Process for continuously producing polyoxymethylenedimethyl ethers at low temperature

A technology of polyoxymethylene dimethyl ether and paraformaldehyde, applied in the preparation of organic compounds, membranes, physical/chemical process catalysts, etc., to reduce costs and energy consumption, high product selectivity, and achieve long-term continuous operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

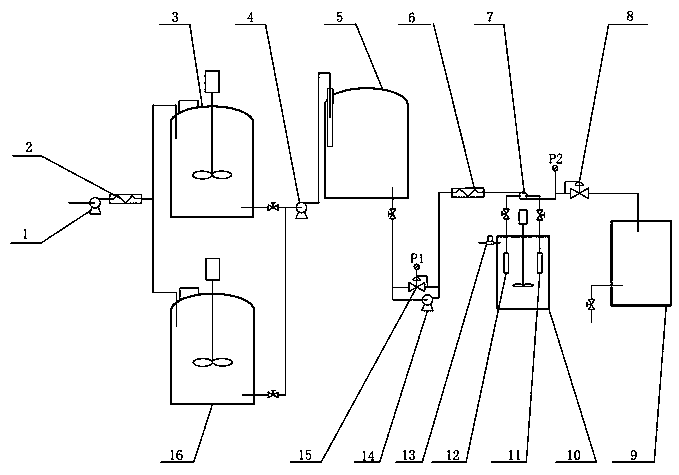

Method used

Image

Examples

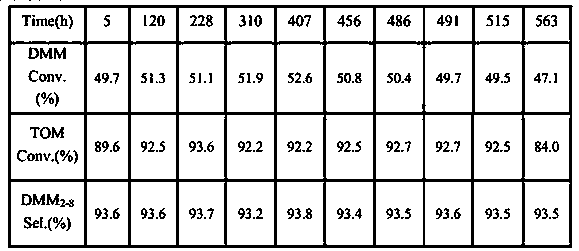

Embodiment 1

[0040] 20 g of MCM-22 molecular sieve catalysts with a high silicon-aluminum ratio are loaded into a reactor 10 with an effective volume of 500 ml. will preheat to 40 oC methylal is injected into the first batching tank 3 (or the second batching tank 16) that has been equipped with paraformaldehyde, and mixed evenly, wherein the molar ratio of methylal:paraformaldehyde is 2:1. The mixed raw materials are continuously injected into the reactor 10 by the second feeding pump 14, and the stirring is maintained continuously, so that the catalyst and the reaction raw materials are uniformly mixed and reacted. During the reaction, the reactor temperature was controlled to be 40° C., the flow rate of the second feed pump 14 was 5 mL / min, the timing switching time of the four-way flow path valve 7 was 6 hours, and the opening pressure of the reaction back pressure valve 8 was 0.5 MPa. The opening pressure of material back pressure valve 15 is 1.3MPa. The initial pressure of the gas f...

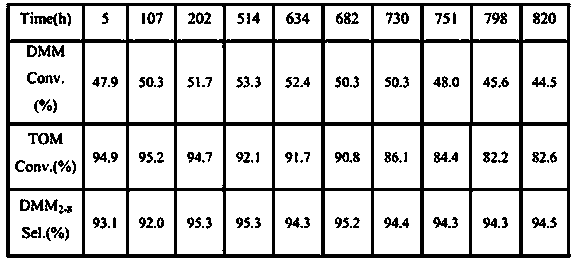

Embodiment 2

[0044] 20 g of ZSM-5 molecular sieve catalysts with a low silicon-aluminum ratio are loaded into a reactor 10 with an effective volume of 500 ml. Inject the methylal preheated to 35°C into the first batching tank 3 (or the second batching tank 16) filled with paraformaldehyde, and mix well, wherein the molar ratio of methylal:paraformaldehyde is 6:1. The mixed raw materials are continuously injected into the reactor 10 by the second feeding pump 14, and the stirring is maintained continuously, so that the catalyst and the reaction raw materials are uniformly mixed and reacted. During the reaction, the reactor temperature was controlled to be 60° C., the flow rate of the second feed pump 14 was 10 mL / min, the timing switching time of the four-way flow path valve 7 was 6 hours, and the opening pressure of the reaction back pressure valve 8 was 0.6 MPa. The opening pressure of material back pressure valve 15 is 1.5MPa. The initial pressure of the gas flow control meter 13 is 5 s...

Embodiment 3

[0048] 20 g of Hβ molecular sieve catalysts were loaded into a reactor 10 with an effective volume of 500 ml. Inject the methylal preheated to 32°C into the first batching tank 3 (or the second batching tank 16) filled with paraformaldehyde, and mix well, wherein the molar ratio of methylal:paraformaldehyde is 10:1. The mixed raw materials are continuously injected into the reactor 10 by the second feeding pump 14, and the stirring is maintained continuously, so that the catalyst and the reaction raw materials are uniformly mixed and reacted. During the reaction, the reactor temperature was controlled to be 69° C., the flow rate of the second feed pump 14 was 10 mL / min, the timing switching time of the four-way flow path valve 7 was 6 hours, and the opening pressure of the reaction back pressure valve 8 was 0.6 MPa. The opening pressure of material back pressure valve 15 is 1.5MPa. The initial pressure of the gas flow control meter 13 is 5 sccm, and then adjusted according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com