Preparation method of blue titanium dioxide particles

A titanium dioxide and particle technology, which is applied in the field of preparation of blue titanium dioxide particles, can solve the problems of unfavorable physical and chemical properties of TiO2, uneven particle surface, and many surface defects, and achieves good visible light response, short reaction time, and preparation. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

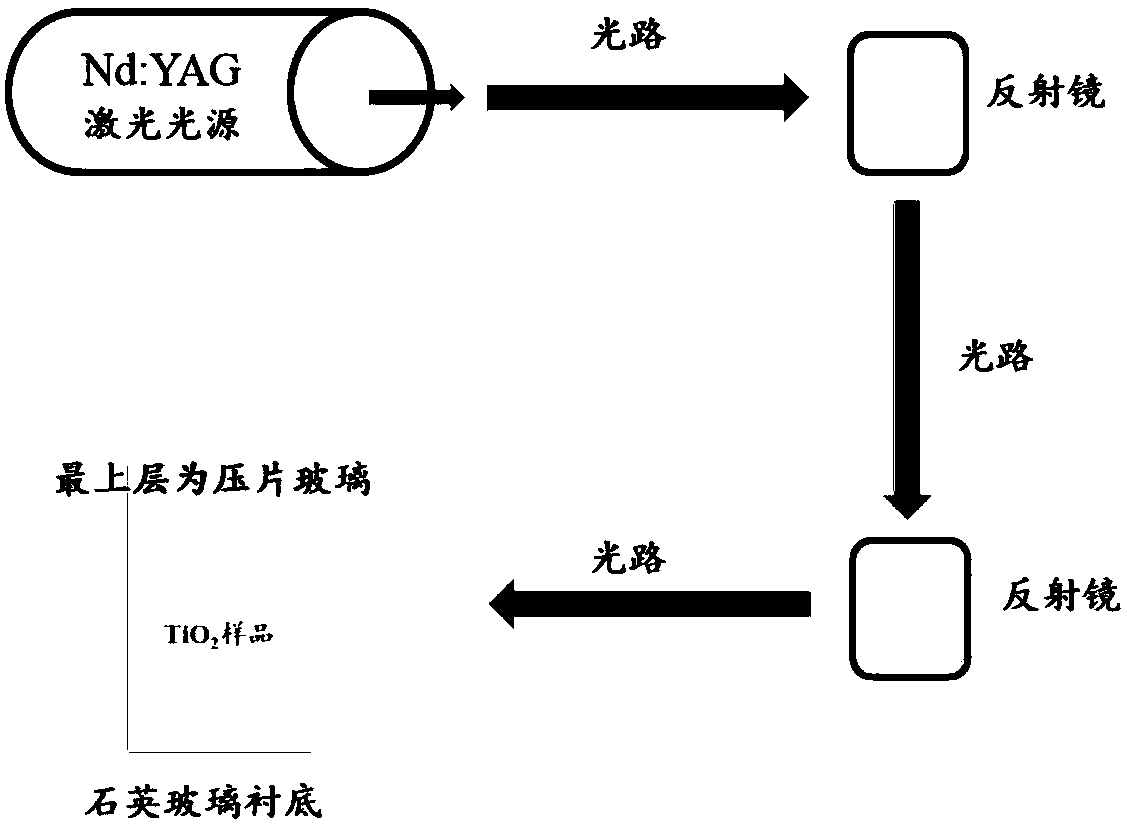

[0043] A TiO irradiated by fast laser 2 Particles, a method for preparing blue titanium dioxide particles with visible light response, the method comprising the steps of:

[0044] 1) In a muffle furnace, at 200 degrees Celsius, for TiO 2 Particles (particle size 100nm) are preheated to clean their surface;

[0045] 2) Step 1) TiO after preheating 2 The particles are tableted on the quartz glass substrate, and the surface flatness of the sample after tableting is guaranteed;

[0046] 3) Utilize the laser to treat the TiO after step 2) 2 The particles were irradiated for 5 seconds, and the parameters of the laser were selected as follows: pulse width 8 nanoseconds; wavelength 355nm; power 3W; frequency 1000Hz;

[0047] 4) Step 3) treated TiO 2 After the particles are remixed evenly, repeat step 2) and step 3) 6 times to obtain uniform blue TiO 2 particles.

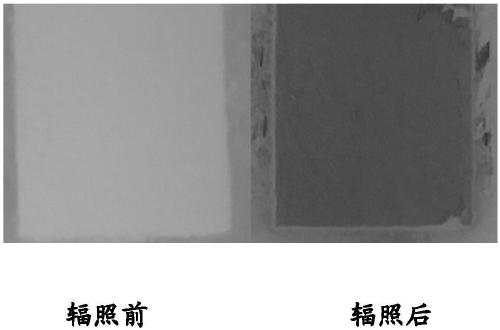

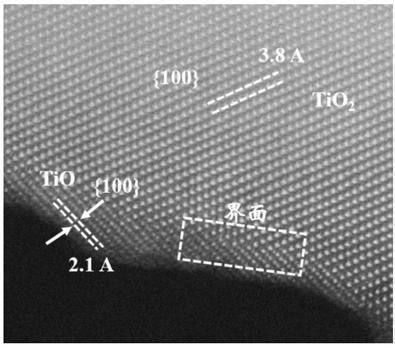

[0048] After treatment by this method, TiO 2 The particles changed from white to uniform blue. Its surface grows ...

Embodiment 2

[0050] A TiO irradiated by fast laser 2 Particles, a method for preparing blue titanium dioxide particles with visible light response, the method comprising the steps of:

[0051] 1) In a muffle furnace, at 300 degrees Celsius, for TiO 2 Particles (particle size 25nm) are preheated to clean their surfaces;

[0052] 2) Step 1) TiO after preheating 2 The particles are tableted on the quartz glass substrate, and the surface flatness of the sample after tableting is guaranteed;

[0053] 3) Utilize the laser to treat the TiO after step 2) 2 The particles were irradiated for 3 seconds, and the parameters of the laser were selected as follows: pulse width 8 nanoseconds; wavelength 1700nm; power 1W; frequency 1000Hz;

[0054] 4) Step 3) treated TiO 2 After the particles are remixed evenly, repeat step 2) and step 3) 6 times to obtain uniform blue TiO 2 particles.

[0055] After treatment by this method, TiO 2 The particles changed from white to uniform blue. Several TiO cladd...

Embodiment 3

[0057] A TiO irradiated by fast laser 2 Particles, a method for preparing blue titanium dioxide particles with visible light response, the method comprising the steps of:

[0058] 1) In a muffle furnace, at 200 degrees Celsius, for TiO 2 Particles (with a particle size of 5000nm) are preheated to clean their surfaces;

[0059] 2) Step 1) TiO after preheating 2 The particles are tableted on the quartz glass substrate, and the surface flatness of the sample after tableting is guaranteed;

[0060] 3) Utilize the laser to treat the TiO after step 2) 2 The particles were irradiated for 10 seconds, and the parameters of the laser were selected as follows: pulse width 8 nanoseconds; wavelength 1064nm; power 5W; frequency 1000Hz;

[0061] 4) Step 3) treated TiO 2 After the particles are remixed evenly, repeat step 2) and step 3) 20 times to obtain uniform blue TiO 2 particles.

[0062] After treatment by this method, TiO 2 The particles changed from white to uniform blue. Sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com