Chitosan/quantum dot nanocomposite film and preparation method and application thereof

A nano-composite, chitosan technology, applied in the fields of optics and polymer chemistry, can solve the problems of uneven distribution, many surface defects, agglomeration, etc., to achieve improved quantum efficiency, clean preparation process, excellent mechanical properties and processability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

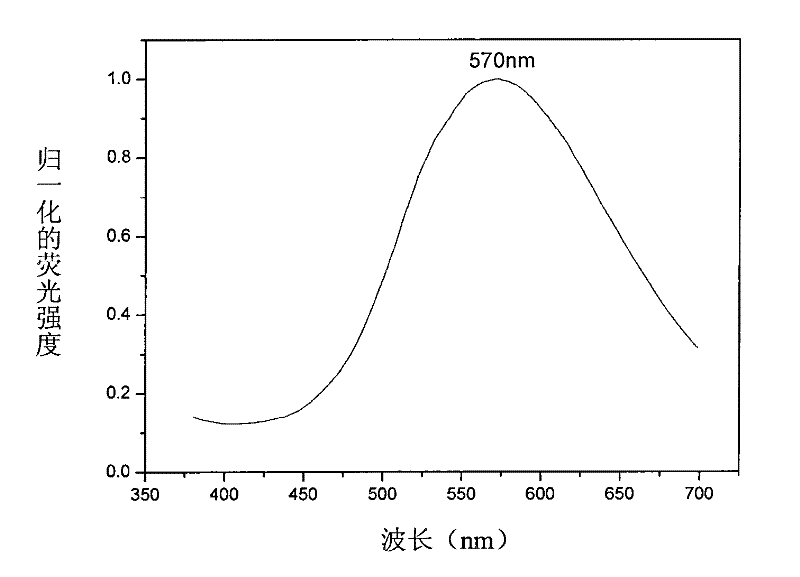

[0033] Weigh 0.186g Dy 2 o 3 Add 1ml of concentrated hydrochloric acid and heat in an electric furnace until the oxides are completely dissolved and all the hydrochloric acid volatilizes to leave white crystals to make 10 -3 M solution of rare earth chloride (DyCl 3 solution). Cd(AC) 2 Dissolve in hot ethanol to obtain a supersaturated solution, then stand for recrystallization, filter and dry to obtain a pure product. Configuration 5mg / ml chitosan dilute acetic acid solution 50ml (the concentration of acetic acid solution is 2%, V / V; The molecular weight of chitosan is 200,000), adds 10 -1 mol / l purified cadmium acetate solution 2ml, DyCl 3 Solution (10 -3 M) 8ml, stirred overnight to reach coordination equilibrium. will contain Cd 2+ The chitosan solution degassed under reduced pressure (reducing the pressure is helpful for degassing), cast on a clean glass plate placed horizontally, dried at room temperature to form a film, and then placed the film in a concentratio...

Embodiment 2

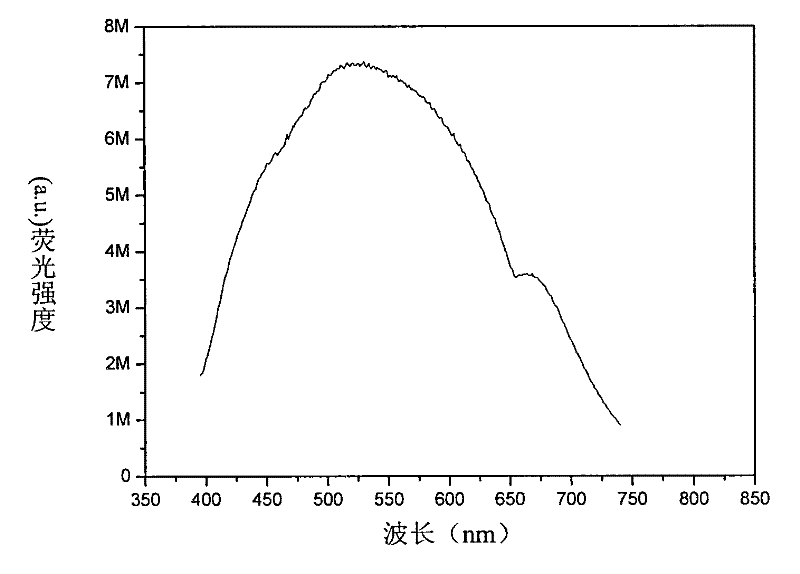

[0035] Weigh 0.187g Tb 4 o 7 Add 1ml of concentrated hydrochloric acid and heat in an electric furnace until the oxides are completely dissolved and all the hydrochloric acid volatilizes to leave white crystals to make 10 -3 Dilute solutions of M rare earth chlorides (TbCl 3 solution). Configuration 5mg / ml chitosan dilute acetic acid solution 50ml (the concentration of acetic acid solution is 2%, V / V; Chitosan molecular weight is 200,000), adds 10 -1 mol / l purified cadmium acetate solution 2ml, TbCl 3 Solution (10 -3 M) 8ml, stirred overnight to reach coordination equilibrium. will contain Cd 2+ The chitosan solution was defoamed under reduced pressure, cast on a clean glass plate placed horizontally, dried at room temperature to form a film, and then the film was placed in a concentration of 5×10 -3 Na of M 2 In the S solution, take it out after reacting for 2 minutes, the appearance of the film changes from colorless to yellow, wash it with a large amount of saturate...

Embodiment 3

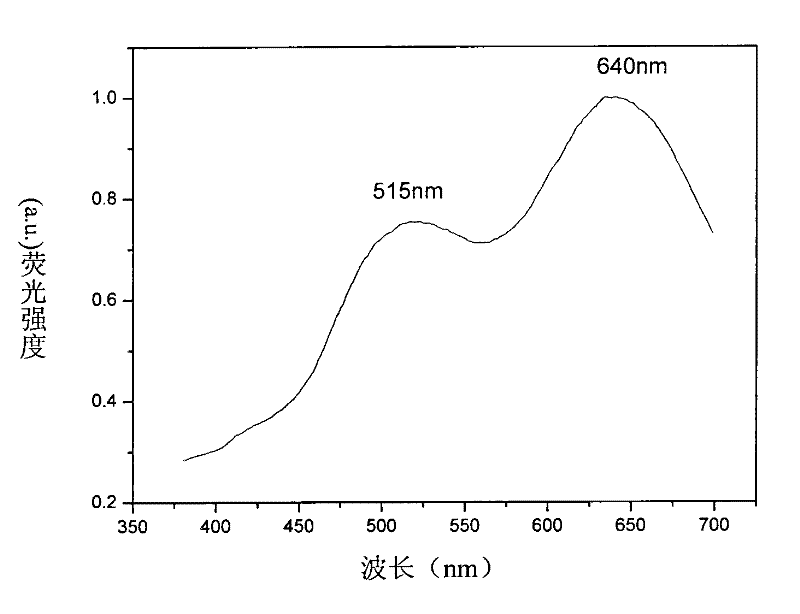

[0037] Weigh 0.185Eu 2 o 3 Add 1ml of concentrated hydrochloric acid and heat in an electric furnace until the oxides are completely dissolved and all the hydrochloric acid volatilizes to leave white crystals to make 10 -3 Dilute solutions of M rare earth chlorides (EuCl 3 solution). Cd(AC) 2 Dissolve in hot ethanol to obtain a supersaturated solution, then stand for recrystallization, filter and dry to obtain a pure product. Configuration 5mg / ml chitosan dilute acetic acid solution 50ml (concentration of acetic acid solution is 2%, V / V; Chitosan molecular weight is 200,000), adds 10 -1 mol / l purified cadmium acetate solution 2ml, EuCl 3 Solution (10 -3 M) 8ml, stirred overnight to reach coordination equilibrium. will contain Cd 2+ The chitosan solution was defoamed under reduced pressure, cast on a clean glass plate placed horizontally, dried at room temperature to form a film, and then the film was placed in a concentration of 5×10 -3 Na of M 2 In the S solution, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com