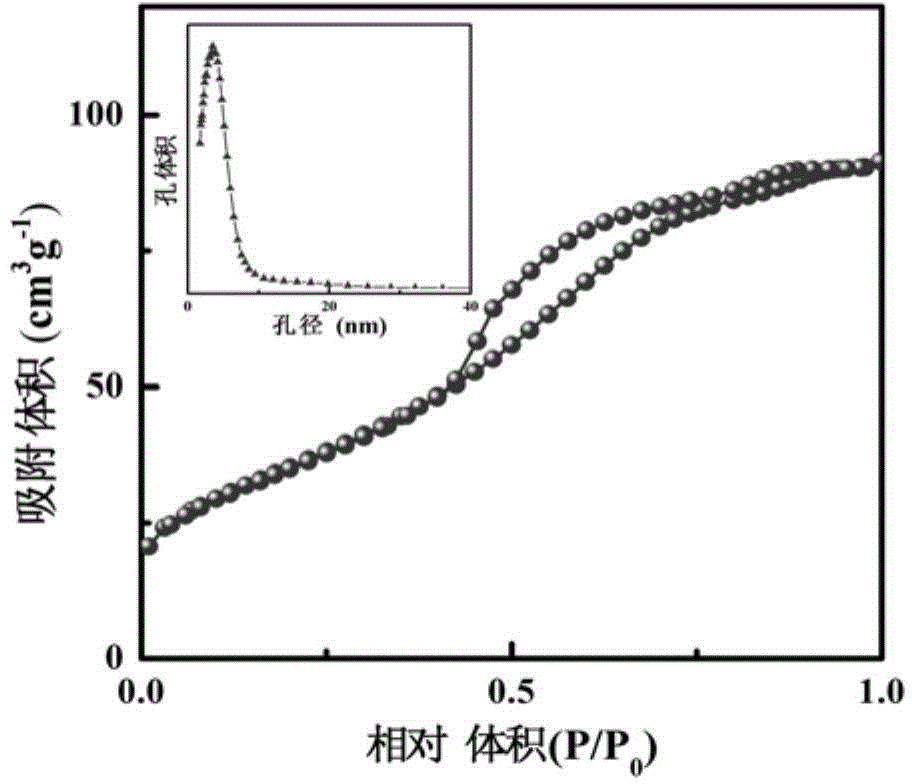

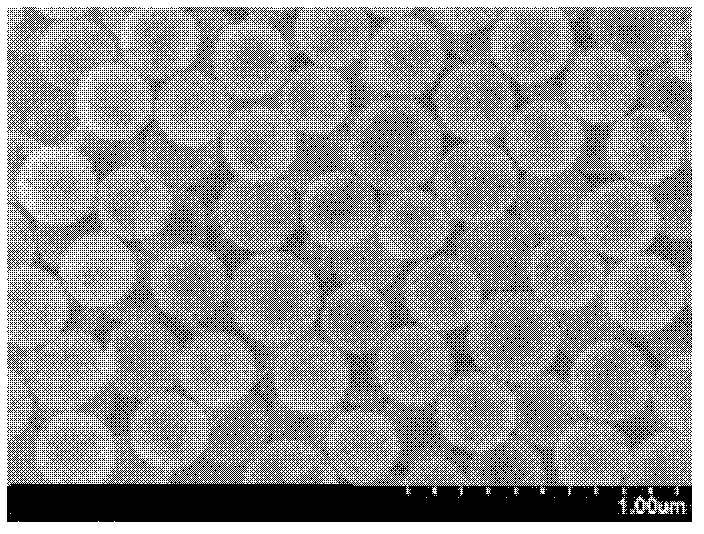

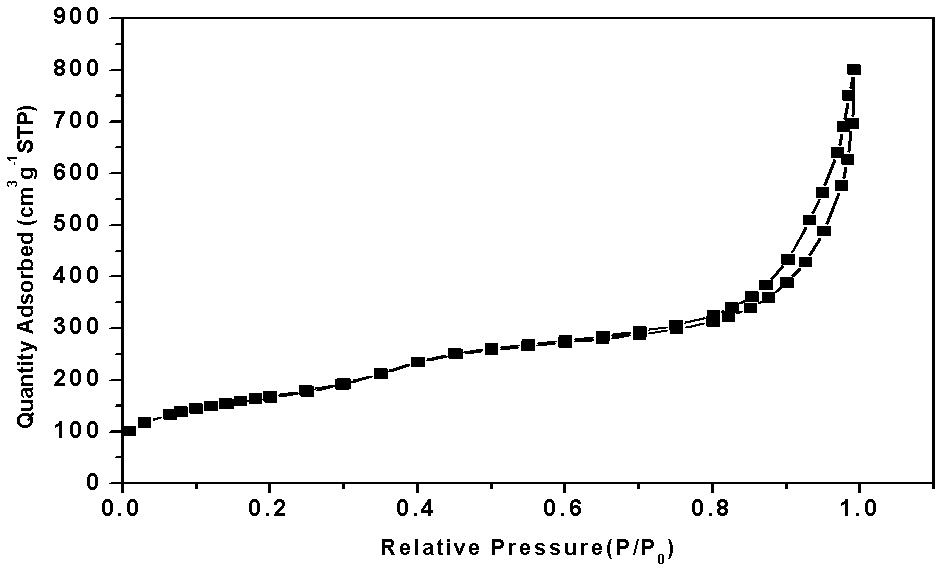

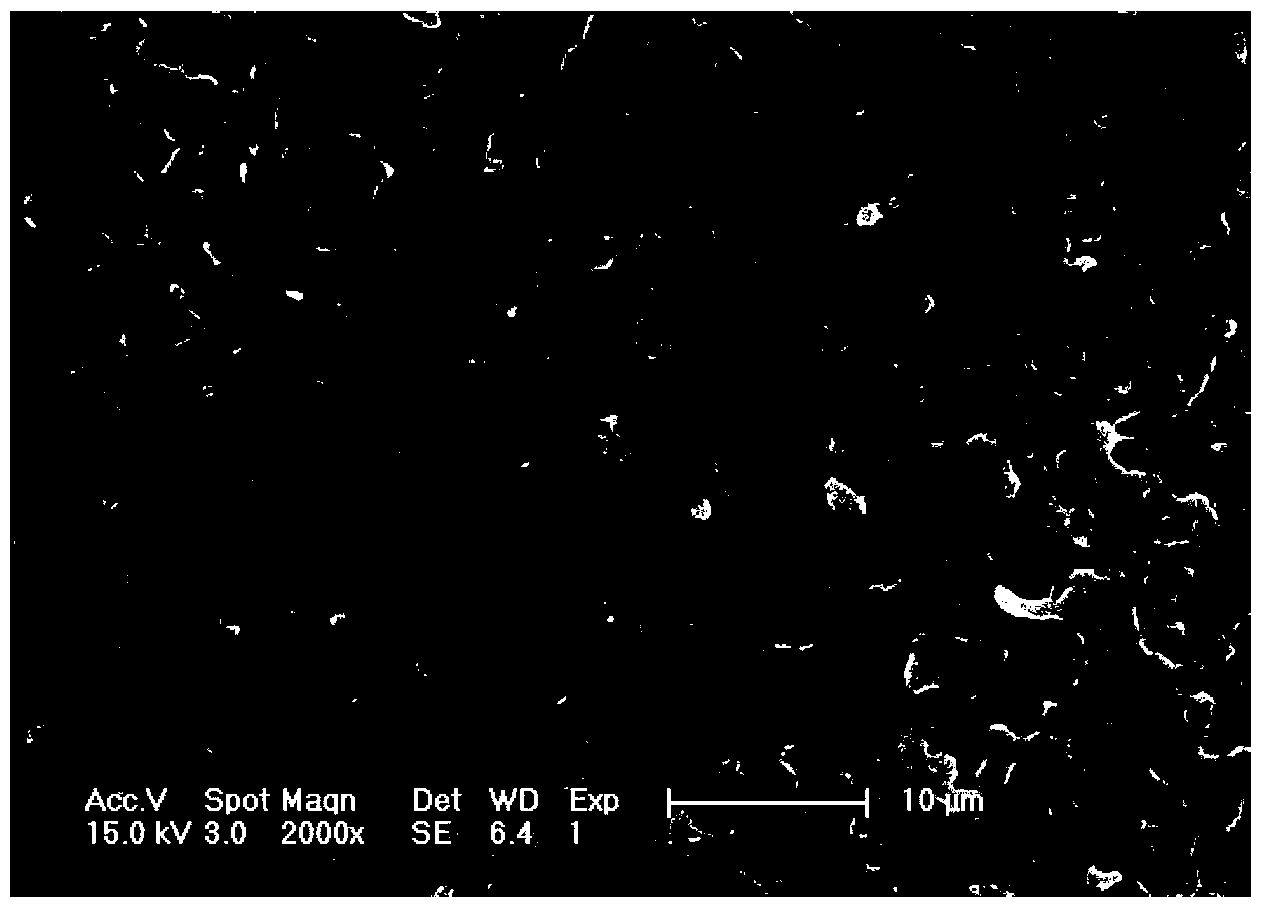

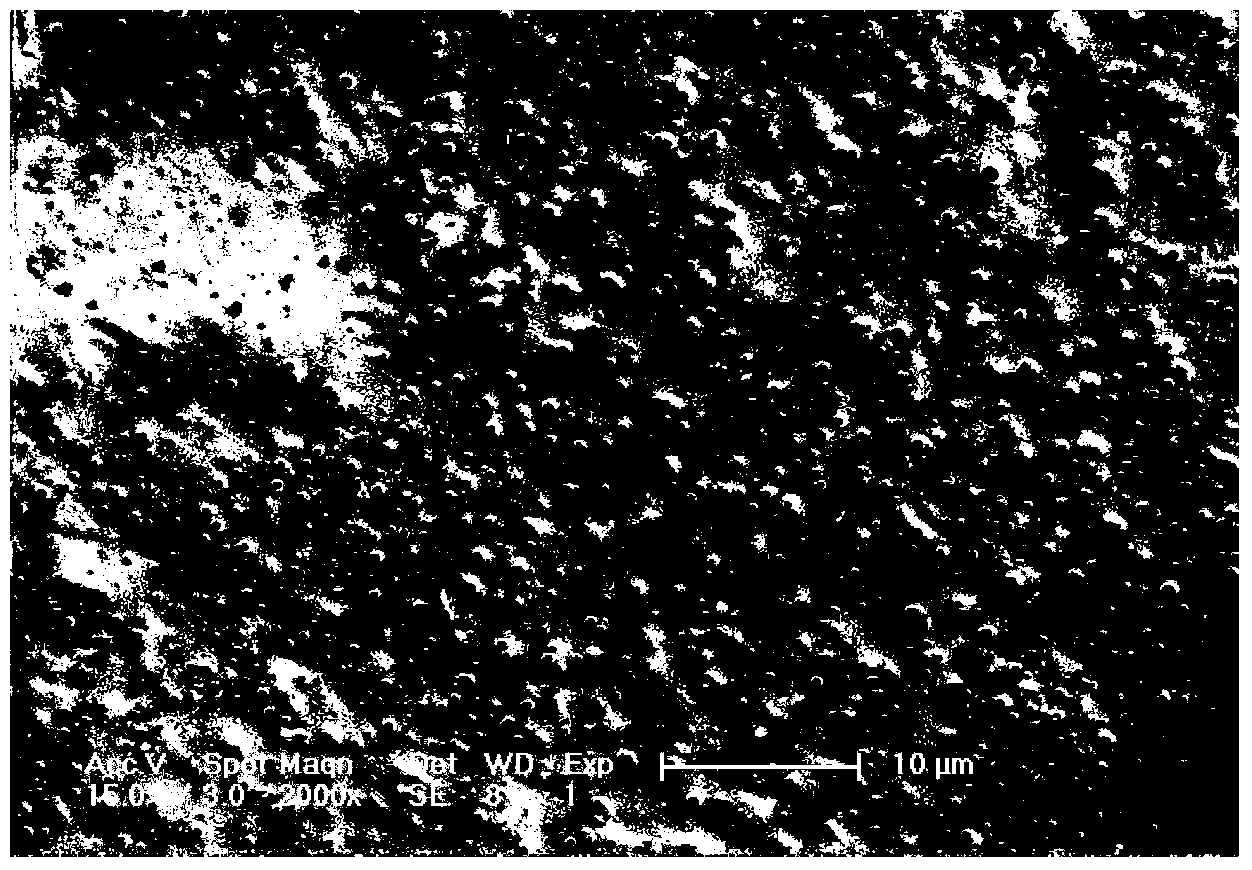

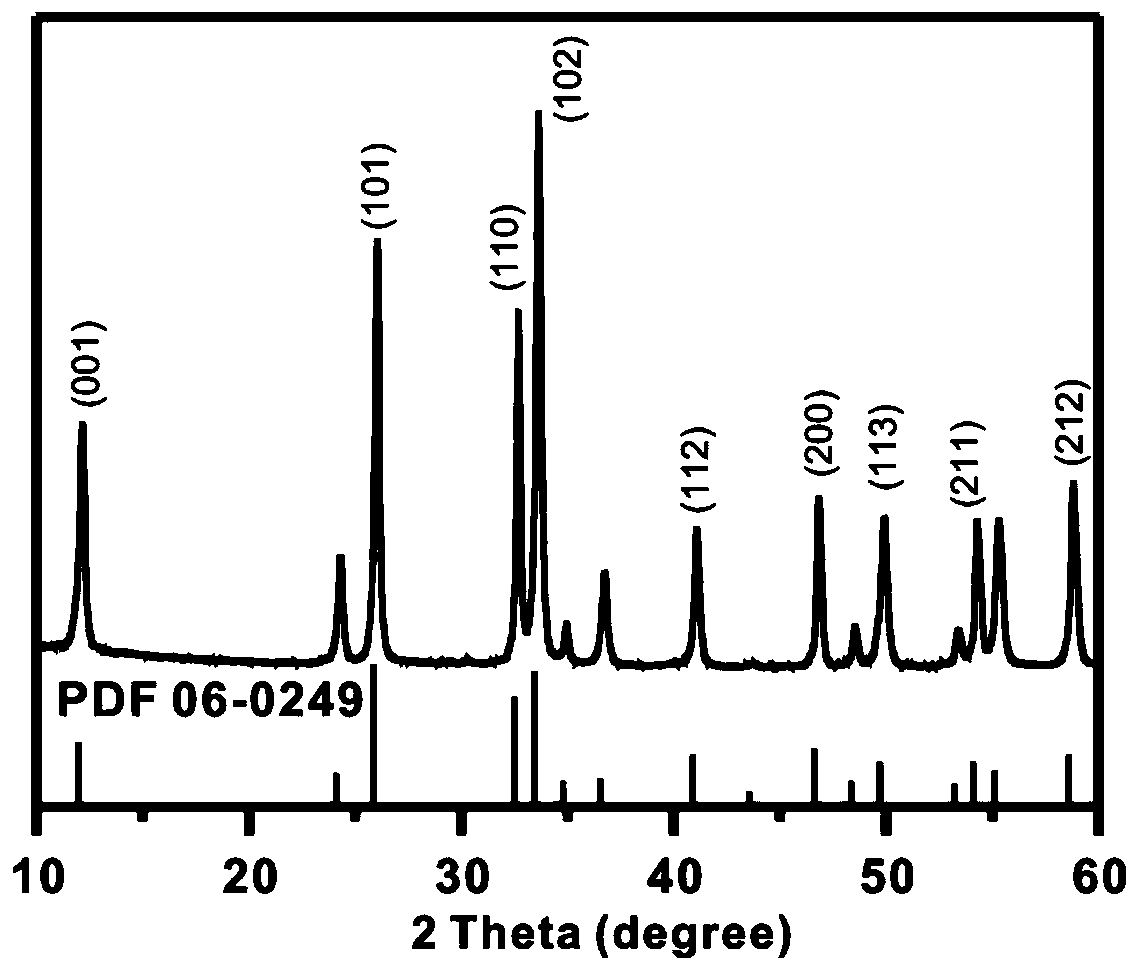

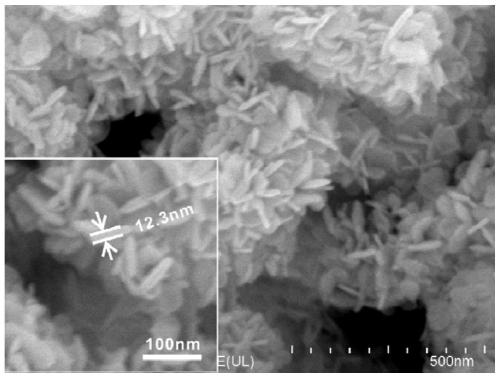

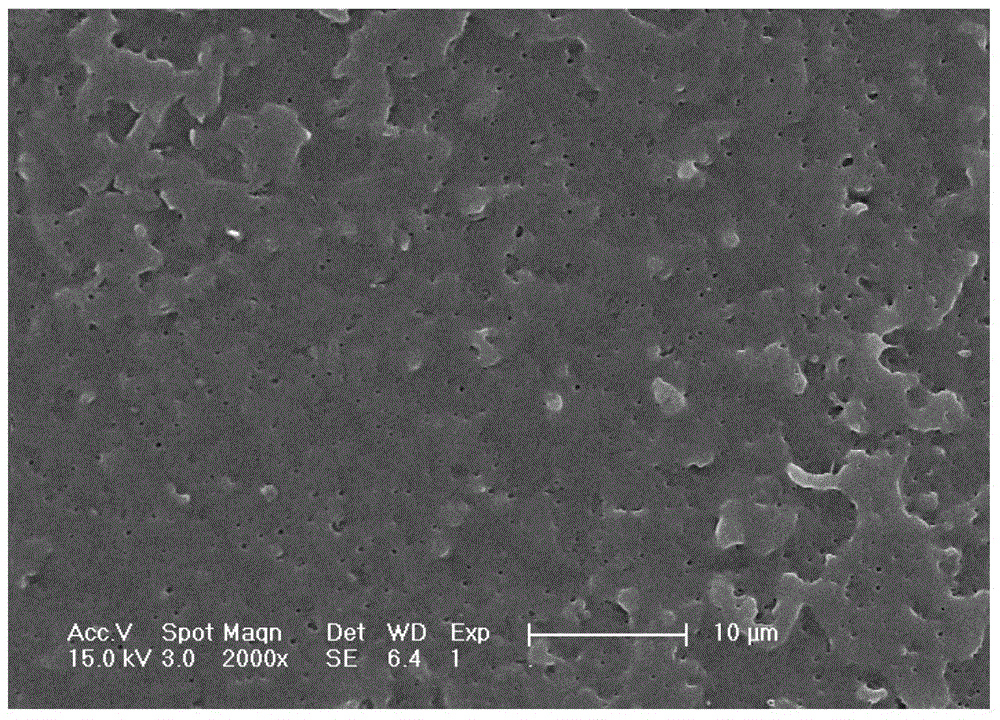

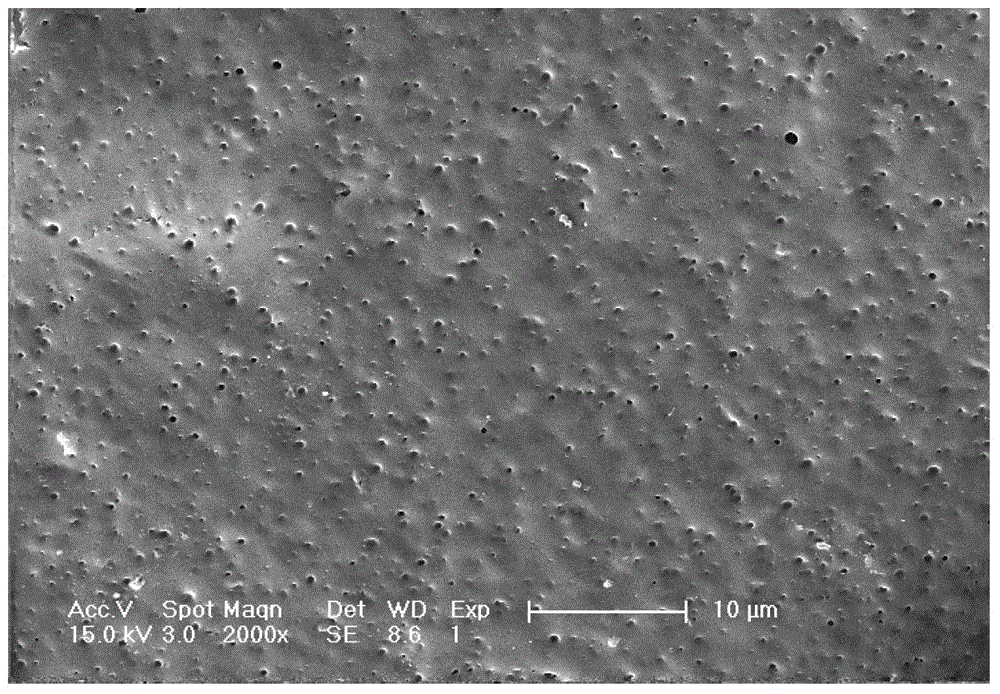

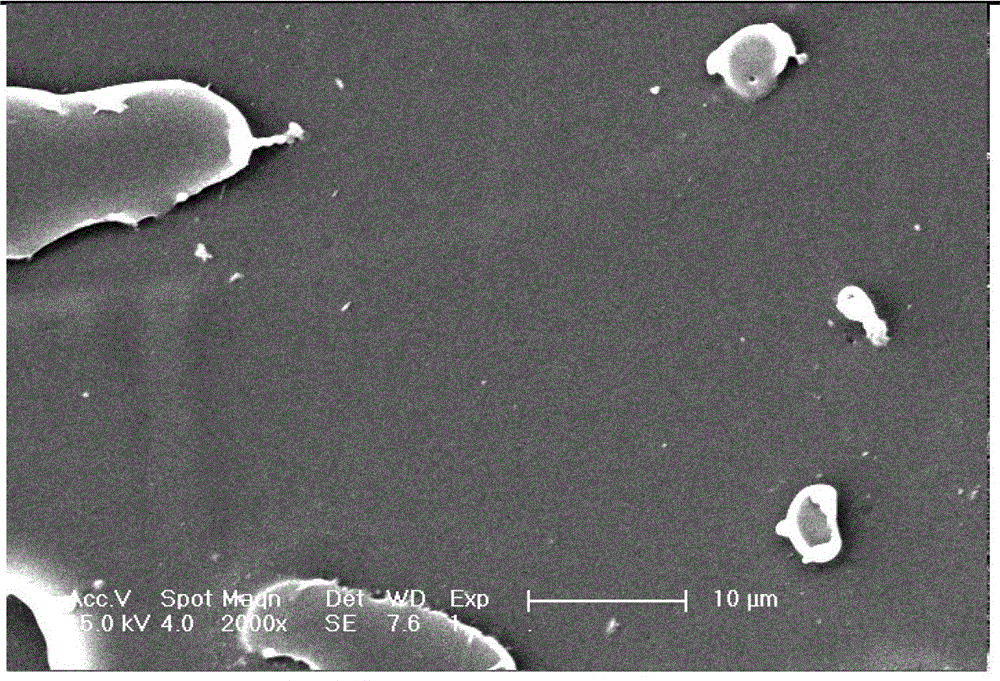

Web-type three-dimensional perforated macroporous-mesoporous-structure titanium dioxide material, and preparation method and application thereof

InactiveCN104787799AEasy to prepareProcess conditions are not harshMaterial nanotechnologyPhysical/chemical process catalystsSelf-assemblyTitanium dioxide

The invention relates to a web-type three-dimensional perforated macroporous-mesoporous-structure titanium dioxide material, and a preparation method and application thereof. The material is formed by regulating the self-assembly of biomolecules; the crystal form is anatase; on the basis of the macroporous structure formed by accumulation of titanium dioxide particles, the embedded mesopores are regulated on the macroporous structure, and the pore wall and particles thereof, thereby forming the three-dimensional perforated macroporous-mesoporous structure; and the pore size of the macropores is 90-100nm, the pore wall thick is 8-10nm, and the pore size of the mesopores distributed in the titanium dioxide particles is 3-5nm. Compared with the prior art, the material provided by the invention has the advantages of simple preparation process and non-severe technological conditions, and can implement large-scale industrial production; and the method is safer and cleaner to operate. The material has the special macroporous-mesoporous perforated pore structure, and thus, is beneficial to transfer and embedment of lithium ions, thereby enhancing the electrochemical properties. The material obtains higher reversible capacity and excellent cycle performance.

Owner:WUHAN UNIV OF TECH

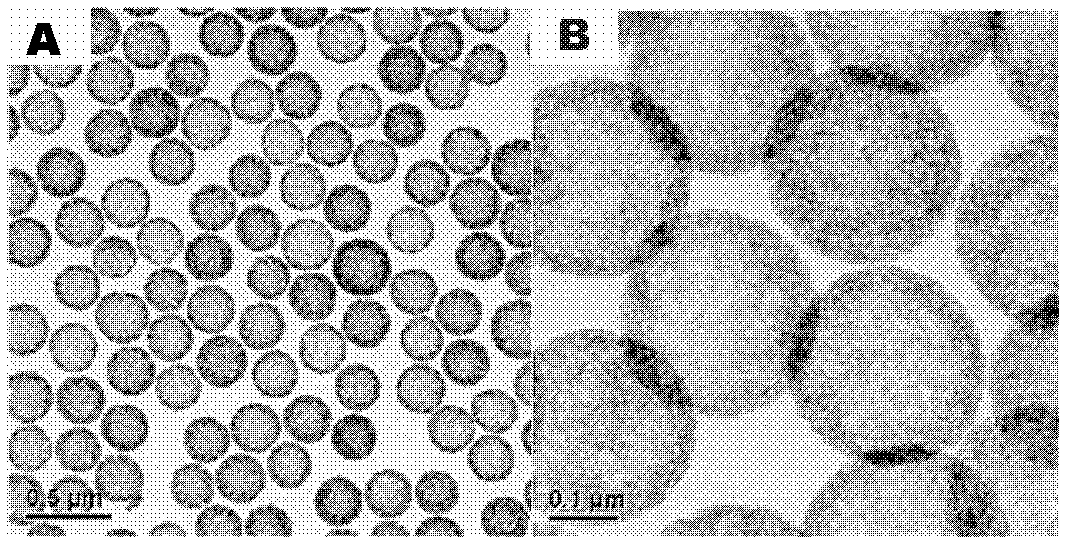

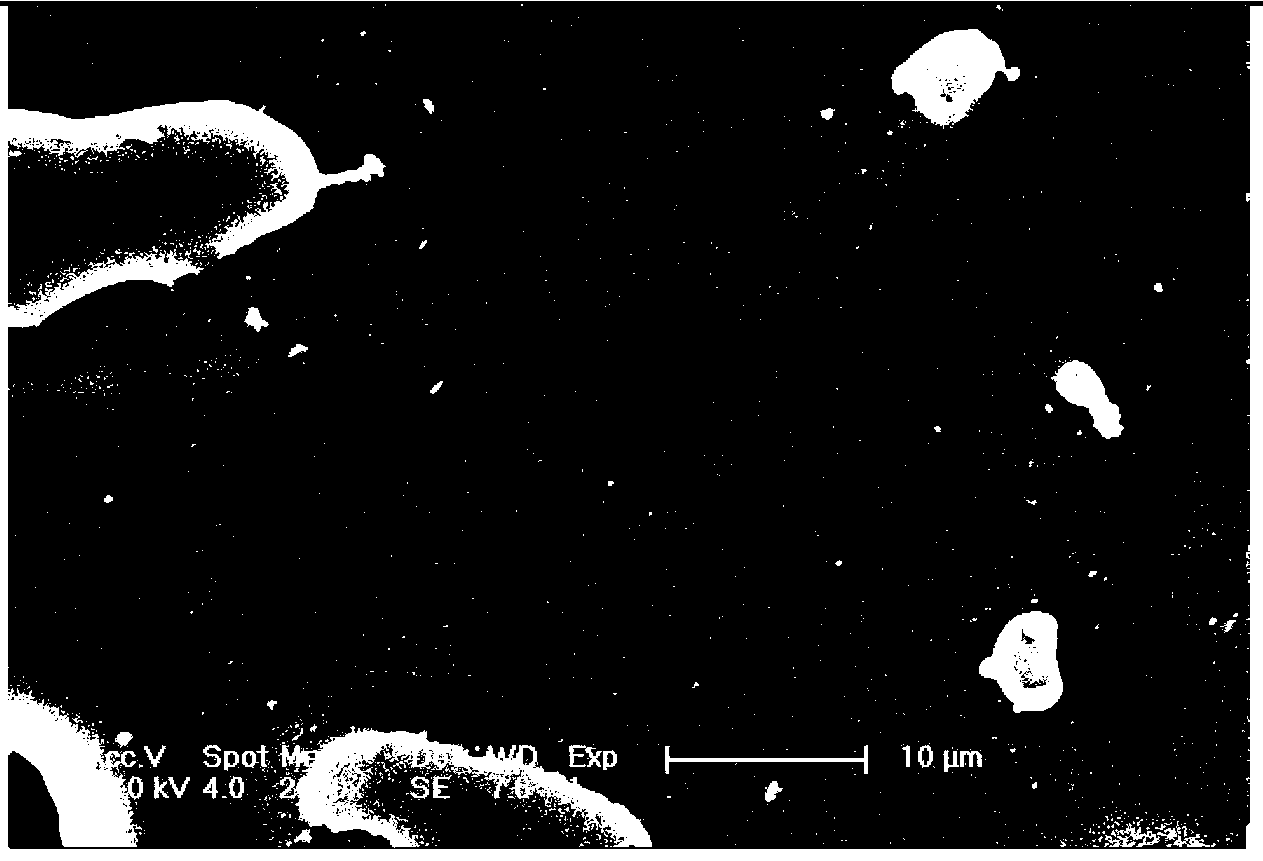

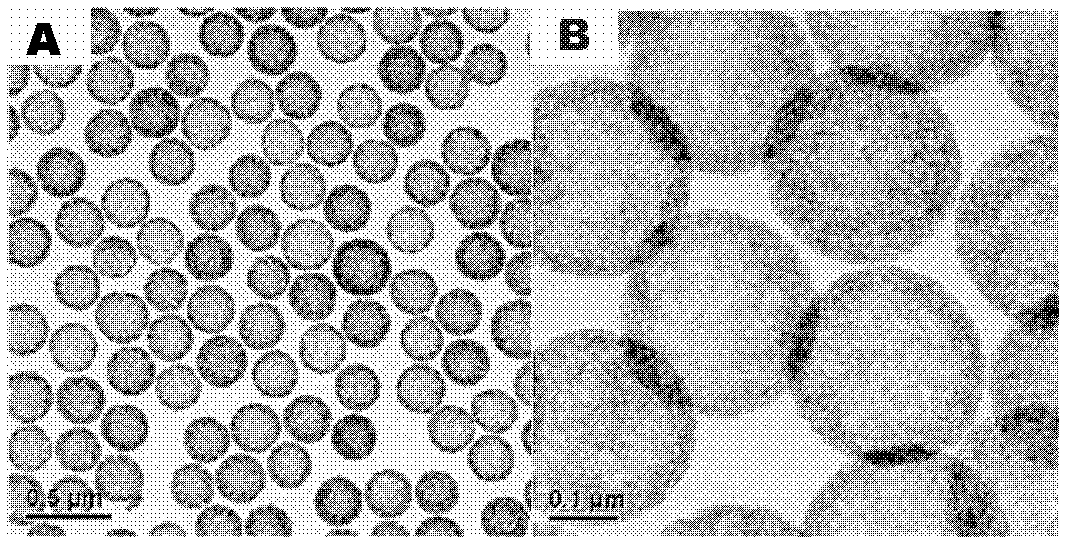

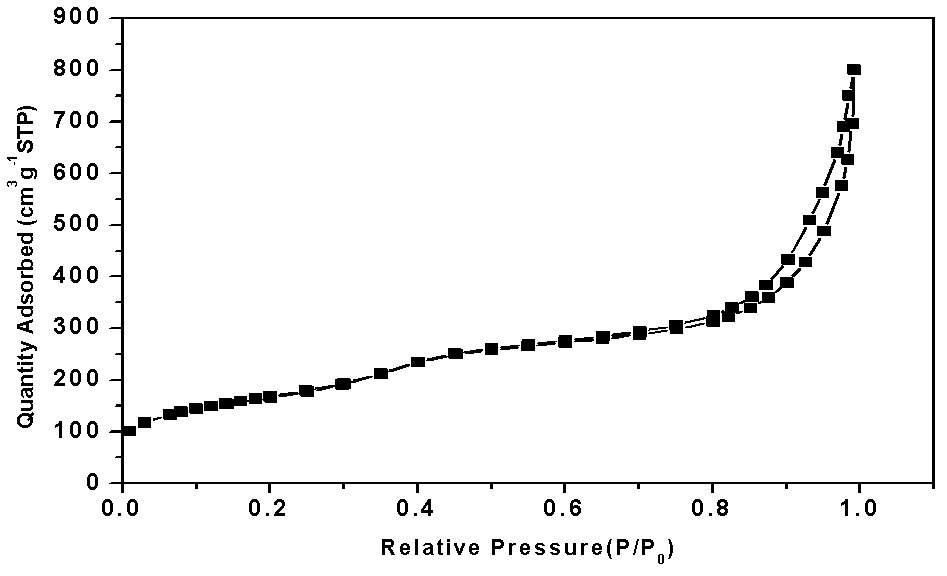

Preparation method of hollow mesoporous silica nanospheres

InactiveCN102491349AGood dispersionValid reservationSilicaNanotechnologyWhite powderMesoporous silica

The invention discloses a preparation method of hollow mesoporous silica nanospheres and relates to a silica nanosphere. The preparation method comprises the following steps: adding the silica nanospheres into water, performing ultrasound treatment to get dispersion liquid of the silica nanospheres, then refluxing the dispersion liquid of the silica nanospheres, further centrifugating and collecting the silica nanospheres; dispersing the silica nanospheres in the water, adding cetyltrimethylammonium bromide and stirring to get the dispersion liquid; further adding NaOH, etching, standing for cooling, collecting sediment, cleaning and airing to get white powder; and removing a cationic surfactant in the white powder to get the hollow mesoporous silica nanospheres with greater aperture.

Owner:XIAMEN UNIV

Method for preparing porous polymer material by selective biodegradation

The invention discloses a method for preparing a porous polymer material by selective biodegradation, belongs to the technical field of a biodegradable high molecular material, and solves the technical problems of a preparation method of the porous polymer material in the prior art that poisons are caused to cells, the connectivity between holes is poor and the porous polymer material cannot be used as a human tissue bracket. The method disclosed by the invention comprises the following steps of: commixing a biodegradable polymer and a non-biodegradable polymer or commixing various biodegradable polymers to obtain a commixed material; and then, carrying out selective degradation on the biodegradable polymers in the commixed material by utilizing the selectivity of a microorganism or an enzyme to obtain the porous polymer material. The preparation method disclosed by the invention is simple in process, moderate, clean and environment-friendly, and strong in selectivity; and the holes of the prepared porous polymer material are controllable and the porous polymer material can be used as a human tissue bracket material.

Owner:吉林省开顺新材料有限公司

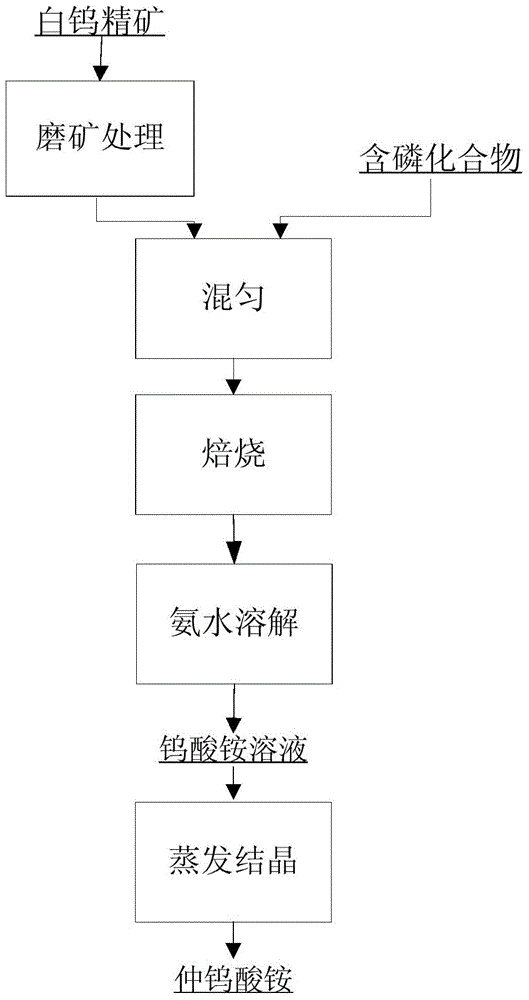

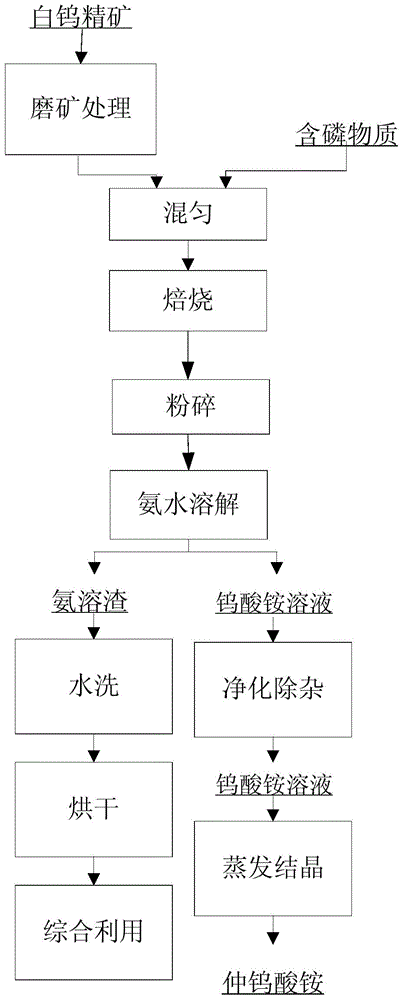

Ammonium paratungstate and preparation method thereof

ActiveCN104803417AAvoid it happening againNo pollution in the processTungsten compoundsTungstateAmmonium paratungstate

The invention discloses ammonium paratungstate and a preparation method thereof. The method for preparing the ammonium paratungstate comprises the following steps: grinding scheelite concentrates to prepare ore powder; adding a phosphorus-containing material into the ore powder and mixing; roasting the ore powder and the phosphorus-containing material which are mixed to obtain roasts containing tungsten trioxide; dissolving the roasts containing the tungsten trioxide by using ammonium hydroxide, and filtering to obtain an ammonium tungstate solution; evaporating and crystallizing the ammonium tungstate solution to prepare the ammonium paratungstate. By virtue of the adoption of the method, the ammonium paratungstate is efficiently and cleanly prepared; no wastewater is discharged.

Owner:CHONGYI ZHANGYUAN TUNGSTEN

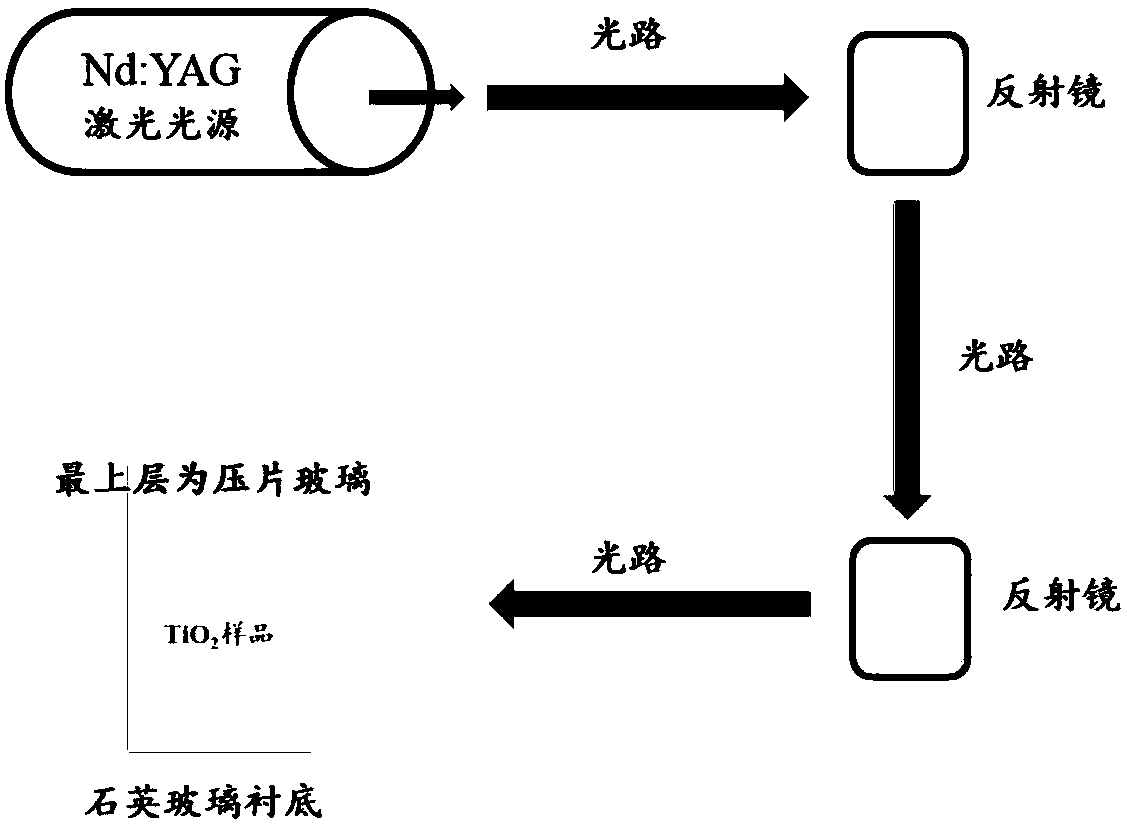

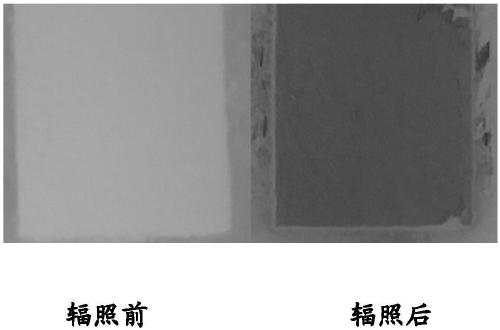

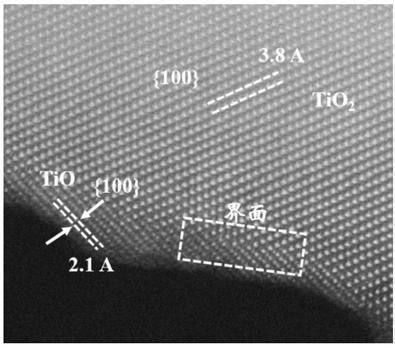

Preparation method of blue titanium dioxide particles

ActiveCN111170362APreparation process cleaningShort reaction timeTitanium dioxideThin membranePicosecond

The invention provides a preparation method of blue titanium dioxide particles. The method comprises the following steps: 1) removing surface impurities of TiO2 particles; 2) tabletting the TiO2 particles treated in the step 1), so that the surfaces of the tabletted TiO2 particles are flat; 3) irradiating the TiO2 particles treated in the step 2) for 3-10 seconds by using rapid laser with a pulsewidth of picoseconds or nanoseconds to obtain TiO2 particles with TiO films growing on the surfaces in situ; and 4) uniformly mixing the TiO2 particles treated in the step 3) again, and repeating thestep 2) and the step 3) until the whole TiO2 particles are uniform in blue color. According to the method, the preparation process is clean and free of pollution, the required single reaction time isextremely short and is only 3-10 seconds, and the preparation efficiency is high; the prepared blue titanium dioxide particles have good color stability in natural air and show good electrical transport performance, the photocurrent density is improved by about 3 times compared with that of the raw material TiO2, and the current impedance is obviously reduced.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

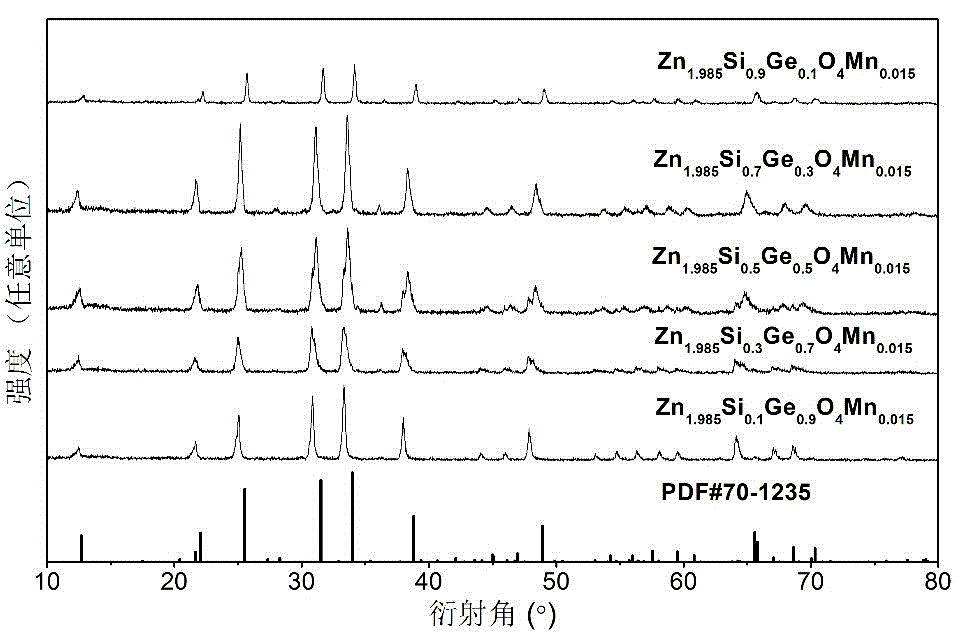

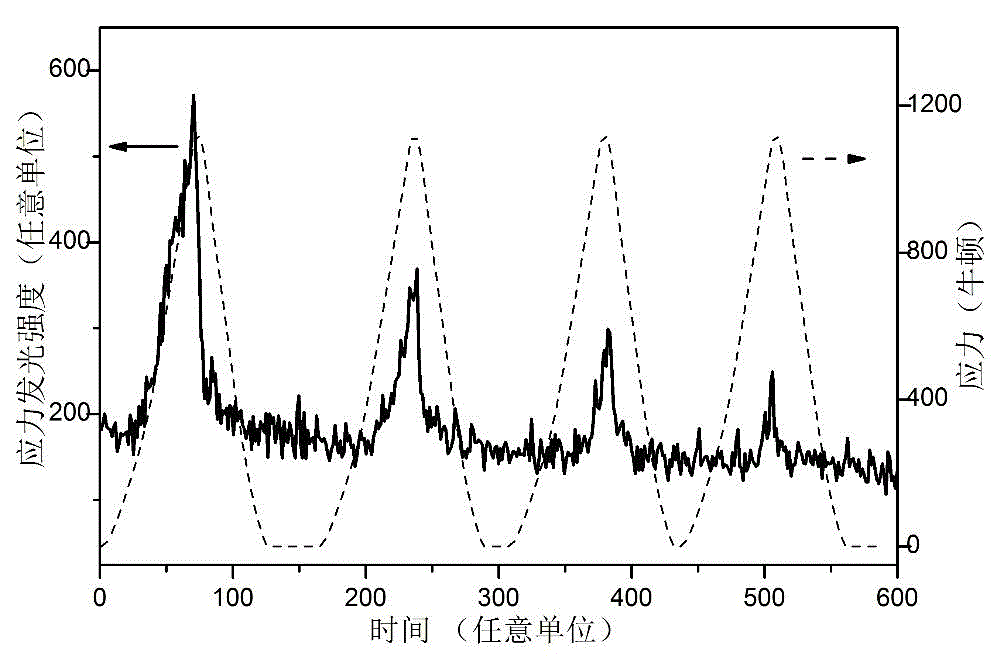

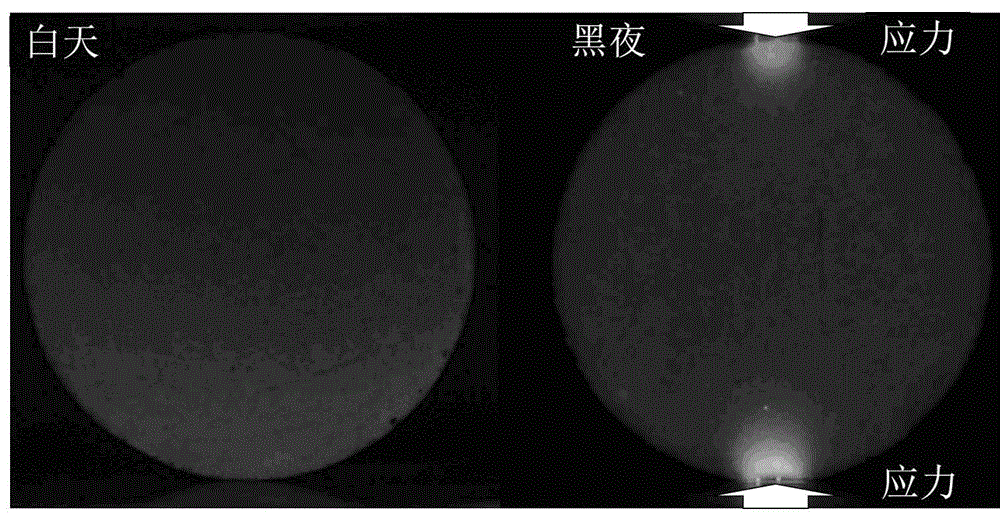

Germanium silicate based elastic stress light-emitting material and preparation method therefor

InactiveCN104974751ANo pollution in the processSimple preparation processLuminescent paintsLuminescent compositionsRare-earth elementPhysical chemistry

The invention relates to a provided germanium silicate based elastic stress light-emitting material and a preparation method thereof. The light-emitting material uses rare earth elements as an activating agent, the chemical construction formula of the light-emitting material is Zn2-xSiyGe1-yRxO4, wherein x is greater than or equal to 0 and smaller than or equal to 0.10, and y is greater than or equal to 0 and smaller than 1; R represents elements of the activating agent or sensitizing agent, which are selected from one or the combination of Mn, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Er and Yb; and x and y represent molar contents respectively. A stress sensor based on the stress light-emitting material has extremely wide application prospect in all fields of production and life for the stress measurement and monitoring of artificial skin, gas storage devices, personal identification, mechanical parts, building facilities and the like.

Owner:TONGJI UNIV

Method for preparing BiOX nanosheets at room temperature in one step

InactiveCN110227503AType controllableSimple preparation processPhysical/chemical process catalystsWater/sewage treatment by irradiationEcological environmentPotassium

The invention discloses a method for preparing BiOX nanosheets at room temperature in one step, and specifically discloses a method for preparing a novel BiOX nanosheet photocatalytic material and catalytic application of the novel BiOX nanosheet photocatalytic material. According to the method, a soluble bismuth salt and a sodium halide salt or a potassium halide salt are adopted as main raw materials to prepare the novel BiOX nanosheet photocatalytic material in one step by using a wet chemical method at normal temperature of 20-35 DEG C. The BiOX (X = Cl, Br, I) nanosheet catalyst is prepared through a one-step process, the operation process is simple, and the type is controllable; the preparation process is carried out at normal temperature of 20-35 DEG C, no high-temperature hydrothermal / solvent thermal processes and high-temperature calcination processes are needed, the conditions are mild, and the requirements for equipment is low; no environment-friendly alkali substances and expensive templating agents are added to the reaction system, and the economy is high; the reaction process is basically free of side reactions, and the yield of BiOX remains 99% or above; and the prepared BiOX nanosheets have high photocatalytic activity, and have great potential in control or repair of the ecological environment.

Owner:HANGZHOU DIANZI UNIV

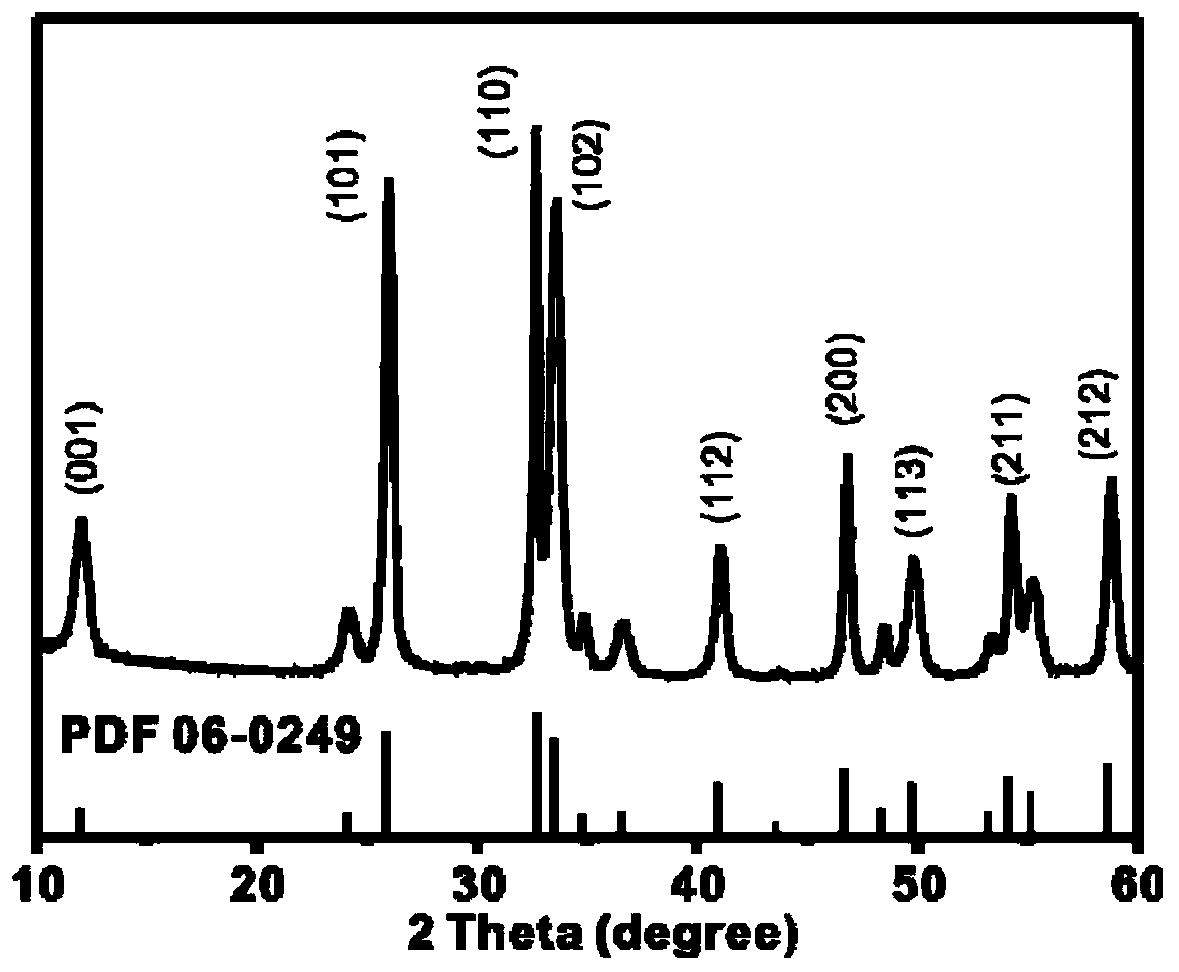

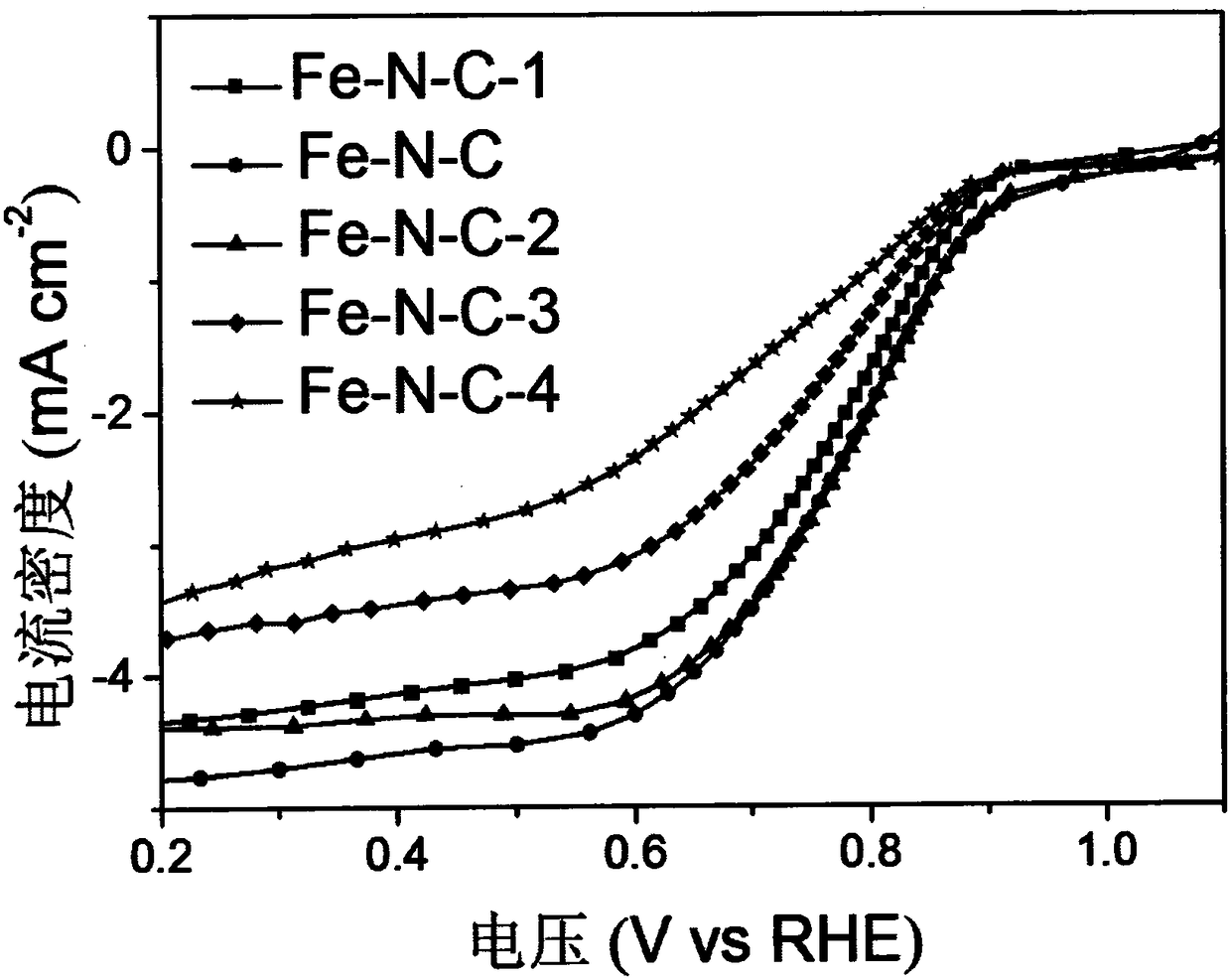

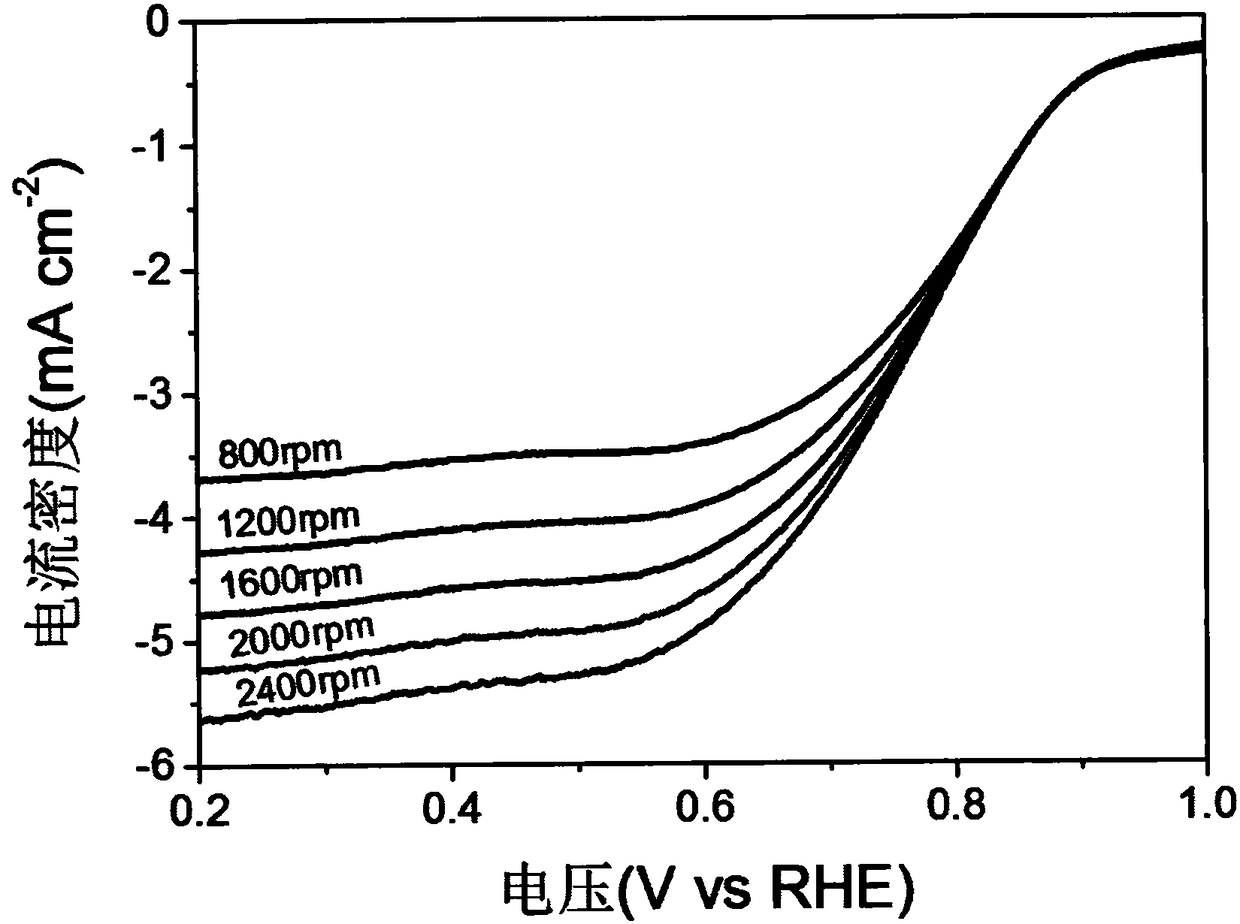

Metal organic gel-based Fe-N-C composite material and preparation method thereof

ActiveCN108199052AEasy to makeCleaning preparationMaterial nanotechnologyCell electrodesCarbonizationChemical stability

The invention discloses a metal organic gel-based Fe-N-C composite material and a preparation method thereof. The raw material of the Fe-N-C composite material comprises terephthalic acid, o-phenylenediamine and ferric nitrate. The preparation method comprises the steps of mixing and dissolving the terephthalic acid and the o-phenylenediamine in N, N-2-methylformamide; dissolving the ferric nitrate in ethyl alcohol; performing ultrasound after the two solutions are mixed to obtain gel; and performing high-temperature carbonization on the gel to obtain the Fe-N-C composite material. The gel isprepared by organic coordination of metal, and a transition metal nitrogen-doped carbon material having high catalytic activity is obtained by a high-temperature carbonization technology. The preparedFe-N-C composite material has relatively high electrocatalytic activity and electrochemical stability and is an ideal oxidization-reduction catalyst.

Owner:DONGHUA UNIV

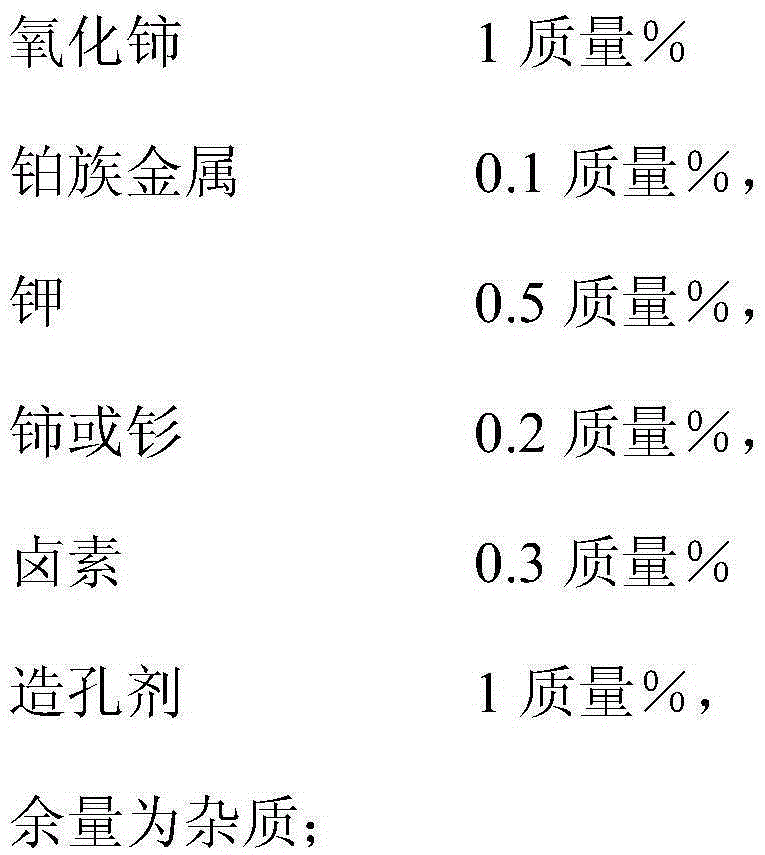

Preparation method of catalyst for preparing propene through propane dehydrogenation

InactiveCN105233844AAvoid it happening againAvoid Contaminated SituationsPhysical/chemical process catalystsHydrocarbonsCalcium silicateCerium

Provided is a preparation method of a catalyst for preparing propene through propane dehydrogenation. The catalyst comprises an alumina carrier and active components which take the carrier as the calculation basis. The active components comprise, by mass, 1%-3% of calcium silicate, 1%-3% of cerium oxide, 0.1%-2.0% of platinum group metal, 0.5%-5.0% of potassium, 0.2%-5.0% of cerium or samarium, 0.3%-10% of halogen, 1%-5% of pore-forming agents and the balance impurities, wherein the molar ratio of the cerium or samarium to the platinum group metal is 7 to 8, the platinum group metal is platinum, and the halogen is chlorine; the alumina carrier is steeped through a soluble cerium or samarium compound solution and a calcium silicate solution, after drying and roasting are conducted, the alumina carrier is steeped through a solution of compounds containing the platinum group metal and halogen hydride, after drying and roasting are conducted, the treated alumina carrier is steeped through a potassium salt solution, and drying and roasting are conducted; the corresponding amount of the cerium oxide and the pore-forming agents are mixed, and the catalyst for preparing the propene through propane dehydrogenation is obtained after roasting is conducted for three hours at 600 DEG C.

Owner:WUXI QINGYANG MACHINERY MFG

Moxa roll carbonized tube

InactiveCN101884592AMaintain potencyKeep the heatDevices for heating/cooling reflex pointsTarElectrical and Electronics engineering

The invention relates to an auxiliary acupuncture and moxibustion instrument, in particular to a maxa roll carbonized tube. The maxa roll carbonized tube is designed with the aim of solving the problem of environment pollution of maxa smoke. The maxa roll carbonized tube comprises a base, a heating electric coil, a carbonized tube, a maxa smoke tar collecting tube and the like in sequence. The maxa roll carbonized tube is characterized in that the base and the carbonized tube are integrated into a whole, the maxa smoke tar collecting tube is arranged below the carbonized tube, and maxa smoke tar flows into a maxa smoke tar collecting cup to be stored; the heating electric coil is in a shape of an inverted cup and covers the carbonized tube; and an upper cover of the carbonized tube is used for clogging the upper port of the carbonized tube. The invention has the advantages that no other excipient is added to the manufactured maxa roll carbon rod, and the efficacy and the thermal power of the maxa roll are maintained; the manufacturing process of the maxa roll carbon rod is clean and is free of pollution; and the maxa roll carbonized tube has high safety and is an auxiliary instrument for environment-friendly treatment of moxa moxibustion.

Owner:贺成功

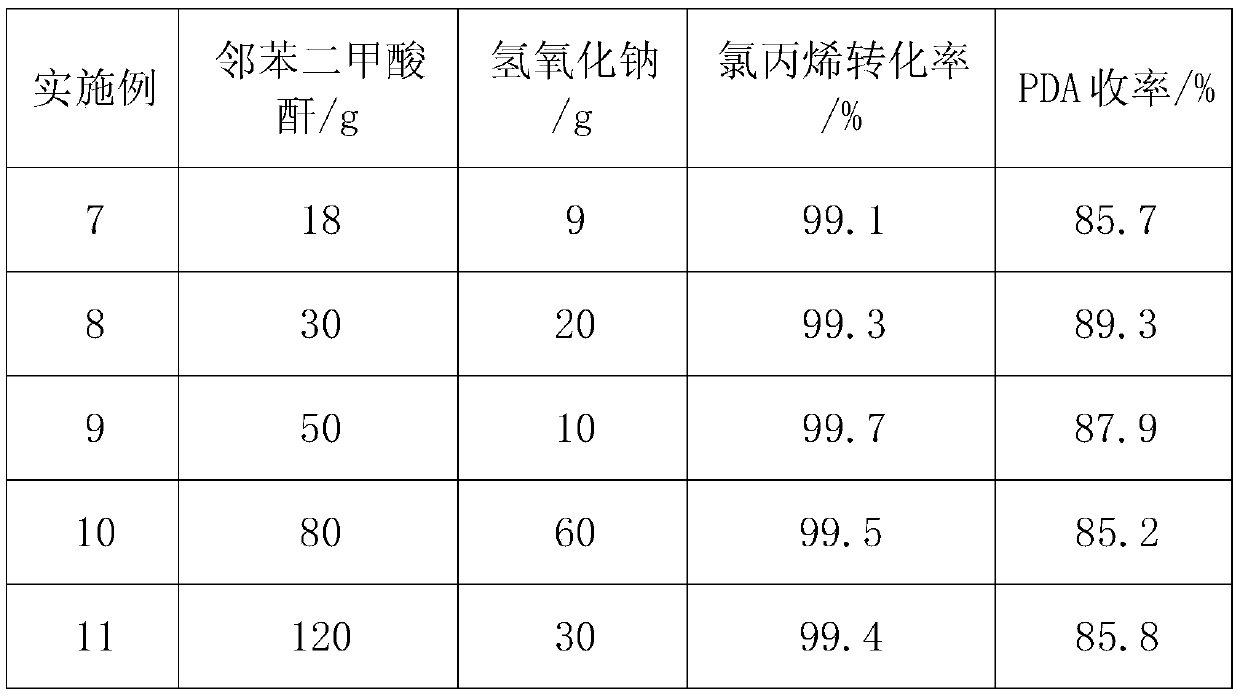

Epoxy chloropropane tail gas safety improvement method

PendingCN109734589ACleaning preparationIncrease added valueOrganic compound preparationCarboxylic acid esters preparationEpoxyOxygen

The invention belongs to the technical field of organic chemical industry, and relates to an epoxy chloropropane tail gas safety improvement method, in particular to a process for preparing epoxy chloropropane by direct epoxidation of hydrogen peroxide. Reaction tail gas contains a small quantity of chloropropene, oxygen and nitrogen, the chloropropene and the oxygen have explosion limit, in orderto eliminate potential danger, the tail gas after reaction is led into under-pressure sodium phthalate water solution, the sodium phthalate water solution reacts with the chloropropene in the tail gas to generate diallyl phthalate, intrinsic safety of a process is ensured, the diallyl phthalate with higher additional values is generated, and VOC (volatile organic compounds) emission is reduced.

Owner:JIANGSU YANGNONG CHEM GROUP +2

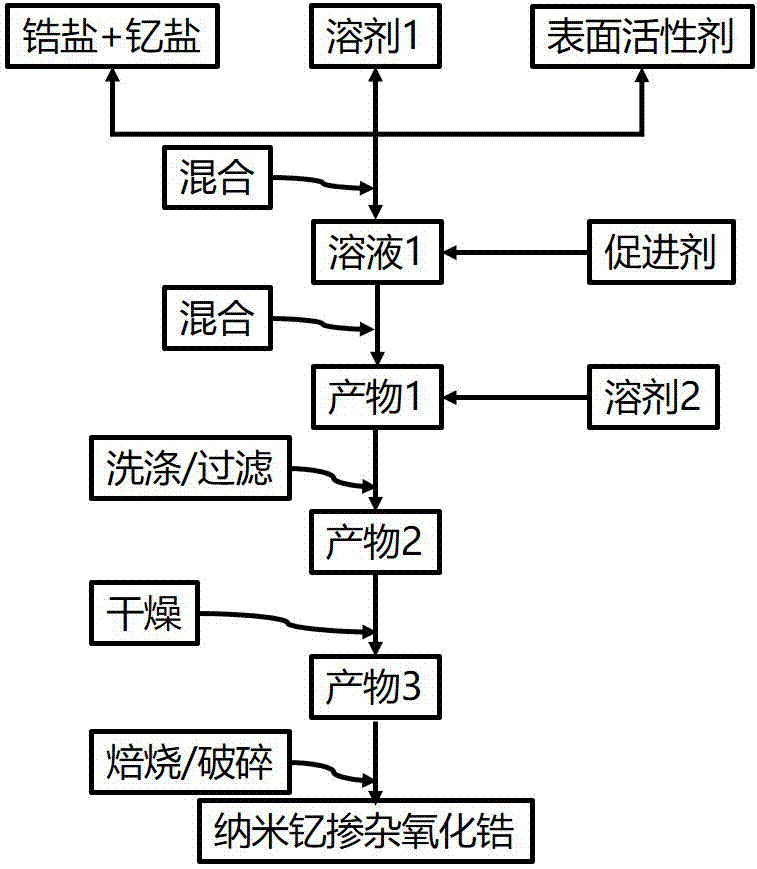

Preparation method for nanometer yttrium doped zirconia powder

InactiveCN107540017ANarrow particle size distributionEasy to castMaterial nanotechnologyZirconium oxidesSolventYttrium

The invention discloses a method for preparing nanometer yttrium doped zirconia through a sol-gel process. The method comprises the following steps: with an inorganic zirconium salt and an inorganic yttrium salt as precursors of yttrium-doped zirconia, dissolving the precursors in a solvent mixed with a surfactant and then gradually adding a promoter; subjecting a product of the previous step to washing, filtering and drying to form initial powder; and then subjecting the initial powder to calcination and crushing to prepare nanometer doped zirconia powder.

Owner:安徽科昂新材料科技有限公司

Method for preparing porous polymer material by selective biodegradation

The invention discloses a method for preparing a porous polymer material by selective biodegradation, belongs to the technical field of a biodegradable high molecular material, and solves the technical problems of a preparation method of the porous polymer material in the prior art that poisons are caused to cells, the connectivity between holes is poor and the porous polymer material cannot be used as a human tissue bracket. The method disclosed by the invention comprises the following steps of: commixing a biodegradable polymer and a non-biodegradable polymer or commixing various biodegradable polymers to obtain a commixed material; and then, carrying out selective degradation on the biodegradable polymers in the commixed material by utilizing the selectivity of a microorganism or an enzyme to obtain the porous polymer material. The preparation method disclosed by the invention is simple in process, moderate, clean and environment-friendly, and strong in selectivity; and the holes of the prepared porous polymer material are controllable and the porous polymer material can be used as a human tissue bracket material.

Owner:吉林省开顺新材料有限公司

Method for preparing dehydrogenation catalyst

ActiveCN101658790AAvoid it happening againAvoid Contaminated SituationsHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsRare earthDehydrogenation

The invention relates to a method for preparing a dehydrogenation catalyst, which comprises the following steps of: (a) measuring the content of specific components of rare earth containing cerium oxide; (b) adding iron oxide and / or an iron oxide precursor, potassium oxide and / or a potassium oxide precursor, a silicate calcium salt and a pore-forming material into the rare earth, and mixing the materials to form a mixture; (c) mixing the mixture with a proper amount of water, kneading the mixture sufficiently, and extruding the mixture into bars to obtain preforms; and (d) drying and calcinating the preforms to obtain the finished product of the dehydrogenation catalyst, wherein the specific components to be measured in the step (a) comprise the cerium oxide in the rare earth and the compounds which are the same as the materials added in the step (b). The method for preparing the dehydrogenation catalyst has the advantages of no pollution and low cost.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +2

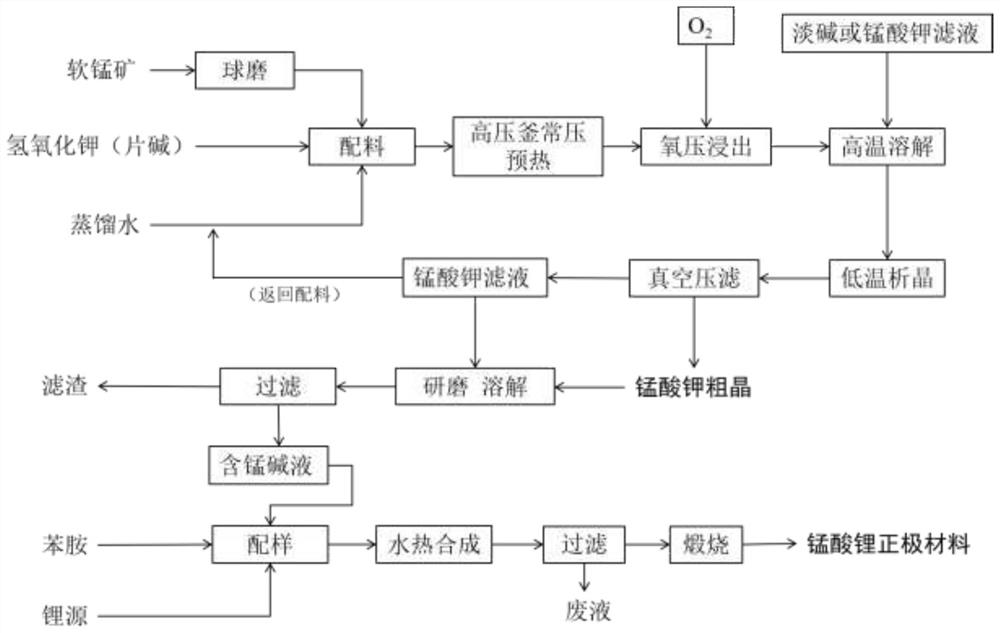

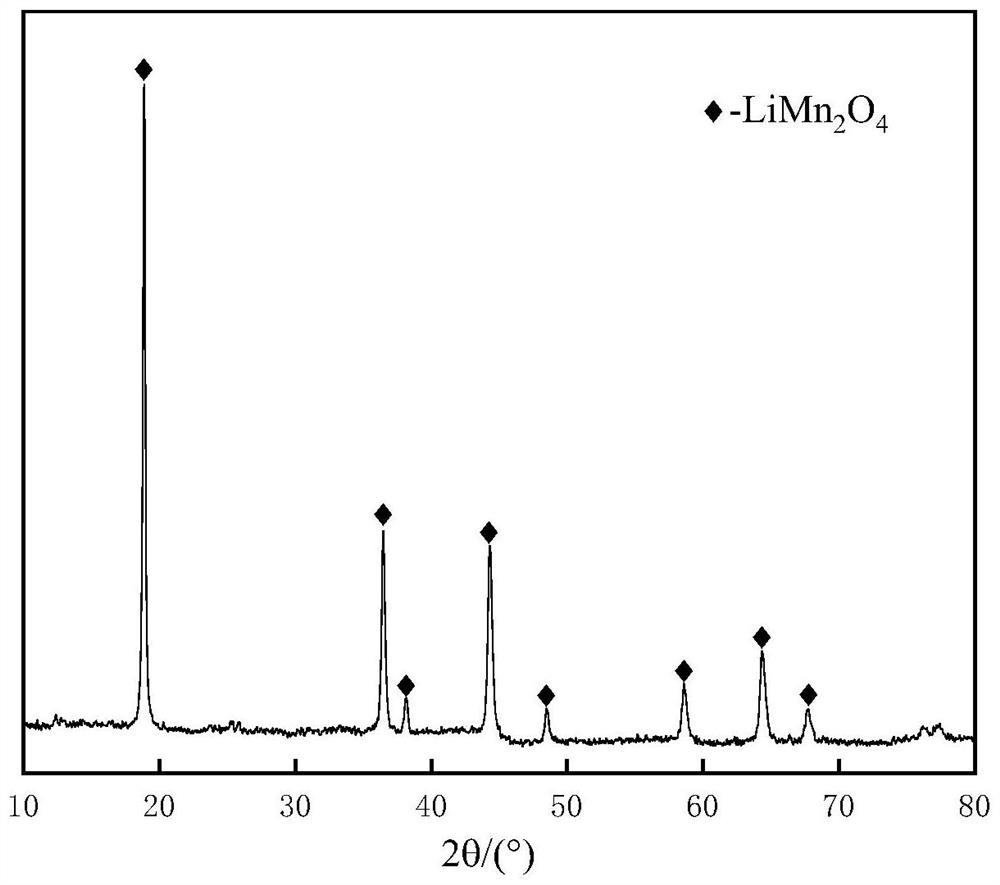

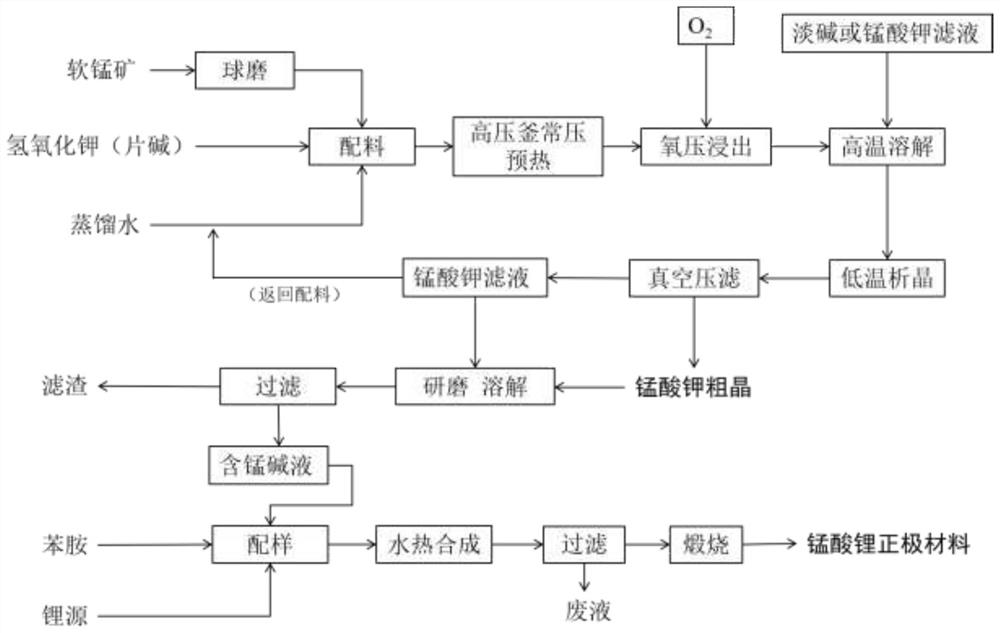

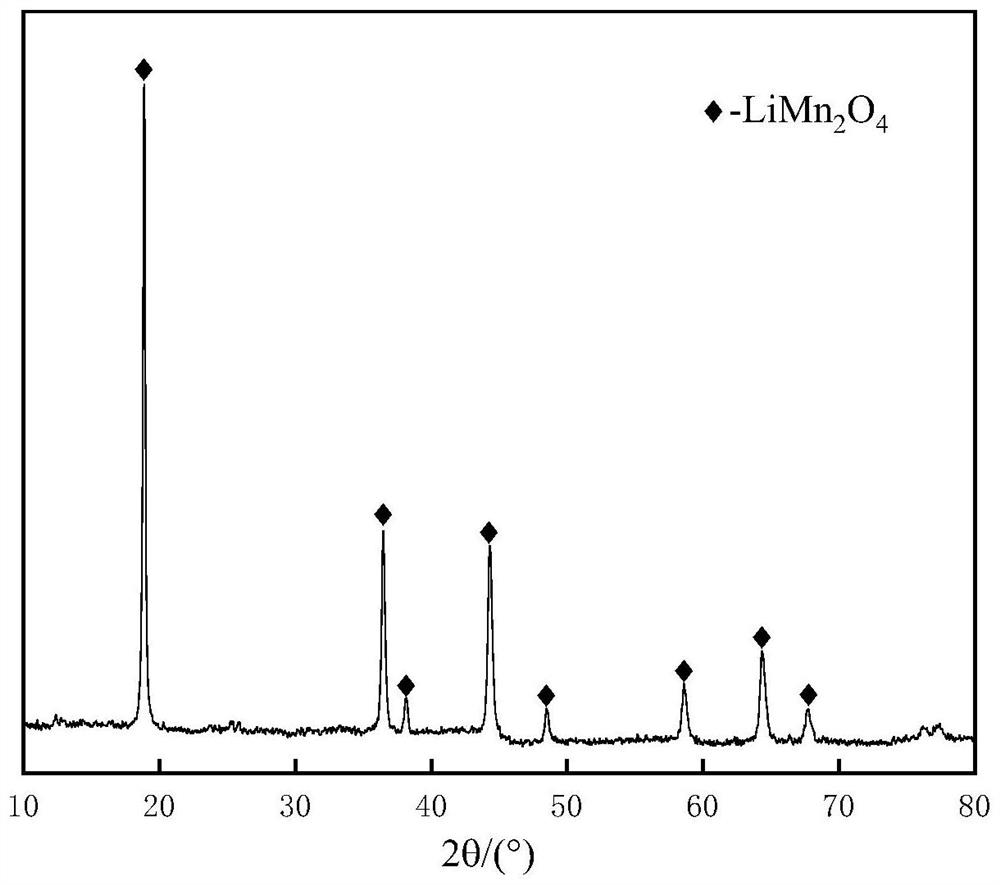

Method for preparing lithium manganate positive electrode material from pyrolusite

ActiveCN113582235ARealize cross fusionMaximize utilizationCell electrodesChemical industryPyrolusiteElectrical battery

The invention belongs to the technical field of manganese ore smelting and lithium ion batteries, and particularly relates to a method for preparing a lithium manganate positive electrode material from pyrolusite. The method comprises the following steps: (1) mixing pyrolusite with a potassium hydroxide solution, and carrying out pressurized oxidation leaching to obtain potassium manganate slurry; (2) performing high-temperature dissolution and low-temperature crystallization on the potassium manganate slurry and alkali liquor, and filtering to obtain potassium manganate coarse crystal and potassium manganate filtrate; (3) dissolving the potassium manganate coarse crystal and the potassium manganate filtrate, grinding, and filtering to obtain manganese-containing alkali liquor; and (4) carrying out constant-temperature hydrothermal reaction on the manganese-containing alkali liquor and a lithium source under the action of a reducing agent aniline to obtain a hydrothermal product, washing the hydrothermal product, drying, and calcining in a muffle furnace for a certain time to obtain the lithium manganate positive electrode material. The method has the advantages of being rich in raw materials, environmentally friendly, low in cost, short in process, capable of saving energy, reducing consumption and the like, maximum utilization of resources is achieved, and the method has great significance in achieving material metallurgy integration.

Owner:GUIZHOU UNIV

Aqueous polymer grafted latex

The present invention provides aqueous multistage copolymers, preferably, all acrylic and allylic or all acrylic copolymers, having as the outermost stage an acid functional, preferably, carboxyl or carboxylate functional, aqueous solution polymer and as the one or more remaining stage(s) a vinyl emulsion polymer, wherein the vinyl emulsion polymer stage(s) in the multistage copolymer comprises 5 wt. % or less of hydrophilic monomer, based on the total weight of monomers used to make the vinyl emulsion polymer stage(s). The multistage copolymer enables incorporation of a much higher amount of hydrophilic monomer into a vinyl emulsion copolymer. In addition, are methods of methods of making the multistage copolymers are provided.

Owner:ROHM & HAAS CO

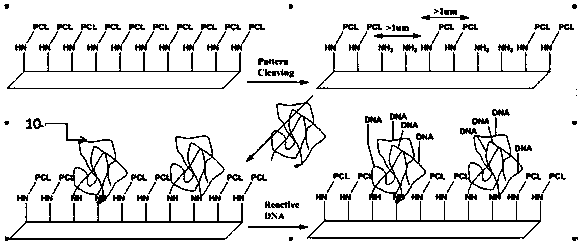

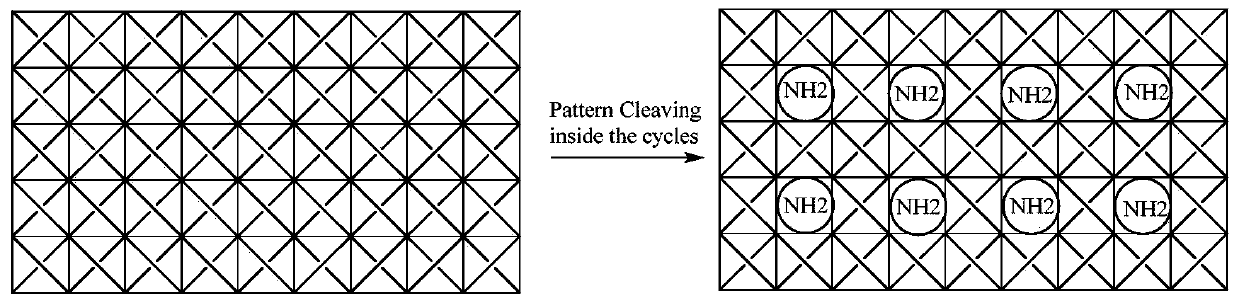

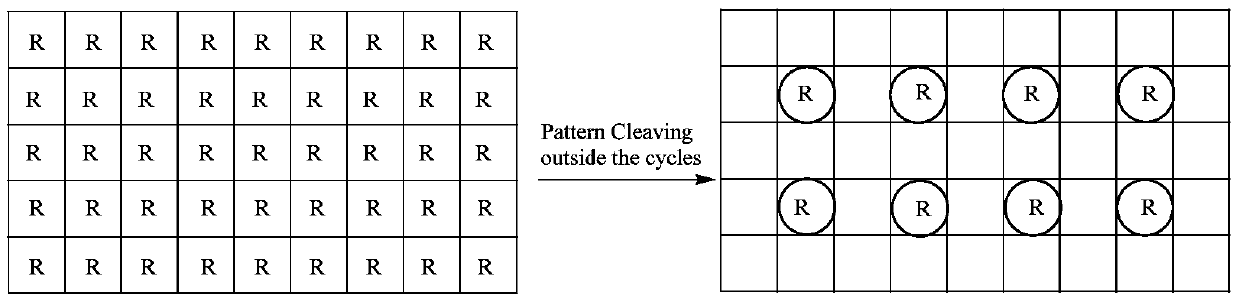

Patterning microarray flowing tank, manufacturing method, detection method and application of flowing tank

PendingCN110066861ARaise the ratioValid sequencing informationMicrobiological testing/measurementDNA microarrayFlow cell

The invention relates to a patterning microarray flowing tank, a manufacturing method, a detection method and application of the flowing tank and relates to the technical field of biology. A layer ofreactive functional groups formed on the surface of a chain-protection transparent solid substrate through activation are chained through photolysis, then a patterning photolysis chain is chained withmolecules to form a reactive microarray, a layer of reactive functional polymers are fixed to the reactive microarray through covalence for forming a three-dimensional reactive functional polymer microarray, and finally a reactive DNA primer and the reactive functional polymers on the microarray are used for a reaction to form a three-dimensional DNA primer microarray. By adopting the surface ofthe patterning microarray flowing tank, the proportion of a monoclonal cluster is further increased, more effective sequencing information is generated, the three-dimensional surface polymers are usedfor forming the three-dimensional surface structure of the DNA primer, the high-density DNA primer structure can be formed, through the surface, the high-signal-to-noise-ratio sequencing informationcan be generated for DNA sequencing, and the manufacturing process is effective, simple and clean.

Owner:南京拓远生物科技有限公司

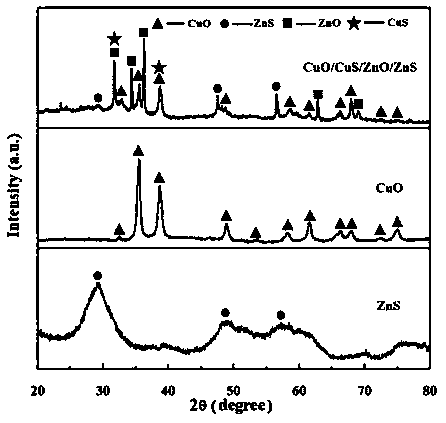

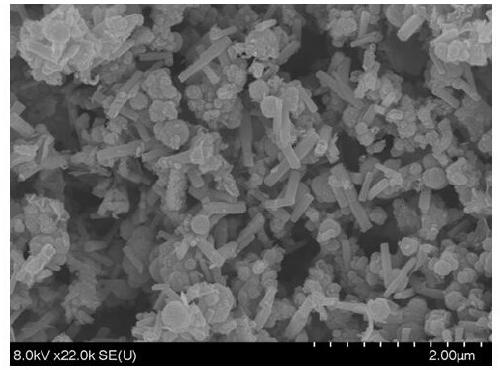

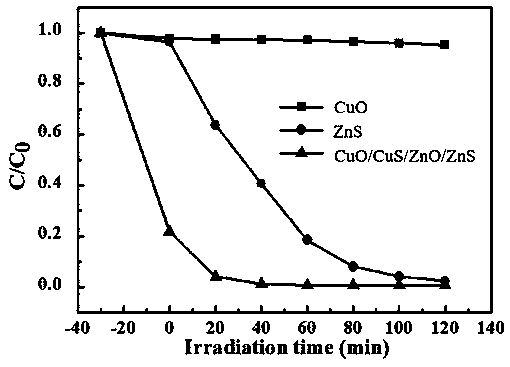

Preparation method of quaternary visible light catalysis nano composite material

ActiveCN111167479AEasy to separateExtend your lifePhysical/chemical process catalystsWater/sewage treatment by irradiationOrganic solventCopper oxide

The invention discloses a preparation method of a quaternary visible light catalysis nano composite material. The preparation method specifically comprises the following steps: (1) uniformly dispersing copper oxide and zinc sulfide in a mass ratio of 1: (1-4) in deionized water to form a mixed solution; and (2) putting the mixed solution obtained in the step (1) into a microwave reactor, carryingout microwave irradiation reaction, cooling to room temperature, and carrying out filtering, washing and drying to obtain the CuO / CuS / ZnO / ZnS quaternary visible light catalysis nano composite material. The obtained CuO / CuS / ZnO / ZnS quaternary visible light catalysis nano composite material has relatively high photocatalytic efficiency under visible light. The preparation method is simple in process, simple and convenient to operate, good in repeatability, clean in process and environment-friendly, and no surfactant or organic solvent is used as a template.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

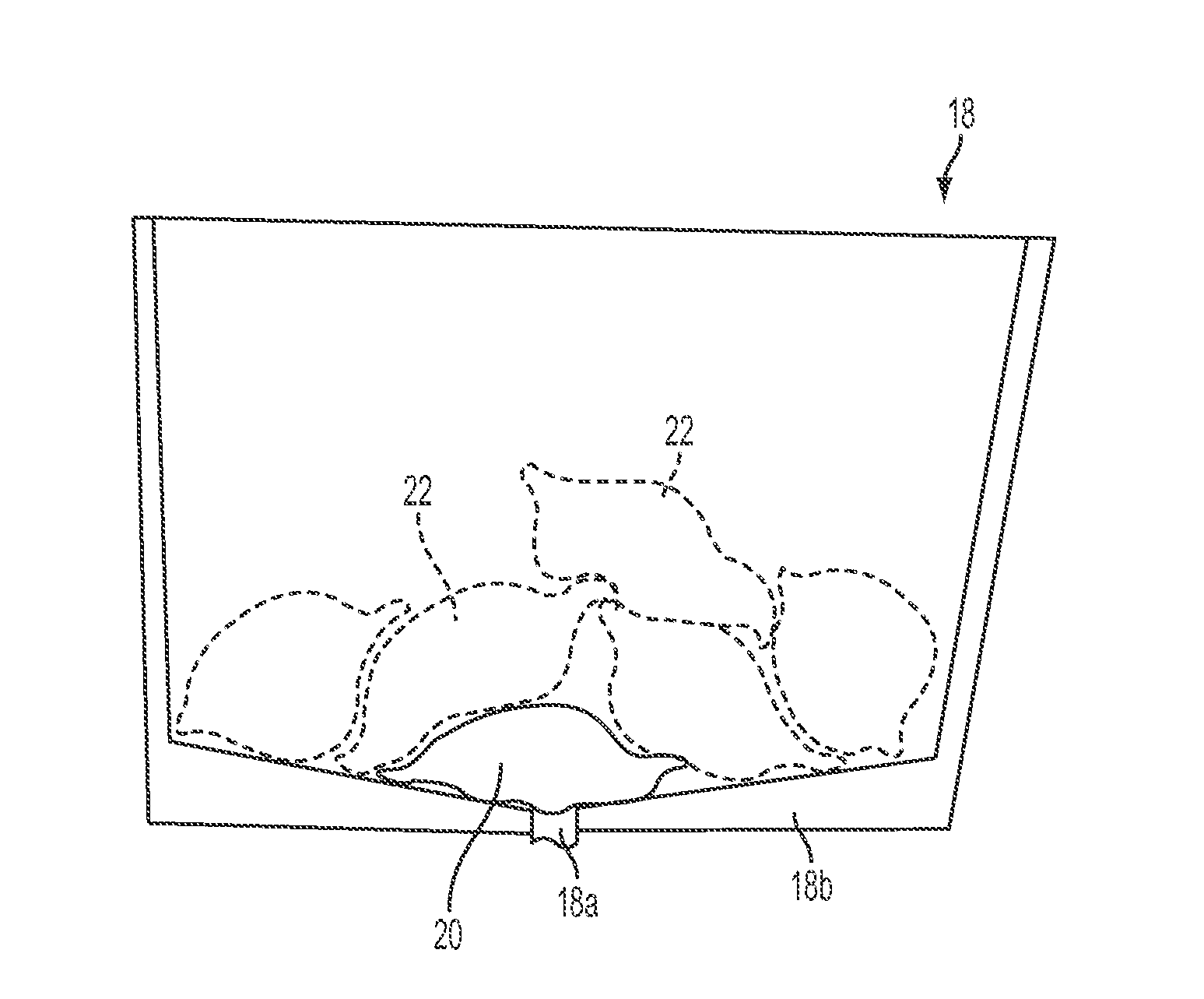

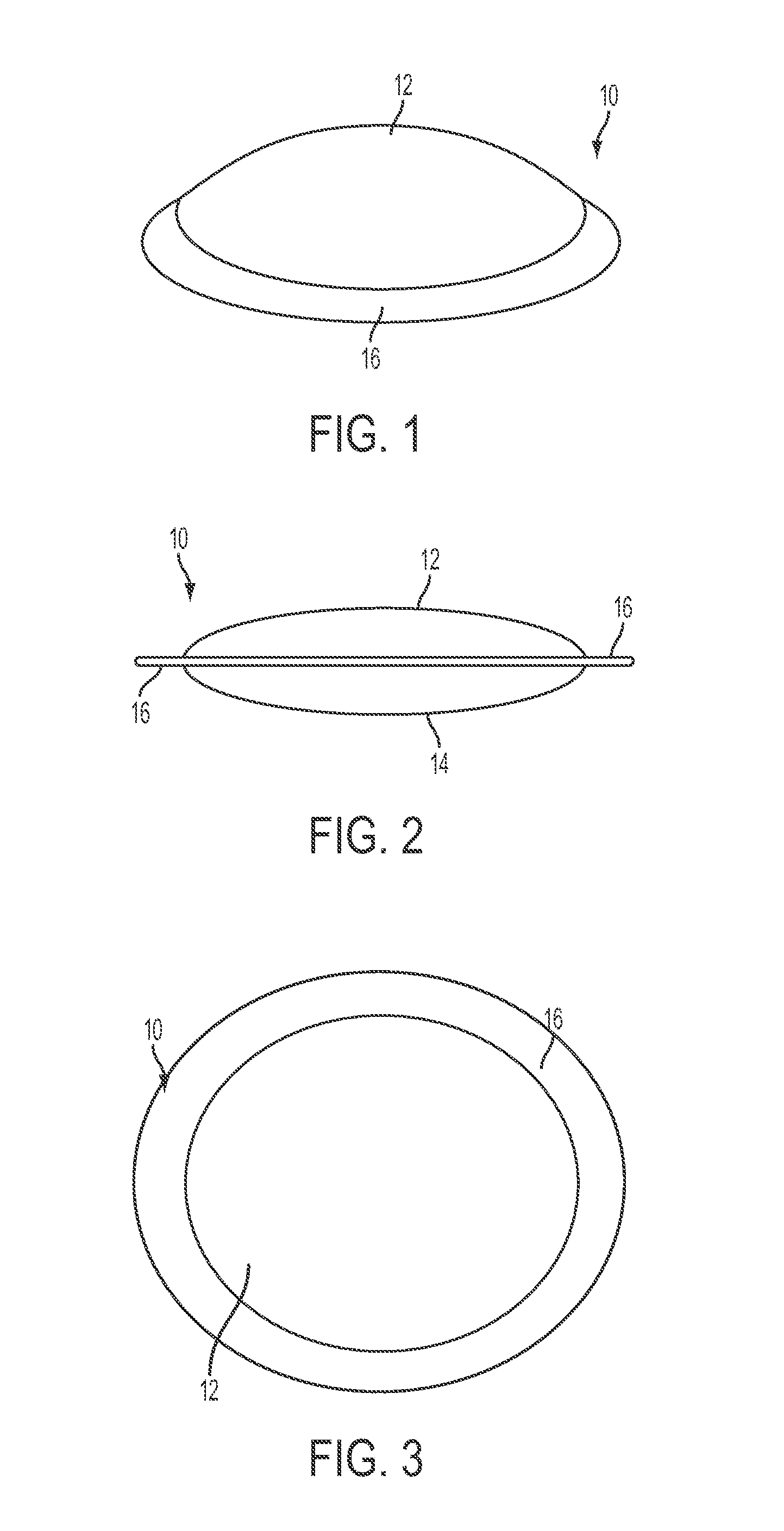

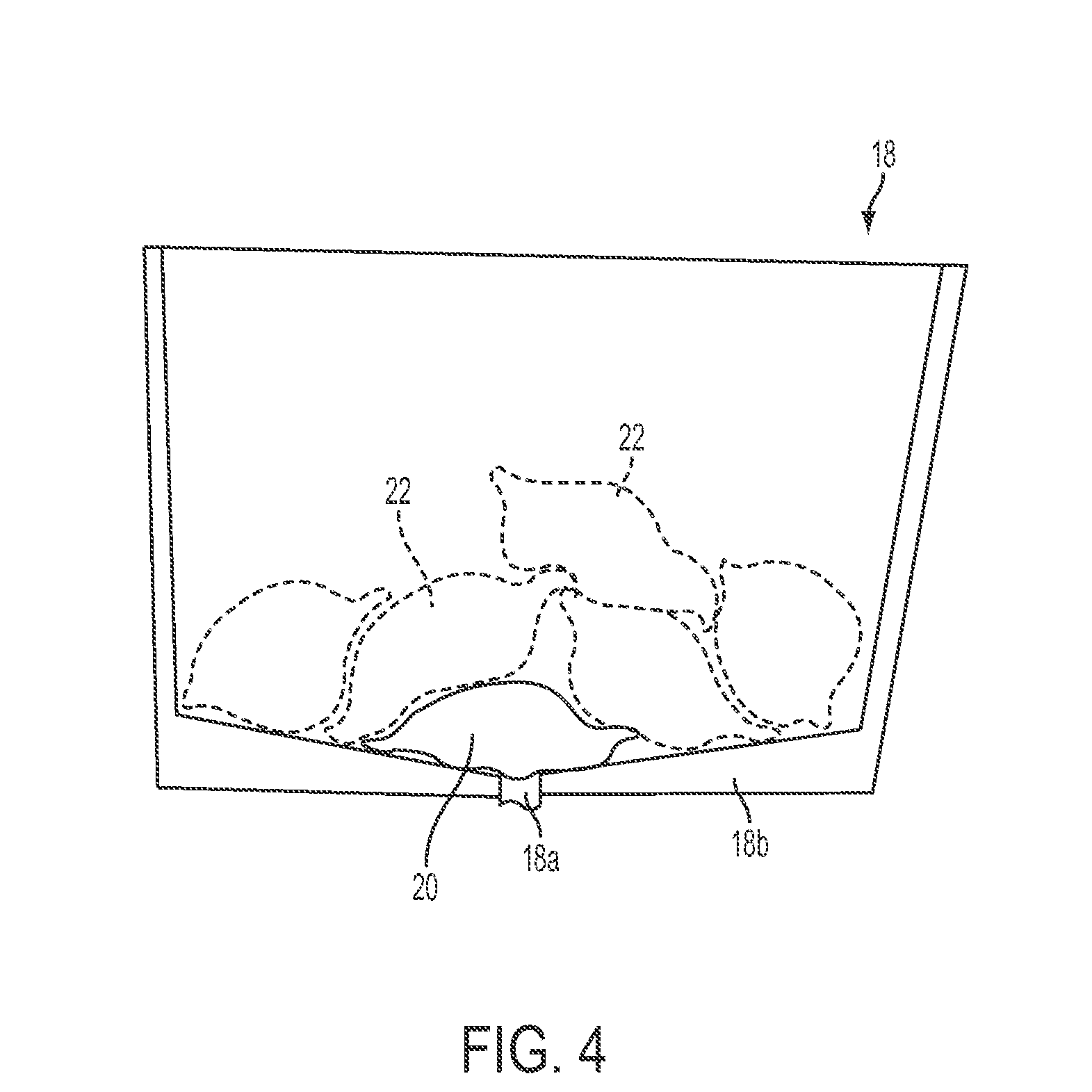

Individual coffee packets with filter

A method of brewing with a brewing device includes providing a plurality of individual filter units. The brewing device has a reservoir for flowing water through a composition in the filter units, such as coffee grounds to brew coffee. The individual coffee filter units each comprise a filter pouch that contains a predetermined amount of coffee grounds or the like. An amount of filter units is selected depending on at least one of (i) the amount of coffee to be brewed and (ii) the strength of the coffee to be brewed. The selected amount of coffee filter units are placed in the reservoir and the brewing device is activated to brew the coffee or the like.

Owner:KASSOUNI VAN M

Carbon-fixing vegetation concrete

ActiveCN108947409AThe production process is simpleRaw materials are cheapBioloigcal waste fertilisersSewage/sludge fertilisersPlant rootsVoid ratio

The invention relates to the fields of ecological remediation and sponge urban construction and discloses carbon-fixing vegetation concrete. The carbon-fixing vegetation concrete is prepared from thefollowing raw materials in parts by weight: 100 parts of cement, 410-450 parts of aggregates, 30-50 parts of a carbon-fixing greening additive, 30-40 parts of water and 0.5-0.9 part of plant seeds, wherein the carbon-fixing greening additive is composed of sludge charcoal, edible mushroom stick, nitrogen phosphorus and potassium complex fertilizer, AM fungus fertilizer and a water-retaining agent.The compressive strength of the carbon-fixing vegetation concrete disclosed by the invention is 8.2MPa-9.6MPa; an apparent pore diameter required by growth of plant roots and survival of small animals, namely, ecological pore diameter, is 0.37mm-0.45mm; the volume ratio of ecological void to ecological concrete, namely, ecological void ratio, is 31%-36%; the survival rate of seeds is high; afterthe seeds survive, the greening rate of the concrete after half a year is 95%-99%.

Owner:曹玉成

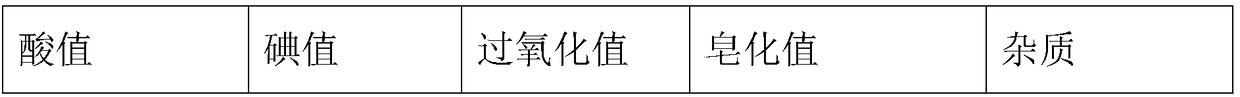

Method for continuously extracting wheat germ oil by using microwave-assisted solvent

InactiveCN108913335AImprove extraction efficiencyCleaning preparationFatty-oils/fats refiningFatty-oils/fats productionWheat germFiltration

The invention discloses a method for continuously extracting wheat germ oil by using a microwave-assisted solvent. The method comprises the following steps of screening raw materials; drying wheat germs; preparing wheat germ powder; carrying out microwave irradiation; obtaining the extracted oil; carrying out extraction; carrying out filtration; carrying out extracting liquid separation; and carrying out secondary filtration. According to the method, the wheat germ powder is subjected to continuous extraction through the microwave-assisted solvent, so that the extraction efficiency of the wheat germ oil is higher, the wheat germs are cleaned and dehumidified in advance, so that the prepared wheat germ powder is much cleaner, the content of impurities in the wheat germ oil is decreased, andthe wheat germ powder is subjected to auxiliary wall breaking and extraction through the microwave, so that the extraction rate of the wheat germ oil is increased; and the wheat germ oil is continuously extracted, so that the extracted wheat germ oil is much purer and less in impurity content.

Owner:广州萃取生物科技有限公司

A method for preparing lithium manganate positive electrode material from pyrolusite

ActiveCN113582235BRealize cross fusionMaximize utilizationCell electrodesChemical industryPyrolusiteElectrical battery

The invention belongs to the technical fields of manganese ore smelting and lithium ion batteries, and in particular relates to a method for preparing a lithium manganate cathode material from pyrolusite. The method comprises the following steps: (1) mixing pyrolusite and potassium hydroxide solution for pressurized oxidative leaching to obtain potassium manganate slurry; (2) dissolving the potassium manganate slurry and lye at high temperature, crystallizing at low temperature, and filtering Obtain potassium manganate coarse crystal and potassium manganate filtrate; (3) dissolving, grinding and filtering potassium manganate coarse crystal and potassium manganate filtrate to obtain manganese-containing lye; (4) manganese-containing lye and lithium source in Under the action of the reducing agent aniline, a constant temperature hydrothermal reaction is carried out to obtain a hydrothermal product, and then the hydrothermal product is washed and dried; calcined in a muffle furnace for a certain period of time to obtain a lithium manganate positive electrode material. This method has many advantages such as abundant raw materials, green environmental protection, low cost, short process, energy saving and consumption reduction, and realizes the maximum utilization of resources, which is of great significance to the realization of material metallurgical integration.

Owner:GUIZHOU UNIV

A kind of preparation method of inorganic composite white pigment with high hiding power

InactiveCN101775239BEfficient use ofReduce manufacturing costPigment physical treatmentWhite petrolatumPresent method

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Preparation method of hollow mesoporous silica nanospheres

InactiveCN102491349BGood dispersionValid reservationSilicaNanotechnologyWhite powderMesoporous silica

The invention discloses a preparation method of hollow mesoporous silica nanospheres and relates to a silica nanosphere. The preparation method comprises the following steps: adding the silica nanospheres into water, performing ultrasound treatment to get dispersion liquid of the silica nanospheres, then refluxing the dispersion liquid of the silica nanospheres, further centrifugating and collecting the silica nanospheres; dispersing the silica nanospheres in the water, adding cetyltrimethylammonium bromide and stirring to get the dispersion liquid; further adding NaOH, etching, standing for cooling, collecting sediment, cleaning and airing to get white powder; and removing a cationic surfactant in the white powder to get the hollow mesoporous silica nanospheres with greater aperture.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com