Preparation process of calcium oxalate crystals in plants

A technology of middle calcium oxalate and preparation process, which is applied in the improvement of process efficiency, separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of high requirements on equipment conditions, hidden dangers of environment and safety, existence of preparation process, etc. The effect of low cost, simple operation and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

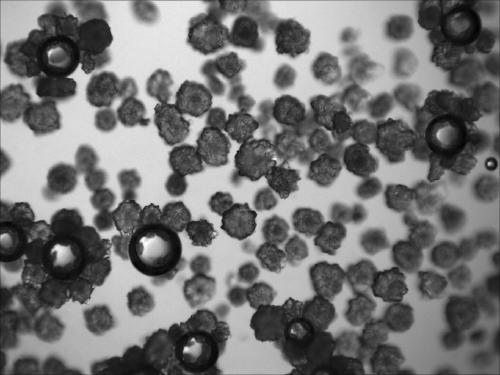

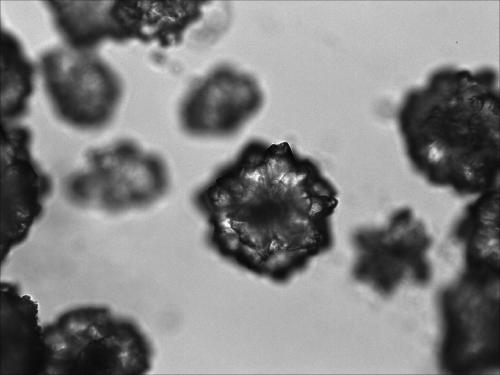

Image

Examples

preparation example Construction

[0030] A preparation process of calcium oxalate crystals in plants comprises the following steps.

[0031] Step 1, coarse crushing to obtain powder.

[0032] Plants containing calcium oxalate crystals are crushed and passed through a 60-120 mesh sieve, and the water content of the plants is less than 10%.

[0033] Step 2, crude extraction to obtain a precipitate.

[0034] Add 5-20% sodium hydroxide solution that is 20-40 times the weight of the plant powder to the plant powder obtained in step 1, decoct for 0.5-2 hours, place it for 12-48 hours, stir gently during the place, and pour it off after the place Clear liquid, filter out a precipitate, add a 5-20% sodium hydroxide solution 20-40 times the weight of a precipitate to a precipitate, decoct for 15-60min, place for 6-24h, and gently stir for 0.5min every 10min during the standing process , Centrifuge or filter at 2000-4000 rpm after the end of standing, and get the secondary precipitate.

[0035] Step 3, cleaning the p...

Embodiment 1

[0040] A preparation process of calcium oxalate crystals in roots and rhizomes of rhubarb (Rheum palmatum L., Rheum tanguticumMaxim.ex Balf. or medicinal rhubarb Rheum officinale Baill.) comprises the following steps.

[0041] Step 1, coarsely crush rhubarb roots and rhizomes to obtain 500 g of powder.

[0042] The rhubarb roots and rhizomes containing calcium oxalate crystals are crushed and passed through an 80-mesh sieve, and the water content of the rhubarb roots and rhizomes is less than 10%.

[0043] Step 2, crude extraction to obtain a precipitate.

[0044] Add 10% sodium hydroxide solution 20 times the weight of rhubarb root and rhizome powder to the rhubarb root and rhizome powder obtained in step 1, decoct for 1 hour, place for 24 hours, stir gently during the place, pour off the supernatant after the place is over , filter out a precipitate, add a 10% sodium hydroxide solution 20 times the weight of a precipitate to a precipitate, decoct for 30min, place for 12h, g...

Embodiment 2

[0051] A preparation process of calcium oxalate crystals in roots and rhizomes of licorice (Glycyrrhiza uralensis Fisch., Glycyrrhiza inflataBat. or Glycyrrhiza glabra L.) comprises the following steps.

[0052] Step 1, coarsely crushing licorice roots and rhizomes to obtain 500 g of powder.

[0053] The rhubarb roots and rhizomes containing calcium oxalate crystals are crushed and passed through a 120-mesh sieve, and the water content of the licorice roots and rhizomes is less than 10%.

[0054] Step 2, crude extraction to obtain a precipitate.

[0055] Add 5% sodium hydroxide solution that is 40 times the weight of licorice root and rhizome powder to the licorice root and rhizome powder obtained in step 1, decoct for 0.5h, place for 12h, stir gently during the place, and pour off the supernatant after the place is over Liquid, filter out a precipitate, add a 5% sodium hydroxide solution 40 times the weight of a precipitate to a precipitate, decoct for 15 minutes, place for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com