A kind of magnetic carboxymethyl chitosan nano material and preparation method thereof

A technology of carboxymethyl chitosan and nanomaterials, applied in the field of material science, can solve the problems of poor water solubility of chitosan, achieve the effects of avoiding self-aggregation and uneven distribution, improving stability, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) To purify chitosan, add 5g of chitosan powder to submerge in 1% acetic acid solution, soak for 5h under magnetic stirring, separate the solution from solid to liquid, wash the solid twice with deionized water, and then wash the block The chitosan is dried at 70°C, and then pulverized into purified chitosan powder.

[0030] (2) Prepare carboxymethyl chitosan, take 50g sodium hydroxide solid, add 100mL ultrapure water to make solution, get the chitosan powder of 2g purification and add above-mentioned solution, magnetic stirring 3h, put into refrigerator and freeze overnight, Transfer the swollen sample into a 200mL three-neck flask, slowly add 20mL of isopropanol and stir evenly, take 1g of chloroacetic acid and add it into the flask in 4 times, with an interval of 20min each time, mechanically stir for 12h after adding all of them, filter out the isopropanol, and add an appropriate amount Dissolve in ultrapure water, adjust the pH to be neutral with dilute acetic ac...

Embodiment 2

[0036] Step (1) and (2) among the embodiment 1 are discarded, do not add carboxymethyl chitosan in the step (3), all the other steps are exactly the same as embodiment 1, make the nano iron ferric oxide that is wrapped nanomaterials.

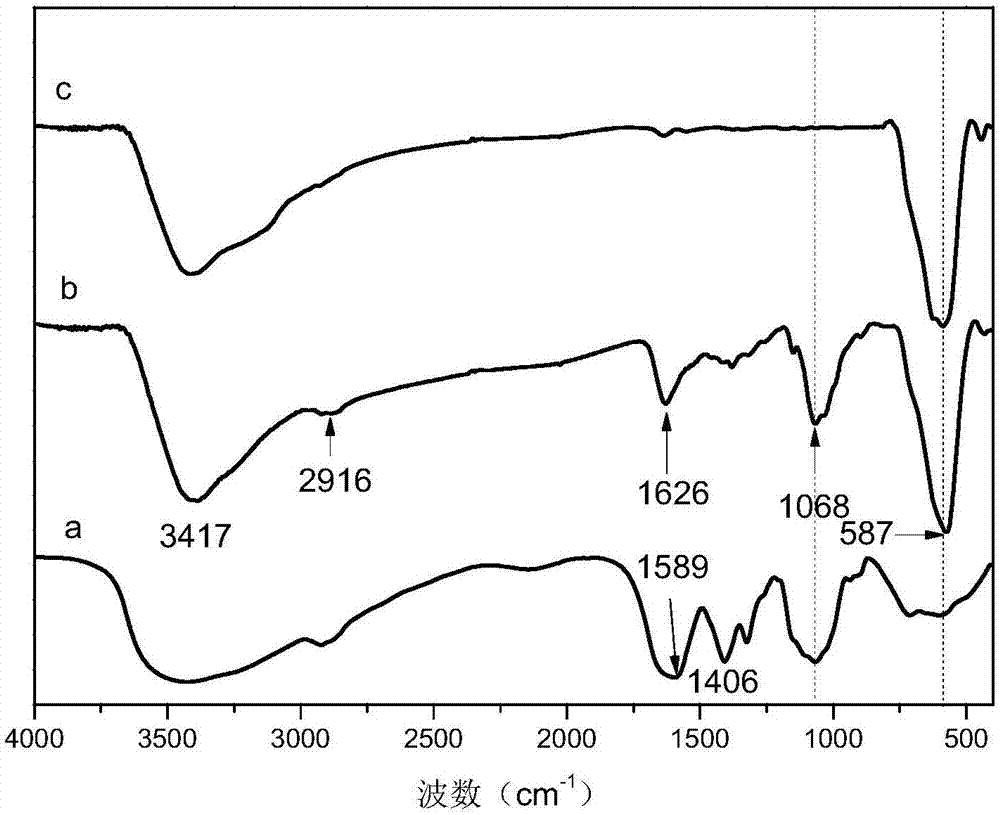

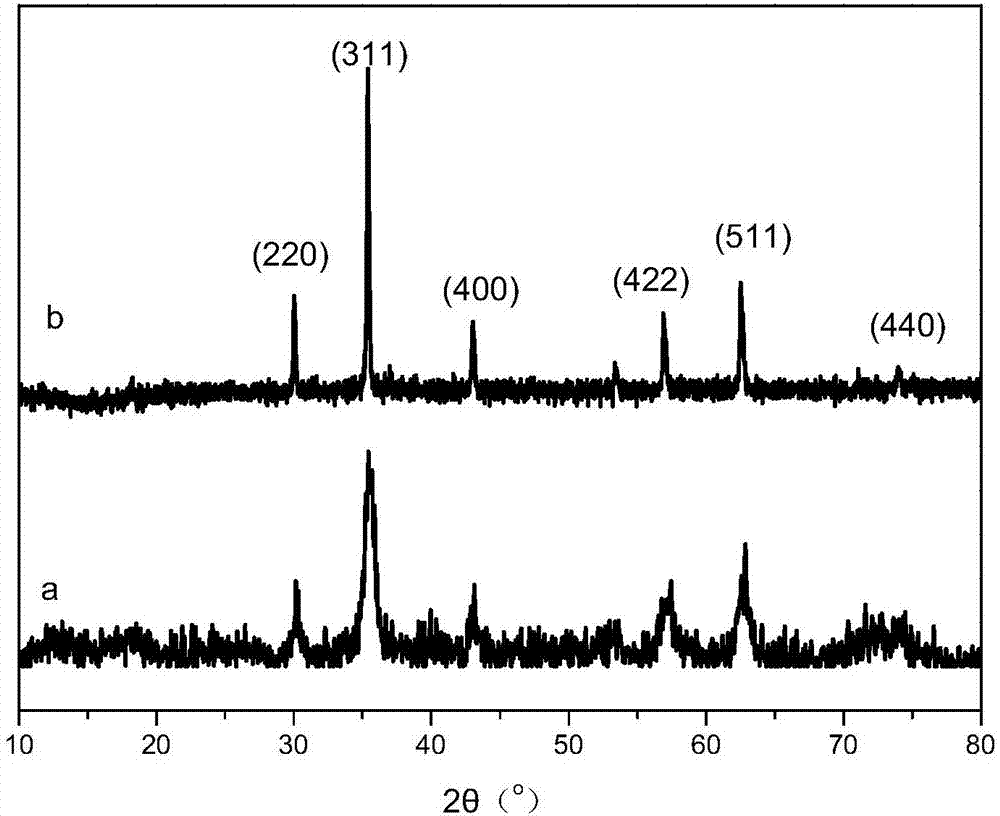

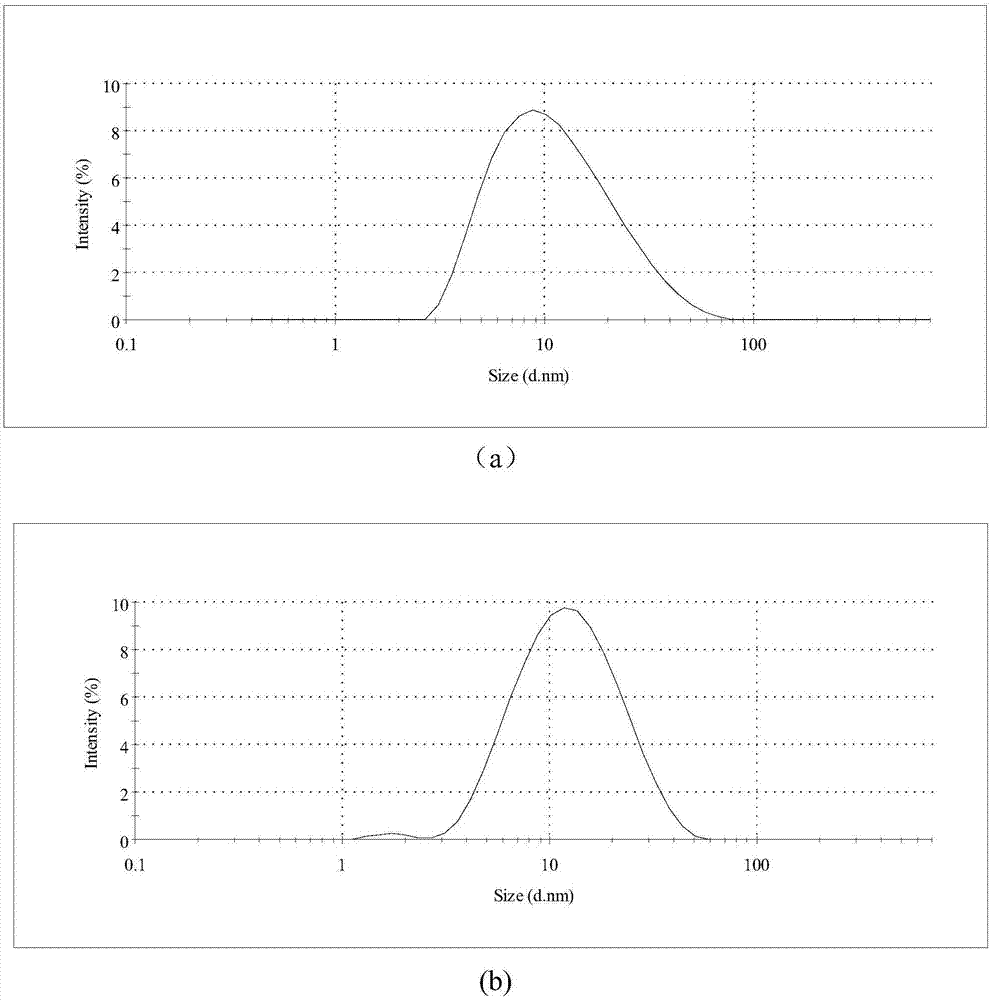

[0037] like figure 1 As shown, there is no characteristic peak of carboxymethyl chitosan in the infrared spectrum, at 587cm -1 The absorption peak at is the vibration peak of Fe-O. The XRD test results are shown in figure 2 (b), the diffraction peaks appear at 2θ=30.24°, 35.40°, 43.48°, 53.64°, 57.04°, 62.68°, corresponding to the cubic phase Fe 3 o 4 (220), (311), (400), (422), (511) and (440) planes, which proves that the prepared crystals are mainly Fe 3 o 4 . The particle size and particle size distribution of the nanoparticles are as follows image 3 As shown in (b), the particle size is about 9nm, PDI=0.242.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com