Flame-retarding compound, flame-retardant prepared thereby and preparation method thereof

A compound and flame retardant technology, which is applied in the field of phosphorus nitrogen intumescent flame retardant compounds, to achieve the effects of improved flame retardant performance, small mechanical properties, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

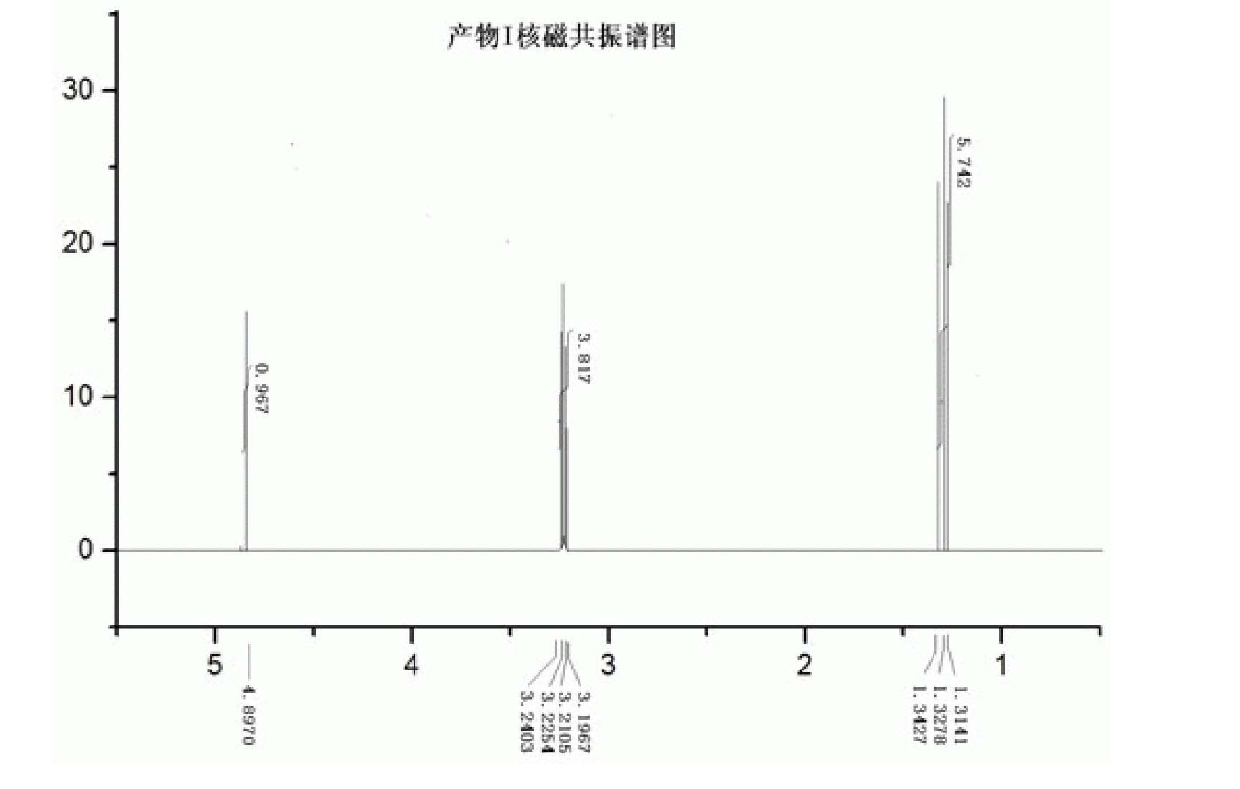

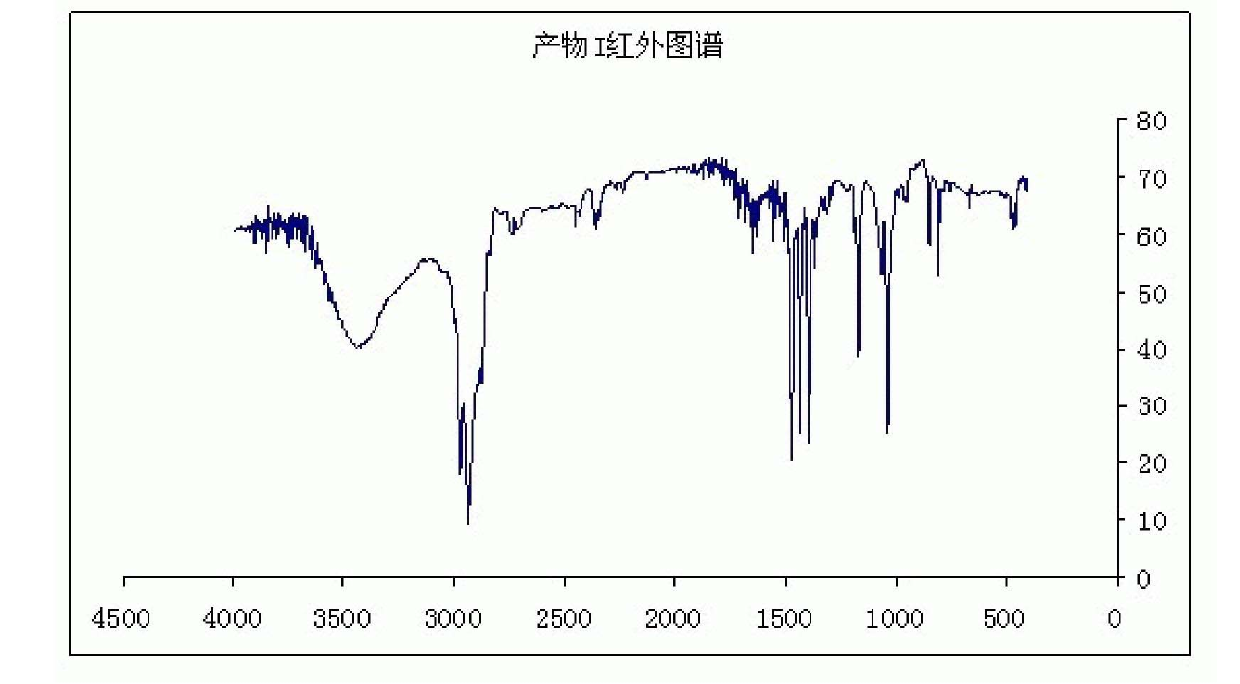

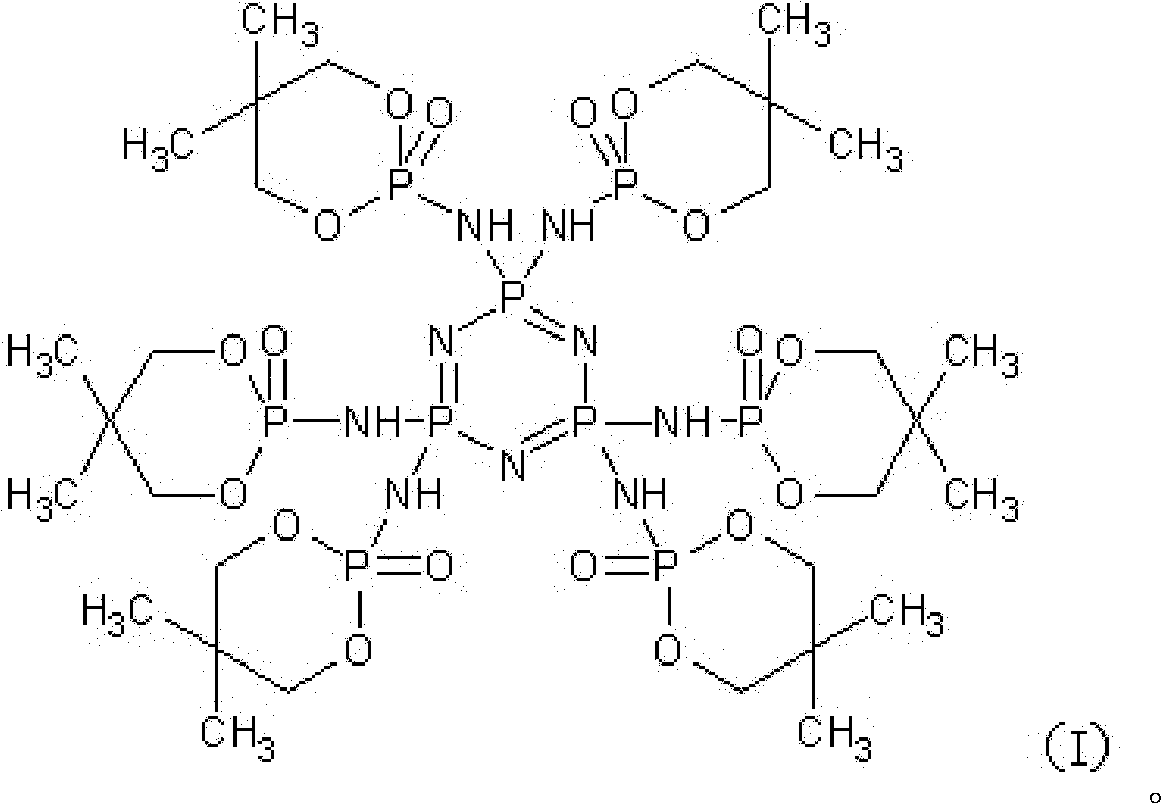

[0027] Embodiment 1: The flame retardant compound has the following structure:

[0028]

Embodiment 2

[0029] Example 2: The preparation method of the flame retardant compound of Example 1: Add 9 g of phthalimide and 4 g of hexachlorotrimeric phosphazene into a 250 ml three-necked flask with a condenser, use 90 g of DMF as the solvent, and heat to 80 ° C The reaction was 6.5 hours. After the reaction was completed, let stand to cool, wash with water 3 times, 300ml each time, filter under reduced pressure to obtain brown insoluble matter, and dry to obtain A.

[0030] Put A 10g, 4.8g NaOH and 150ml ethanol into a 250ml Erlenmeyer flask, magnetically stir for 4.5 hours, vacuum filter after the reaction, and evaporate the filtrate to obtain white solid B.

[0031] Add 2.4g of B into a 250ml three-necked flask with a condenser tube, and add 11g of 5,5-dimethyl-1,3-dioxo-2-phosphacyclocaprolactoyl chloride, with DMF90g as solvent, in oil at 80°C Reacted in the bath for 4 hours, and filtered under reduced pressure to obtain insoluble C as a white solid.

[0032] The product C was d...

Embodiment 3

[0035] Embodiment 3: the preparation method of the flame retardant prepared by flame retardant compound:

[0036] Put 200g of the flame retardant and 1000g of polypropylene (PP) into a high-speed mixer and mix for 3 minutes; use a co-rotating twin-screw extruder to mix and granulate once, and then dry the pellets at about 80°C for 2 hours. Conventional injection molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com