A kind of preparation method of the inorganic composite white pigment that replaces titanium dioxide in a high proportion

A technology of titanium dioxide and white pigments, which is applied in the treatment of inorganic pigments, chemical instruments and methods, and the treatment of dyed polymer organic compounds. It can solve the problems of low replacement ratio of titanium dioxide and incomplete coating of titanium dioxide in composite products, and achieve easy-to-achieve scale The effect of production, tight coating and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

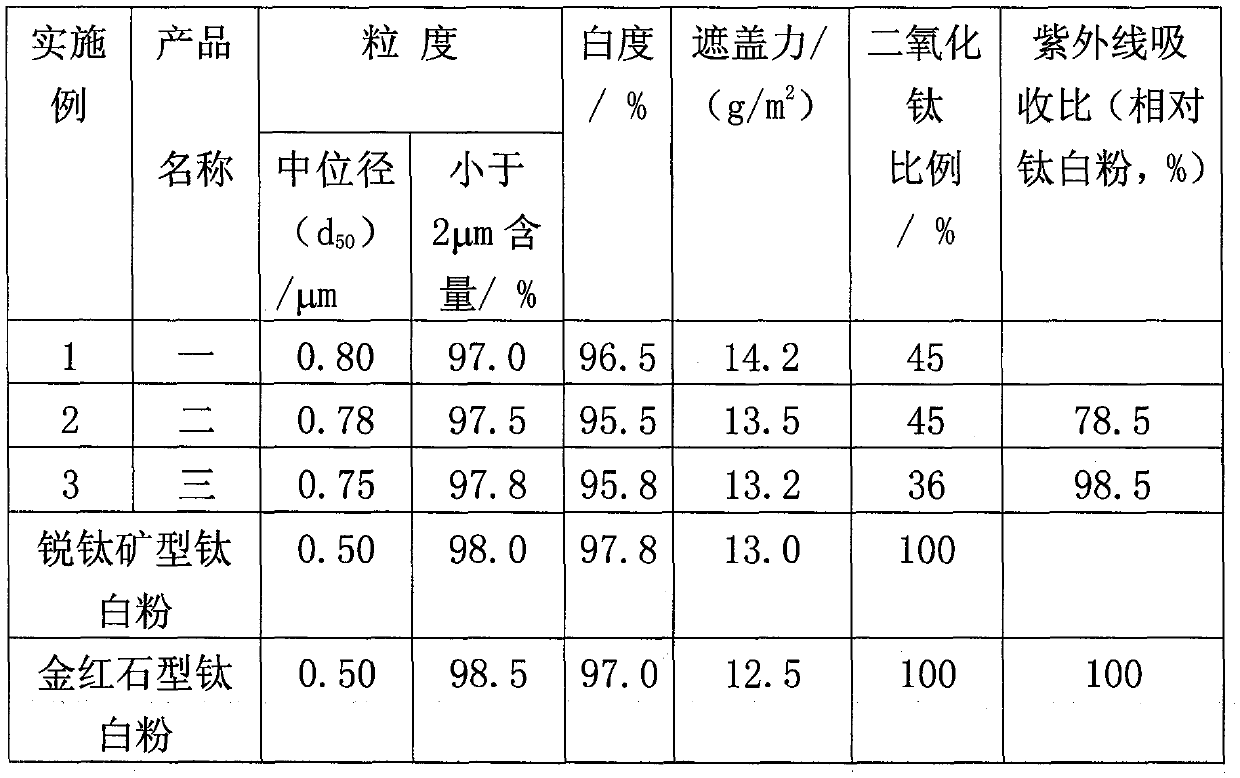

Examples

Embodiment 1

[0022] 1. Selection of raw materials:

[0023] Calcite is used as inorganic white powder with a particle size of less than 45 μm; anatase titanium dioxide is used as pigment grade titanium dioxide; sodium polyacrylate solution with a concentration of 25% is added to adjust the surface properties of particles; dilute sulfuric acid is used as a pH regulator;

[0024] 2. Raw material ratio and preparation process steps:

[0025] (1) Measure calcite powder, water and sodium polyacrylate solution, wherein the solid content of calcite powder is 70%, and the sodium polyacrylate content accounts for 0.44% of the calcite powder amount, mix the above-mentioned calcite powder with water, and then add Sodium polyacrylate was stirred at high speed for 60 minutes to form a suspension, and then wet-grinded with a vertical stirring mill, so that the particle size of the ground product was less than 2 μm and the content was 80%, and the median diameter was d 50 1.35μm;

[0026](2) Measure an...

Embodiment 2

[0031] 1. Selection of raw materials:

[0032] Calcite is used as inorganic white powder with a particle size of less than 45 μm; rutile titanium dioxide is used as pigment grade titanium dioxide; sodium polyacrylate solution with a concentration of 25% is added to adjust the surface properties of particles; dilute sulfuric acid is used as a pH regulator;

[0033] 2. Raw material ratio and preparation process steps:

[0034] (1) Measure calcite powder, water and sodium polyacrylate solution, wherein the solid content of calcite powder is 70%, and the sodium polyacrylate content accounts for 0.44% of the calcite powder amount, mix the above-mentioned calcite powder with water, and then add Sodium polyacrylate was stirred at high speed for 60 minutes to form a suspension, and then wet-grinded with a vertical stirring mill, so that the particle size of the ground product reached 80% of the content of less than 2 μm, and the median diameter d 50 1.35μm;

[0035] (2) Measure ruti...

Embodiment 3

[0040] 1. Selection of raw materials:

[0041] White carbon black is used as inorganic white powder with a particle size of less than 45 μm; anatase titanium dioxide is used as pigment grade titanium dioxide; sodium silicate solution with a concentration of 15% is added to adjust the particle surface properties; dilute sulfuric acid is used as pH adjustment agent;

[0042] 2. Raw material ratio and preparation process steps:

[0043] (1) Measure white carbon black powder, water and sodium silicate solution, wherein the solid content of white carbon black powder is 40%, and sodium silicate content accounts for 0.44% of the amount of white carbon black powder, the above white carbon black Mix the powder with water, then add sodium silicate and stir at high speed for 60 minutes to form a suspension, then use a vertical stirring mill for wet grinding, so that the particle size of the ground product is less than 2 μm, the content is 80%, and the median diameter is d 50 1.35μm;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com